Ta yaya injin walda na laser yake aiki?

Injin walda na laser yana amfani da babban ƙarfin bugun laser don dumama kayan da za a sarrafa a cikin ƙaramin kewayon, kuma a ƙarshe yana narke shi don samar da takamaiman wurin waha na narke, wanda zai iya yin walda tabo, walda ta baya, walda ta gwiwa, walda ta rufewa, da sauransu. Fa'idodinsa na musamman sun buɗe sabon filin aikace-aikacen walda na laser, yana ba da walda daidai ga kayan da ke da shinge mai sirara da ƙananan sassa.

Menene ake amfani da injin walda na laser?

1. Walda

Babban manufar injin walda na laser babu shakka shine walda. Ba wai kawai zai iya walda kayan ƙarfe masu sirara kamar faranti na bakin ƙarfe, faranti na aluminum, da faranti na galvanized ba, har ma ana iya amfani da shi don sassan ƙarfe na walda, kamar kayan kicin. Ya dace da lebur, madaidaiciya, baka da walda na kowane siffa ana amfani da shi sosai a cikin injunan daidaito, kayan ado, kayan lantarki, batura, agogo, sadarwa, sana'o'in hannu da sauran masana'antu. Yana iya kammala walda da kyau a cikin yanayi daban-daban masu rikitarwa kuma yana da ingantaccen samarwa. Idan aka kwatanta da walda na argon arc na gargajiya da walda na lantarki. Kuma sauran hanyoyin suna da fa'idodi mafi bayyane.

Ta amfani da injin walda na laser, dinkin walda yana da ƙaramin faɗi, babban zurfi, ƙaramin yanki na girgizar zafi, ƙaramin nakasa, santsi da kyakkyawan dinkin walda, ingancin walda mai girma, babu ramukan iska, ingantaccen sarrafawa, ingantaccen ingancin walda, babu buƙatar magani ko magani mai sauƙi bayan gwangwanin walda.

2. Gyara

Amfani da injin walda na laser ba wai kawai ga walda ba ne, har ma don gyara lalacewa, lahani, karcewar mold, da ramin yashi, fashewa, nakasa da sauran lahani na kayan aikin ƙarfe. Mold ɗin zai lalace bayan dogon lokaci na amfani. Idan aka jefar da shi kai tsaye, asarar za ta yi yawa. Ana iya sake amfani da mold ɗin mai matsala gaba ɗaya ta hanyar gyara mold ɗin mai matsala ta hanyar injin walda na laser, musamman lokacin gyara saman da ya yi laushi, guje wa matsaloli biyu na matsin zafi da maganin bayan walda. Hanya ɗaya, tana adana lokacin samarwa da farashin samarwa sosai.

Wane tsari ne na walda yake aiki da injin walda na laser?

1. Walda tsakanin guda

Har da walda ta duwawu, walda ta ƙarshe, walda ta haɗar tsakiya, da walda ta haɗar tsakiya.

2. Waya zuwa waya walda

Haɗe da walda mai waya zuwa waya, walda mai giciye, walda mai layi ɗaya, da walda mai siffar T.

3. Walda na waya ta ƙarfe da sassan toshe

Walda ta laser za ta iya cimma nasarar haɗa wayar ƙarfe da sassan toshe, kuma girman sassan toshe na iya zama ba bisa ƙa'ida ba. Ya kamata a kula da girman siffofi na abubuwan filamentary yayin walda.

4. Walda na ƙarfe daban-daban

Walda na nau'ikan karafa daban-daban yana magance ma'aunin walda da walda. Walda ta laser tsakanin kayan daban-daban tana yiwuwa ne kawai idan aka haɗa wasu kayan.

Yadda ake zaɓar tushen laser da ya dace?

Tushen Laser Yg:

Karfe mai sheet, hanyoyin haɗin kayan ado na zinare, masu kunna bugun zuciya na titanium, ruwan reza don walda da laser mai pulsed.

Wannan nau'in laser yana hana ƙarfen narkewa ko lalacewa.

