Umatshini wokucoca iFortune Laser CW 1000W/1500W/2000W ububanzi, umatshini wokucoca onefomathi enkulu engama-650mm

Umatshini wokucoca iFortune Laser CW 1000W/1500W/2000W ububanzi, umatshini wokucoca onefomathi enkulu engama-650mm

Ukusetyenziswa komatshini wokucoca nge-laser kwimveliso yemizi-mveliso

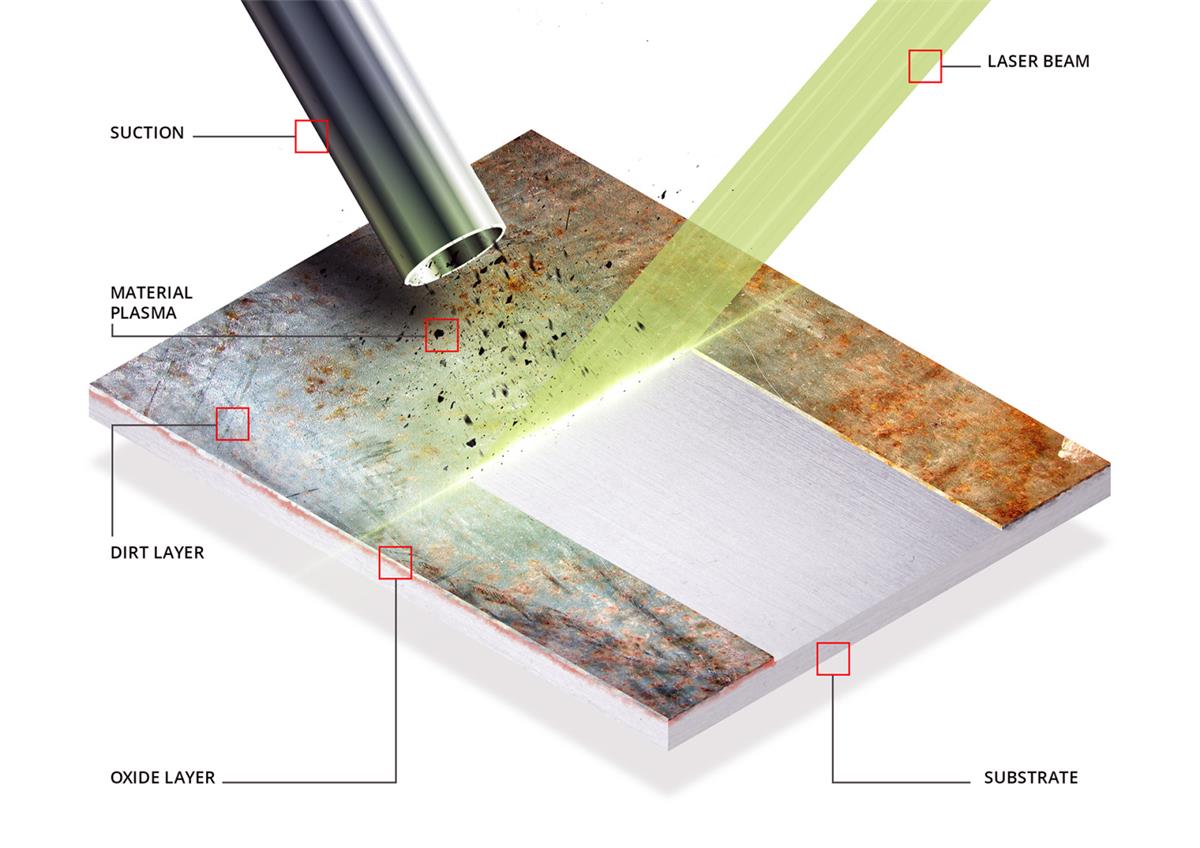

Kwinkqubo yokuvelisa nokuvelisa imveliso kwimizi-mveliso, ukuqinisekisa umgangatho wemveliso, kuyimfuneko ukucoca amabala, amabala eoyile, umhlwa kunye nezinye izinto ezingcolisayo kumphezulu wemveliso. Iindlela zemveli zokucoca isanti kunye neendlela zokucoca ezirhabaxa zibangele ungcoliseko olukhulu kunye nomonakalo kwindalo esingqongileyo kunye nezinto ngokwazo, nto leyo engafanelekanga ekugcinweni nasekusetyenzisweni kamva. Ngoku ukusetyenziswa kwetekhnoloji entsha yokucoca nge-laser kwenza ukucoca kwimizi-mveliso kube lula.

