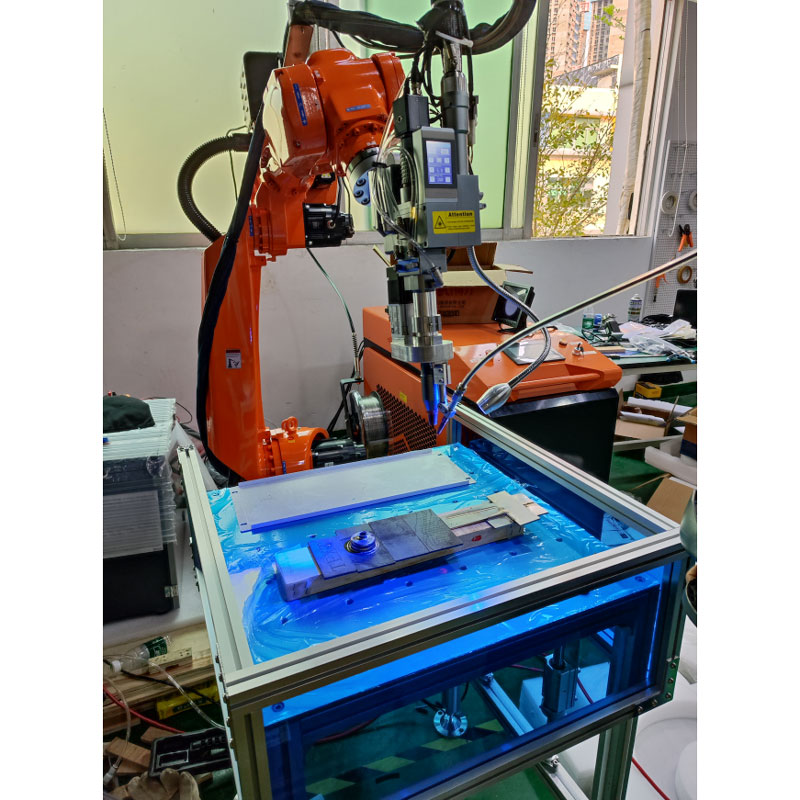

Mochini oa ho tjheseletsa oa Laser oa Lerumo oa Liroboto oa Liindasteri

Mochini oa ho tjheseletsa oa Laser oa Lerumo oa Liroboto oa Liindasteri

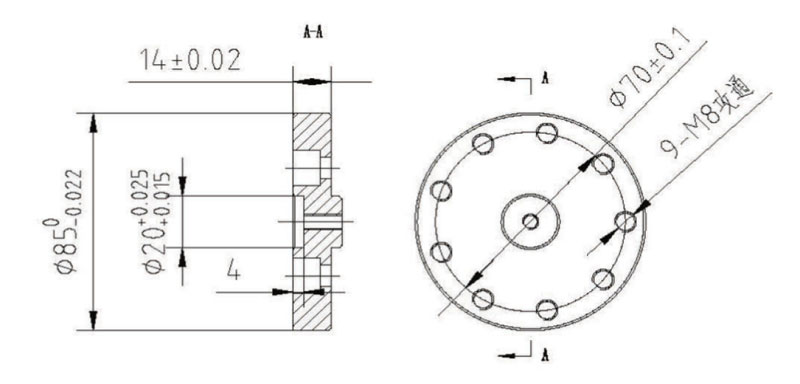

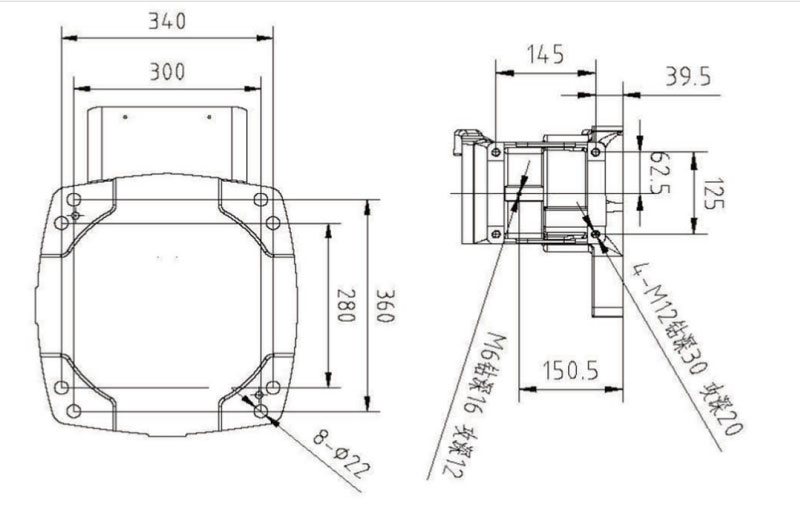

