Raws li qhov xav tau ntawm kev vuam hlau thiab qhov tsos ntawm cov hlau vuam tau nce siab dua thiab siab dua, tshwj xeeb tshaj yog rau cov khoom uas muaj nqi ntxiv siab thiab qhov xav tau zoo vuam, cov txheej txheem vuam ib txwm yuav ua rau deformation ntawm cov khoom ua haujlwm vim muaj cua sov ntau, thiab lwm yam. Qhov teeb meem, xav tau kev sib tsoo thiab kev ua duab ntau, ua rau cov nqi nce siab.

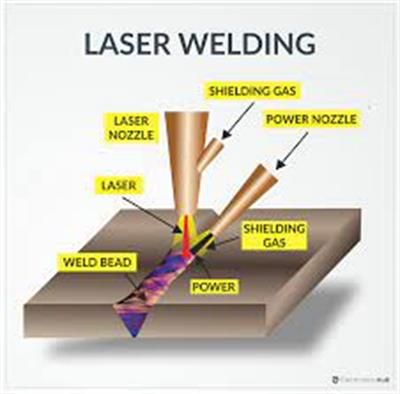

Txawm li cas los xij,laser vuammuaj zog ceev heev thiab thaj chaw cuam tshuam los ntawm cua sov tsawg heev, uas tsis yog tsuas yog txhim kho qhov ua haujlwm vuam zoo xwb, tab sis kuj txhim kho qhov zoo thiab txo lub sijhawm ua tiav tom qab.

Yog li ntawd, daim ntawv thov laser vuam hauv kev tsim cov hlau niaj hnub no tau dhau los ua nrov dua. Ntau tus neeg siv khoom txhawj xeeb txog cov nqi yuav khoom siv, kev vuam zoo thiab zoo, kev sib tsoo ceev, cov khoom siv tom qab ua tiav, kev siv hluav taws xob, kev nyuaj ua haujlwm, kev tiv thaiv kev nyab xeeb, cov nqi tom qab muag thiab ntau lwm yam.

Muaj ntau hom tshuab vuam hauv khw. Cov neeg siv khoom yuav tsum xav txog cov hauv qab no thaum xaiv lub tshuab vuam laser:

1. Cov yam ntxwv ntawm qhov muag: qhov loj ntawm qhov chaw (qhov loj ntawm lub laser pas nrig, qhov loj ntawm lub fiber thiab hom, qhov tawm ntawm lub taub hau), qhov siab ntawm lub dav hlau focal, qhov tob ntawm daim teb, qhov chaw ntawm qhov chaw, lub kaum sab xis ntawm qhov tshwm sim;

2. Cov yam ntxwv tswj: xaiv hom kev tswj tawm tswv yim thiab lub zog waveform.

Tom qab piv ntau hom kev vuam, peb lub tuam txhab tau tsim peb hom khoom siv vuam laser: fiber optic plaub-seem tsis siv neeg vuam, neeg hlau tsis siv neeg vuam, thiabtes tuav laser weldingrau qhov xav tau sib txawv ntawm kev lag luam hlau. Cov teeb pom kev ntawm peb lub cuab yeej siv cov laser fiber, tsis tas yuav siv khoom siv thiab kev txij nkawm, qhov zoo ntawm lub teeb zoo, thiab qhov ceev vuam ceev, uas yog lub hauv paus ntsiab lus zoo tshaj plaws rau kev ua tiav hauv kev lag luam hlau.

Kev xaiv cov khoom siv

01. Tsis siv neeg fiber welding

Scope ntawm daim ntawv thov:feem ntau yog siv rau cov khoom loj ntawm cov hlau me me thiab nruab nrab, cov khoom muaj qhov raug siab, thiab kev ua cov khoom siv tuaj yeem ua tiav nrog cov cuab yeej zoo thiab cov khoom siv.

Kev siv tshuab ua haujlwm tau zoo:Cov zis laser muaj zog heev, qhov chaw rov ua dua qhov tseeb, lub rooj ua haujlwm plaub-seem deb, lub kaw lus ua haujlwm yooj yim heev, kev tsom mus rau thiab tig lub taub hau vuam tsis siv neeg, paub txog qhov sib piv ntawm kev ua haujlwm thiab kev tsim khoom tsis siv neeg;

Muaj zog thiab zoo nkauj:qhov vuam muaj qhov sib piv siab (sib sib zog thiab nqaim), tsis tas yuav muaj cov hlau nplaum, qhov ua rau thaj chaw yaj me me, qhov vuam muaj zog thiab tawv (txawm tias tshaj qhov khoom siv hauv paus), thiab ci ntsa iab thiab zoo nkauj;