Iimpawu zoMatshini wokucoca iLaser we-1000W 1500W 2000W

Iiparamitha zobugcisa zomatshini wokucoca i-Fortune Laser Mini Laser

Uqwalaselo oluphambili

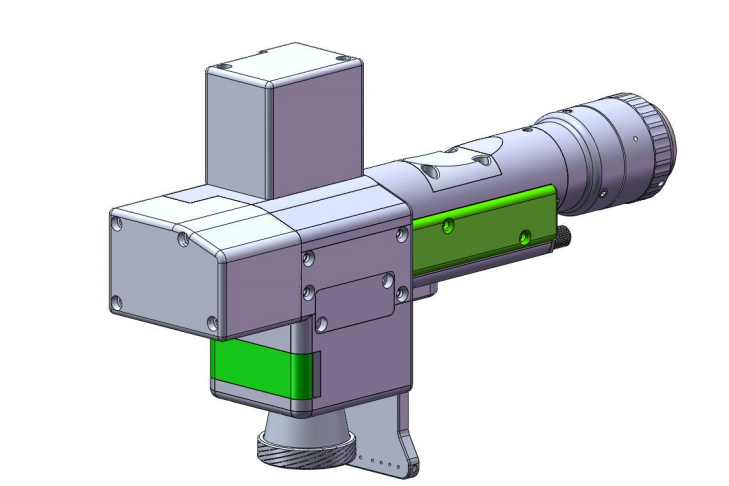

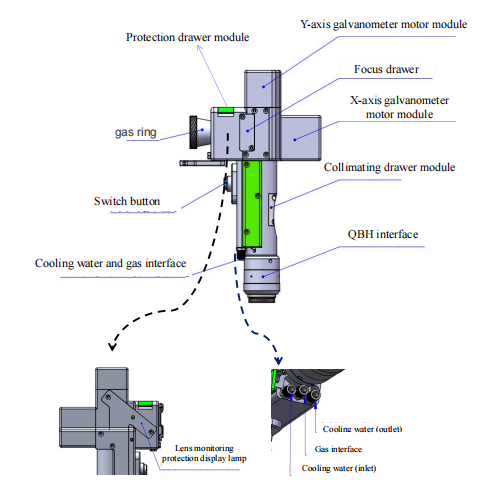

