Liroboto tsa ho tjheseletsa ka laserli fetotse lefapha la ho tjheseletsa ka ho hlahisa likarolo tse tsoetseng pele tse eketsang bokgoni le tlhahiso. Liroboto tsena li fana ka mefuta e mengata ea mesebetsi e nolofatsang ts'ebetso ea ho tjheseletsa, e eketsang ho nepahala le ho netefatsa polokeho e phahameng. Sengoloa sena se ikemiseditse ho hlahlobisisa bokhoni ba liroboto tsa ho tjheseletsa ka laser, ho totobatsa karolo ea tsona ho eketseng katleho ea ho tjheseletsa le boiketsetso bo felletseng. Re tla boela re hlahlobe litlhaloso tse fapaneng tsa lihlahisoa tse kang ts'ebetso ea ho tjheseletsa, ts'ebetso ea ho itšireletsa, ts'ebetso ea ho lemoha ho tjheseletsa, ts'ebetso ea ho thibela ho thulana, ts'ebetso ea ho lemoha liphoso, ts'ebetso ea ho ikopanya le terata e khomarelang ea ho tjheseletsa, ts'ebetso ea ho qala bocha ho robeha ha arc.

1. Mosebetsi oa ho chechela:

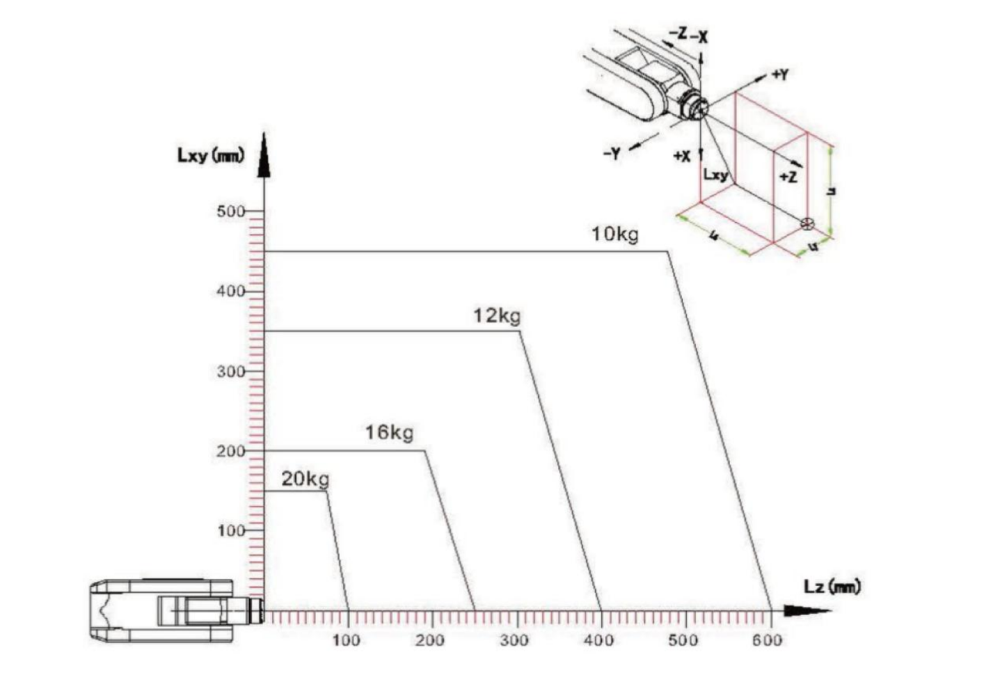

E 'ngoe ea likarolo tsa bohlokoa tsaroboto ea ho tjheseletsa ka laserke mosebetsi oa eona oa ho sisinyeha. Tšobotsi ena e lumella roboto ho tsamaea ka motsamao o sisinyehang, e koahelang sebaka se seholo ho feta mekhoa ea setso ea ho tjheseletsa. Tšobotsi ea ho sisinyeha e netefatsa hore lehlaseli la laser le koahela sebaka se seholo sa bokaholimo, e fokotsa nako ea ho tjheseletsa e hlokahalang bakeng sa merero e meholo. Ka ho eketsa sebaka sa ho koahela, tšobotsi ea ho tjheseletsa e thusa ho fihlela tlhahiso e phahameng le bokhoni lits'ebetsong tsa ho tjheseletsa.

2. Mosebetsi oa ho itšireletsa:

Liroboto tsa ho tjheseletsa ka laser li hlomelloa ka likarolo tsa ho itšireletsa ho netefatsa hore li phela nako e telele le ho thibela tšenyo e ka bang teng. Tšobotsi ena e sebetsa e le thibelo e sireletsang khahlanong le maemo a mabe a kang ho chesa haholo, ho kheloha ha motlakase kapa ho feto-fetoha ha matla. Likarolo tsa ho itšireletsa tsa roboto ha li sireletse feela likarolo tsa eona tsa ka hare, empa hape li thibela tšenyo efe kapa efe ea kantle ho tsoa ho litlhase tsa ho tjheseletsa kapa lithōle. Ka ho boloka botšepehi ba eona, roboto e ka fana ka liphetho tsa ho tjheseletsa tsa boleng bo holimo ka linako tsohle le ho lelefatsa bophelo ba eona.

