Muchina weKushongedza weFiber Laser weFortune Laser Unobata Nemaoko

Muchina weKushongedza weFiber Laser weFortune Laser Unobata Nemaoko

Magadzirirwo ehunyanzvi eLaser Welder ane Maoko eFortune Laser

| Muenzaniso | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Rudzi rweLaser | 1070nm Fiber Laser | ||

| Simba reLaser rezita | 1000W | 1500W | 2000W |

| Sisitimu Yekutonhodza | Kutonhodza Mvura | ||

| Nzira yekushanda | Kuenderera mberi / Kuchinja-chinja | ||

| Kumhanya kwewelder | 0~120 mm/s | ||

| Dhayamita yeFocal Spot | 0.5mm | ||

| Tembiricha iri pakati nepakati | 15~35 ℃ | ||

| Hunyoro hwezvakatipoteredza | <70% isina kunyorovesa | ||

| Ukobvu hwekunamira | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Zvinodiwa pakukwesha mipata | ≤1.2mm | ||

| Voltage Inoshanda | AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Kukura kweKabhineti | 120*60*120cm | ||

| Dimension yePakeji yemapuranga | 154*79*137cm | ||

| Huremu | 285KG | ||

| Kureba kwefaibha | Yakajairwa 10M, kureba kwakarebesa kwakagadziridzwa i15M | ||

| Kushandiswa | Kusundira nekugadzirisa simbi isingasvibi, simbi yekabhoni, aruminiyamu. | ||

Welder yeLaser inotakurika yesimbi

| Zvinhu | Simba rekuburitsa (W) | Kupinda kwakanyanya (mm) |

| Simbi isina ngura | 1000 | 0.5-3 |

| Simbi isina ngura | 1500 | 0.5-4 |

| Simbi isina ngura | 2000 | 0.5-5 |

| Simbi yekabhoni | 1000 | 0.5-2.5 |

| Simbi yekabhoni | 1500 | 0.5-3.5 |

| Simbi yekabhoni | 2000 | 0.5-4.5 |

| Aruminiyamu chiwanikwa | 1000 | 0.5-2.5 |

| Aruminiyamu chiwanikwa | 1500 | 0.5-3 |

| Aruminiyamu chiwanikwa | 2000 | 0.5-4 |

| Pepa rakarukwa | 1000 | 0.5-1.2 |

| Pepa rakarukwa | 1500 | 0.5-1.8 |

| Pepa rakarukwa | 2000 | 0.5-2.5 |

Mavara Matatu Esarudzo Dzako

Mabhenefiti eMuchina weKushongedza weLaser Unobata Nemaoko

1. Kushandiswa kwewelding kwakafara:

Musoro wekunamira weruoko une fiber yepakutanga ye10M (hurefu hwakareba hwakagadziriswa i15M), iyo inokunda zvipingamupinyi zvenzvimbo yebasa, uye inogona kunamira panze uye kunamira kure;

2. Zviri nyore kushandisa uye zvinochinjika:

Kuwedera kwelaser kunobata maoko kune mapulley anofambiswa, akasununguka kubata, uye anogona kugadzirisa chiteshi chero nguva, pasina chiteshi chine nzvimbo yakatarwa, chisina kuchinjika uye chinochinjika, uye chakakodzera mamiriro akasiyana-siyana enzvimbo yekushandira.

