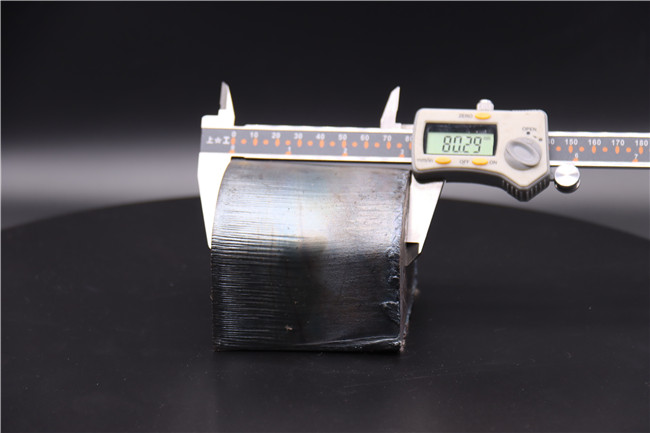

Kamar yadda muka sani, injunan yanke laser na fiber ƙwararre ne wajen yanke zanen ƙarfe kuma an yi amfani da su sosai. To menene tasirin yanke zanen ƙarfe mara kyau - zanen ƙarfe mai tsatsa kuma waɗanne fannoni ya kamata a kula da su?

1. Yanke faranti masu tsatsa zai rage ingancin sarrafawa, ingancin yankewa zai kuma tabarbare, kuma yawan tarkacen kayan zai karu daidai gwargwado. Saboda haka, idan yanayi ya ba da dama, a lokacin sarrafa ƙarfe, yi ƙoƙarin amfani da ƙananan faranti masu tsatsa gwargwadon iko ko kuma a yi wa faranti masu tsatsa magani kafin a sarrafa su. Yi amfani da shi.

2. A lokacin yanke faranti, musamman lokacin da ake hudawa da yankewa, ramuka na iya fashewa, wanda zai gurɓata ruwan tabarau mai kariya. Wannan yana buƙatar mu fara magance faranti mai tsatsa, kamar amfani da niƙa don cire tsatsa. Tabbas, faranti ƙasa da 5MM. Tasirin ba shi da girma, galibi saboda faranti masu kauri masu tsatsa, amma ingancin yankewa zai ci gaba da shafar, wanda bai yi kyau kamar ingancin yanke faranti masu cancanta ba.

3. Daidaiton tasirin yankewa ya fi na farantin tsatsa mara daidaito. Daidaiton farantin tsatsa yana shan laser daidai gwargwado, don haka za a iya yanke shi da kyau. Ga farantin da ba shi da tsatsa mara daidaito, ana ba da shawarar a shafa saman don ya zama daidai gwargwado na zanen sannan a yi yanke laser na zanen.

Lokacin Saƙo: Maris-27-2024