1. Ƙarfin yankewa naInjin yanke laser

1. Ƙarfin yankewa naInjin yanke laser

a. Kauri a yanka

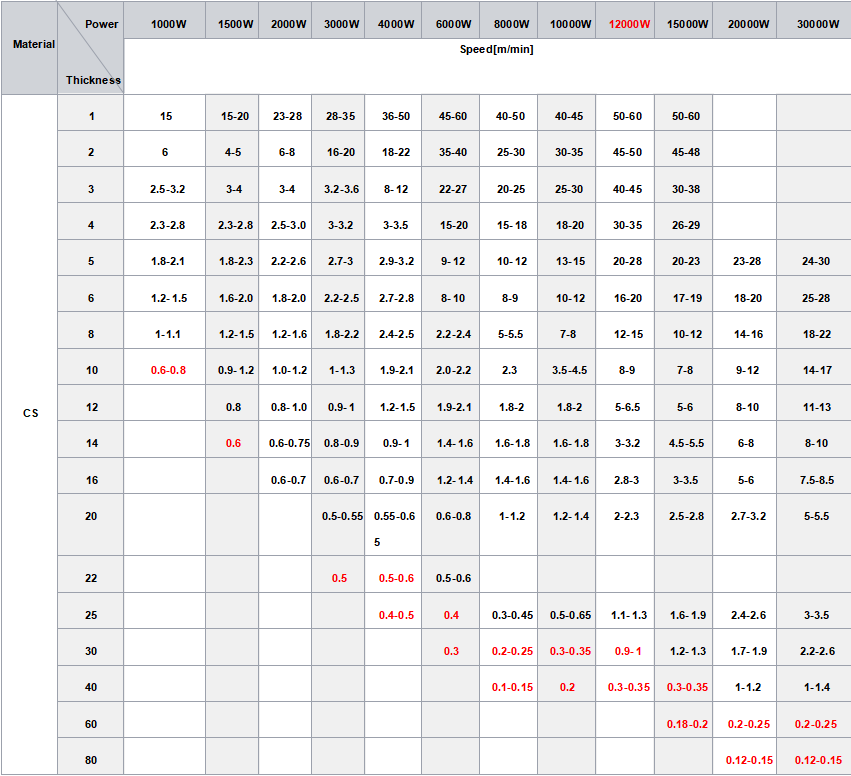

Kauri na yankewaInjin yanke laserYana shafar abubuwa da yawa kamar ƙarfin laser, saurin yankewa, nau'in kayan aiki, da sauransu. Gabaɗaya, kewayon kauri da injin yanke laser 3000W zai iya yankewa shine 0.5mm-20mm. Musamman:

1) Ga ƙarfen carbon, kauri da injin yanke laser mai ƙarfin 3000W zai iya yankewa shine 0.5mm-20mm.

2) Ga bakin karfe, kauri da injin yanke laser 3000W zai iya yankewa shine 0.5mm-12mm.

3) Ga ƙarfen aluminum, kauri da injin yanke laser 3000W zai iya yankewa shine 0.5mm-8mm.

4) Ga karafa marasa ƙarfe kamar tagulla da taliya, kauri da injin yanke laser mai ƙarfin 3000W zai iya yankewa shine 0.5mm-6mm.

Ya kamata a lura cewa bayan an yi amfani da waɗannan bayanai, ainihin tasirin yankewa yana shafar abubuwa kamar aikin kayan aiki da ƙwarewar aiki.

Saurin yanke na'urar yanke laser mai ƙarfin 3000W yana shafar abubuwa kamar nau'in kayan aiki, kauri, da yanayin yankewa. Gabaɗaya, saurin yanke na'urar yanke laser na iya kaiwa mita da yawa zuwa mita 1000 a minti ɗaya. Musamman:

1) Ga ƙarfen carbon, saurin yanke injin yanke laser mai ƙarfin 3000W zai iya kaiwa mita 10-30 a minti ɗaya.

2) Ga bakin karfe, saurin yanke injin yanke laser mai karfin 3000W zai iya kaiwa mita 5-20 a minti daya.

3) Ga ƙarfen aluminum, saurin yanke na'urar yanke laser mai ƙarfin 3000W zai iya kaiwa mita 10-25 a minti ɗaya.

4) Ga karafa marasa ƙarfe kamar tagulla da taliya, saurin yanke injin yanke laser mai ƙarfin 3000W zai iya kaiwa mita 5-15 a minti ɗaya.

