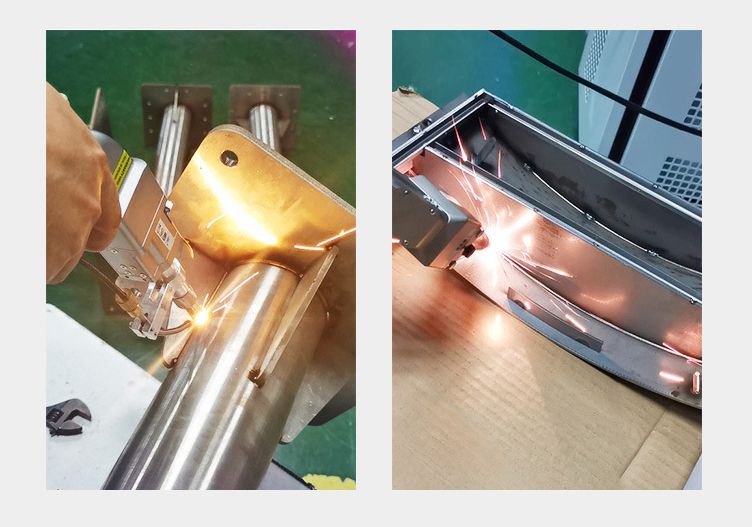

Parizvino, mumunda wekusanganisa simbi, michina yekubatanidza laser inobatwa nemaoko ndiyo inoshandiswa zvakanyanya. Chaizvoizvo, simbi dzinogona kusanganiswa nekusanganisa kwetsika dzinogona kusanganiswa ne laser, uye mhedzisiro yekusanganisa nekumhanya zvichave zviri nani pane maitiro ekubatanidza etsika. Kubatanidza kwetsika kwakaoma kusanganisa zvinhu zvesimbi zvisina ferrous zvakaita sealuminium alloy, asi kusanganisa ne laser kune mashandisirwo akasiyana-siyana, uye alloy yealuminium nezvimwe zvinhu zvinogona kusanganiswa zviri nyore.

Danda relaser rine simba rakakwana, uye rinoburitswa pachinhu kuburikidza nefiber ye optical, richitorwa uye richiratidzwa, uye simba rechiedza rinotorwa richapedzisa kushandurwa kwekupisa, kupararira, kutungamirwa, kuendeswa uye mwaranzi, uye chinhu chacho chichakanganiswa nechiedza kuti chigadzire kupisa kwakafanana - Kunyunguduka - Kuvaporization - Kuchinja muma microfacets esimbi.

Mhando dzekushandiswa kwemichina ye laser welding inobatwa nemaoko dziri kuramba dzichiwedzera kukura. Inoshandiswa mumakabati ekicheni neimba yekugezera, fenicha yesimbi isingatsvedzeri, mabhokisi ekuparadzira, masuo nemahwindo esimbi isingatsvedzeri, uye masitepisi nemaelevator. Paunenge uchiishandisa, unofanirwa kutarisisa zvakanyanya kuchengetedzeka.

Saka ndedzipi nzira dzekudzivirira nadzo kushandiswa kwakachengeteka kwemichina ye laser welding inobatwa nemaoko?

1. Pakushandisa muchina we laser welding unobatwa nemaoko, mushandi anofanira kudzidziswa zvakasimba asati ashanda pabasa. Laser haigone kurova vanhu kana zvinhu zvakavapoteredza, zvikasadaro inogona kuunza migumisiro yakaipa zvikuru. , sekutsva, kana moto, izvi zvine njodzi huru, munhu wese anofanira kunyatsoteerera kuchengetedzeka.

2. Kunyangwe maitiro ekunamira emuchina we laser welding unobatwa neruoko achishandiswa pabasa, unoramba uchiburitsa kupenya kwakanyanya. Saka, mushandi anofanira kunge aine magirazi ekudzivirira akakosha ekudzivirira maziso ake. Kana vasina kupfeka magirazi ekudzivirira, hazvibvumirwi kushandisa muchina we laser welding unobatwa neruoko.

3. Paunenge uchishandisa muchina we laser welding unobatwa nemaoko, gara uchitarisa chikamu chewaya yemagetsi. Panzvimbo dzedivi rekupinda nedivi rekubuda, pamwe chete nezvikamu zvewaya zvekunze nezvikamu zvewaya yemukati, nezvimwewo, zvakakosha kutarisa kana paine kusarongeka kwezvikushi zvewaya. Kana ngura ikawanikwa, ngura inofanira kubviswa nekukurumidza. Bvisa kuti uchengetedze kufambisa kwemagetsi kwakanaka uye kudzivirira tsaona dzemagetsi.

