Umatshini wokuwelda weFiber Laser ophathwayo weFortune Laser

Umatshini wokuwelda weFiber Laser ophathwayo weFortune Laser

Iiparamitha zobugcisa ze-Fortune Laser Handheld Laser Welder

| Imodeli | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Uhlobo lweLaser | I-Laser yeFiber ye-1070nm | ||

| Amandla eLaser aqhelekileyo | 1000W | 1500W | 2000W |

| Inkqubo yokupholisa | Ukupholisa Amanzi | ||

| Indlela yokusebenza | Ukuqhubekeka / Ukuguqulwa | ||

| Uluhlu lwesantya somshiseli | 0~120 mm/s | ||

| Ububanzi beFocal Spot | 0.5mm | ||

| Uluhlu lobushushu obuphakathi | 15~35 ℃ | ||

| Uluhlu lokufuma kokusingqongileyo | <70% ngaphandle kokufuma | ||

| Ubukhulu beWelding | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Iimfuneko zesithuba sokuwelda | ≤1.2mm | ||

| I-Voltage yokusebenza | I-AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Ubungakanani beKhabhinethi | 120*60*120cm | ||

| Ubungakanani bePakeji yoMthi | 154*79*137cm | ||

| Ubunzima | 285KG | ||

| Ubude befayibha | I-10M esemgangathweni, ubude obude obulungiselelwe wena yi-15M | ||

| Isicelo | Ukuwelda nokulungisa intsimbi engagqwaliyo, intsimbi yekhabhoni, i-aluminium alloy. | ||

I-Laser Welder ephathwayo ephathekayo yesinyithi

| Izinto eziphathekayo | Amandla okukhupha (W) | Ukungena okuphezulu (mm) |

| Yenziwe ngentsimbi eshayinayo | 1000 | 0.5-3 |

| Yenziwe ngentsimbi eshayinayo | 1500 | 0.5-4 |

| Yenziwe ngentsimbi eshayinayo | 2000 | 0.5-5 |

| Intsimbi yekhabhoni | 1000 | 0.5-2.5 |

| Intsimbi yekhabhoni | 1500 | 0.5-3.5 |

| Intsimbi yekhabhoni | 2000 | 0.5-4.5 |

| I-alloy ye-aluminiyam | 1000 | 0.5-2.5 |

| I-alloy ye-aluminiyam | 1500 | 0.5-3 |

| I-alloy ye-aluminiyam | 2000 | 0.5-4 |

| Ishidi lesinyithi | 1000 | 0.5-1.2 |

| Ishidi lesinyithi | 1500 | 0.5-1.8 |

| Ishidi lesinyithi | 2000 | 0.5-2.5 |

Imibala Emithathu Yeenketho Zakho

Iingenelo zoMatshini wokuWelda weLaser ophathwa ngesandla

1. Uluhlu olubanzi lwe-welding:

Intloko yokuwelda ephathwayo ixhotyiswe nge-fiber ye-optical eyi-10M yokuqala (ubude obude obulungiselelweyo yi-15M), eyoyisa imida yendawo yokusebenza, kwaye inokuwelda ngaphandle nangaphandle komgama omde;

2. Kulula ukuyisebenzisa kwaye iguquguqukayo:

Ukuwelda nge-laser ephathwa ngesandla kuxhotyiswe ngee-pulleys ezishukumayo, ezikhululekileyo ukuzibamba, kwaye zinokulungisa isikhululo nangaliphi na ixesha, ngaphandle kwesikhululo esinendawo esisigxina, esikhululekileyo nesiguquguqukayo, kwaye sifanelekile kwiimeko ezahlukeneyo zemeko yokusebenza.

