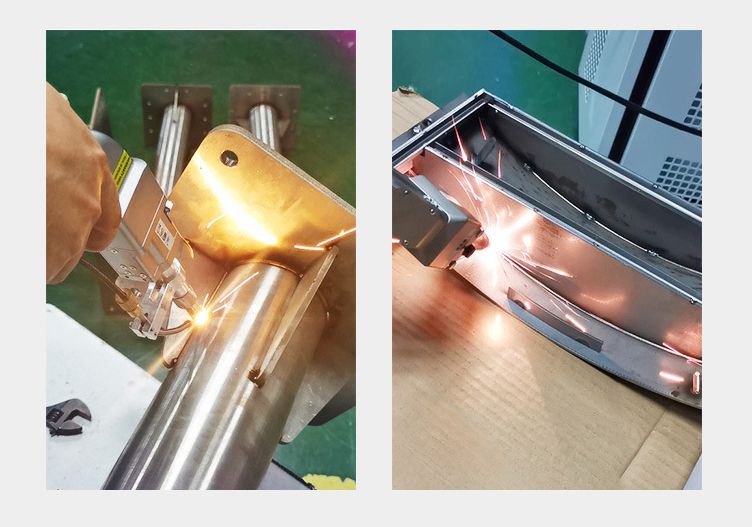

Okwangoku, kwicandelo lokuwelda ngesinyithi, oomatshini bokuwelda nge-laser abaphathwa ngesandla basetyenziswa kakhulu. Ngokusisiseko, iintsimbi ezinokuwelda nge-welding yendabuko zinokuwelda nge-laser, kwaye isiphumo kunye nesantya sokuwelda ziya kuba ngcono kuneenkqubo zokuwelda zendabuko. Ukuwelda kwendabuko kunzima ukuwelda izixhobo zesinyithi ezingezizo i-ferrous ezifana ne-aluminium alloy, kodwa ukuwelda nge-laser kunoluhlu olubanzi lwezicelo, kwaye i-aluminium alloy kunye nezinye izinto nazo zinokuwelda ngokulula.

Umqadi welaser unobunzima obaneleyo, kwaye ubonakala kwinto ngefayibha ye-optical, ngokuhambelanayo ufunxwa kwaye ubonakaliswe, kwaye amandla okukhanya afunxwayo aya kugqiba ukuguqulwa kobushushu obufanelekileyo, ukusasazwa, ukuhanjiswa, ukuhanjiswa kunye nemitha, kwaye into iya kuchaphazeleka kukukhanya ukuvelisa ubushushu obuhambelanayo - Ukunyibilika - Ukufudumala - Utshintsho kwii-microfacets zesinyithi.

Uluhlu lokusetyenziswa koomatshini bokuwelda nge-laser abaphathwa ngesandla luya lusanda lusanda. Lusetyenziswa kwiikhabhathi zasekhitshini nakwiigumbi zokuhlambela, kwifenitshala yentsimbi engagqwaliyo, kwiibhokisi zokusasaza, kwiindonga zomnyango neefestile zentsimbi engagqwaliyo, nakwizitebhisi nakwiilifti. Xa ulusebenzisa, kufuneka unikele ingqalelo ekhethekileyo kukhuseleko.

Ngoko ke zeziphi iindlela zokuthintela ukusetyenziswa ngokukhuselekileyo koomatshini bokuwelda be-laser abaphathwa ngesandla?

1. Xa usebenzisa umatshini wokuwelda welaser ophathwa ngesandla, umqhubi kufuneka aqeqeshwe ngokungqongqo ngaphambi kokuba asebenze emsebenzini. Ilaser ayinakubetha abantu okanye izinto ezikufutshane, kungenjalo inokubangela iziphumo ezibi kakhulu. , njengokutsha, okanye imililo, oku kuyingozi kakhulu, wonke umntu kufuneka anikele ingqalelo ekhethekileyo kukhuseleko.

2. Nangona inkqubo yokudibanisa umatshini wokudibanisa i-laser ephathwayo isebenza ngokuchasene nomsebenzi, iya kuvelisa ukukhanya okuphezulu. Ke ngoko, umqhubi kufuneka axhotyiswe ngeeglasi zokukhanya ezikhethekileyo zokukhusela amehlo akhe. Ukuba akazinxibi iiglasi zokujonga, akuvumelekanga ukusebenzisa umatshini wokudibanisa i-laser ephathwayo.

3. Xa usebenzisa umatshini wokuwelda we-laser ophathwa ngesandla, jonga rhoqo inxalenye yocingo lwentambo yombane. Kwindawo yecala lokufaka kunye necala lokukhupha, kunye neendawo zocingo zentambo yangaphandle kunye neendawo zocingo zentambo yangaphakathi, njl.njl., kuyimfuneko ukujonga ngononophelo ukuba kukho ukukhululeka kwezikrufu zocingo. Ukuba kufunyenwe umhlwa, umhlwa kufuneka ususwe ngokukhawuleza. Susa ukuze kugcinwe umbane oqhuba kakuhle kwaye kuthintelwe iingozi zokutshayiswa kombane.

