Mochini o Kopaneng oa ho Tjhesetsa oa Laser o Tšoaretsoeng ka Motlakase

Mochini o Kopaneng oa ho Tjhesetsa oa Laser o Tšoaretsoeng ka Motlakase

Mochini o Kopaneng oa ho Tjhesetsa oa Laser o Tšoaretsoeng ka Motlakase

Mochini o Kopaneng oa ho tjheseletsa oa Laser o Tšoaretsoeng ka Motlakaseho tsoa ho Fortune Laser Technology Co., Ltd., tharollo ea theknoloji e phahameng e etselitsoeng ho fetola mesebetsi ea hau ea ho tjheseletsa, ho seha le ho hloekisa. Sesebelisoa sena se feto-fetohang, se sebetsang ka botlalo se kopanya theknoloji e tsoetseng pele ea laser le moralo o bonolo ho o sebelisa, e leng se etsang hore e be sesebelisoa se matla bakeng sa mefuta e mengata ea lits'ebetso, ho tloha tlhahisong ea indasteri ho ea mererong ea malapa.

Ke Hobane'ng ha U Lokela ho Khetha Sesepa sa Rona sa Laser?

Tshebetso e Ikhethang:Sesebelisoa sa rona sa ho welda ka laser se sebedisa laser ya faeba ya watt tse 1000–2000 ho fana ka bokgoni bo phahameng ba phetoho ya electro-optical le boleng bo hodimo ba mahlasedi, e leng se fellang ka matheba a mangata a welda le ho kenella ka botebo. E sebetsa haholoholo bakeng sa ho welda dikarolo tse tshesane haholo tseo hangata ho leng thata ho di sebedisa ho sebedisa mekgwa ya setso jwalo ka welda ya argon arc.

Ts'ebetso e se nang Tlhokomelo:Dumela diphetoho tse etsahalang kgafetsa le ditjeo tse hodimo tsa tshebetso. Mochini wa rona o etseditswe ho se hloke tlhokomelo, o sebedisa motlakase o tlase mme o se ke wa sebediswa, e leng se fokotsang haholo ditjeo tsa ho sebetsa nako e telele.

Moralo o Bonolo ho Basebelisi:Moralo o monyane le o kopaneng haholo, o nang le moea o pholileng o kentsweng kahare, o etsa hore o tenyetsehe ebile o be bonolo ho o sebedisa. Tshebetso e bonolo hoo o sa hlokeng ho ba setsebi sa theknoloji se nang le boiphihlelo ho qala.

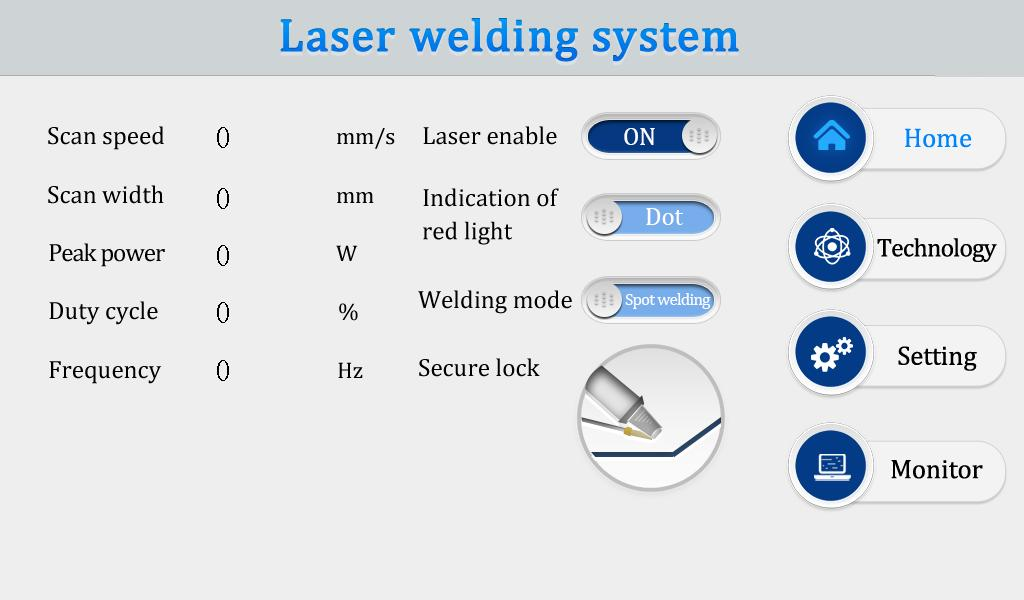

Polokeho e Ntlafalitsoeng:Mochini ona o na le ntlafatso ea tšireletso ea polokeho e thibelang ho ntšoa ha laser holim'a tšepe feela. Bakeng sa tšireletso e eketsehileng, senotlolo sa fatše se sireletsehileng se hloka hore hlooho ea ho tjheseletsa e kopane le sesebelisoa sa mosebetsi pele laser e ka kenngoa tšebetsong, e leng ho thibelang ho ntšoa ha leseli ka phoso le kotsi e ka bang teng.