3. Iindlela ezininzi zokuwelda:

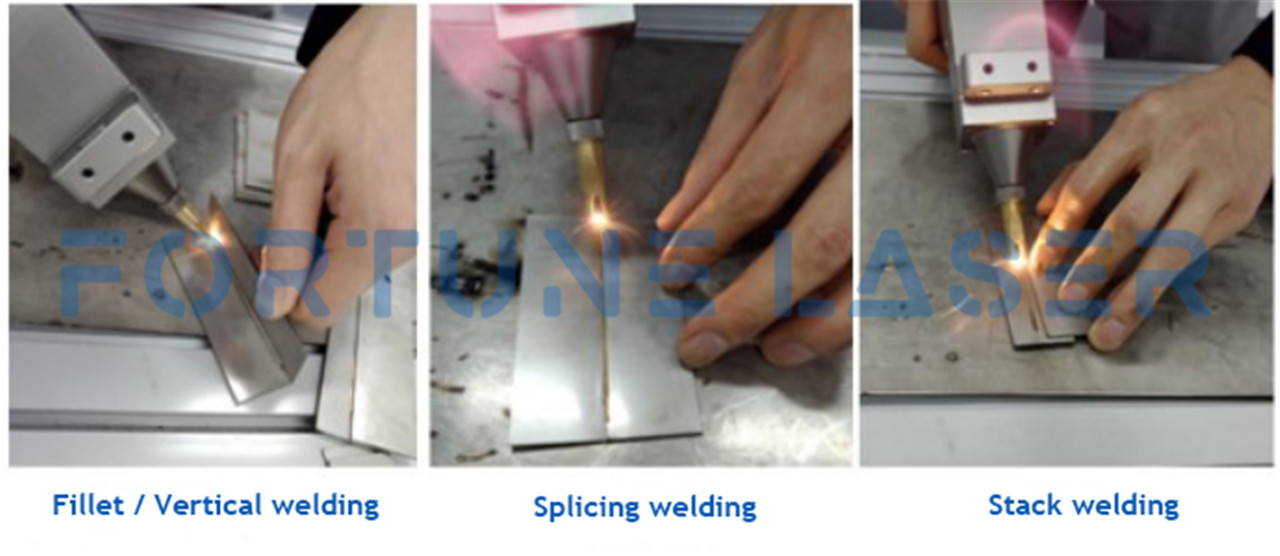

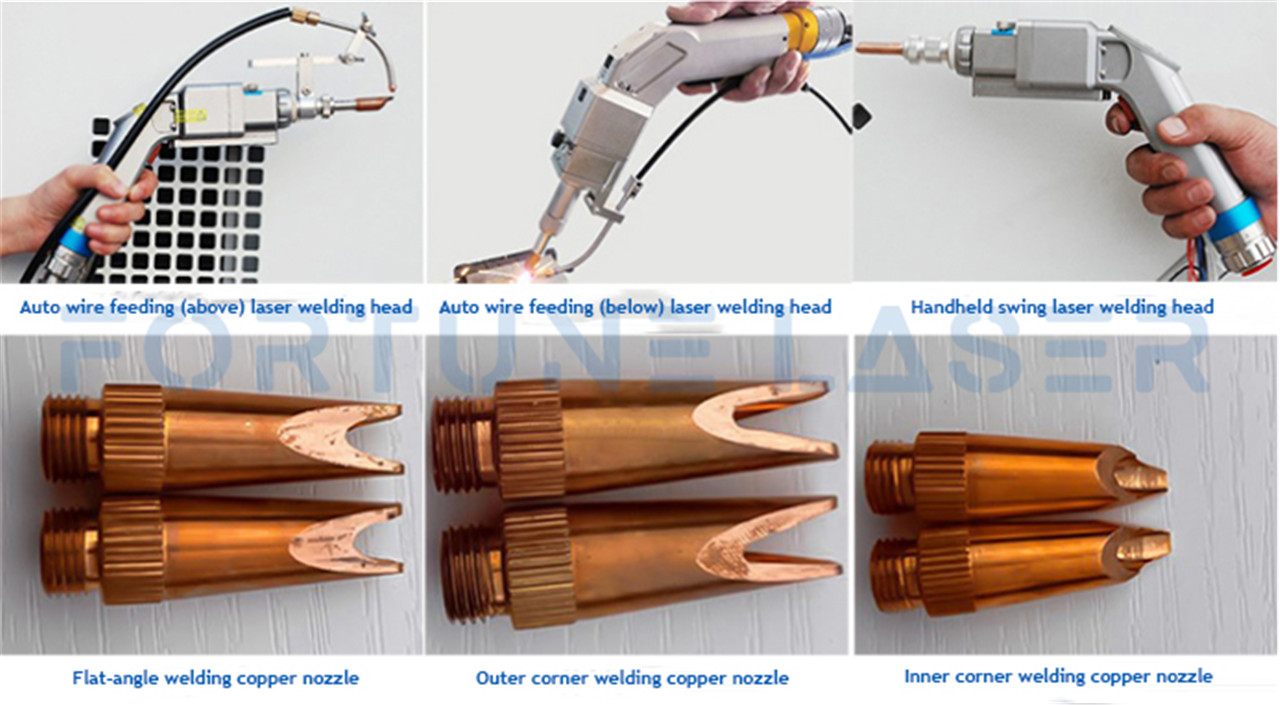

Ukuwelda nangayiphi na i-engile kunokwenziwa: ukuwelda okudibeneyo, ukuwelda kwe-butt, ukuwelda okuthe nkqo, ukuwelda kwe-flat fillet, ukuwelda kwe-fillet yangaphakathi, ukuwelda kwe-fillet yangaphandle, njl.njl., kwaye kunokuwelda iziqwenga zomsebenzi ezahlukeneyo ezidityanisiweyo kunye neziqwenga zomsebenzi ezinkulu ezineemilo ezingaqhelekanga. Qaphela ukuwelda nangayiphi na i-engile. Ukongeza, ingagqibezela ukusika, ukuwelda kunye nokusika kungatshintshwa ngokukhululekileyo, tshintsha nje umlomo wobhedu wokuwelda uye kumlomo wobhedu wokusika, nto leyo elula kakhulu.

4. Isiphumo esihle sokuwelda:

Ukuwelda nge-laser ephathwa ngesandla kukuwelda nge-thermal fusion. Xa kuthelekiswa nokuwelda kwendabuko, ukuwelda nge-laser kunamandla aphezulu kwaye kunokufezekisa iziphumo ezingcono zokuwelda. Indawo yokuwelda ayinampembelelo ingako kubushushu, kulula ukuyiguqula, imnyama, kwaye ineempawu ngasemva. Ubunzulu bokuwelda bukhulu, ukunyibilika kwanele, kwaye kuqinile kwaye kuthembekile, kwaye amandla okuwelda afikelela okanye adlule kwisinyithi esisisiseko ngokwaso, esingenakuqinisekiswa ngoomatshini abaqhelekileyo bokuwelda.

5. Akunyanzelekanga ukuba umthungo wokuwelda upholishwe.

Emva kokuwelda kwendabuko, indawo yokuwelda kufuneka ipholishwe ukuqinisekisa ukuba ithambile kwaye ayirhabaxa. Ukuwelda kwelaser ebanjwe ngesandla kubonisa ngokuchanekileyo iingenelo ezingaphezulu kwisiphumo sokucubungula: ukuwelda okuqhubekayo, ukugoba kunye nokungabikho kwezikali zentlanzi, ubuhle kunye nokungabikho kwezibazi, kunye neenkqubo ezimbalwa zokupolisha ezilandelayo.