3. Mosebetsi oa ho lemoha ho tjheseletsa:

Bokhoni ba ho lemoha ho tjheseletsa ke karolo ea bohlokoa ealiroboto tsa ho tjheseletsa ka laser, e ba nolofalletsang ho lemoha le ho arabela diphetohong tikolohong ya ho tjheseletsa. Tshebetso ena e sebedisa di-sensor tse tswetseng pele ho lekanya ka nepo diphetoho tse kang botenya ba tshepe, ho hokahanya manonyeletso le mocheso wa tikoloho. Ka ho ikamahanya le diphetoho tsena ka nako ya sebele, roboto ya ho tjheseletsa e netefatsa ho tjheseletsa ka nepo tseleng e lakatsehang, e leng se fellang ka boleng bo se nang sekoli ba ho tjheseletsa le ho fokotsa tlhoko ya diphetoho tsa letsoho.

4. Mosebetsi oa ho thibela ho thulana:

Polokeho ke ea bohlokoa tikolohong efe kapa efe ea indasteri, 'meliroboto tsa ho tjheseletsa ka laserli na le likarolo tsa ho thibela ho thulana ho thibela likotsi kapa tšenyo. Tšobotsi ena e sebelisa motsoako oa li-sensor, lik'hamera le li-algorithms tsa software ho lemoha litšitiso tseleng ea roboto. Hang ha e fumanoe, roboto e fetola tsela ea eona ka bo eona ho qoba ho thulana. Tšobotsi ena ha e sireletse roboto feela tšenyong, empa hape e netefatsa polokeho ea basebetsi le lisebelisoa tse haufi, e felisa kotsi ea likotsi le litokiso tse turang.

5. Mosebetsi oa ho lemoha liphoso:

E le ho netefatsa ts'ebetso e tsoelang pele le e sa khaotseng ea ho tjheseletsa, roboto ea ho tjheseletsa ea laser e na le ts'ebetso ea ho lemoha liphoso. Tšobotsi ena e lula e lekola ts'ebetso ea roboto, ho kenyeletsoa likarolo tse kang likhoele, phepelo ea motlakase le litsamaiso tsa ho pholisa. Ka ho khetholla liphoso tse ka bang teng kapa ho hloleha mohatong oa pele, liroboto li ka nka khato ea thibelo kapa tsa tsebisa basebetsi ka bothata. Ho lemoha le ho rarolla liphoso ka nako ho ka thusa ho eketsa bokhoni, ho fokotsa nako ea ho se sebetse le ho eketsa tlhahiso.

6. Mosebetsi oa ho kopanya terata e khomarelang ka ho tjheseletsa le mosebetsi oa ho qala bocha kamora ho robeha ha arc:

Tšobotsi e ikhethang ea liroboto tsa ho tjheseletsa ka laser ke bokhoni ba ho sebetsana le likhokahano tsa terata e khomarelang le ho qala bocha ts'ebetso ea ho tjheseletsa ntle le bothata kamora ho robeha ha arc. Ts'ebetso ea ho tjheseletsa terata e khomarelang e nolofalletsa roboto ho utloa le ho lokisa khokahano le terata ea ho tjheseletsa, ho netefatsa liphetho tse ntle ka ho fetisisa tsa ho tjheseletsa esita le bakeng sa thepa e thata. Ho phaella moo, ts'ebetso ea ho qala bocha ho robeha ha arc e lumella roboto ho qala hape ho tjheseletsa ka bo eona kamora ho sitisoa ha nakoana ntle le ho kenella ha motho. Litšobotsi tsena li nolofalletsa ho tjheseletsa boleng bo holimo ka linako tsohle, ho fokotsa liphoso le ho ntlafatsa katleho ea ho tjheseletsa ka kakaretso.

Ha re phethela:

Liroboto tsa ho tjheseletsa ka lasere fana ka likarolo tse ngata tse tsoetseng pele tse eketsang bokgoni ba ho tjheseletsa le ho nolofalletsa boiketsetso bo felletseng lits'ebetsong tse fapaneng. Tšobotsi ea ho sisinyeha e nolofalletsa tšireletso e nepahetseng le e potlakileng, e eketsang tlhahiso. Ho itšireletsa, ho lemoha ho tjheseletsa, ho thibela ho thulana, ho lemoha liphoso le mesebetsi e meng ho netefatsa ts'ebetso e sireletsehileng, e nepahetseng le e tsoelang pele. Ho phaella moo, mesebetsi ea ho kopanya terata e khomarelang le ho qala bocha ho tjheseletsa e thusa ho ntlafatsa boleng ba ho tjheseletsa le katleho ka kakaretso. Ka ho sebelisa bokhoni bona bo tsoetseng pele, liroboto tsa ho tjheseletsa tsa laser li fetotse tšimo ea ho tjheseletsa haholo, e leng se nolofalletsang bahlahisi ho fihlela liphetho tse ntle tsa ho tjheseletsa ka ho eketsa boiketsetso le tlhahiso.

Nako ea poso: Phato-03-2023