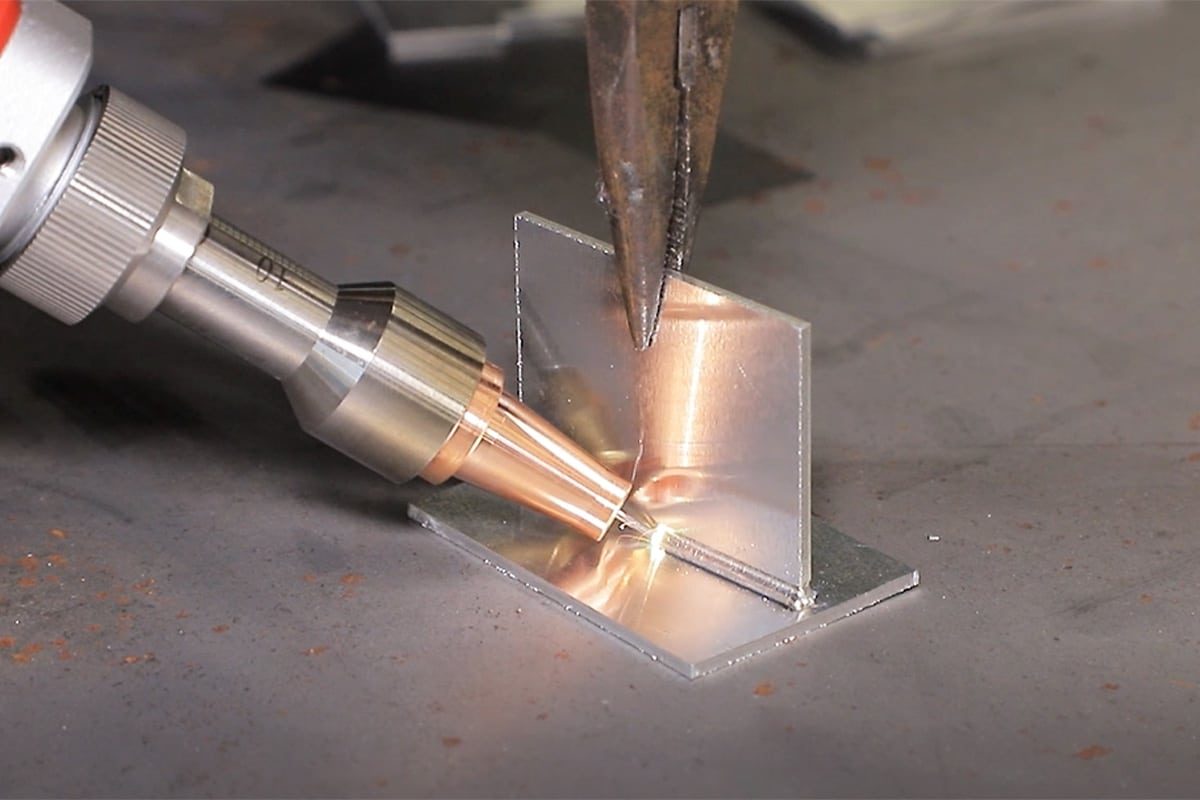

Ga injiniyoyi, masu ƙera kayayyaki, da manajojin ayyuka, ƙalubalen koyaushe ne: yadda ake haɗa sassan ƙarfe ba tare da lanƙwasawa, canza launi ba, da kuma rage juriyar tsatsa wanda ke addabar hanyoyin gargajiya.Laser walda bakin karfe, wata fasaha mai kawo sauyi wadda ke samar da gudu, daidaito, da inganci mara misaltuwa wanda walda ta gargajiya ta TIG da MIG ba za su iya daidaitawa ba.

Walda ta Laser tana amfani da hasken da aka tattara sosai don narkewa da haɗa bakin ƙarfe tare da ƙaramin shigarwar zafi mai sarrafawa. Wannan tsari mai inganci yana magance matsalolin da suka shafi gurɓatar zafi da ƙarar walda kai tsaye.

Muhimman Amfanin Laser Welding Bakin Karfe:

-

Gudun Musamman:Yana aiki sau 4 zuwa 10 cikin sauri fiye da walda ta TIG, wanda hakan ke ƙara yawan aiki da kuma yawan aiki.

-

Ƙarancin Ruɗewa:Zafin da aka mayar da hankali a kai yana ƙirƙirar ƙaramin yanki mai fama da zafi (HAZ), wanda ke rage ko kawar da karkacewa sosai, yana kiyaye daidaiton girman ɓangaren.

-

Inganci Mai Kyau:Yana samar da walda mai tsabta, mai ƙarfi, kuma mai kyau wanda ke buƙatar niƙa ko kammalawa bayan walda.

-

Kayayyakin da aka Kiyaye:Ƙarancin zafi da ake samu yana kiyaye ƙarfin ƙarfen da ke cikinsa da kuma juriyar tsatsa, yana hana matsaloli kamar "lalacewar walda".

