Sezvo simba rekupinza uye chitarisiko chesimbi yekuwachisa sheet metal zviri kuramba zvichikwira, kunyanya kune zvikamu zvine kukosha kwakanyanya uye zvinodiwa zvemhando yepamusoro yekuwedhisa, nzira dzechinyakare dzekuwachisa dzichatungamira mukushanduka kwechinhu chebasa nekuda kwekupisa kukuru, nezvimwewo. Dambudziko, rinoda nzira dzakawanda dzekukuya nekugadzira, zvichikonzera kukwira kwemitengo.

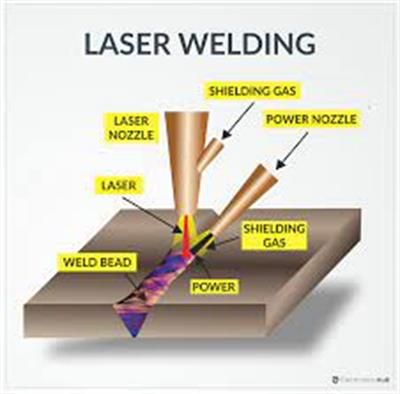

Zvisinei,welding nelaserine simba rakawanda uye nzvimbo isinganyanyi kukanganiswa nekupisa, izvo zvisingangobatsiri chete pakugadzirisa simbi zvakanyanya, asiwo zvinovandudza mhando uye zvinoderedza nguva yekugadzirisa mushure mekushandiswa.

Saka, kushandiswa kwe laser welding mukugadzirwa kwesimbi dzemazuva ano kuri kuramba kuchifarirwa. Vatengi vazhinji vari kunetseka nemitengo yekutenga michina, kushanda zvakanaka kwe welding uye mhando, kumhanya kwekukuya, zvinhu zvinoshandiswa mushure mekugadzirisa, kushandiswa kwesimba, kuoma kwekushanda, dziviriro yekuchengetedza, mari yekutevera mushure mekutengesa nezvimwe zvinhu zvakawanda.

Kune mhando dzakawanda dzemichina yekuwedera pamusika. Vatengi vanofanira kufunga nezvezvinhu zvinotevera pavanosarudza muchina wekuwedera nelaser:

1. Hunhu hweOptical: saizi yenzvimbo (dhayamita yetsvimbo yelaser, dhayamita yefiber uye mhando, maparamita emusoro wekubuda), kukwirira kwenzvimbo yakatarisana, kudzika kwemunda, nzvimbo yenzvimbo, kona yenzvimbo yenzvimbo;

2. Hunhu hwekudzora: kusarudzwa kwemaitiro ekudzora mhinduro uye simba remafungu.

Mushure mekuenzanisa nzira dzakasiyana-siyana dzekuwelda, kambani yedu yakatanga mhando nhatu dzemichina yekuwelda nelaser: fiber optic four-dimensional automatic welding, robot automatic welding, uyewelding inobatwa nemaoko nelaserkune zvinodiwa zvakasiyana-siyana zveindasitiri yesimbi dzemachira. Matsime emwenje emidziyo mitatu iyi anoshandisa fiber lasers, hapana zvinodyiwa uye kugadziriswa kunodiwa, mhando yedanda rakanaka, uye kumhanya kwekuwelda kunokurumidza, inova ndiyo musimboti wakanakisa wekugadzirisa muindasitiri yesimbi dzemachira.

Kusarudzwa kwemidziyo

01. Kuisa otomatiki fiberg

Mashandisirwo ekushandisa:Inonyanya kushandiswa pakugadzira simbi diki nepakati, chigadzirwa chacho chine magadzirirwo akanyatsojeka, uye kugadzirwa kwesimbi kunogona kuitwa nekushandisa maturusi nemagadzirirwo akanaka.

Kushanda otomatiki kwepamusoro-soro:kuburitswa kwelaser ine simba guru, nzvimbo inodzokororwa nekudzokorora kwakanyatsojeka, bhenji rebasa riri kure rine mativi mana, sisitimu yekushandisa iri nyore kwazvo, kutarisisa otomatiki uye kutenderera kwemusoro wewelding, zvichiita kuti zvive nyore kwazvo kugadzira nekugadzira otomatiki;

Yakasimba uye yakanaka:weld ine chiyero chepamusoro (yakadzika uye yakamanikana), hapana waya yekuzadza inodiwa, kusvibiswa kwenzvimbo yekunyunguduka kudiki, weld ine simba rakawanda uye kusimba (inotopfuura zvinhu zvepasi), uye yakajeka uye yakanaka;