Ga ƙarfe masu siriri da haske.

Tushen Laser na CW:

Wannan ya fi tsada idan aka kwatanta da na'urorin laser masu bugun zuciya. Haka kuma yana rage farashin aiki.

Mafi inganci akan ƙarfe masu tsauri.

An ba da shawarar don walda sassa masu kauri.

Zai iya haifar da matsala idan aka yi amfani da shi a kan ƙarfe ko sassan da suka yi siriri sosai. A wannan yanayin, laser ɗin na iya lalata, narkewa ko lalata ɓangaren.

Wadanne irin injunan walda ne ake da su jimilla?

Ana kuma san injunan walda na laser da injunan walda na laser. Rarrabuwar takamaiman sune kamar haka:

1. Injin walda na Laser da hannu:

Wannan wataƙila shine nau'in kayan aikin walda da aka fi amfani da su a kasuwa. Sau da yawa ana amfani da su don walda zanen ƙarfe daban-daban.

2. Injin walda mai amfani da laser:

Ana iya amfani da shi don kayan ado na zinariya da azurfa, cike ramuka na kayan lantarki, ƙurajen walda, kayan haɗin walda, da sauransu.

3. Injin walda na laser ta atomatik:

Ya dace da walda ta atomatik na layuka madaidaiciya da da'irori na kayan aikin ƙarfe, kuma galibi ana amfani da shi a masana'antu kamar batirin wayar hannu, kayan ado, kayan lantarki, firikwensin, agogo da agogo, injunan daidaito, sadarwa, da ayyukan hannu.

4. Injin walda na Laser mold:

Ana amfani da shi galibi don gyaran mold a masana'antun ƙera mold da ƙera mold kamar wayoyin hannu, kayayyakin dijital, motoci da babura, kuma galibi ana amfani da shi don walda da hannu.

5. Injin walda na laser mai amfani da fiber na gani:

Ga sassan da ke da wahalar samu don walda, ana aiwatar da walda mai sassauƙa ta hanyar watsawa mara hulɗa, wanda ke da sassauci mafi girma. Hasken laser zai iya gano rabuwar lokaci da kuzari, kuma yana iya sarrafa katako da yawa a lokaci guda, wanda ke ba da yanayi don walda daidai.

6. Injin walda na laser mai amfani da fiber galvanometer:

Cikakken haɗin tsarin motsi na galvanometer da tsarin walda na laser. Yana adana lokacin sanya wuri mara komai cikin sauƙi yayin walda mai maki ɗaya, kuma yana inganta inganci sau 3-5 idan aka kwatanta da tsarin aiki na lantarki na gargajiya.

Gabatarwa ga takamaiman nau'ikan injunan walda:

Injin walda na Laser da hannu

Kayan aikin sarrafa ƙarfe na laser da aka fi sani a kasuwa sune injin walda na hannu na laser. A cikin kayan walda na gargajiya, haɗin gogewa mai kyau da fasaha ana buƙatar su don biyan buƙatun samarwa na yau da kullun, kuma saurin yana da jinkiri, kuma bayyanar walda yana buƙatar gogewa daga baya. Sarrafawa yana ɗaukar lokaci kuma yana da wahala.

Gabatarwar samfuri: Yi amfani da zare na gani don watsa laser, kuma ka mayar da hankali kan hasken laser kai tsaye a kan sashin walda ta hanyar bindigar feshi da hannu. Yana da halaye na babban daidaito, inganci mai yawa da kuma yankin da zafi ke shafa, kuma ya dace da walda ƙananan sassa, masu rikitarwa ko masu wahalar isa.

Babban fa'idar:

1 Aikin yana da sauƙi, babu buƙatar ƙwarewar fasahar walda ta ƙwararru, kuma ana iya fara aikin bayan sa'o'i 2 na horo mai sauƙi.

2 Saurin walda yana da sauri sosai, kuma na'urar walda ta laser da hannu za ta iya maye gurbin fitowar na'urorin walda 3 zuwa 5 na yau da kullun.