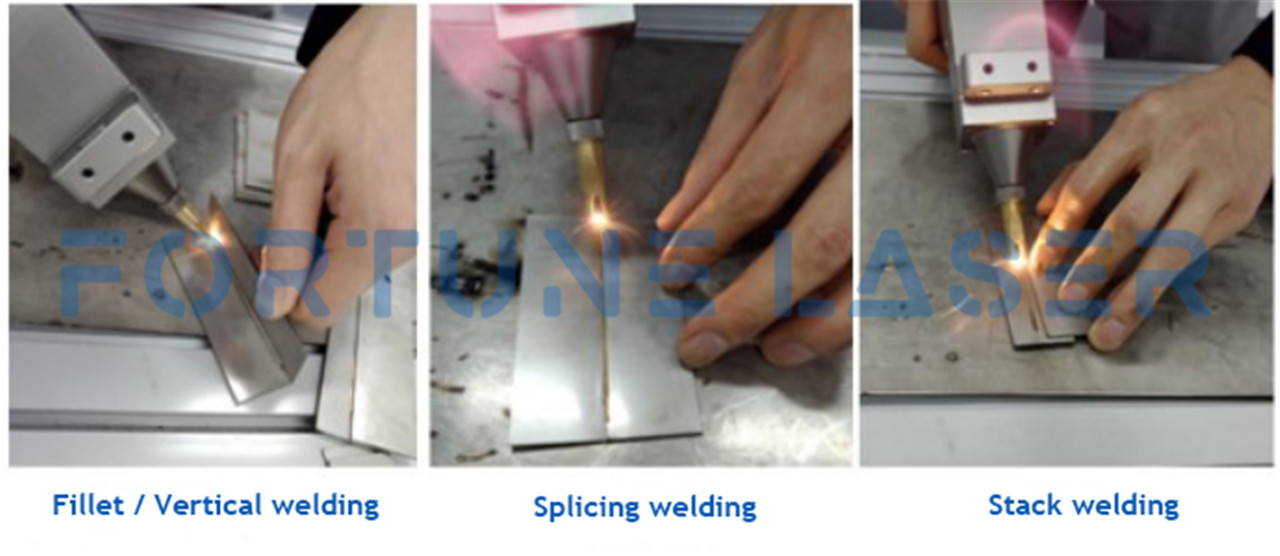

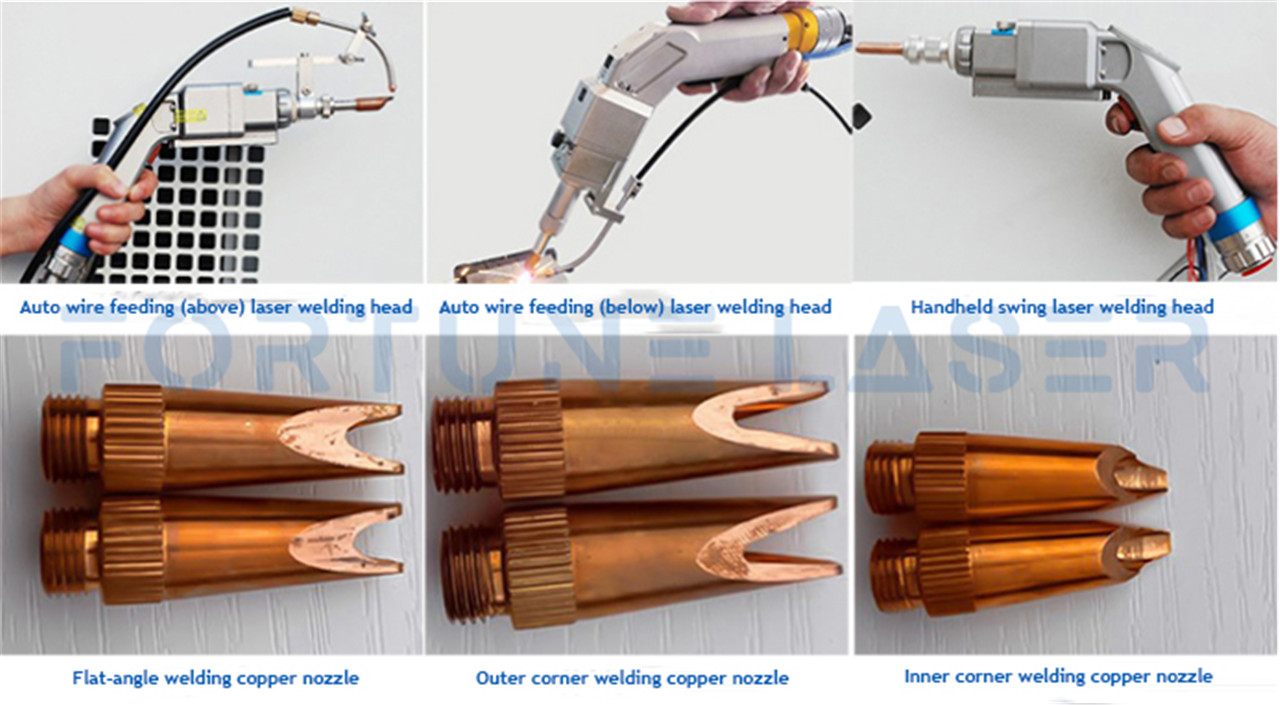

3. Nzira dzakasiyana-siyana dzekunamira:

Kuwedera chero pakona kunogona kuitwa: kuwedera kunopindirana, kuwedera pamabutt, kuwedera kwakatwasuka, kuwedera kwakatwasuka, kuwedera kwemukati mefillet, kuwedera kwekunze kwefillet, nezvimwewo, uye kunogona kuwedera zvidimbu zvakasiyana-siyana zvakaoma zvakawedera uye zvidimbu zvikuru zvebasa zvine maumbirwo asina kurongeka. Ziva kuwedera chero pakona. Pamusoro pezvo, zvinogona zvakare kupedzisa kucheka, kuwedera uye kucheka kunogona kuchinjwa zvakasununguka, ingochinja nozzle yemhangura yekuwedera kuita nozzle yemhangura yekuchekera, izvo zviri nyore kwazvo.

4. Mhedzisiro yakanaka yekushongedza:

Kupinza nelaser inobatwa nemaoko kunobatanidza thermal fusion welding. Kana tichienzanisa nekupinza kwechinyakare, kuisa nelaser kune simba rakawanda uye kunogona kuita kuti pave nemigumisiro iri nani yekuisa. Nzvimbo yekupinza haina simba rakawanda rekupisa, haisi nyore kuichinja, ine dema, uye ine mavanga kumashure. Kudzika kwekuisa kwakakura, kunyunguduka kwakakwana, uye kwakasimba uye kwakavimbika, uye simba rekuisa rinosvika kana kupfuura simbi yekutanga pachayo, izvo zvisingagone kuvimbiswa nemichina yekupinza yakajairwa.

5. Musono wekunamira haudi kukweshwa.

Mushure mekushongedza kwechinyakare, nzvimbo yekushongedza inofanira kukweshwa kuti ive nechokwadi chekuti yakatsetseka uye haina kukweshwa. Kushongedza nelaser kunobata nemaoko kunoratidza zvakanakira zvakawanda mukugadzirisa: kushongedza kunoenderera mberi, kukweshwa kwakatsetseka uye kusina makwande ehove, kunaka uye kusina mavanga, uye maitiro mashoma ekupukuta anotevera.