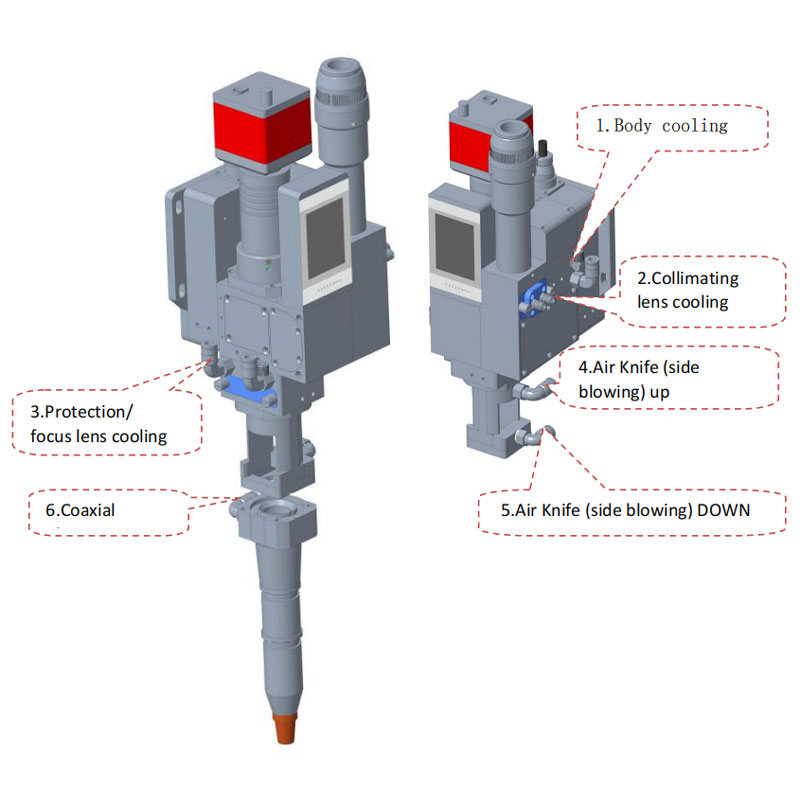

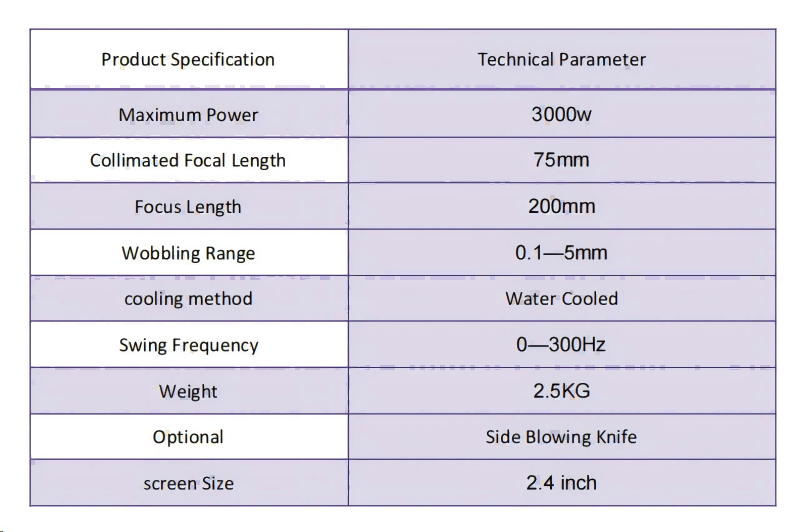

2. Hlooho ea ho tjheseletsa

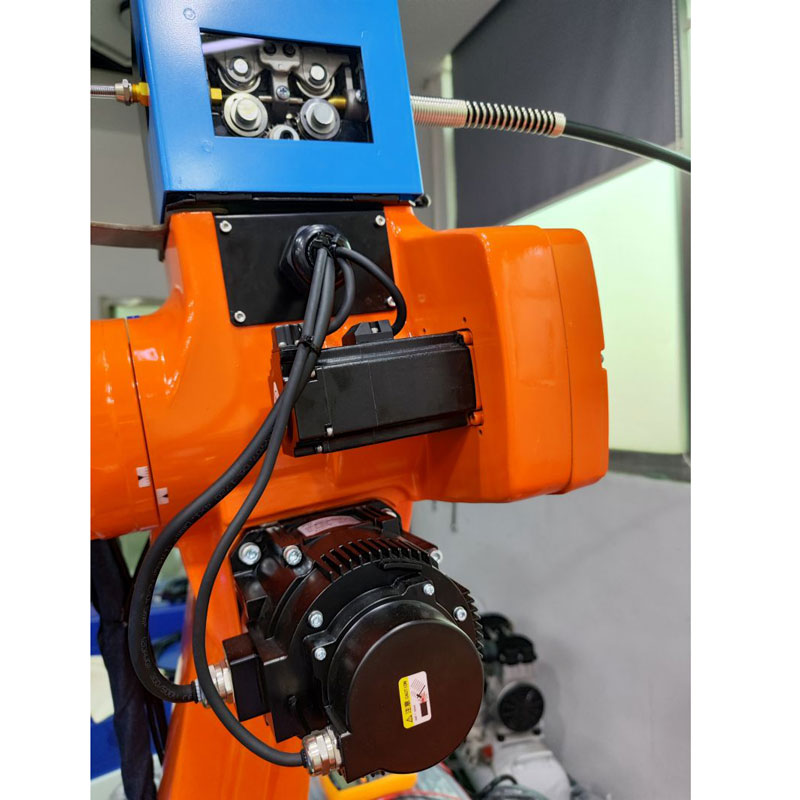

3. Sistimi ea ho tjheseletsa ea Laser (Mohloli oa Laser le Sistimi ea Chiller le Taolo) le sesebelisoa sa ho fepa ka terata