2. Faɗin amfani daInjin yanke laser

Injin yanke laser mai ƙarfin 3000W ana amfani da shi sosai a fannin sarrafa ƙarfe, kera injina, kera motoci, sararin samaniya, kayan lantarki, kayan aikin likita, kayan adon gine-gine da sauran fannoni. Musamman, ana iya amfani da shi don yankewa da sarrafa kayan da ke ƙasa:

1) Kayan ƙarfe kamar ƙarfe na carbon da bakin ƙarfe.

2) Ƙaramin ƙarfe kamar ƙarfe mai ƙarfi na magnesium da ƙarfe mai ƙarfi na magnesium.

3) Gubar, jan ƙarfe, taliya, tin, da sauran ƙarfe marasa ƙarfe.

4) Kayan da ba na ƙarfe ba kamar itace, filastik, roba, da fata.

5) Kayan da suka yi rauni kamar gilashi, yumbu, da dutse.

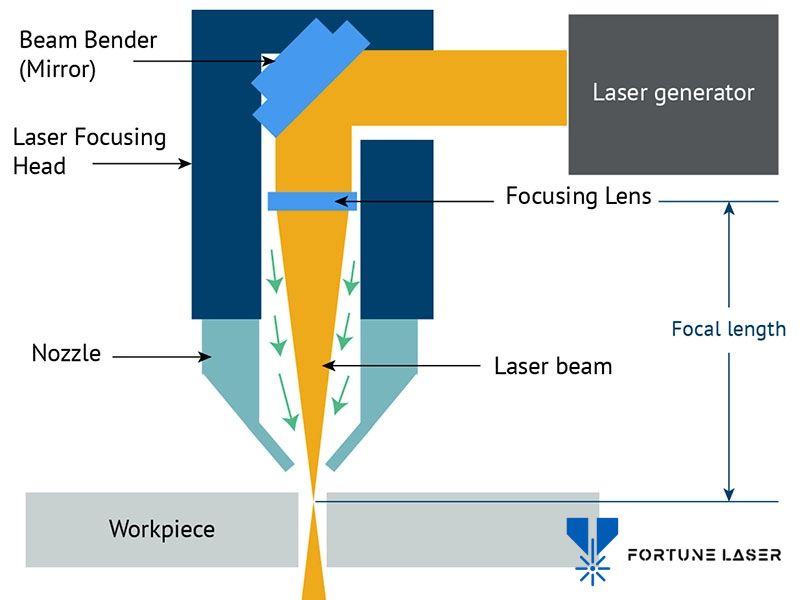

3. Ka'idar aiki naInjin yanke laser

Ka'idar aiki na injin yanke laser shine amfani da hasken laser mai ƙarfi don haskaka saman kayan, ta yadda kayan zai iya narkewa da sauri, ya zama tururi ko ƙonewa, ta haka ne za a cimma manufar yankewa. Musamman, ƙa'idar aiki na injin yanke laser mai ƙarfin 3000W ya haɗa da waɗannan matakai:

1. Injin samar da laser yana samar da hasken laser mai ƙarfi sosai.

2. Tsarin gani yana mai da hankali kan hasken laser don samar da hasken laser mai yawan kuzari.

3. Ana haskaka hasken laser mai yawan kuzari a saman kayan, ta yadda kayan zai iya narkewa da sauri, ya zama tururi ko kuma ya ƙone.

4. Kan yanke yana tafiya tare da hanyar da aka tsara, kuma hasken laser yana bin diddigin motsi don cimma ci gaba da yankewa.

5. Iskar gas mai taimako (kamar iskar oxygen, iskar oxygen, da sauransu) na fitar da tarkacen da ke fitowa yayin aikin yankewa domin tabbatar da tsaftar saman yankewa.

4. Gargaɗin aiki naInjin yanke laser 3000W

1. Masu aiki suna buƙatar yin horo na ƙwararru kuma su saba da hanyoyin aiki da buƙatun aminci na kayan aiki.

2. Sanya kayan kariya, safar hannu da sauran kayan kariya yayin aiki don hana lalacewar hasken laser da kuma lalacewar feshi.

3. A riƙa duba aiki da daidaiton kayan aikin akai-akai domin tabbatar da cewa kayan aikin suna aiki yadda ya kamata.

4. Yi aiki da kyau bisa ga sigogin yanke kayan don guje wa mummunan tasirin yankewa ko lalacewar kayan aiki saboda sigogi marasa dacewa.

5. Kula da tasirin yankewa yayin yankewa. Idan an sami wani rashin daidaituwa, duba shi nan take.

6. Bayan yankewa, tsaftace wurin yankewa akan lokaci don cire ragowar kwararar ruwa da oxides don tabbatar da tsafta da daidaiton saman yankewa.

Lokacin Saƙo: Janairu-09-2025