3 Walda ba ta da abubuwan amfani, wanda hakan ke rage farashin samarwa.

4 Bayan an gama walda, dinkin walda yana da haske da tsafta, kuma ana iya yin sa ba tare da niƙa ba.

5. Ƙarfin injin walda na laser ya taru, kewayon hasken zafi kaɗan ne, kuma samfurin ba shi da sauƙin lalacewa.

6 Ƙarfin injin walda na laser yana da ƙarfi sosai, kuma ƙarfin walda yana da yawa sosai.

7. Ana sarrafa kuzari da ƙarfin injin walda na laser ta hanyar dijital, wanda zai iya biyan buƙatun walda daban-daban, kamar cikakken shiga, shiga, walda tabo da sauransu.

Kayan aiki da aikace-aikacen masana'antu: galibi ana amfani da su a cikin kayan lantarki, sassan motoci, kayan aiki, injinan daidaitacce, kayan aikin sadarwa da sauran masana'antu bakin ƙarfe, ƙarfe na carbon, ƙarfe na silicon, ƙarfe na aluminum, ƙarfe na titanium, takardar galvanized, takardar galvanized, jan ƙarfe, da sauransu. Walda mai sauri na kayan ƙarfe daban-daban da walda tsakanin wasu kayan daban-daban.

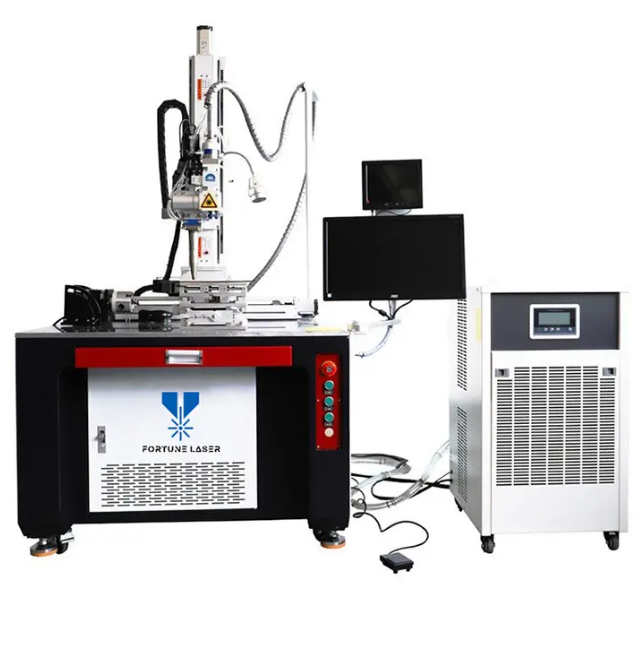

Injin walda na Laser ta atomatik - Injin walda na Laser ta atomatik mai girma biyu

Gabatarwar Samfura:

Injin yana amfani da ramin tattara haske mai fitila biyu da aka shigo da shi daga Burtaniya, tare da ƙarfi mai ƙarfi, bugun jini mai iya shiryawa da kuma tsarin sarrafawa mai wayo. Axis na Z na benci na aiki zai iya motsawa sama da ƙasa ta hanyar lantarki don mayar da hankali, kuma PC na masana'antu yana sarrafa shi. An sanye shi da tebur mai motsi na atomatik mai girma uku na X/Y daban. Wani zaɓi na juyawa (80mm ko p 125mm zaɓi) don cimma walda ta laser ta atomatik mai girma biyu. Tsarin sa ido yana amfani da na'urar microscope, ja haske da CCD. An sanye shi da tsarin sanyaya ruwa na waje.

Babban fa'idar:

1. Ana amfani da ramin mai amfani da wutar lantarki mai fitila biyu da aka shigo da shi daga Burtaniya, wanda ke jure tsatsa kuma yana jure zafi mai yawa, kuma tsawon rayuwar ramin shine shekaru 8-10.