4. Faka i-ferrule yokukhusela. Ukusetyenziswa komatshini wokuwelda we-laser ophathwa ngesandla kufuna ne-ferrule yokukhusela, ukuze igesi ikwazi ukuphuma ngokulinganayo, kungenjalo itotshi yokuwelda ingatsha ngenxa yesekethe emfutshane.

Xa usebenzisa umatshini wokuwelda welaser ophathwa ngesandla, ungabhekisa kule ndlela ingentla yokusebenza, ukuqinisekisa ukhuseleko lokusetyenziswa kunye nokuphepha iingozi kangangoko kunokwenzeka. Izixhobo zelaser ziya kubangela ilahleko ethile ngexesha lokusetyenziswa, kwaye ukulungiswa ngokufanelekileyo kunokunciphisa ilahleko kunye nokungaphumeleli. Oku kufuna ukuhlolwa rhoqo kwezixhobo zelaser.

Zithini iindlela zokulungisa oomatshini bokuwelda nge-laser kunye nee-chillers eziphathwayo?

1. Jonga rhoqo umbane wezixhobo. Nokuba iingcingo zikhululekile, nokuba i-insulation yentambo ikhululekile okanye ixotyulwe.

2. Coca uthuli rhoqo. Indawo yokusebenza yomatshini wokuwelda inothuli, kwaye uthuli olungaphakathi komatshini wokuwelda lunokucocwa rhoqo. Izikhewu phakathi kwe-reactance coil kunye ne-coil coil, kunye ne-power semiconductors kufuneka zicocwe ngokukodwa. I-chiller kufuneka icoce uthuli olukwisikrini sothuli kunye namaphiko e-condenser.

3. Itotshi yokuwelda yinxalenye ebalulekileyo yomatshini wokuwelda, ekufuneka ihlolwe kwaye itshintshwe rhoqo. Ngenxa yokuguguleka, umngxuma wombhobho uba mkhulu, nto leyo eya kubangela ukungazinzi kwe-arc, ukonakala kwembonakalo ye-weld okanye ucingo olunamathelayo (ukutsha ngasemva); isiphelo sencam yoqhagamshelwano sinamathele kwi-spatter, kwaye ukutyibiliza kwentambo kuya kuba yinto engalinganiyo; incam yoqhagamshelwano ayiqiniswanga ngokuqinileyo. , uqhagamshelo olunemisonto luya kufudumala kwaye lufakwe i-weld lufe. Itotshi eyonakeleyo kufuneka itshintshwe rhoqo. I-chiller kufuneka itshintshe amanzi ajikelezayo malunga nenyanga.

4. Nika ingqalelo kubushushu obungqongileyo. Ubushushu bendawo yokusebenza yetotshi yokuwelda kunye ne-chiller akufuneki bube phezulu kakhulu, enye iya kuchaphazela ukuchithwa kobushushu kunye nokuphola kwe-chiller, kwaye enye iya kuchaphazela ukusebenza okuqhelekileyo komatshini wokuwelda. Ingakumbi ehlotyeni elishushu, kufuneka kuqwalaselwe ngakumbi kubushushu begumbi, kwaye izixhobo kufuneka zisetyenziswe kwindawo enomoya omninzi kangangoko kunokwenzeka. Ubushushu ebusika akufuneki bube phantsi kakhulu, ukuba ubushushu bamanzi ajikelezayo buphantsi kakhulu, i-chiller ayinakuqalwa.

Emva kokuba kwenziwe ulondolozo lwemihla ngemihla, umgangatho wokuwelda womatshini wokuwelda we-laser ophathwa ngesandla ungcono, isiphumo sokupholisa se-chiller singcono, kwaye ubomi benkonzo bunokwandiswa.

Oku kungasentla yeyona ngongoma iphambili yendlela yokwenza ulondolozo lwemihla ngemihla lomatshini wokuwelda welaser ophathwa ngesandla. Kufuneka kuqatshelwe ukuba xa usebenzisa umatshini wokuwelda welaser ophathwa ngesandla, umqhubi kufuneka afumane uqeqesho lobuchwephesha ukuze aqonde ukusetyenziswa kwesibane ngasinye senkqubo kunye neqhosha ngalinye, kwaye aqhelane nolwazi olusisiseko lwezixhobo.

Ukuba ufuna ukufunda okungakumbi malungaukuwelda nge-laser, okanye ufuna ukuthenga umatshini wokuwelda we-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuposa: Jan-10-2023