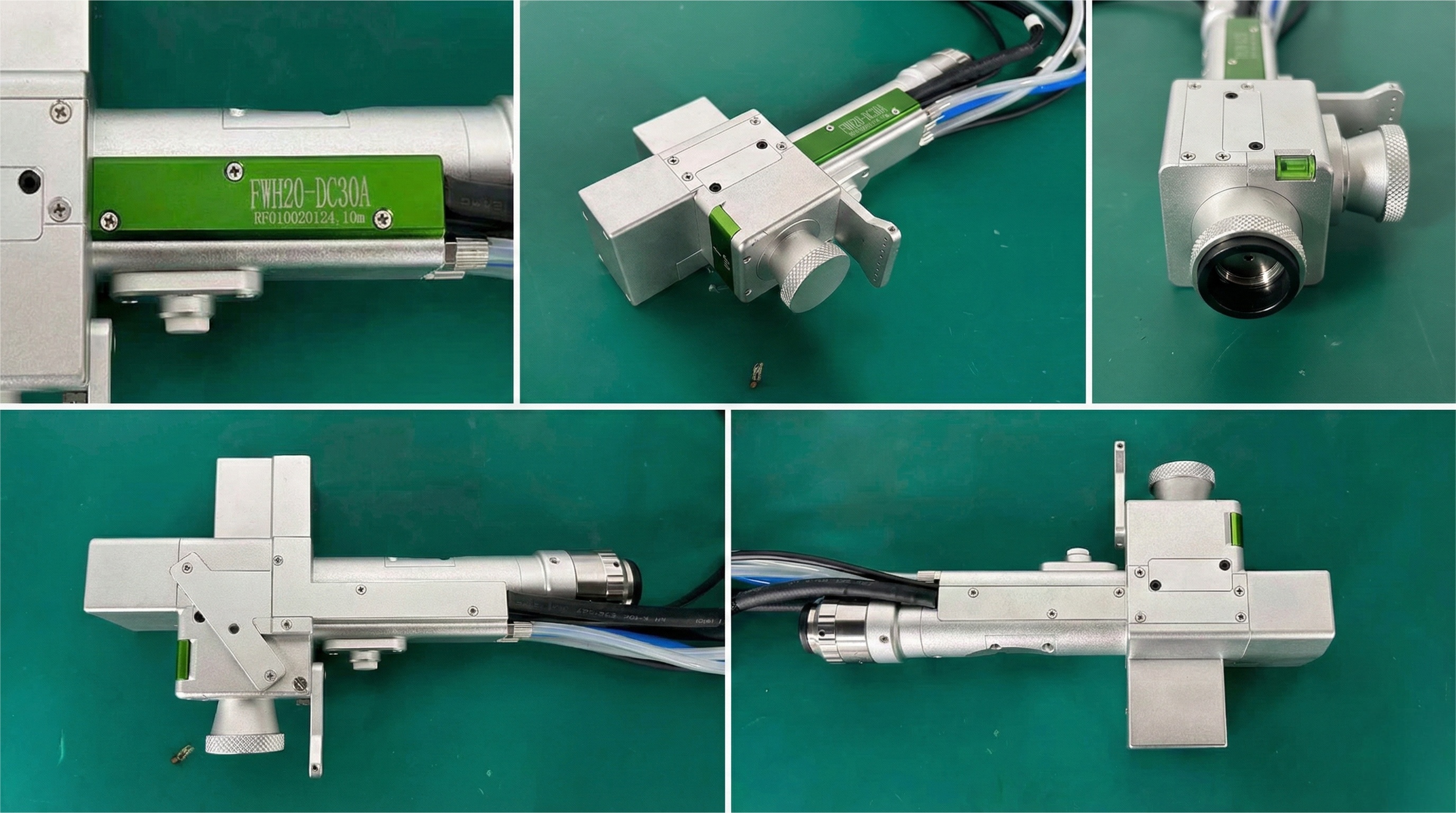

● Intloko yelaser eneenjongo ezimbini ephathwa ngesandla nezenzekelayo, intloko yelaser ye-2D. Kulula ukuyibamba nokuyidibanisa ne-automation; kulula ukuyisebenzisa kwaye inemisebenzi eyahlukeneyo;

