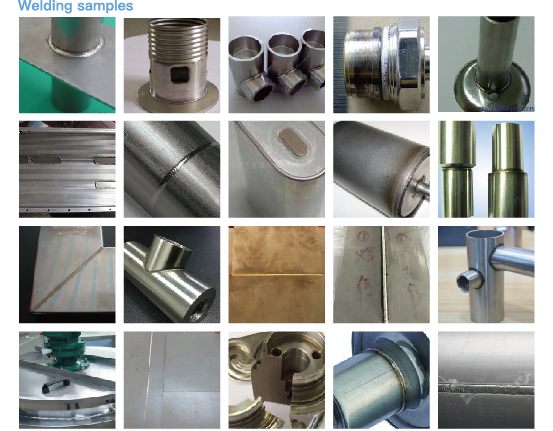

Umatshini wokuwelda we-Fortune Laser Automatic 300W Yag Laser Mold

Umatshini wokuwelda we-Fortune Laser Automatic 300W Yag Laser Mold

Imigaqo esisiseko yoMatshini weLaser

Umatshini wokuwelda we-laser odibanisa ii-axis ezine usebenzisa i-ceramic reflector cavity ephucukileyo, amandla anamandla, i-laser pulse ecwangcisiweyo kunye nolawulo lwenkqubo olukrelekrele. I-Z-axis yetafile yokusebenza ingashukunyiswa phezulu nasezantsi ukuze igxile, ilawulwe yi-PC yemizi-mveliso. Ixhotyiswe ngetafile yokuhamba ezenzekelayo ye-X/Y/Z axis esemgangathweni eyahlukileyo, exhotyiswe ngenkqubo yokupholisa yangaphandle. Enye into ejikelezayo ekhethwayo (iimodeli ze-80mm okanye ze-125mm azinyanzelekanga). Inkqubo yokubeka iliso isebenzisa i-microscope kunye ne-CCD

Umatshini wokuWelda weLaser oZenzekelayo oyi-300w Uphawu

Iiparamitha zobugcisa zomatshini wokuwelda we-laser ozenzekelayo we-Fortune Laser

| Imodeli | I-FL-Y300 |

| Amandla eLaser | 300W |

| Indlela Yokupholisa | Ukupholisa Amanzi |

| Ubude beLaser | 1064nm |

| Ukusebenza ngeLaser Medium Nd 3+ | I-YAG Ceramic Conde |

| Ububanzi bebala | i-φ0.10-3.0mm ehlengahlengiswayo |

| Ububanzi bePulse | I-0.1ms-20ms ehlengahlengiswayo |

| Ubunzulu bokuWelda | ≤10mm |

| Amandla oomatshini | 10KW |

| Inkqubo yoLawulo | I-PLC |

| Ukujolisa kunye nokubeka indawo | I-Microskopu |

| I-Stroke yeTheyibhile yokusebenzela | 200×300mm (ukuphakanyiswa kombane kwe-Z-axis) |

| Imfuno yamandla | Yenzelwe wena |