Makina Owotcherera a Laser a Fortune Laser Automatic 300W Yag Laser Mold

Makina Owotcherera a Laser a Fortune Laser Automatic 300W Yag Laser Mold

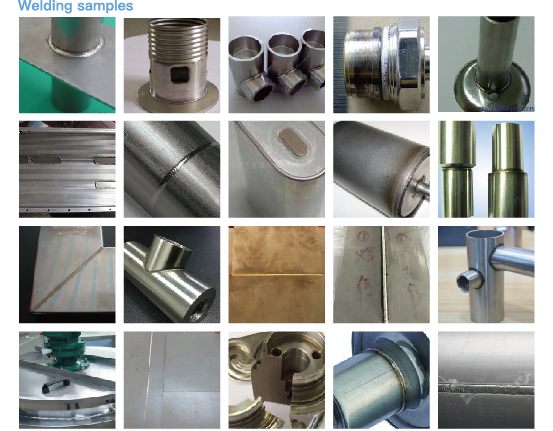

Mfundo Zoyambira za Makina a Laser

Makina olumikizirana a laser okhala ndi ma axis anayi amagwiritsa ntchito chowunikira chapamwamba cha ceramic cha nyali imodzi, mphamvu yamphamvu, pulse ya laser yokonzedwa komanso kasamalidwe kanzeru ka dongosolo. Z-axis ya tebulo logwirira ntchito imatha kusunthidwa mmwamba ndi pansi kuti iyang'anitsidwe, yoyendetsedwa ndi PC yamakampani. Yokhala ndi tebulo loyenda lokhazikika la X/Y/Z lokhala ndi magawo atatu, lokhala ndi makina ozizira akunja. Chosinthira china chosankha (mitundu ya 80mm kapena 125mm ndi yosankha). Dongosolo lowunikira limagwiritsa ntchito maikulosikopu ndi CCD

Makina Owotcherera a Laser Odzipangira a 300w

Makina Opangira Makina Owotcherera a Laser Okhaokha a Fortune Laser

| Chitsanzo | FL-Y300 |

| Mphamvu ya Laser | 300W |

| Njira Yoziziritsira | Kuziziritsa Madzi |

| Utali wa Mafunde a Laser | 1064nm |

| Laser Yogwira Ntchito Pakati Pakati 3+ | YAG Ceramic Conde |

| Malo awiri | φ0.10-3.0mm yosinthika |

| Kukula kwa Kugunda | 0.1ms-20ms yosinthika |

| Kuzama kwa kuwotcherera | ≤10mm |

| Mphamvu ya Makina | 10KW |

| Dongosolo Lowongolera | PLC |

| Cholinga ndi Kuyika Malo | Maikulosikopu |

| Stroke Yogwira Ntchito | 200×300mm (kukweza kwamagetsi kwa Z-axis) |

| Kufunika kwa Mphamvu | Zosinthidwa |