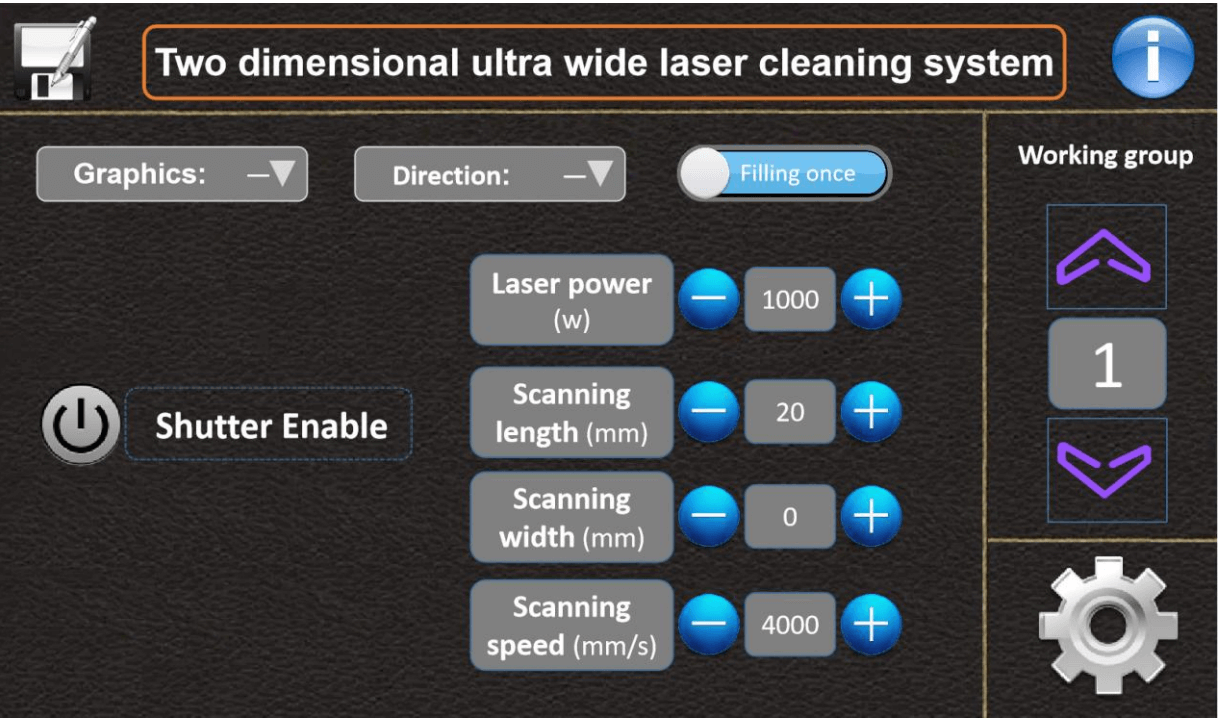

● Isoftware ye-AIMPLE

Ivenkile yemizobo eyahlukeneyo yeparametha

1. Isoftware elula khetha iiparameter ezilungisiweyo kwangaphambili ngqo

2. Gcina kwangaphambili zonke iintlobo zemifanekiso yeparameter iintlobo ezintandathu zemizobo zinokukhethwa umgca othe tye/ojikelezayo/isangqa/unxande/ukuzalisa unxande/ukuzalisa isangqa

3. Kulula ukuyisebenzisa nokuyiqhuba

4. Ujongano olulula

5. Ulwimi lungaba yisiNgesi/isiTshayina okanye ezinye iilwimi (ukuba kuyimfuneko)

Intloko yeLaser Yazisa

Cinezela iswitshi ephambili yesikrini uze ucinezele iswitshi yokhuseleko, kwaye isibane esibomvu siya kujika ukuze sibonwe kwangaphambili. Ukuba ufuna ukutshintsha imizobo kunye nezinye iiparameter, kufuneka ufake igama lokugqitha ukuze ufake ujongano oluphambili. Qaphela: Emva kokucinezela isitshixo sokhuseleko, iswitshi yemvume yokukhupha umoya ikwimo evulekileyo, uze ucinezele iswitshi yokulawula, isibane singakhutshwa.

Ngaba uyazi ukuba zi-5 iindlela zokusebenzisa oomatshini bokucoca nge-laser kwimveliso yemizi-mveliso?

1. Ukucoca kwishishini le-elektroniki

Ishishini le-elektroniki lisebenzisa ii-laser ukucoca izinto ezi-oxidating, kwaye ishishini le-elektroniki lifanelekile ukusebenzisa ii-laser ukucoca izinto ezi-oxidating. Ngaphambi kokuba ibhodi yesekethe ifakwe i-solder, ii-component pin kufuneka zi-oxidized ngokupheleleyo ukuqinisekisa isiphumo soqhagamshelwano lombane, kwaye ii-pin akufuneki zonakaliswe ngexesha lenkqubo yokususa ukungcola. Ukucocwa kwe-laser kunokuhlangabezana neemfuno zokusetyenziswa, kwaye ukusebenza kakuhle komsebenzi kuphezulu kakhulu. Inaliti kufuneka itshiswe nge-laser kube kanye kuphela.

2. Unyango lwangaphambi kokugquma kunye nokuwelda.

Ukulungiswa kokuwelda nge-laser yenye yeendlela ezininzi zokucoca nge-laser, okuluncedo ekucoceni umaleko womphezulu wesinyithi kunye ne-aluminium kwizinto ezingcolisayo ezifana neentsimbi ze-ferrous kunye ne-non-ferrous, ii-lubricants, njl.njl., ukulungiselela ukuwelda okusemgangathweni ophezulu. Ikwaqinisekisa ukuba amalungu athambileyo nangenazo iimbobo aqinileyo.

