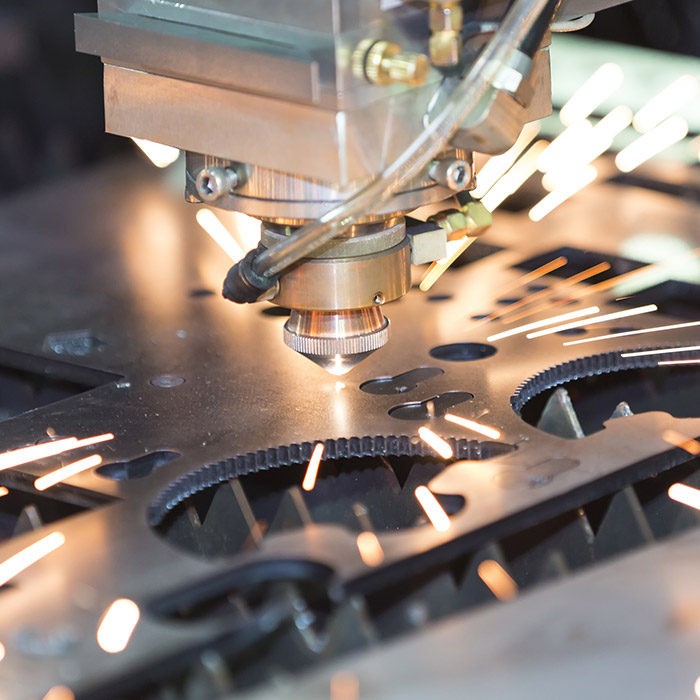

Kudula kwa laser, komwe kumadziwikanso kuti kudula kwa laser beam kapena CNC laser cutting, ndi njira yodulira kutentha yomwe imagwiritsidwa ntchito nthawi zambiri pokonza zitsulo.

Posankha njira yodulira pulojekiti yopangira chitsulo, ndikofunikira kuganizira mphamvu za chida chomwe mwasankha kutengera zosowa za pulojekiti yanu. Pa ntchito zambiri zopangira pogwiritsa ntchito chitsulo, kudula kwa laser ndi chisankho chabwino. Nazi zabwino zina za makina odulira laser omwe muyenera kudziwa.

Mtengo Wotsika Kwambiri

Poyerekeza ndi njira zina zodulira, kudula kwa laser ndikotsika mtengo kwambiri. Pogwiritsa ntchito makina odziyimira pawokha a CNC, ndalama zogwirira ntchito ndizochepa, ndipo makinawo ndi osavuta kugwiritsa ntchito. Kuphatikiza apo, laser siikhala yofewa kapena yofooka monga momwe zida zina zodulira zimachitira. Pachifukwa ichi, palibe kusintha kofunikira pakati pa ndondomekoyi, zomwe zimapangitsa kuti pakhale kupanga bwino komanso nthawi yochepa yotsogolera. Pakakhala zosokoneza zochepa pakudula, ndalama zimakhala zochepa.

Kuthamanga Kwambiri ndi Kuchita Bwino

Ma laser amatha kudula zinthu mwachangu kwambiri. Liwiro lenileni lidzadalira mphamvu ya laser, mtundu wa zinthu ndi makulidwe ake, kulekerera kwake komanso kukhwima kwa ziwalozo. Komabe, zimayenda mwachangu kwambiri poyerekeza ndi zida zina zodulira. Kuwonjezera pa liwiro lodulira mwachangu, odulira laser amatha kugwira ntchito kwa nthawi yayitali, zomwe zimapangitsa kuti ntchito yonse yodulira ikhale yogwira mtima.

Kuwongolera / Kuwongolera kwa CNC

Chimodzi mwa ubwino wodula pogwiritsa ntchito laser ndikuti makinawo amayendetsedwa ndi CNC controls, zomwe zimapangitsa kuti pakhale zigawo ndi zinthu zomwe sizikusintha kwenikweni komanso zolakwika zochepa. Kudula pogwiritsa ntchito automation kumatanthauzanso kuti pakufunika ntchito yochepa kuti makinawo agwire ntchito zake, zomwe zimapangitsa kuti ntchitoyi ikhale yogwira mtima kwambiri. Kudula pogwiritsa ntchito automation kumabweretsa magwiridwe antchito ambiri, zinthu zabwino kwambiri, komanso kutaya zotsala zochepa. Kupatula kudula kwa 2D, odulira pogwiritsa ntchito laser ndi oyeneranso kudula pogwiritsa ntchito 3D. Makinawa ndi oyenera kupanga zitsanzo, mitundu ndi nkhungu, chitoliro, chubu, zitsulo zozungulira, chitsulo chokulirapo, pepala lathyathyathya, ndi zina zambiri.

Kulondola Kwambiri

Odulira laser ali ndi luso lapadera kwambiri, amatha kupanga madulidwe ang'onoang'ono komanso kulekerera kolimba. Amapanga m'mbali ndi ma curve oyera, akuthwa, komanso osalala. Kudula kwakukulu. Amapanganso ma burring ochepa (ngakhale opanda) chifukwa laser imasungunula zinthuzo, m'malo mozidula. Odulira laser ndi oyenera kwambiri pokonza chitsulo cha pepala chifukwa ndi olondola kwambiri ndipo amapanga madulidwe olondola komanso apamwamba.

Mtengo wogwirira ntchito, liwiro la makinawo, komanso kugwiritsa ntchito mosavuta kwa CNC control kumapangitsa kuti odulira laser akhale oyenera zinthu ndi mapulojekiti ambiri akuluakulu. Popeza odulira laser ndi olondola komanso olondola, mutha kukhala otsimikiza kuti zotsatira zake ndi zapamwamba kwambiri. Odulira laser amatha kudula zinthu zosiyanasiyana zachitsulo, kuphatikizapo aluminiyamu, mkuwa, mkuwa, chitsulo chofatsa, chitsulo cha kaboni, chitsulo chosapanga dzimbiri, ndi zina zotero, zomwe zimapangitsa kuti ikhale njira yabwino kwambiri yopangira chitsulo cha pepala. Makinawa amatha kuthana ndi zovuta komanso mapangidwe ovuta, kuonetsetsa kuti ntchito iliyonse ili pafupi.

Takulandirani kuti mulumikizane ndi Fortune Laser kuti mudziwe zambiri zokhudza makina odulira zitsulo a laser pa ntchito yanu yopangira zitsulo lero!

KODI TINGATHANDIZE BWANJI LERO?

Chonde lembani fomu ili pansipa ndipo tidzakuyankhani posachedwa.