Kev cuam tshuam me me ntawm cua sov:lub zog laser yog siab, thiabtxheej txheem vuamnws ceev heev, yog li ntawd qhov cua sov nkag mus rau hauv qhov workpiece tsawg heev, thaj chaw cuam tshuam los ntawm cua sov me me, thiab qhov workpiece tsis deform;

Qhov ceev siab:Cov pa roj tawm sai sai thaum lub vuam sib txuas tau tsim, thiab qhov nkag mus ntawm vuam sib txuas tsis muaj qhov hws. Ntxiv mus, qhov txias sai tom qab vuam ua rau cov qauv vuam zoo thiab qhov vuam ceev heev.

Kev Tswj:Nws tuaj yeem tswj tau txhua yam haujlwm xws li kev vuam txoj kab, qhov loj me, kev sib kis ntawm lub teeb, kev hloov kho lub zog ntawm lub teeb, kev tswj hwm stroke, kev nres tsheb ceev ceev, thiab lwm yam;

Kev ua haujlwm yooj yim:kev ua haujlwm ntawm cov nyees khawm, kev saib xyuas ntawm lub vijtsam, kev ua haujlwm yooj yim thiab ceev;

Kev ua tau zoo ruaj khov:Lub tshuab raug tswj hwm nruj me ntsis los ntawm pab pawg neeg ua haujlwm zoo los ntawm cov khoom mus rau tag nrho lub tshuab, thiab yuav raug tshuaj xyuas thiab sim ua ntej tawm hauv lub Hoobkas, yog li lub tshuab ua haujlwm ruaj khov heev;

Ntau yam kev siv:plaub-axis ntev-stroke txuas, cov waveforms sib txawv tuaj yeem teeb tsa rau cov txheej txheem raws li cov ntaub ntawv vuam sib txawv, yog li cov kev vuam sib txawv tuaj yeem phim cov kev xav tau vuam. Haum rau kev vuam hauv ntau yam lag luam, cov khoom lag luam thiab cov txheej txheem.

Lub taub hau viav vias:qhov loj thiab cov duab ntawm lub teeb pom kev tuaj yeem hloov kho, uas tuaj yeem siv dav thiab tuaj yeem hloov kho rau kev vuam ntawm ntau yam khoom.

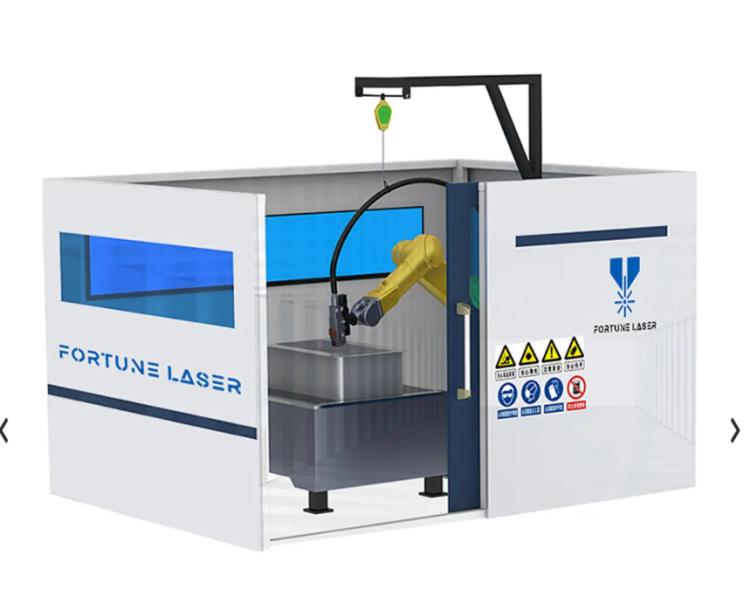

02. Neeg hlau vuam

Cov ntawv thov: Nws feem ntau yog siv rau cov hlau loj loj nruab nrab thiab loj. Nws muaj qhov tseeb siab thiab txav tau yooj yim. Nws haum rau ntau yam workpieces nrog cov ces kaum trajectory nyuaj. Nws tuaj yeem ua rau ntau qhov chaw vuam kom zoo dua. Nws yog tib txoj kev xaiv los hloov kev ua haujlwm tes thiab txo qhov siv zog ua haujlwm.

Siv lub caj npab robotic rau-axis, qhov ntau ntawm kev vuam yog dav.

Qhov tseeb ntawm qhov chaw rov ua dua yog siab dua, txog li 0.05 hli.

