Muchina wekuisa welaser rudzi rwemuchina wekuisa welding unoshandiswa zvakanyanya mukugadzira maindasitiri, uye zvakare muchina unokosha pakugadzirisa zvinhu zvelaser. Kubva pakutanga kwekugadzirwa kwemuchina wekuisa welaser kusvika pari zvino tekinoroji yakura zvishoma nezvishoma, mhando dzakawanda dzemuchina wekuisa welding dzakagadzirwa, kusanganisira muchina wekuisa welaser unoshandiswa zvakanyanya nemaoko, mubatsiri ane simba pakushanda kwekuisa welding.

Sei uchishandisa gasi rekudzivirira pakupinza nemuchina we laser welding unobatwa nemaoko? Muchina we laser welding unobatwa nemaoko imhando itsva yenzira yekubatanidza, inonyanya kushandiswa pakupinza zvinhu zvine madziro matete uye zvikamu zvakanyatsonaka, izvo zvinogona kuita kuti pave nekupinza kwemavara, kupinza kwezvigaro, kupinza kwemakumbo, kupinza kwezvigaro, nezvimwewo, zvine chiyero chakakwirira, upamhi hudiki hwe weld, uye kupisa. Nzvimbo diki yakakanganiswa, kushanduka kudiki, kumhanya kwe weld nekukurumidza, musono we weld wakatsetseka uye wakanaka, hapana chikonzero chekubata kana kungoda kurapwa kuri nyore mushure mekupinza, musono we weld wemhando yepamusoro, hapana porosity, kutonga kwakaringana, nzvimbo diki yekutarisa, kunyatsorongeka kwepamusoro, otomatiki iri nyore kuita.

1. Inogona kuchengetedza lenzi inotarisa kubva mukusvibiswa kwehutsi hwesimbi uye kudonha kwemadonhwe emvura

Gasi rekudzivirira rinogona kudzivirira lenzi inotarisisa yemuchina we laser welding kubva mukusvibiswa kweutsi hwesimbi uye madonhwe emvura, kunyanya mukusungirirwa kwesimba guru, nekuti kubuda kwemhepo kunova nesimba guru, uye zvinonyanya kukosha kuchengetedza lenzi panguva ino.

2. Gasi rekudzivirira rinoshanda mukubvisa plasma kudzivirirwa kubva pakuwelding nelaser ine simba guru

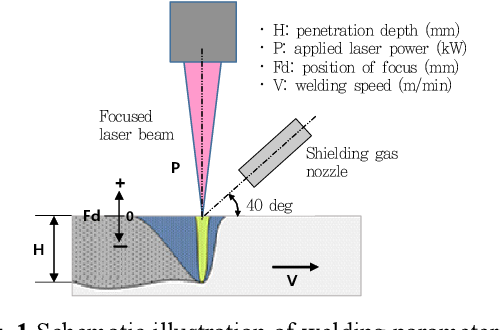

Utsi hwesimbi hunotora danda relaser uye hunoiswa muplasma cloud, uye gasi rinodzivirira rakatenderedza utsi hwesimbi rinoiswawo ion nekuda kwekupisa. Kana paine plasma yakawandisa, danda relaser rinodyiwa neplasma. Plasma iripo pamusoro pebasa sesimba rechipiri, izvo zvinoita kuti kupinda kwemvura kuwedzere kudzika uye pamusoro pedziva re weld pool.

Kuwanda kwemaerekitironi anosanganiswa kunowedzerwa nekuwedzera kuungana kwemaerekitironi nemaion nemaatomu asina kusanganiswa kuti kuderedze huwandu hwemaerekitironi muplasma. Kana maatomu asina kusanganiswa akajeka, kuungana kunowedzera uye huwandu hwekubatana hunowedzera; kune rumwe rutivi, gasi rinodzivirira chete rine simba re ionization harizowedzere huwandu hwemaerekitironi nekuda kwe ionization yegasi pacharo.

3. Gasi rinodzivirira rinogona kudzivirira workpiece kubva mukuoxidation panguva yekushongedza

Muchina we laser welding unofanira kushandisa rudzi rwegasi dziviriro, uye purogiramu yacho inofanira kuiswa nenzira yekuti gasi rinodzivirira rinotanga raburitswa uye laser yozoburitswa, kuitira kudzivirira oxidation ye pulsed laser panguva yekugadzirisa nguva dzose. Gasi risina simba rinogona kudzivirira dziva rakanyungudutswa. Kana zvimwe zvinhu zvakasungirirwa pasinei ne oxidation yepamusoro, dziviriro yacho ingasafungwa nezvayo, asi pamashandisirwo mazhinji, helium, argon, nitrogen nemamwe magasi anowanzo shandiswa sedziviriro kudzivirira workpiece kuti isasungirirwa panguva yekusungirirwa.