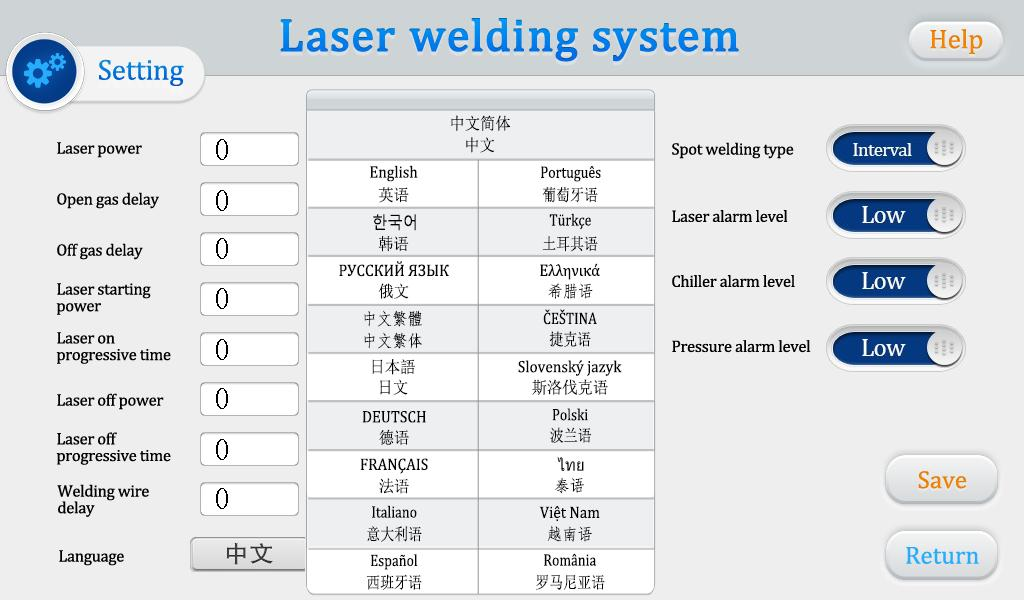

Phihlello ea Lefatše ka Bophara:Sebopeho sa rona se sebetsang ka ho hlaka se tshehetsa dipuo tse fetang 20, se etsa hore mochini o fumanehe ho basebetsi ba lefatshe lohle mme se nolofaletsa basebedisi ho sebetsa ka tsela e se nang mathata lefatsheng ka bophara.