4. Isa ferrule inodziisa moto. Kushandisa muchina we laser welding unobatwa nemaoko kunodawo ferrule inodziisa moto, kuitira kuti gasi ribude zvakaenzana, zvikasadaro tochi yewelding inogona kudzima nekuda kwe short circuit.

Kana uchishandisa muchina we laser welding unobatwa nemaoko, unogona kushandisa nzira iri pamusoro apa, kuitira kuti uve nechokwadi chekuti wakachengeteka pakushandisa uye kudzivirira tsaona zvakanyanya sezvinobvira. Midziyo ye laser inokonzera kurasikirwa kwakati panguva yekushandisa, uye kugadzirisa kwakakodzera kunogona kuderedza kurasikirwa nekukundikana. Izvi zvinoda kuongororwa nguva nenguva kwemuchina we laser.

Ndezvipi matanho ekuchengetedza michina ye laser welding nemachillers anobatwa nemaoko?

1. Gara uchitarisa magetsi ari mumidziyo. Kana waya dzakasununguka, kana kuti chinodzivirira waya chakasununguka kana kuti chakabviswa.

2. Gara uchichenesa guruva. Nzvimbo yekushanda yemuchina wekunamira ine guruva, uye guruva riri mukati memuchina wekunamira rinogona kucheneswa nguva nenguva. Mipata iri pakati pe coil ye reactance ne coil ye coil, uye ma semiconductor emagetsi anofanirwa kucheneswa zvakanyanya. Chiller inofanira kuchenesa guruva riri pachiratidziro cheguruva uye mafins e condenser.

3. Tochi yekuwedera chikamu chakakosha chemuchina wekuwedera, chinofanira kuongororwa uye kutsiviwa nguva nenguva. Nekuda kwekusakara, mukana wemuromo wemuromo unokura, izvo zvinokonzeresa kusagadzikana kwearc, kuora kwechitarisiko cheweld kana waya inonamira (ichitsva kumashure); mugumo wemuromo wekusangana unonamira kuti uparare, uye waya inodyidzana ichava isina kuenzana; muromo wekusangana hausi wakasimba zvakasimba. , tambo yekubatanidza ichapisa uye ichafa. Tochi yakakuvara inofanira kutsiviwa nguva nenguva. Chiller inofanira kutsiva mvura inotenderera kanenge kamwe chete pamwedzi.

4. Tembiricha yekunze. Tembiricha yenzvimbo yekushanda yetochi yekuwelda neyechiller haifanirwe kunge yakanyanya kukwira, imwe ichakanganisa kupisa nekutonhodza kwechiller, uye imwe ichakanganisa mashandiro akajairika emuchina wekuwelda. Kunyanya muzhizha rinopisa, kutarisisa kwakanyanya kunofanira kupihwa kutembiricha yemukamuri, uye michina inofanira kushandiswa munzvimbo ine mhepo yakawanda sezvinobvira. Tembiricha munguva yechando haifanirwe kunge yakaderera zvakanyanya, kana tembiricha yemvura inotenderera yakaderera zvakanyanya, chiller haigone kutanga.

Mushure mekunge kugadziriswa kwezuva nezuva kwaitwa, mhando yekuwedera yemuchina wekuwedera welaser unobatwa neruoko inova nani, mhedzisiro yekutonhodza yemuchina wekutonhodza inova nani, uye hupenyu hwebasa hunogona kuwedzerwa.

Zviri pamusoro apa ndizvo zvinonyanya kukosha pakugadzirisa muchina we laser welding wezuva nezuva. Zvinofanira kucherechedzwa kuti pakushandisa muchina we laser welding welding weruoko, mushandi anofanira kudzidziswa nehunyanzvi kuti anzwisise mashandisirwo chaiwo emwenje wega wega wesystem indicator nebhatani rega rega, uye kujairana neruzivo rwekutanga rwemuchina.

Kana uchida kudzidza zvakawanda nezvewelding nelaser, kana kuti muchida kutenga muchina we laser welding wakanakisisa kwamuri, ndapota siyai meseji pawebhusaiti yedu uye titumirei email zvakananga!

Nguva yekutumira: Ndira-10-2023