Simba diki rekupisa:simba re laser rakakwira, uyemaitiro ekunamirainokurumidza zvikuru, saka kupisa kunopinzwa pachinhu chebasa kwakaderera zvikuru, nzvimbo inokanganiswa nekupisa idiki, uye chinhu chebasa hachikanganisike;

Kuwanda kwevanhu:Gasi rinobuda nekukurumidza kana musono we weld wagadzirwa, uye musono we weld unopinda hauna maburi. Uyezve, kutonhora nekukurumidza mushure mekusonwa kunoita kuti chimiro che weld chive chakanaka uye huwandu hwekusonwa huve hwakanyanya.

Kudzora:Inogona kudzora mabasa ese akadai sekugadzika kwemusono we welding, saizi yenzvimbo, kutumirwa kwedanda, kugadzirisa simba rechiedza, kudzora sitiroko, kumira nekukurumidza nekukurumidza, nezvimwewo;

Kushanda zviri nyore:mashandiro epakati pemabhatani, kutarisa kwechiso nemaziso, kushanda kuri nyore uye nekukurumidza;

Kushanda kwakagadzikana:Muchina uyu unodzorwa zvakasimba nechikwata chehunyanzvi hwemhando yepamusoro kubva kuzvikamu kusvika kumuchina wese, uye uchaongororwa zvakanaka uye kuongororwa usati wabuda mufekitori, saka mashandiro emuchina uyu akagadzikana zvikuru;

Mhando dzakasiyana dzemashandisirwo:Kubatana kwe-four-axis long-stroke linkage, ma waveform akasiyana anogona kuiswa kune process parameters zvichienderana nezvinhu zvakasiyana zve welding, kuitira kuti parameters dze welding dzikwanise kuenderana nezvinodiwa zve welding. Yakakodzera welding mumaindasitiri akasiyana-siyana, zvigadzirwa uye nzira.

Musoro wekutenderera:Saizi nechimiro chenzvimbo ine chiedza zvinogona kugadziriswa, izvo zvinogona kushandiswa zvakanyanya uye zvinogona kugadziriswa kuti zvienderane nekusonwa kwezvigadzirwa zvakasiyana-siyana.

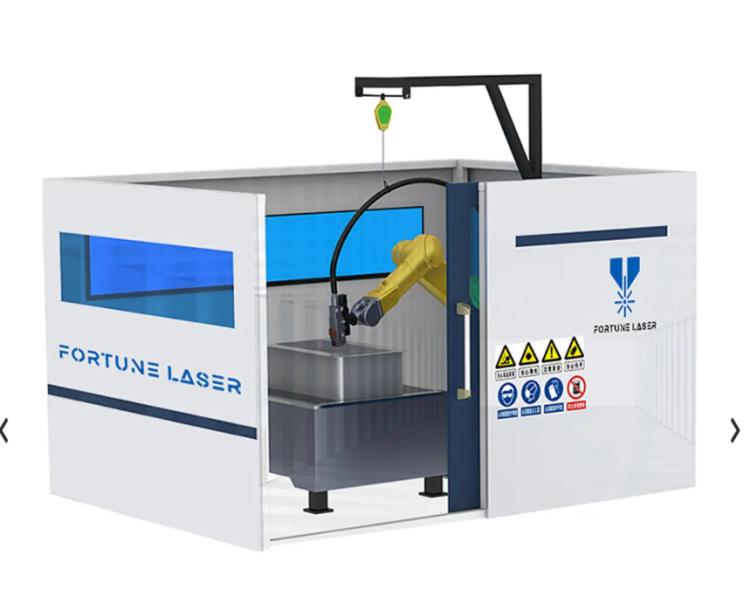

02. Kusonerera marobhoti

Mashandisirwo: Inonyanya kushandiswa pamatanda makuru esimbi yepakati nepakati nehombe. Ine kunyatsorongeka kwepamusoro uye kufamba kunochinjika. Yakakodzera maworkpieces akasiyana-siyana ane makona akaomarara enzira. Inogona kugadzirwa kuita nzvimbo dzakawanda kuti ivandudze kushanda kwewelding. Ndiyo yega sarudzo yekutsiva basa remaoko uye kuderedza simba rebasa.

Uchishandisa ruoko rwerobhoti rune mativi matanhatu, huwandu hwewelding hwakafara.

Kurongeka kwenzvimbo dzakadzokororwa kwakakwira, kusvika ku0.05 mm.