Liparamente tsa Sehlahisoa

| Sehlopha sa Liparamente | Lebitso la Paramethara | Lintlha le Litlhaloso |

| Laser le Tshebetso | Mofuta oa Laser | Laser ea faeba ea 1000–2000 watt |

| Bokgoni ba Electro-Optical | Bokgoni bo phahameng ba phetoho | |

| Boleng ba Mahlasedi | E phahametse tsohle, e fetisoang ka faeba | |

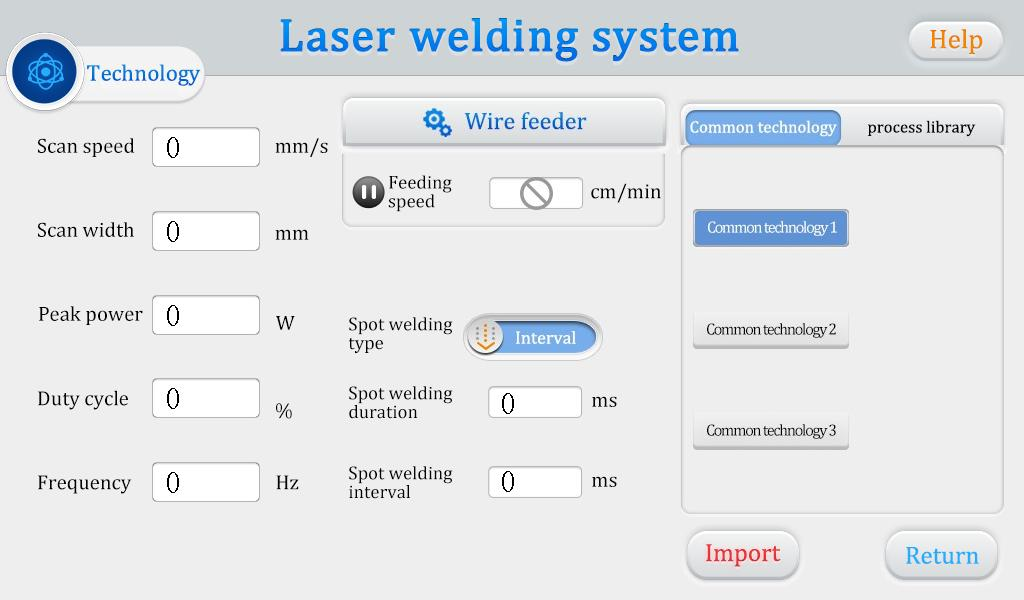

| Amplitude ea ho sisinyeha | 0mm ho isa ho 6mm, e ka fetoloang ka sistimi ea taolo ea PLC | |

| Lebelo la ho Sekena (Ho Wellisa) | 2–6000 mm/s (lebelo le tloaelehileng ke 300 mm/s) | |

| Bophara ba Sekene (Ho Cheseletsa) | 0–6 mm (bophara bo tloaelehileng ke 2.5–4 mm) | |

| Matla a Tlhōrō | E tlameha ho ba ka tlase ho kapa ho lekana le matla a laser leqepheng la litlhophiso | |

| Potoloho ea Mosebetsi | 0–100% (kamehla: 100%) | |

| Maqhubu a ho otla ha pelo | Sebaka se kgothaletswang: 5–5000 Hz (kamehla: 2000 Hz) | |

| Mekhoa ea Ts'ebetso | Mekhoa e Tšehelitsoeng | Ho tjheseletsa, ho Seha le ho Hloekisa |

| Mekhoa ea ho tjheseletsa | Ho tjheseletsa ka ho tswelang pele le ka matheba | |

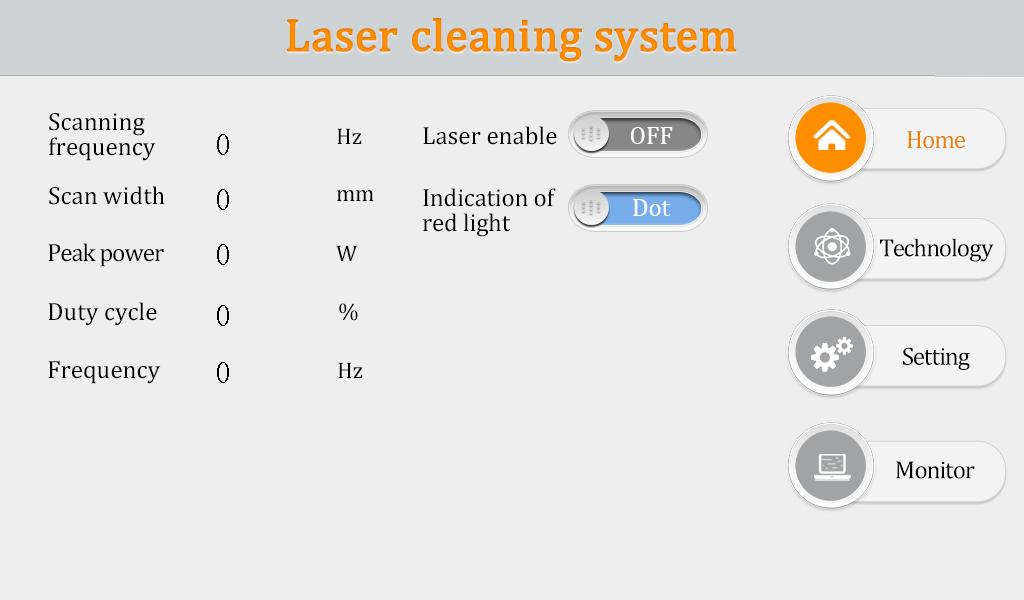

| Bophara ba ho Sekena (Ho Hloekisa) | 0–30 mm (ka lense e shebaneng le F150) | |

