LITABA LE BLOG

LITABA LE BLOG

-

Mechini ea ho seha ka laser e tla fihlela mechine ea ho punch 'me e be le sebaka se seholo sa' maraka

Lihlahisoa tsa indasteri ea ts'ebetso ea laser ea naha ea heso li kenyelletsa haholo-holo mefuta e fapaneng ea mechini ea ho tšoaea laser, mechini ea ho tjheseletsa, mechini ea ho seha, mechini ea ho seha, mechini ea ho betla, mechini ea kalafo ea mocheso, mechini ea ho etsa mahlakore a mararo le mechini ea ho taka, jj., e nkang sebaka se seholo sa...Bala haholoanyane -

Papiso ea mokhoa oa ho seha khalase, melemo ea ho seha khalase ea laser ka potlako haholo

Ho hlaha ha difouno tse bohlale ho fetotse mekhoa ea bophelo ea batho haholo, 'me ntlafatso e tsoelang pele ea maemo a bophelo a batho le eona e hlahisitse litlhoko tse phahameng bakeng sa lifouno tse bohlale: ho phaella ntlafatsong e tsoelang pele ea sistimi, lisebelisoa tsa hardware le litlhophiso tse ling tse sebetsang, ...Bala haholoanyane -

Malebela a tlhokomelo bakeng sa mechini ea ho seha ka laser lehlabula le chesang

Ka lebaka la mocheso o phahameng o tlang hlabula, mechine e mengata ea ho seha ka laser e tla hlahisa mocheso o mongata ha e sebetsa, e leng se bakang mathata a mang. Ka hona, ha u sebelisa mochini oa ho seha ka laser hlabula, ela hloko ho lokisa lisebelisoa ka mokhoa oa ho li pholisa. Maemong a mocheso o phahameng, batho...Bala haholoanyane -

Mosebetsi oa ho fumana moeli o iketsang oa mochini oa ho itšeha ka laser ke ofe?

Ha theknoloji ea laser e ntse e hola butle-butle, mechine ea ho seha ka laser e ntse e ntlafatsoa khafetsa lilemong tsa morao tjena, 'me bokhoni ba ho seha, boleng ba ho seha le mesebetsi ea ho seha ea mechine ea ho seha ka laser li ntlafalitsoe le ho feta. Mechine ea ho seha ka laser e fetohile ho tloha mosebetsing o le mong oa ho seha...Bala haholoanyane -

Litharollo bakeng sa katleho e tlase ea tlhahiso ea mechini ea ho itšeha ka laser

Lebaka leo ka lona mechine ea ho seha ea fiber laser e hlomphuoang haholo indastering ea ts'ebetso ea tšepe ke haholo-holo ka lebaka la bokhoni ba eona bo phahameng ba tlhahiso le melemo ea litšenyehelo tsa basebetsi. Leha ho le joalo, bareki ba bangata ba fumana hore bokhoni ba bona ba tlhahiso ha boa ntlafala haholo kamora ho e sebelisa ka nako e itseng....Bala haholoanyane -

Mechini ea ho itšeha ka laser e na le litšenyehelo tse tlase le phaello e phahameng ho feta mechini ea setso

Mechini ea theknoloji e phahameng e qothisana lehlokoa haholoanyane 'marakeng Ka nts'etsopele ea mahlale a macha le mechini le lisebelisoa tse ncha, lifeme tse ngata le bahlahisi ba mechini ba hlahisa lisebelisoa tsa theknoloji e phahameng, tse ka ntlafatsang katleho ea tlhahiso ea rona le ho netefatsa boleng. Ho feta moo, ba ka ...Bala haholoanyane -

Malebela a tlhokomelo bakeng sa mechini ea ho seha ka laser lehlabula le chesang

Ka lebaka la mocheso o phahameng o tlang hlabula, mechine e mengata ea ho seha ka laser e tla hlahisa mocheso o mongata ha e sebetsa, e leng se bakang mathata a mang. Ka hona, ha u sebelisa mochini oa ho seha ka laser hlabula, ela hloko ho lokisa lisebelisoa ka mokhoa oa ho li pholisa. Maemong a mocheso o phahameng, batho...Bala haholoanyane -

U lokela ho ela hloko eng ha u seha lipoleiti tse mafome ka mochini oa ho seha oa laser oa fiber?