6. Kusondera neotomatiki waya yekudyisa.

Mukufunga kwevanhu vazhinji, basa rekubatanidza simbi rinoitwa "magirazi ekuruboshwe, waya yekubatanidza simbi yeruoko rwerudyi". Asi nemuchina wekubatanidza simbi welaser unobatwa neruoko, simbi iyi inogona kupedzwa zviri nyore, izvo zvinoderedza mutengo wekugadzira nekugadzira zvinhu.

7. Zvakachengeteka kunemushandi.

Nemaaramu akawanda ekuchengetedza, muromo wewelding unoshanda chete kana switch yabatwa painobata simbi, uye mwenje unovharwa otomatiki mushure mekunge workpiece yabviswa, uye touch switch ine tembiricha yemuviri. Kuchengetedzeka kwakanyanya kuti ive nechokwadi chekuti mushandi akachengeteka panguva yebasa.

8. Chengetedza mari yebasa.

Kana tichienzanisa nekuwelda nearc, mutengo wekugadzirisa unogona kuderedzwa neinenge 30%. Basa racho riri nyore, riri nyore kudzidza, uye rinotanga nekukurumidza. Muganho wehunyanzvi hwevashandi hauna kukwira. Vashandiwo zvavo vanogona kutora nzvimbo dzavo mushure mekudzidziswa kwenguva pfupi, izvo zvinogona kuwana mhedzisiro yemhando yepamusoro yekuwelda.

9. Zviri nyore kuchinja kubva panzira dzechinyakare dzekusonerera kuenda pakusonerera nelaser yefiber.

Unogona kudzidza mashandisiro emuchina wekusonerera weFortune Laser fiber laser mukati memaawa mashoma, uye hapana dambudziko rekutsvaga nyanzvi dzekusonerera, hapana kunetseka nezvehurongwa hwekuunza hushoma. Uyezve, nehunyanzvi hutsva uhwu nekudyara mari, uchave pamberi pemusika uye uchagamuchira purofiti yakawedzerwa kupfuura nzira dzechinyakare dzekusonerera.