Robhoti iri rine kusimba kwakanaka uye hupenyu hurefu hwebasa.

Kubudirira kwekugadzira kwacho kwavandudzika zvikuru, uye kunogona kushanda nguva dzose kwemaawa makumi maviri nemana. Pamwe chete nekushandisa maturusi netambo yekuunganidza, inogona kugadzira otomatiki huwandu hwezvinhu.

Musoro wekutenderera: saizi nechimiro chenzvimbo yechiedza zvinogona kugadziriswa, izvo zvinogona kushandiswa zvakanyanya uye zvinogona kugadziriswa kuti zvienderane newelding yemhando dzakasiyana-siyanazvigadzirwa.

03. Kushongedza nelaser nemaoko

Mashandisirwo:Inonyanya kushandiswa pakugadzira simbi isiri yemhando yepamusoro. Kune mhando dzakawanda dzezvigadzirwa, zvisingakodzeri kushandiswa pakugadzira zvinhu zvakasiyana-siyana, kudzivirira mari yakawanda. Kukombama kwechigadzirwa hakusi kwakanyanya, uye musiyano wacho wakakura zvakanyanya, izvo zvinogadzirisa dambudziko rekuoma kwekutsvaga vashandi. Modhi iyi yakawana rumbidzo kubva kuvatengi.

Kushanda kuri nyore:Iyomuchina we laser welding unobatwa nemaokozviri nyore kudzidza uye kushandisa, uye mushandi anogona kuwana mhedzisiro yemhando yepamusoro yekuwedera.

Kushanda zvakanaka kwewelding:Kupinza kwelaser kunobata nemaoko kunokurumidza kupfuura kupinza kweargon arc. Zvichibva pakuchengetedza vashandi vaviri vekupinza, kushanda zvakanaka kwekugadzira kunogona kupetwa kaviri zviri nyore.

Hapana zvinodyiwa zvekunamira:Kubatanidza kunogona kuitwa zviri nyore pasina waya yekuzadza panguva yekushanda, izvo zvinoderedza mutengo wezvinhu pakugadzira nekugadzirisa.

Mhedzisiro yakanaka yekushongedza:Kupinza nelaser nemaoko kunopisa nekunyungudutsa. Kana tichienzanisa nekupinza kwechinyakare, kuisa nelaser kune simba rakawanda uye mhedzisiro iri nani.

Kushandurwa kwesimba rakawanda:Kushanda zvakanaka kwe laser pakushandura ma photoelectric kwakakwira kusvika 30%, uye kushandiswa kwesimba kwakaderera.

Zviri nyore kushandisa uye zvinochinjika:welding inobatwa nemaoko nelaser, yakasununguka uye inochinjika, uye inogona kusvikwa

Misono yeweld haidi kukweshwa: kukweshwa kunoenderera mberi, kutsetseka pasina makwande ehove, kwakanaka uye kusina mavanga, zvichideredza maitiro ekukuya anotevera.

Musoro wekutenderera:Saizi nechimiro chenzvimbo ine chiedza zvinogona kugadziriswa, izvo zvinogona kushandiswa zvakanyanya uye zvinogona kugadziriswa kuti zvienderane nekusonwa kwezvigadzirwa zvakasiyana-siyana.

Pakusarudza simba remagetsi relaser, kazhinji, pasi pepfungwa yekuburitsa simba remagetsi relaser rakafanana, hupamhi hwepulse, nzvimbo yekuwelding yakakura; simba repamusoro resimba remagetsi relaser rakakwirira, ndipo pakadzika nzvimbo yekuwelding. Parizvino, hapana nzira dzakakwana dzekugadzirisa simba remagetsi relaser. Vashandisi vanogona kuongorora zvishoma nezvishoma mukushandiswa kwavo kuti vawane simba remagetsi relaser rakakodzera zvigadzirwa zvavo.

Kusarudzwa kwemuchina we laser welding kwakakosha zvikuru pahuwandu hwegoho rekugadzirisa batch; saka, kana mamiriro ezvinhu achibvumira, vashandisi vanogona kushandisa muchina we laser power real-time negative feedback zvakanyanya sezvinobvira kuti vawedzere huwandu hwakanaka hwezvigadzirwa.

Kana muchida kudzidza zvakawanda nezve laser welding, kana kuti muchida kutenga muchina we laser welding wakanakisisa kwamuri, ndapota siyai meseji pawebhusaiti yedu uye titumirei email zvakananga!

Nguva yekutumira: Kukadzi-17-2023