2. Ingancin samarwa yana da girma, saurin walda yana da sauri, kuma ana iya cimma samar da taro ta atomatik na layin taro.

3. Ana iya juya kan laser a 360°, kuma ana iya motsa hanyar gani gaba ɗaya a 360° sannan a miƙa ta gaba da baya.

4. Ana iya daidaita girman wurin hasken ta hanyar lantarki.

5. Ana iya motsa dandalin aiki ta hanyar lantarki a girma uku.

Abubuwan da suka dace da aikace-aikacen masana'antu:

Ya dace da kettles, kofunan injin tsotsa, kwano na bakin ƙarfe, firikwensin, wayoyi na tungsten, diodes masu ƙarfi (transistors), ƙarfe na aluminum, casings na kwamfutar tafi-da-gidanka, batirin wayar hannu, maƙallan ƙofa, molds, kayan haɗin lantarki, matattara, nozzles, kayayyakin bakin ƙarfe, golf Kan ƙwallon ƙafa, sana'o'in ƙarfe na zinc da sauran walda. Zane-zanen da za a iya haɗawa sun haɗa da: maki, layuka madaidaiciya, da'ira, murabba'i ko duk wani zane-zanen jirgin sama da aka zana ta software na AutoCAD.

Haɗakar tebur, daban, ƙaramin walda tabo ta laser

Gabatarwar Samfura:

Injin walda na Laser ana amfani da shi ne musamman don gyara ramuka da ƙurajen walda na kayan ado na zinariya da azurfa. Walda na Laser yana ɗaya daga cikin mahimman fannoni na amfani da fasahar sarrafa kayan Laser. Tsarin walda na tabo yana da nau'in watsa zafi, wato, hasken laser yana dumama saman kayan aikin, kuma zafin saman yana bazuwa zuwa ciki ta hanyar watsa zafi. Ta hanyar sarrafa faɗi, kuzari, ƙarfin kololuwa da maimaita sigogin bugun laser kamar mita suna sa kayan aikin su narke su samar da takamaiman wurin narkewa. Saboda fa'idodinsa na musamman, an yi amfani da shi cikin nasara a cikin sarrafa kayan ado na zinariya da azurfa da walda na ƙananan sassa.

Siffofin Samfura:

Saurin gudu, inganci mai yawa, zurfin zurfi, ƙaramin nakasa, ƙaramin yanki mai zafi, ingancin walda mai yawa, babu gurɓataccen haɗin solder, ingantaccen aiki da kariyar muhalli.

Babban fa'idar:

1. Ana iya daidaita kuzari, faɗin bugun jini, mita, girman tabo, da sauransu a cikin babban kewayon don cimma tasirin walda iri-iri. Ana sarrafa sigogin kuma ana daidaita su a cikin ramin da aka rufe, wanda yake mai sauƙi kuma mai inganci.

2. Ana amfani da ramin da aka yi amfani da shi wajen tattara yumbu da aka shigo da shi daga Burtaniya, wanda ke da juriya ga tsatsa, juriya ga zafin jiki mai yawa, kuma yana da ingantaccen aikin canza wutar lantarki ta hanyar amfani da hasken rana.

3. Yi amfani da tsarin inuwa ta atomatik mafi ci gaba a duniya, wanda ke kawar da ƙaiƙayin idanu a lokutan aiki.

4. Yana da ikon yin aiki akai-akai na tsawon awanni 24, dukkan injin yana da ingantaccen aikin aiki, kuma ba shi da gyara cikin awanni 10,000.

5. Tsarin da aka tsara ta hanyar ɗan adam, daidai da ergonomics, zai iya aiki na dogon lokaci ba tare da gajiya ba.

Injin walda na Laser Mold

Gabatarwar Samfura:

Injin walda na laser mold wani samfuri ne na musamman da aka ƙera don masana'antar mold. Ana amfani da wannan injin musamman don maye gurbin injin walda na argon arc na gargajiya don gyara ƙirar daidai. Manyan abubuwan da ke cikin injin duk samfuran da aka shigo da su ne. Tsarin aikin software yana ɗaukar babban allon nuni na lu'ulu'u mai ruwa, kuma tsarin haɗin yana da sauƙi kuma bayyananne, kuma mai aiki yana da sauƙin koyo da amfani. Hakanan ana iya tsara nau'ikan hanyoyin aiki iri-iri da aka riga aka adana su da kanka, kuma ana iya amfani da aikin ƙwaƙwalwar ajiya na dindindin ga kayan aiki daban-daban.