Jwalo ka ha re tseba kaofela, mechine ya ho seha ya faeba ka laser ke ditsebi tsa ho seha maqephe a tshepe mme e sebediswa haholo. Jwale ditlamorao tsa ho seha maqephe a tshepe a sa phethahalang - maqephe a tshepe a rusitseng ke dife mme ke dintlha dife tse lokelang ho elwa hloko? 1. Ho seha dipoleiti tse rusitseng ho tla fokotsa bokgoni ba ho sebetsa, ...Bala haholoanyane -

U lokela ho ela hloko eng ha u seha lipoleiti tse mafome ka mochini oa ho seha oa laser oa fiber?

Jwalo ka ha re tseba kaofela, mechine ya ho seha ya faeba ka laser ke ditsebi tsa ho seha maqephe a tshepe mme e sebedisitswe haholo. Jwale ditlamorao tsa ho seha maqephe a tshepe a sa phethahalang - maqephe a tshepe a rusitseng ke dife mme ke dintlha dife tse lokelang ho elwa hloko? 1. Ho seha dipoleiti tse rusitseng ho tla fokotsa bokgoni ba ho sebetsa,...Bala haholoanyane -

Melemo ea ho sebelisa mechine ea ho itšeha ka laser indastering ea mechini ea temo ke efe?

Lilemong tsa morao tjena, ka lebaka la ho tsosolosoa ha sebaka sa mobu o lenngoeng le keketseho ea sekhahla sa ho lema bocha mobu, tlhoko ea mechini ea temo ke "temo, libaka tsa mahaeng le balemi" e tla bontša mokhoa o tiileng oa kholo, o eketsehang ka sekhahla sa 8% selemo le selemo. Mechine ea temo e...Bala haholoanyane -

Ke lokela ho etsa eng haeba ho chesa ho feta tekano ho hlaha nakong ea ho itšeha ka laser?

Ho seha ka laser ho sebedisa seipone se shebaneng ho tsepamisa lehlasedi la laser hodima thepa ho qhibilihisa thepa. Ka nako e ts'oanang, khase e hatelletsoeng e nang le lehlasedi la laser e sebediswa ho foka thepa e qhibilihisitsweng le ho etsa hore lehlasedi la laser le thepa di tsamaye ha di bapiswa ka ...Bala haholoanyane -

Mekhoa e meraro e tiileng ea ho ntlafatsa katleho ea ho itšeha ka laser

Mechini ea ho seha ea faeba ka laser joale e se e le sesebelisoa sa bohlokoa le sa bohlokoa tšimong ea ho seha tšepe, 'me e nka sebaka sa mekhoa ea setso ea ho sebetsana le tšepe ka potlako. Ka lebaka la nts'etsopele e potlakileng ea moruo, palo ea lik'hamphani tsa ho sebetsana le tšepe e eketsehile ka potlako, 'me ...Bala haholoanyane -

Ke lisebelisoa life le botenya boo mechine ea ho seha ka laser ea CNC e ka sebelisoang ho bo seha?

Mechini ea ho seha ka laser e nepahetseng ea CNC e fetotse tlhahiso ka bokhoni ba eona ba ho seha mefuta e fapaneng ea lisebelisoa ka ho nepahala le katleho e sa bapisoeng. Mabapi le lisebelisoa tsa ho seha le botenya, mechini ea ho seha ka laser e ka sebetsana le mefuta e mengata ea lisebelisoa, ...Bala haholoanyane -

