Lefatšeng la kajeno le potlakileng, boiketsetso bo fetohile karolo ea bohlokoa ea liindasteri lefatšeng ka bophara. Haholo-holo, tšebeliso ealiroboto tsa ho tjheseletsa ka lasere fetotse mekhoa ea tlhahiso mafapheng a 'maloa. Liroboto tsena li fana ka melemo e mengata, ho tloha ho nepahala le ho nepahala ho isa ho katleho e eketsehileng le ho fokotsa litšenyehelo tsa basebetsi. Sehloohong sena, re hlahloba mefuta e mengata ea lits'ebetso tsa liroboto tsa ho tjheseletsa ka laser le kamoo li fetolang liindasteri tse fapaneng kateng.

Indasteri ea likoloi e rua molemo haholo ka ho kopanngoa ha liroboto tsa ho tjheseletsa ka laser. Liroboto tsena li sebelisoa haholo lits'ebetsong tsa ho tjheseletsa 'mele le tsa ho tjheseletsa likarolo. Ka ho nepahala le lebelo la tsona le ikhethang, liroboto tsa ho tjheseletsa ka laser li netefatsa ho thehoa ha manonyeletso ka botlalo 'me li kenya letsoho ho tšoarelleng le matla a koloi ka kakaretso. Ts'ebetso ena e iketsang ha e eketse tlhahiso feela, empa hape e fokotsa monyetla oa liphoso, e leng se fellang ka likoloi tsa boleng bo holimo tse fihlelang le ho feta litebello tsa bareki.

Tlhahiso ea lisebelisoa tsa elektroniki ke sebaka se seng moo tšebeliso ea liroboto tsa ho tjheseletsa ka laser e holileng haholo. Liroboto tsena li sebelisetsoa ho tjheseletsa karolo e itseng, ho netefatsa likhokahano tse sebetsang hantle le tse tšepahalang ka har'a lisebelisoa tsa elektroniki. Ho phaella moo,liroboto tsa ho tjheseletsa ka laserli bapala karolo ea bohlokoa ho tjheseletsa boto ea potoloho, ho netefatsa khokahano e nepahetseng lipakeng tsa likarolo ka bomong. Ka ho nolofatsa ts'ebetso ea tlhahiso, liroboto tsena li ntlafatsa boleng le ho tšoarella ha lihlahisoa tsa elektroniki ha ka nako e ts'oanang li fokotsa kotsi ea liphoso le ho hloleha.

Indasteri ea lifofane, e tsebahalang ka litekanyetso tsa eona tse tiileng tsa boleng, le eona e qalile ho sebelisa liroboto tsa ho tjheseletsa ka laser. Liroboto tsena li sebelisoa haholo ho tjheseletsa likarolo, ho netefatsa botšepehi le matla a likarolo tsa bohlokoa tsa lifofane. Mohlala, liroboto tsa ho tjheseletsa ka laser li thusa ho tjheseletsa mapheo a lifofane, li thusa ho ntlafatsa polokeho ka kakaretso le ho tiea ha meaho ena ea bohlokoa. Ka ho iketsetsa ts'ebetso ea ho tjheseletsa, liroboto tsena ha li eketse ho nepahala le ho nepahala feela, empa hape li fokotsa kotsi ea liphoso tsa batho, tse ka behang botšepehi ba sebopeho sa sefofane kotsing.

Indasteri ea tlhahiso ea lisebelisoa tsa bongaka e itšetlehile haholo ka liroboto tsa ho tjheseletsa ka laser bakeng sa lits'ebetso tsa ho tjheseletsa likarolo le ho kopanya lisebelisoa tsa bongaka. Liroboto tsena li netefatsa ho tjheseletsa ka nepo le ka mokhoa o tsitsitseng likarolo tse rarahaneng tsa lisebelisoa tsa bongaka tse kang lisebelisoa tsa ho buoa le li-implant. Ka ho boloka maemo a boleng bo holimo nakong ea ts'ebetso ea tlhahiso,liroboto tsa ho tjheseletsa ka laserli thusa ho ntlafatsa polokeho le katleho ea lisebelisoa tsena tsa bongaka, qetellong li ruisa bakuli molemo. Ho feta moo, tlhaho ea tsona e iketsang e eketsa katleho ea tlhahiso, e leng se lumellang bahlahisi ho fihlela tlhoko e ntseng e eketseha ea lisebelisoa tsena tse pholosang bophelo.