Siffofin Samfura:

1. Yankin da zafi ya shafa ƙarami ne kuma ba zai haifar da nakasu ga daidaiton molds ba;

2. Zurfin walda yana da girma kuma walda ta yi ƙarfi. Ta narke gaba ɗaya, ba tare da wata alama ta gyara ba. Babu wani rami a haɗin da ke tsakanin ɓangaren da aka ɗaga narkar da ruwan da aka yi amfani da shi a cikin ƙasa;

3. Ƙarancin iskar shaka, aikin ba zai canza launi ba;

4. Ba za a sami ramukan iska ko ramukan yashi ba bayan walda;

5. Ana iya sarrafa walda, musamman ma ya dace da gyaran mold tare da buƙatun gogewa;

6. Aikin zai iya kaiwa taurin Rockwell 50 ~ 60 bayan walda.

Aikace-aikace:

Mould, madaidaicin allurar ƙera, simintin da aka yi da ƙarfe, tambari, bakin ƙarfe da sauran kayan tauri kamar su fashe-fashe, guntu, lalacewar injin niƙa gefen da gyara gefen rufewa, walda; babban daidaito, diamita na wurin walda na laser shine 0.2nm ~ 1.5nm kawai; yankin dumama ƙarami ne, sarrafawa Ba za a lalata kayan aikin ba; ana iya goge shi bayan walda ba tare da shafar tasirin ba.

Na'urar walda ta Laser ta atomatik ta fiber transmission

Gabatarwar Samfura:

Injin walda na laser transmission fiber wani nau'in kayan aikin walda ne na laser wanda ke haɗa hasken laser mai ƙarfi zuwa fiber na gani, bayan watsawa mai nisa, yana haɗuwa da haske a layi ɗaya ta madubin haɗuwa, kuma yana yin walda akan kayan aiki. Yana walda manyan ƙira da sassan daidaito marasa shiga, kuma yana aiwatar da walda mai sassauƙa ta hanyar watsawa mara taɓawa, wanda ke da sassauci mafi girma. Hasken laser na iya cimma rabuwar lokaci da kuzari, kuma yana iya sarrafa katako da yawa a lokaci guda, yana samar da yanayi mafi dacewa don walda.

Babban fasali:

1. Tsarin sa ido na kyamarar CCD na zaɓi, wanda ya dace da lura da matsayi daidai;

2. Rarraba makamashin wurin walda iri ɗaya ne, kuma yana da mafi kyawun wurin haske da ake buƙata don halayen walda;

3. Daidaita da nau'ikan walda masu rikitarwa, walda tabo na na'urori daban-daban, da walda na faranti masu sirara a cikin 1mm;

4. Ana amfani da ramin da aka shigo da shi daga yumbu, wanda ke jure tsatsa, yana jure zafi mai yawa, kuma tsawon rayuwar ramin yana tsakanin shekaru 8 zuwa 10), kuma tsawon rayuwar fitilar argon ya wuce miliyan 8; ana iya keɓance kayan aiki da kayan aiki na musamman na atomatik don cimma yawan samar da kayayyaki.

Aikace-aikace:

Ana amfani da shi sosai wajen samar da na'urorin sadarwa na gani, kayan lantarki, injunan likitanci, agogo, gilashi, kayayyakin sadarwa na dijital, sassan daidai, kayan aiki da sauran masana'antu, da kuma gyaran manyan walda na mold, simintin mutu da kuma injection smolder.

Lokacin Saƙo: Yuni-02-2023