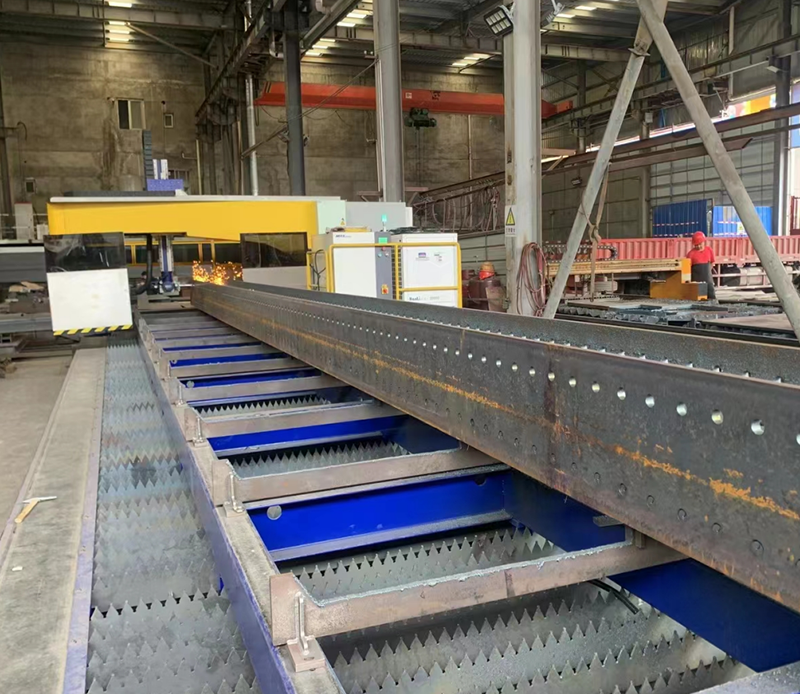

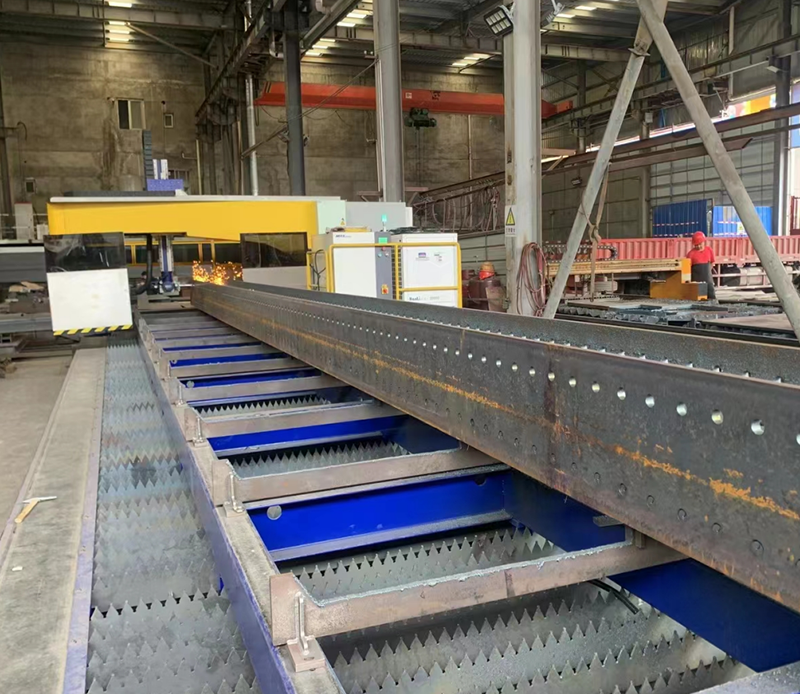

Tlhoko ea 'maraka oa ho itšeha ha tšepe ea laser e bōpehileng joaloka H

Ka lebaka la melemo e mengata ea mechini ea ho seha ea tšepe ea laser e bōpehileng joaloka H le tlhoko e phahameng ea 'maraka bakeng sa lihlahisoa tsa tšepe tse bōpehileng joaloka H, tlhoko ea mechini ea ho seha ea tšepe ea laser e bōpehileng joaloka H indastering e fapaneng e ntse e eketseha. ...Bala haholoanyane -

Melemo ea Mochini oa ho Seha oa Laser oa Faeba oa 10000 Watt

Mechini ea ho seha faeba ka laser e fetotse tlhahiso ea indasteri, 'me ho hlaha ha matla a li-watts tse 10,000 ho isa bokhoni ba bona boemong bo bocha ka ho feletseng. Mochini oa ho seha faeba ka laser oa li-watts tse 10,000 o na le botsitso bo phahameng, sebopeho se senyenyane, le tsela e tsitsitseng ea optical. Ke...Bala haholoanyane