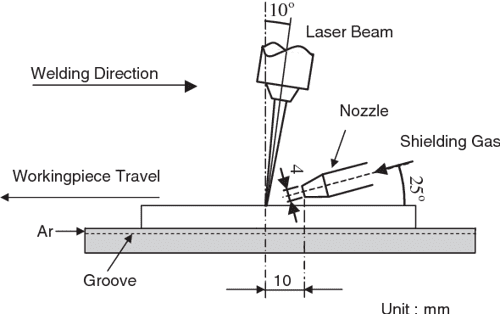

4. Magadzirirwo emaburi emuromo

Gasi rekudzivirira rinopinzwa nekumanikidzwa kwakati kuburikidza nemuromo kuti risvike pamusoro pechinhu chebasa. Chimiro chemvura chinotenderera chemuromo uye dhayamita yemugero wekubudisa zvinhu zvakakosha zvikuru. Rinofanira kunge rakakura zvakakwana kuti rifambise gasi rekudzivirira rakapfapfaidzwa kuti rifukidze pamusoro pewelding, asi kuti ridzivirire lenzi zvinobudirira uye kudzivirira utsi hwesimbi kuti husasvibise kana kuti simbi isaparadze lenzi, saizi yemuromo inofanirawo kuganhurirwa. Mwero wekuyerera kwemvura unofanirawo kudzorwa, zvikasadaro kuyerera kwegasi rekudzivirira kuchava nenyonganyonga, uye mhepo ichabatanidzwa mudziva rakanyungudutswa, zvichizopedzisira zvaita maburi.

Mukusanganisa ne laser, gasi rekudzivirira rinokanganisa chimiro che weld, kunaka kwe weld, kupinda kwe weld uye hupamhi hwekupinda. Kazhinji, kuputira gasi rekudzivirira kunobatsira pakusanganisa, asi rinogonawo kukonzera mhedzisiro yakaipa.

Basa Rakanaka:

1) Kufuridza gasi rekudzivirira zvakanaka kunodzivirira dziva reweld zvinobudirira kuderedza kana kutodzivirira oxidation;

2) Kufuridza gasi rekudzivirira zvakanaka kunogona kuderedza zvinobudirira kupararira kunokonzerwa nekunamira;

3) Kufuridza gasi rinodzivirira nemazvo kunogona kukurudzira kupararira kwakafanana kwedziva rekuwelda kana richioma, zvichiita kuti chimiro chekuwelda chifanane uye chive chakanaka;

4) Kufuridzwa kwakakodzera kwegasi rinodzivirira kunogona kuderedza zvinobudirira mhedzisiro yesimbi vapor plume kana plasma cloud palaser, uye kuwedzera mwero wekushandiswa kwakanaka kwelaser;

5) Kufuridza gasi rekudzivirira nemazvo kunogona kuderedza kupinza kwesimbi.

Chero bedzi mhando yegesi, mwero wekuyerera kwegesi, uye nzira yekuvhuvhuta zvakanaka, zvinogona kuwana mhedzisiro yakanaka. Zvisinei, kushandiswa zvisina kunaka kwegesi inodzivirira kunounzawo mhedzisiro yakaipa pakuwelding.

Mhedzisiro Yakaipa:

1) Kusakwana kwegasi rekudzivirira kunogona kukonzera kusashanda zvakanaka kwesimbi:

2) Kusarudza rudzi rusina kunaka rwegasi kunogona kukonzera kuputika kweweld, uye kunogonawo kukonzera kudzikira kwehunhu hwemuchina weweld;

3) Kusarudza mwero wekuyerera kwemhepo usingashandiswi negasi zvakanaka kunogona kukonzera kuoxidation kwakanyanya kweweld (ingave mwero wekuyerera kwemhepo wakakura kana kuti mudiki), uye zvinogonawo kukonzera kuti simbi yedziva reweld ikanganiswe zvakanyanya nemasimba ekunze, zvichikonzera kuputsika kweweld kana kusagadzirwa zvakanaka;

4) Kusarudza nzira isiriyo yekuisa gasi kuchaita kuti weld itadze kuwana mhedzisiro yekudzivirira kana kutoti haina mhedzisiro yekudzivirira kana kuve nemhedzisiro yakaipa pakuumbwa kweweld;

5) Kuzara kwegasi rinodzivirira kuchaita kuti weld ipinde, kunyanya kana uchibatanidza maplate matete, izvi zvinoderedza weld inopinda.

Kazhinji, helium inoshandiswa segasi rinodzivirira, rinogona kudzvinyirira plasma zvakanyanya, nokudaro richiwedzera kudzika kwekupinda uye richiwedzera kumhanya kwewelding; uye ine huremu hwakareruka uye inogona kubuda, uye hazvisi nyore kukonzera maburi. Ehe, kubva pamhedzisiro yedu chaiyo yewelding, mhedzisiro yekushandisa argon protection haina kuipa.

Kana uchida kudzidza zvakawanda nezve laser welding, kana kuti uchida kutenga muchina we laser welding wakanakisisa kwauri,ndapota siyai meseji pawebhusaiti yedu uye mutitumire email zvakananga!

Nguva yekutumira: Kukadzi-04-2023