6. Ukuwelda ngei-feeder yentambo ezenzekelayo.

Ngokwembono yabantu abaninzi, umsebenzi wokuwelda "ziiglasi zesandla sasekhohlo, ucingo lokuwelda olune-clamp yesandla sasekunene". Kodwa ngomatshini wokuwelda we-laser ophathwa ngesandla, ukuwelda kungagqitywa ngokulula, nto leyo enciphisa iindleko zezinto zokwakha ekuveliseni nasekucubunguleni.

7. Kukhuselekile ngakumbiumsebenzisi.

Ngee-alamu zokhuseleko ezininzi, incam yokuwelda isebenza kuphela xa iswitshi ichukunyiswa xa ichukumisa isinyithi, kwaye isibane sitshixwa ngokuzenzekelayo emva kokuba isiqwenga somsebenzi sisusiwe, kwaye iswitshi yokuchukumisa inokuqonda ubushushu bomzimba. Ukhuseleko luphezulu ukuqinisekisa ukhuseleko lomqhubi ngexesha lomsebenzi.

8. Gcina iindleko zabasebenzi.

Xa kuthelekiswa nokuwelda nge-arc, iindleko zokucubungula zingancitshiswa malunga ne-30%. Lo msebenzi ulula, kulula ukuwufunda, kwaye ukhawuleza ukuwuqalisa. Umlinganiselo wobuchwephesha wabaqhubi awuphezulu. Abasebenzi abaqhelekileyo banokuthatha izikhundla zabo emva koqeqesho olufutshane, olunokufikelela ngokulula kwiziphumo zokuwelda ezikumgangatho ophezulu.

9. Kulula ukutshintsha ukusuka kwiindlela zemveli zokuwelda ukuya kwi-fiber laser welding.

Ungafunda indlela yokusebenzisa umatshini wokuwelda we-Fortune Laser fiber laser kwiiyure ezimbalwa, kwaye ungabi naxhala lokukhangela iingcali zokuwelda, ungakhathazeki malunga neshedyuli yokuhambisa exineneyo. Ngaphezu koko, ngolu buchwepheshe butsha kunye notyalo-mali, uya kuba phambili kwimarike kwaye wamkele inzuzo eyongezelelekileyo kuneendlela zendabuko zokuwelda.