Minda yeKushandiswa kweMuchina weKushongedza weLaser Welding weHandheld

Muchina we laser unosungirirwa nemaoko unonyanya kushandiswa pakugadzira simbi hombe nepakati, makabati, chassis, masuo nemahwindo ealuminium alloy, mabheseni ekuwachisa esimbi isina ngura nezvimwe zvinhu zvikuru zvebasa, zvakaita sekona yerudyi yemukati, kona yerudyi yekunze, welding ye flat weld, nzvimbo diki inokanganiswa nekupisa panguva yekuwelding, deformation diki, uye kudzika kwewelding. Welding yakakura, yakasimba.

Michina yeFortune Laser inokweshwa neruoko inoshandiswa zvakanyanya mumabasa akaomarara uye asina kurongeka ekubatanidza midziyo yekicheni neyekugezera, indasitiri yemidziyo yemumba, indasitiri yekushambadzira, indasitiri yemould, indasitiri yezvigadzirwa zvesimbi isina ngura, indasitiri yeinjiniya yesimbi isina ngura, indasitiri yemasuo nemahwindo, indasitiri yemabasa emaoko, indasitiri yezvinhu zvemumba, indasitiri yefenicha, indasitiri yezvikamu zvemotokari, nezvimwewo.

Kuenzanisa kweMuchina weKukwesha weLaser Welding weHandheld neArgon Arc Welding

1. Kuenzanisa kushandiswa kwesimba:Kana tichienzanisa ne arc welding yechinyakare, muchina we laser welding unobatwa nemaoko unochengetedza ingangoita 80% kusvika 90% yesimba remagetsi, uye mutengo wekugadzirisa unogona kuderedzwa neinenge 30%.

2. Kuenzanisa kwemhedzisiro yeWelding:Kupinza neruoko uchishandisa laser kunogona kupedzisa kupinza nesimbi dzakasiyana. Kumhanya kwacho kunokurumidza, kuchinja kwacho kudiki, uye nzvimbo inokanganiswa nekupisa idiki. Musono we weld wakanaka, wakatsetseka, hauna/ushoma, uye hauna kusvibiswa. Muchina we laser welding unobatwa neruoko unogona kushandiswa pazvikamu zvidiki zvakavhurika uye pakupinza neunyanzvi.

3. Kuenzanisa maitiro ekutevera:Kupisa kushoma panguva yekukwesha nemaoko nelaser, kushanduka kudiki kwebasa, nzvimbo yakanaka yekukwesha inogona kuwanikwa, hapana kana kugadziriswa kuri nyore chete (zvichienderana nezvinodiwa nemhedzisiro yenzvimbo yekukwesha). Muchina wekukwesha nelaser unobatwa neruoko unogona kuderedza zvakanyanya mari yekushanda kwemabasa ekukwesha nekuenzana.

| Rudzi | Kushongedza arc yeArgon | Kushongedza kweYAG | Inobatwa nemaokoLaserkusona | |

| Hunhu hwekunamira | Kupinza kupisa | Hombe | Diki | Diki |

|

| Kugadziriswa kwechinhu chebasa/kuchekwa pasi | Hombe | Diki | Diki |

|

| Kuumbwa kwesimbi | Maitiro ehove | Maitiro ehove | Yakapfava |

|

| Kugadziriswa kunotevera | ChiPolish | ChiPolish | Hapana |

| Shandisa mashandiro | Kumhanya kwekushongedza | Zvishoma nezvishoma | Pakati | Kukurumidza |

|

| Kuoma kwekushanda | Zvakaoma | Zviri nyore | Zviri nyore |

| Kudzivirirwa uye kuchengetedzeka kwezvakatipoteredza | Kusvibiswa kwezvakatipoteredza | Hombe | Diki | Diki |

|

| Kukuvara kwemuviri | Hombe | Diki | Diki |

| Mutengo weWelder | Zvinoshandiswa | Tsvimbo yekunamira | Rambi reLaser, rambi rexenon | Hapana chikonzero |

|

| Kushandiswa kwesimba | Diki | Hombe | Diki |

| Nzvimbo yemidziyo pasi | Diki | Hombe | Diki | |