Tam sim no, hauv kev vuam hlau, cov tshuab vuam laser tes siv dav. Yeej, cov hlau uas tuaj yeem vuam los ntawm kev vuam ib txwm muaj tuaj yeem vuam los ntawm laser, thiab cov nyhuv vuam thiab qhov ceev yuav zoo dua li cov txheej txheem vuam ib txwm muaj. Kev vuam ib txwm muaj nyuaj rau vuam cov khoom siv hlau tsis yog hlau xws li txhuas alloy, tab sis kev vuam laser muaj ntau yam kev siv, thiab txhuas alloy thiab lwm yam khoom siv kuj tuaj yeem vuam tau yooj yim.

Lub teeb laser muaj lub zog txaus, thiab raug tso tawm rau ntawm qhov khoom los ntawm cov fiber ntau optical, nqus tau thiab cuam tshuam, thiab lub zog teeb uas nqus tau yuav ua tiav qhov kev hloov pauv cua sov, kev sib kis, kev coj mus los, kev xa khoom thiab kev tawg hluav taws xob, thiab qhov khoom yuav raug cuam tshuam los ntawm lub teeb los tsim cov cua sov sib xws - Melting - Vaporization - Kev hloov pauv hauv cov hlau microfacets.

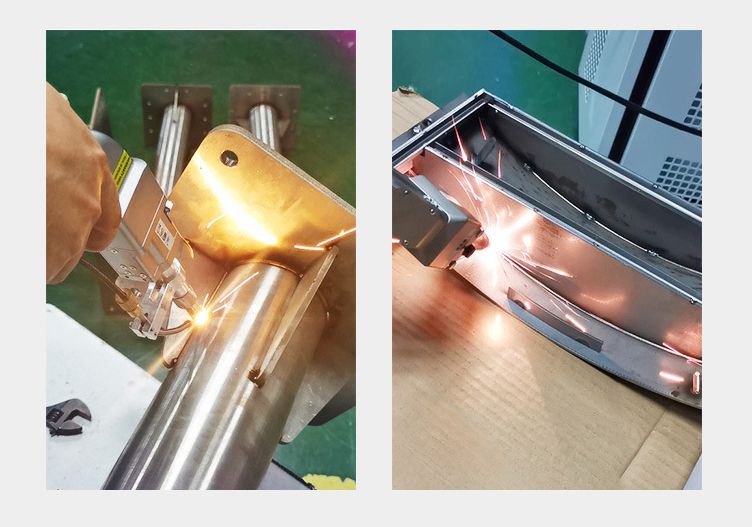

Cov tshuab laser vuam siv tes tau siv dav dua thiab dav dua. Nws siv rau hauv chav ua noj thiab chav dej txee, rooj tog hlau tsis xeb, thawv faib khoom, qhov rooj thiab qhov rai hlau tsis xeb, thiab ntaiv thiab elevators. Thaum siv nws, koj yuav tsum tau them sai sai rau kev nyab xeeb.

Yog li cas cov kev ceev faj rau kev siv cov tshuab laser vuam tes zoo?

1. Thaum siv lub tshuab vuam laser tes tuav, tus neeg teb xov tooj yuav tsum tau kawm ua ntej ua haujlwm. Lub laser tsis tuaj yeem ntaus tib neeg lossis cov khoom nyob ib puag ncig, txwv tsis pub nws yuav coj cov txiaj ntsig loj heev. , xws li kub hnyiab, lossis hluav taws, qhov no txaus ntshai heev, txhua tus yuav tsum tau them sai sai rau kev nyab xeeb.

2. Txawm hais tias cov txheej txheem vuam ntawm lub tshuab vuam laser tes ua haujlwm tawm tsam qhov workpiece, nws tseem yuav tsim cov teeb pom kev zoo siab. Yog li ntawd, tus neeg teb xov tooj yuav tsum tau nruab nrog cov tsom iav tiv thaiv teeb pom kev zoo tshwj xeeb los tiv thaiv lawv lub qhov muag. Yog tias lawv tsis hnav tsom iav, Nws tsis raug tso cai siv lub tshuab vuam laser tes.

3. Thaum siv lub tshuab laser vuam tes, xyuas cov xov hlau ntawm cov xov hluav taws xob tas li. Ntawm qhov chaw ntawm sab nkag thiab sab tawm, nrog rau cov xov hlau ntawm cov xov hlau sab nraud thiab cov xov hlau ntawm cov xov hlau sab hauv, thiab lwm yam, nws yog ib qho tsim nyog los xyuas kom zoo seb puas muaj qhov xoob ntawm cov ntsia hlau xov hlau. Yog tias pom xeb, yuav tsum tshem tawm xeb sai sai. Tshem tawm kom tswj tau qhov hluav taws xob zoo thiab tiv thaiv kev raug mob hluav taws xob.