| Motlakase le Tikoloho | Phepelo ea motlakase | 220VAC ± 10%, matla a kakaretso a 6kW |

| Moqhekelli oa Matla | E hloka sethibela-moea sa C32 se nang le tšireletso ea ho lutla | |

| Mocheso oa Kamore ea Mosebetsi | 0°C ho isa ho 40°C | |

| Mongobo oa Kamore ea Mosebetsi | <60%, ha e koahele | |

| Tlhokomelo ea Boemo ba Matla | E bonts'a li-voltage le maqhubu a phepelo a 24V, ±15V | |

| Litšobotsi tsa Polokeho | Ho ntšoa ha Laser | E lekanyelitsoe holim'a tšepe feela |

| Senotlolo sa Tšireletso sa Lefatše | E hloka hore hlooho ea ho tjheseletsa e kopane le sehokelo sa mosebetsi bakeng sa ho kenya tšebetsong ka laser | |

| Sehlopha | Sehlahisoa sa laser sa sehlopha sa 4 | |

| Litemoso tsa Polokeho | E lemosa ka motlakase o phahameng, mahlaseli a laser le likotsi tsa mollo | |

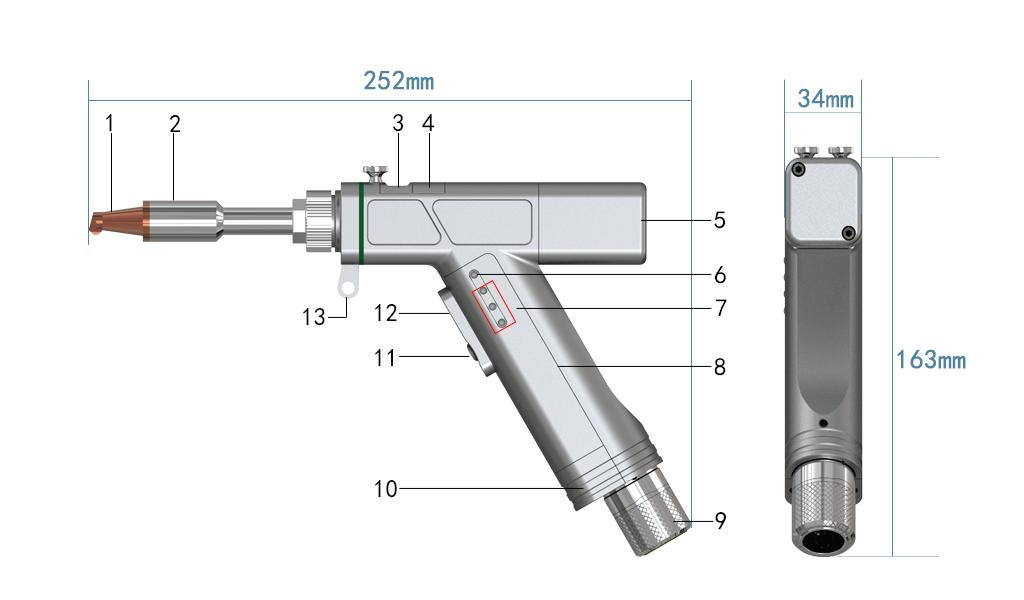

| Moralo le Tšebeliso | Hlooho e Tšoaroang ka Letsoho | E hlomelitsoe ka faeba ea optical e tsoang kantle ho naha ea limithara tse 10 |

| Moralo | E kopane ebile e kopantsoe haholo, e nang le moea o pholileng o hahiloeng kahare | |

| Lipuo tsa Sebopeho | E tšehetsa lipuo tse 19 ka mofuta o tloaelehileng | |

| Boemo ba Bokhoni ba Mosebelisi | Ho bonolo ho e sebetsa; ha ho hlokahale setsebi se nang le boiphihlelo | |

| Tlhokomelo | Ho hloekisa | Hlakola likarolo tsa kantle, lense e sireletsang, 'me u boloke tikoloho e se na lerōle |

| Sistimi ea ho Pholisa | Hlahloba le ho hlwekisa lerōle le tsoang mothapong oa moea khafetsa | |

| Likarolo tsa ho Apara | Lense e sireletsang le nozzle ea koporo | |

| Maqhubu a Tlhokomelo | Litlhahlobo tsa letsatsi le letsatsi le halofo ea selemo lia khothaletsoa |

Hlooho ea ho tjheseletsa ea Laser

Leqephe la Lehae