1). Mohloli oa laser oa Maxphotonics oa 1500W/2000W/3000W bakeng sa khetho

2). Sehatsetsi sa metsi

3). Sistimi ea Taolo

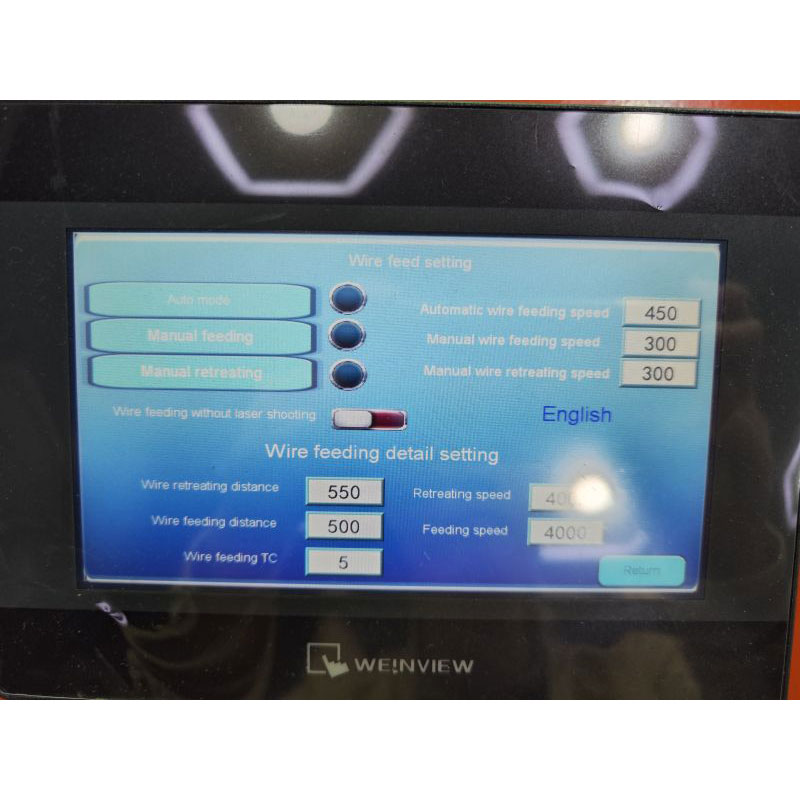

4). Sesebelisoa sa ho fepa ka terata se iketsang

Re kope theko e ntle kajeno!

Ngola molaetsa oa hau mona 'me u o romelle ho rona