Tus neeg hlau muaj kev ruaj khov zoo thiab lub neej ua haujlwm ntev.

Qhov ua tau zoo ntawm kev tsim khoom tau zoo dua qub, thiab nws tuaj yeem ua haujlwm tas li 24 teev. Ua ke nrog cov cuab yeej thiab cov kab sib dhos, nws tuaj yeem ua tiav kev tsim khoom loj.

Lub taub hau viav vias: qhov loj thiab cov duab ntawm lub teeb pom kev tuaj yeem hloov kho, uas tuaj yeem siv dav thiab tuaj yeem hloov kho rauwelding ntawm ntau yamcov khoom.

03. Siv tes ua laser vuam

Cov ntawv thov:Feem ntau siv rau cov hlau tsis yog tus qauv. Muaj ntau hom khoom, tsis haum rau ntau yam khoom siv, zam kev nqis peev ntau dhau. Qhov tseeb ntawm cov khoom khoov tsis siab, thiab qhov sib txawv loj dhau, uas daws qhov teeb meem ntawm kev nrhiav neeg ua haujlwm nyuaj. Cov qauv no tau txais kev qhuas los ntawm cov neeg siv khoom.

Kev ua haujlwm yooj yim:Lubtshuab laser vuam tesyooj yim kawm thiab siv, thiab tus neeg teb xov tooj tuaj yeem ua tiav cov txiaj ntsig vuam zoo.

Kev ua haujlwm vuam zoo:Kev vuam laser tes tuav sai dua li kev vuam argon arc. Raws li kev txuag ob tus neeg ua haujlwm vuam, qhov ua tau zoo ntawm kev tsim khoom tuaj yeem yooj yim ob npaug.

Tsis muaj cov khoom siv vuam:Kev vuam tuaj yeem ua tiav tau yooj yim yam tsis muaj cov hlau nplaum thaum lub sijhawm ua haujlwm, uas txo cov nqi khoom siv hauv kev tsim khoom thiab kev ua tiav.

Cov nyhuv vuam zoo:Kev vuam laser tes yog kev vuam kub-yaj. Piv nrog kev vuam ib txwm muaj, kev vuam laser muaj zog ntau dua thiab muaj txiaj ntsig zoo dua.

Kev hloov pauv hluav taws xob zoo:Qhov kev hloov pauv photoelectric ntawm lub laser yog siab txog li 30%, thiab kev siv hluav taws xob qis dua.

Siv tau yooj yim thiab hloov tau yooj yim:tes tuav laser vuam, dawb thiab yoog tau, ncav cuag tau ntau yam

Cov kab sib txuas tsis tas yuav tsum tau txhuam: kev sib txuas tas mus li, du tsis muaj nplai ntses, zoo nkauj thiab tsis muaj qhov txhab, txo cov txheej txheem sib tsoo tom qab.

Lub taub hau viav vias:qhov loj thiab cov duab ntawm lub teeb pom kev tuaj yeem hloov kho, uas tuaj yeem siv dav thiab tuaj yeem hloov kho rau kev vuam ntawm ntau yam khoom.

Thaum xaiv lub zog laser waveform, feem ntau hais lus, nyob rau hauv lub hauv paus ntawm kev tso tawm tib lub zog laser, qhov dav dua qhov dav ntawm lub pulse, qhov loj dua qhov chaw vuam; qhov siab dua lub zog siab tshaj plaws ntawm lub zog laser waveform, qhov tob dua qhov chaw vuam. Tam sim no, tsis muaj cov txheej txheem teeb tsa laser zog waveform tiav. Cov neeg siv tuaj yeem maj mam tshawb nrhiav hauv cov txheej txheem ntawm kev siv kom pom lub zog laser waveform haum rau lawv cov khoom.

Kev xaiv lub tshuab laser vuam yog qhov tseem ceeb heev rau qhov txiaj ntsig ntawm kev ua tiav ntau lawm; yog li ntawd, yog tias muaj xwm txheej tso cai, cov neeg siv tuaj yeem siv lub zog laser tiag tiag lub sijhawm tsis zoo vuam tshuab ntau li ntau tau los txhim kho qhov txiaj ntsig zoo ntawm cov khoom.

Yog tias koj xav paub ntxiv txog laser welding, lossis xav yuav lub tshuab laser welding zoo tshaj plaws rau koj, thov tawm lus rau ntawm peb lub vev xaib thiab xa email rau peb ncaj qha!

Lub sijhawm tshaj tawm: Lub Ob Hlis-17-2023