4. Muab lub ferrule insulating rau saum. Kev siv lub tshuab vuam laser tes kuj xav tau lub ferrule insulating, kom cov pa roj tuaj yeem ntws tawm sib npaug, txwv tsis pub lub teeb vuam yuav hlawv tawm vim muaj luv luv.

Thaum koj siv lub tshuab laser vuam tes, koj tuaj yeem xa mus rau txoj kev saum toj no los ua haujlwm, kom ntseeg tau tias muaj kev nyab xeeb ntawm kev siv thiab zam kev raug mob ntau li ntau tau. Cov khoom siv laser yuav ua rau muaj qee qhov kev poob thaum siv, thiab kev saib xyuas kom zoo tuaj yeem txo qhov kev poob thiab kev ua tsis tiav. Qhov no yuav tsum tau kuaj xyuas cov khoom siv laser tsis tu ncua.

Cov kev ceev faj txij nkawm rau cov tshuab laser vuam tes thiab cov chillers yog dab tsi?

1. Xyuas kom tseeb tias cov khoom siv fais fab tsis tu ncua. Seb cov xov hlau puas xoob, seb cov xov hlau rwb thaiv tsev puas xoob lossis tev tawm.

2. Ntxuav cov hmoov av tas li. Qhov chaw ua haujlwm ntawm lub tshuab vuam muaj hmoov av ntau, thiab cov hmoov av hauv lub tshuab vuam tuaj yeem ntxuav tas li. Qhov sib txawv ntawm cov reactance coil thiab coil coils, thiab cov fais fab semiconductors yuav tsum tau ntxuav tshwj xeeb. Lub chiller yuav tsum ntxuav cov hmoov av ntawm lub vijtsam hmoov av thiab cov fins ntawm lub condenser.

3. Lub teeb vuam yog ib feem tseem ceeb ntawm lub tshuab vuam, uas yuav tsum tau kuaj xyuas thiab hloov pauv tas li. Vim yog hnav thiab tsim kua muag, qhov qhib ntawm lub nozzle loj dua, uas yuav ua rau arc tsis ruaj khov, puas tsuaj ntawm qhov zoo li ntawm lub vuam lossis cov hlau nplaum (kub rov qab); qhov kawg ntawm lub taub hau sib cuag tau lo rau spatter, thiab cov hlau pub yuav tsis sib npaug; lub taub hau sib cuag tsis nruj. , qhov txuas xov yuav kub thiab raug welded tuag. Lub teeb puas tsuaj yuav tsum tau hloov pauv tas li. Lub chiller yuav tsum tau hloov cov dej ncig txog ib hlis ib zaug.

4. Ua tib zoo saib qhov kub thiab txias ntawm ib puag ncig. Qhov kub ntawm qhov chaw ua haujlwm ntawm lub teeb vuam thiab lub tshuab txias yuav tsum tsis txhob siab dhau, ib qho yuav cuam tshuam rau qhov cua sov thiab txias ntawm lub tshuab txias, thiab lwm qhov yuav cuam tshuam rau kev ua haujlwm ib txwm ntawm lub tshuab vuam. Tshwj xeeb tshaj yog nyob rau lub caij ntuj sov kub, yuav tsum tau them sai sai rau qhov kub hauv chav, thiab cov khoom siv yuav tsum tau ua haujlwm hauv qhov chaw muaj cua ntau li ntau tau. Qhov kub thaum lub caij ntuj no yuav tsum tsis txhob qis dhau, yog tias qhov kub ntawm cov dej ncig qis dhau, lub tshuab txias tsis tuaj yeem pib.

Tom qab kev saib xyuas txhua hnub ua tiav lawm, qhov zoo ntawm lub tshuab vuam laser tes zoo dua, qhov txias ntawm lub tshuab chiller zoo dua, thiab lub neej ua haujlwm tuaj yeem ntev dua.

Qhov saum toj no yog qhov tseem ceeb ntawm kev ua txhua hnub ntawm lub tshuab laser vuam tes. Nws yuav tsum tau sau tseg tias thaum siv lub tshuab laser vuam tes, tus neeg teb xov tooj yuav tsum tau kawm txog kev siv tshwj xeeb ntawm txhua lub teeb qhia qhov system thiab txhua lub pob, thiab paub txog cov khoom siv yooj yim tshaj plaws.

Yog koj xav paub ntxiv txoglaser vuam, lossis xav yuav lub tshuab vuam laser zoo tshaj plaws rau koj, thov tawm lus rau ntawm peb lub vev xaib thiab xa email rau peb ncaj qha!

Lub sijhawm tshaj tawm: Lub Ib Hlis-10-2023