3. Ukucoca isikhunta

Ukucocwa kwee-molds zamatayara ngexesha lokuveliswa kufuneka kukhuseleke kwaye kuthembeke ukunciphisa ixesha lokungasebenzi. Ngenxa yokuba indlela yokucoca nge-laser inokudityaniswa nge-optical fiber ukucoca i-engile efileyo okanye iindawo ezinzima ukuzicoca ze-mold ezibangelwa kukukhanya, kulula kakhulu ukuyisebenzisa.

4. Ukucocwa kwepeyinti yenqwelo-moya endala

Emva kokuba inqwelo-moya isebenze ixesha elithile, umphezulu wenqwelo-moya kufuneka upeyintwe kwakhona, ngoko ke kuyimfuneko ukufumana indlela yokususa ipeyinti endala. Indlela yendabuko yokucoca nokupeyinta ngoomatshini kulula ukonakalisa umphezulu wesinyithi wenqwelo-moya, nto leyo ebangela iingozi ezifihlakeleyo ekubhabheni kwenqwelo-moya. Akulula ukonakalisa umaleko womphezulu xa usebenzisa umatshini wokuhlamba impahla.

5. Ukucoca kwendawo

Ukucoca nge-laser kunokucoca iipeyinti kunye neengubo kwimveliso yemizi-mveliso efana neemoto, kugcina ukuthembeka kwezinto ezisetyenziswa phantsi komhlaba.

Ukuphathwa kwemeko eqhelekileyo yokungavumeleki

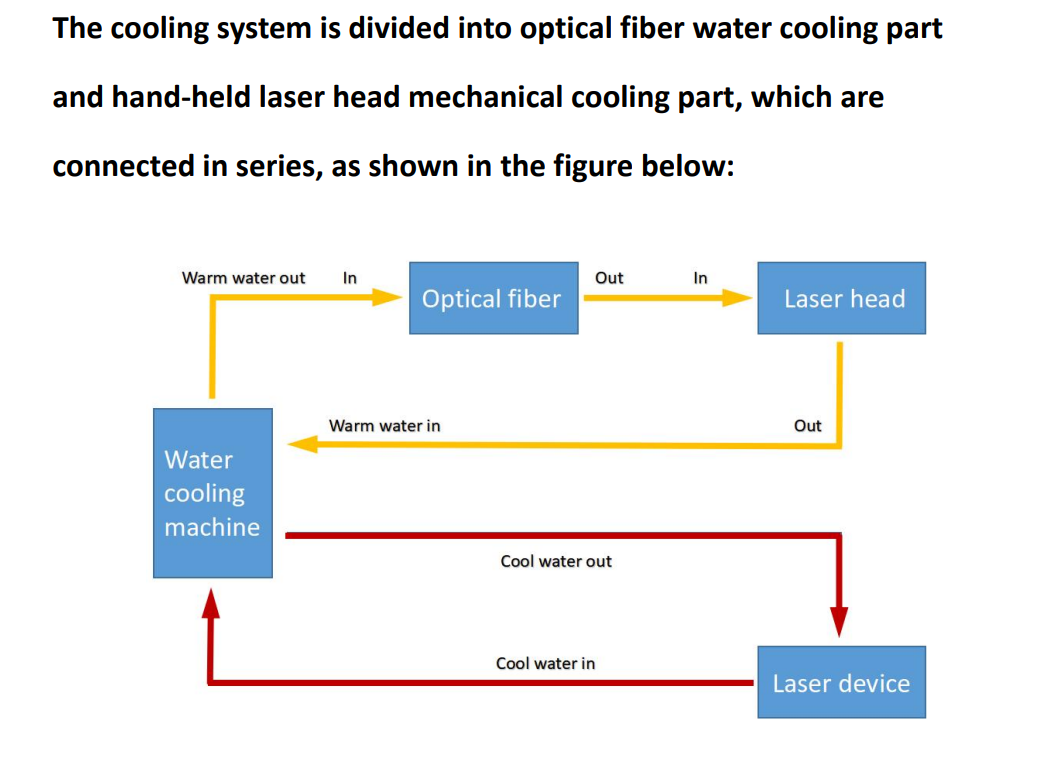

1. I-alamu yokupholisa amanzi kunye neLaser:

(1) I-alamu yelaser: Isibandisi samanzi asivuliwe. Cima ilaser uze uyivule kwakhona.