Iintsimi zesicelo soMatshini wokuWelda weLaser ophathwayo

I-laser welder ephathwayo yenzelwe ikakhulu i-sheet metal enkulu nephakathi, iikhabhathi, i-chassis, iifreyimu zomnyango kunye neefestile ze-aluminium alloy, izitya zokuhlamba zentsimbi engagqwaliyo kunye nezinye izinto ezinkulu zokusebenza, ezifana ne-inner right angle, i-outer right angle, i-flat weld welding, indawo encinci echaphazeleka bubushushu ngexesha lokuwelda, i-deformation encinci, kunye nobunzulu be-welding. I-welding enkulu, enamandla.

Oomatshini bokuwelda be-laser abaphathwa ngesandla be-Fortune Laser basetyenziswa kakhulu kwiinkqubo ezinzima nezingaqhelekanga zokuwelda kwishishini lasekhitshini nelangasese, kwishishini lezixhobo zasekhaya, kwishishini lentengiso, kwishishini le-mold, kwishishini leemveliso zentsimbi engagqwaliyo, kwishishini lobunjineli bentsimbi engagqwaliyo, kwishishini leengcango neefestile, kwishishini lezandla, kwishishini leempahla zasekhaya, kwishishini lefenitshala, kwishishini leenxalenye zeemoto, njl.

Uthelekiso loMatshini wokuWelda weLaser ophathwa ngesandla kunye neArgon Arc Welding

1. Uthelekiso lokusetyenziswa kwamandla:Xa kuthelekiswa nokuwelda kwe-arc yendabuko, umatshini wokuwelda we-laser ophathwa ngesandla ugcina malunga ne-80% ukuya kwi-90% yamandla ombane, kwaye iindleko zokucubungula zingancitshiswa malunga ne-30%.

2. Uthelekiso lwempembelelo yokuwelda:Ukuwelda ngesandla nge-laser kunokugqibezela ukuwelda kwentsimbi eyahlukileyo kunye nentsimbi eyahlukileyo. Isantya siyakhawuleza, ukuguquka kwayo kuncinci, kwaye indawo echaphazeleka bubushushu incinci. Umthungo wokuwelda umhle, uthambile, awunazo iimbobo ezininzi, kwaye awungcolisi. Umatshini wokuwelda we-laser ophathwa ngesandla ungasetyenziselwa iindawo ezincinci ezivulekileyo kunye nokuwelda ngokuchanekileyo.

3. Uthelekiso lwenkqubo yokulandelela:Ukufakwa kobushushu obuphantsi ngexesha lokuwelda ngesandla nge-laser, ukuguqulwa okuncinci kwento yokusebenza, umphezulu omhle wokuwelda unokufumaneka, akukho okanye unyango olulula kuphela (kuxhomekeke kwiimfuno zomphumo womphezulu wokuwelda). Umatshini wokuwelda we-laser ophathwa ngesandla unokunciphisa kakhulu iindleko zomsebenzi zenkqubo enkulu yokupolisha kunye nokulinganisa.

| Uhlobo | Ukuwelda kwe-argon arc | Ukuwelda kwe-YAG | Iphathwa ngesandlaIlezaukuwelda | |

| Umgangatho wokuwelda | Igalelo lobushushu | Mkhulu | Encinci | Encinci |

|

| Ukuguqulwa kwesakhiwo somsebenzi/undercut | Mkhulu | Encinci | Encinci |

|

| Ukwenziwa kwe-Weld | Ipateni yobukhulu beentlanzi | Ipateni yobukhulu beentlanzi | Ithambile |

|

| Ukucubungula okulandelayo | Polish | Polish | Akukho nanye |

| Sebenzisa umsebenzi | Isantya sokuwelda | Icotha | Ephakathi | Ngokukhawuleza |

|

| Ubunzima bokusebenza | Kunzima | Kulula | Kulula |

| Ukhuseleko nokusingqongileyo | Ungcoliseko lokusingqongileyo | Mkhulu | Encinci | Encinci |

|

| Ukulimala komzimba | Mkhulu | Encinci | Encinci |

| Iindleko zokudibanisa | Izinto ezisetyenziswayo | Intonga yokuwelda | Ikristale yelaser, isibane sexenon | Akukho mfuneko |

|

| Ukusetyenziswa kwamandla | Encinci | Mkhulu | Encinci |

| Indawo yomgangatho wezixhobo | Encinci | Mkhulu | Encinci | |