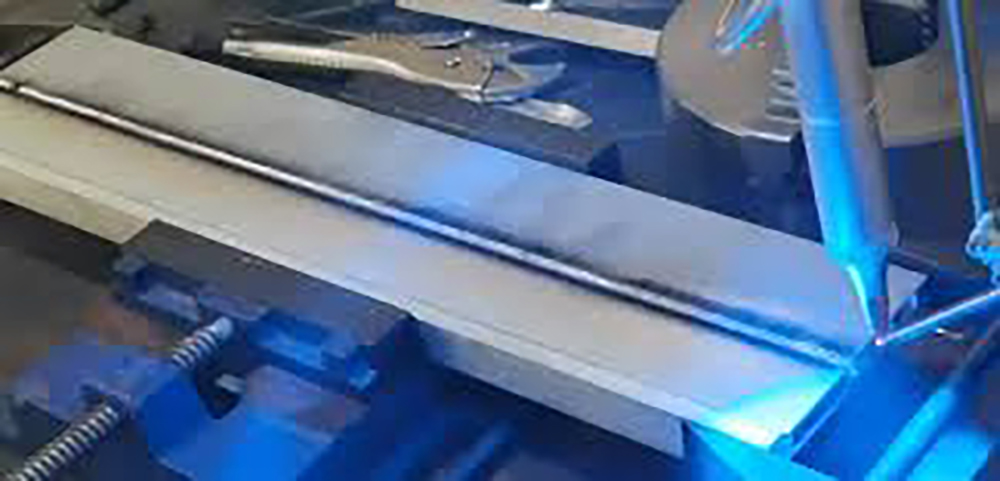

Indastering ea kaho, liroboto tsa ho tjheseletsa ka laser li fumane sebaka sa tsona ts'ebetsong ea ho tjheseletsa ka liphaephe le ho tjheseletsa fatše. Bokhoni ba liroboto tsena ba ho etsa li-weld tse nepahetseng libakeng tse thata bo kentse letsoho haholo ho ntlafatseng boleng le matla a liphaephe tse sebelisoang mererong ea liphaephe le meralo ea motheo. Ho phaella moo, liroboto tsa ho tjheseletsa ka laser li thusa ho tjheseletsa meaho ea fatše, ho netefatsa ho tšoarella le bophelo bo bolelele ba tšebeletso ea merero ea kaho. Liroboto tsena li eketsa tlhahiso le ho potlakisa ts'ebetso ea kaho, e leng se fellang ka ho phethoa ha merero ka nako ha li ntse li boloka maemo a boleng bo holimo ka ho fetisisa.

Ntle le lits'ebetso tsa indasteri, liroboto tsa ho tjheseletsa ka laser li etsa menehelo e kholo thutong le lipatlisisong tsa mahlale.lirobotoli ipakile li le bohlokoa haholo lipatlisisong le nts'etsopele, lilaboratoring tsa univesithi le litsi tsa lipatlisiso tsa mahlale. Liroboto tsa ho tjheseletsa ka laser li nolofalletsa bafuputsi ho hlahloba mekhoa le thepa e mecha ea ho tjheseletsa, ho ntšetsa pele lefapha la theknoloji ea ho tjheseletsa. Tlhaho ea tsona e iketsahallang le ho nepahala ho hoholo li lumella bo-rasaense ho etsa liteko ka ho nepahala ho sa bapisoeng le letho, e leng se lebisang ho litšibollo tse ncha le boqapi mafapheng a fapaneng.

Ka bokhutšoanyane, ts'ebeliso ealiroboto tsa ho tjheseletsa ka lasere fetotse liindasteri tse ngata, e fetotse mekhoa ea tlhahiso le boleng bo ntlafetseng ba sehlahisoa. Ho tloha tlhahisong ea likoloi ho ea ho lisebelisoa tsa elektroniki, lifofane, tlhahiso ea lisebelisoa tsa bongaka, kaho, le thuto le lipatlisiso tsa mahlale, tšusumetso ea liroboto tsa ho tjheseletsa ka laser ha e latoloe. Ka ho iketsetsa mesebetsi ea ho tjheseletsa, liroboto tsena li fana ka ho nepahala ho sa bapisoeng, botsitso le katleho, qetellong ho eketsa tlhahiso le ho fokotsa litšenyehelo. Ha liindasteri li ntse li tsoela pele ho amohela boiketsetso, bokamoso ba liroboto tsa ho tjheseletsa ka laser bo bonahala bo tšepisa ha li ntse li tsoela pele ho hatela pele le ho fetola lefats'e la tlhahiso.

Nako ea poso: Phato-15-2023