(2) I-alamu yokupholisa amanzi: Ubushushu betanki yamanzi buphezulu kakhulu, i-compressor yokupholisa amanzi yonakele, i-refrigerant ayikho, okanye indlela yokupholisa amanzi ayinawo amandla okupholisa aneleyo. Ukuba inqanaba lamanzi kwitanki yamanzi alinelanga i-alamu, yongeza amanzi okupholisa.

2Isikrini esingaqhelekanga:

Ukuba isikrini sicinyiwe, jonga ukuba iingcingo ezine eziphambili zebhokisi yokulawula kunye nesikrini ziqhagamshelwe ngokufanelekileyo na nokuba kukho uqhagamshelo olubonakalayo.

3. Akukho kukhanya kukhutshiweyo:

(1) Ingaba i-laser iqalwa ngokwesiqhelo na.

(2) Ingaba isikrini sinayo imvume yokuqalisa na.

(3) Ingaba isikrini sokubonisa siyasebenza na xa kukhutshwa ukukhanya.

(4) Ingaba kukho nayiphi na ingxaki ngoqhagamshelo lwelaser.

(5) Ilensi yokukhusela engcolileyo: ukukhanya kokwenyani kubuthathaka kwaye akubonakali.

(6) Nokuba indlela ye-optical iphakathi na.

4Ukuphela ngequbuliso kokukhanya okuphumayo ngexesha lokucubungula:

I-alamu yelaser (iingxaki eziqhelekileyo: ubushushu belaser buphezulu kakhulu)

Yintoni ekufuneka iqwalaselwe xa uthenga umatshini wokucoca nge-laser?

1. Ngokubanzi, ixabiso lomatshini wokucoca nge-laser linxulumene namandla awo, okukhona amandla e-laser ephezulu, kokukhona ixabiso libiza kakhulu. Kodwa ukuthengwa kwe-laser kusaxhomekeke kwiimfuno zakho ezithile, njengokucoca okulula umhlwa odadayo, umatshini wokucoca nge-laser onamandla aphantsi unokwanelisa, kodwa umatshini wokucoca nge-laser onamandla aphezulu unokubangela umonakalo kwindawo yokusebenza.

2. Ukuze kufezekiswe isiphumo esingcono sokucoca i-substrate ehambelanayo eza kucocwa, kudla ngokufuneka ukuba kulungiswe iiparameter ezihambelanayo ezifana nobude befayibha, ubunzulu be-lens yentsimi, amandla okukhupha, ububanzi be-pulse kunye nesantya sokuskena ngokweempawu ze-substrates ezahlukeneyo.

3. Oomatshini bokucoca nge-laser bahlulwe baba ngoomatshini bokucoca nge-laser abaphathwa ngesandla kunye noomatshini abakhulu bokucoca nge-laser yedesktop. Oomatshini bokucoca nge-laser abahlukeneyo banemisebenzi kunye neendawo ezahlukeneyo. Umzekelo, abanye oomatshini bokucoca nge-laser abaphathwa ngesandla bafanelekela kuphela izixhobo ze-semiconductor, kuba imeko-bume ye-semiconductor ifuna ukhuseleko olukhulu lokusingqongileyo, kwaye ukungcola kweekhemikhali akunakubonakala. Nangona kunjalo, ezinye iinqanawa ezinkulu zahlukile, kwaye imeko-bume yahlukile, kwaye kuya kubakho izikhewu ezahlukeneyo kububanzi bokusetyenziswa. Kuphela ngokukhetha izixhobo zokucoca ezijolise kuzo nezifanelekileyo apho sinokufikelela khona kwisiphumo esifunekayo.

4. Iziqinisekiso zomenzi womatshini wokucoca i-laser ziya kunxulunyaniswa nothotho lwemiba yenkonzo. Njengomatshini wokucoca, izixhobo zokucoca i-laser zineemfuno ezithile zenkqubo. Ixabiso liya kwahluka kakhulu ngokuxhomekeke kwinkqubo, kwaye kunjalo nakwizixhobo zoshishino. Ngaphambi kokukhetha izixhobo zokucoca, kucetyiswa ukuba uqwalasele iziqinisekiso zabavelisi bezixhobo zokucoca i-laser. Kufanelekile ngakumbi ukuchonga kwakhona izakhono zabo ngokutyelela abathengi abasebenzisana nabo abakhoyo.