Mochini oa ho tjheseletsa oa Fortune Laser o Iketsang oa 1000W/1500W/2000W oa Faeba Laser o Tsoelang Pele

Mochini oa ho tjheseletsa oa Fortune Laser o Iketsang oa 1000W/1500W/2000W oa Faeba Laser o Tsoelang Pele

Melao-motheo ea Motheo ea Mochini oa Laser

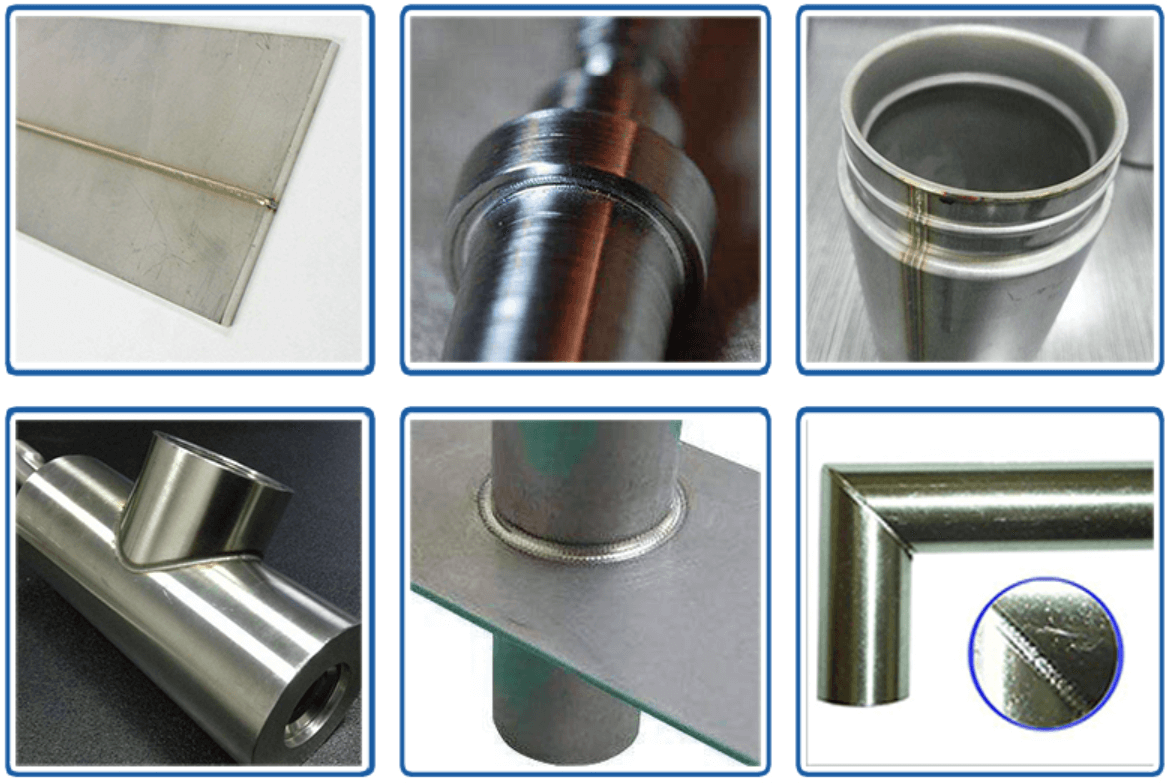

Mochini o tjheseletsang ka laser o tswelang pele ke mofuta o mocha wa mokgwa wa ho tjheseletsa. Ka kakaretso o bopilwe ka "moamoheli wa ho tjheseletsa" le "benche ya mosebetsi ya ho tjheseletsa". Lehlasedi la laser le hokahantswe le faeba ya optical. Kamora phetiso ya sebaka se selelele, e sebetswa ho ba lesedi le shebaneng le lona ka nako e le nngwe. Ho tjheseletsa ho tswelang pele ho etswa hodima sesebediswa sa mosebetsi. Ka lebaka la ho tswela pele ha lesedi, phello ya ho tjheseletsa e matla mme seam ya ho tjheseletsa e ntle le ho feta. Ho ya ka ditlhoko tse fapaneng tsa diindasteri tse fapaneng, disebediswa tsa ho tjheseletsa ka laser di ka bapisa sebopeho le benche ya mosebetsi ho ya ka sebaka sa tlhahiso mme tsa etsa tshebetso e iketsahallang, e ka fihlelang ditlhoko tsa basebedisi ka botlalo diindastering tse fapaneng.

Bongata ba mechini ea ho tjheseletsa ea laser ea fiber e tsoelang pele e sebelisa li-laser tse matla haholo tse nang le matla a fetang li-watts tse 500. Ka kakaretso, li-laser tse joalo li lokela ho sebelisoa bakeng sa lipoleiti tse fetang 1mm. Mochini oa eona oa ho tjheseletsa ke ho tjheseletsa ho kenella ka botebo ho latela phello ea lesoba le lenyenyane, ka karolelano e kholo ea botebo-ho-bophara, e ka fihlang ho feta 5:1, lebelo le potlakileng la ho tjheseletsa, le phetoho e nyane ea mocheso.

Mochini oa ho tjheseletsa oa Laser o Tsoelang Pele oa 1000W 1500w 2000w tšobotsi

Liparamente tsa Tekheniki tsa Mochini oa ho Wellisa oa Laser o Tsoelang Pele oa Fortune Laser

Lisebelisoa

1. Mohloli oa laser

2. Thapo ea Laser ea Faeba

3. Hlooho ea ho tjheseletsa ea laser ea QBH

4. 1.5P chiller

5. PC le sistimi ea ho tjheseletsa

6. 500*300*300 Seteishene sa Phetolelo ea Motlakase sa Servo sa Linear sa 500*300*300

7. Sistimi ea taolo ea li-axis tse 'ne ea 3600

8. Sistimi ea khamera ea CCD

9. Khabinete ea Mainframe