Wannan jagorar tana ba da ilimin ƙwararru da ake buƙata don canzawa daga fahimta ta asali zuwa aikace-aikacen amincewa, yana tabbatar da cewa zaku iya amfani da cikakken ƙarfin wannan dabarar kera kayayyaki ta zamani.

Walda ta Laservs. Hanyoyin Gargajiya: Kwatanta Kai-da-Kai

Zaɓar tsarin walda mai kyau yana da matuƙar muhimmanci ga nasarar aikin. Ga yadda walda ta laser ke taruwa akan TIG da MIG don aikace-aikacen ƙarfe na bakin ƙarfe.

Walda ta Laser da Walda ta TIG

An san aikin walda na Tungsten Inert Gas (TIG) da inganci mai kyau, amma yana fama da rashin ci gaba a yanayin samarwa.

-

Sauri & Yawan aiki:Walda ta Laser tana da sauri sosai, wanda hakan ke sa ta zama zaɓi mafi sauƙi don kera ta atomatik da girma mai yawa.

-

Zafi & Rugujewa:Bakin TIG wani tushen zafi ne mara inganci, mai yaɗuwa wanda ke haifar da babban HAZ, wanda ke haifar da karkacewa sosai, musamman akan siririn ƙarfe. Hasken da laser ke mayar da hankali a kai yana hana wannan lalacewar zafi mai yawa.

-

Aiki da kai:Tsarin laser yana da sauƙin sarrafa kansa ta atomatik, yana ba da damar yin aiki mai yawa, mai maimaitawa ba tare da ƙwarewar hannu ba fiye da TIG.

Walda ta Laser da Walda ta MIG

Walda ta Karfe Inert Gas (MIG) tsari ne mai amfani da yawa, wanda ke da sauƙin cirewa, amma ba shi da daidaito kamar na'urar Laser.

-

Daidaito & Inganci:Walda ta Laser tsari ne da ba ya taɓawa wanda ke samar da walda mai tsabta, ba tare da tsatsa ba. Walda ta MIG tana da saurin tsatsa wanda ke buƙatar tsaftacewa bayan walda.

-

Juriyar Gibi:Walda ta MIG ta fi sauƙi ga rashin kyawun haɗin gwiwa domin wayar da ake amfani da ita tana aiki a matsayin cikawa. Walda ta Laser tana buƙatar daidaito daidai da kuma jure wa matsewa.

-

Kauri na Kayan Aiki:Duk da cewa na'urorin laser masu ƙarfi za su iya ɗaukar sassa masu kauri, MIG sau da yawa ya fi dacewa da faranti masu nauyi. Walda ta laser ta fi kyau a kan kauri mai sirara zuwa matsakaici inda sarrafa karkacewa yake da mahimmanci.

Teburin Kwatantawa Mai Sauƙi

| Fasali | Walda na Laser Beam | Walda ta TIG | Walda ta MIG |

| Gudun Walda | Babban Sosai (4-10x TIG)

| Ƙasa Sosai | Babban |

| Yankin da Zafi Ya Shafi (HAZ) | Mafi ƙanƙanta / Matsakaici Mai Ƙuntatawa | Faɗi | Faɗi |

| Rushewar Zafi | Ba a iya sakaci ba | Babban | Matsakaici zuwa Sama |

| Juriyar Gibi | Ƙasa Sosai (<0.1 mm) | Babban | Matsakaici |

| Bayanin Walda | Kunci & Zurfi | Faɗi & Ba shi da zurfi | Faɗi & Mai Canzawa |

| Farashin Kayan Aiki na Farko | Mai Girma Sosai | Ƙasa

| Ƙasa zuwa Matsakaici

|

| Mafi Kyau Ga | Daidaito, gudu, aiki da kai, kayan siriri

| Aikin hannu mai inganci, kyawun gani

| Kayan da aka ƙera gabaɗaya, kayan da suka yi kauri |

Kimiyyar da ke Bayan Walda: An Bayyana Manyan Ka'idoji

Fahimtar yadda laser ke hulɗa da bakin ƙarfe shine mabuɗin ƙwarewa wajen sarrafa tsarin. Yana aiki ne a cikin yanayi biyu daban-daban waɗanda aka ƙayyade ta hanyar ƙarfin wutar lantarki.

Yanayin Gudanarwa da Yanayin Ramin Maɓalli

-

Walda Mai Gudarwa:A ƙarancin ƙarfin da ake da shi, na'urar laser tana dumama saman kayan, kuma zafin zai "shiga" cikin ɓangaren. Wannan yana haifar da walda mai zurfi, mai santsi, kuma mai kyau, wanda ya dace da kayan da suka yi siriri (ƙasa da 1-2 mm) ko kuma wuraren da ake iya gani inda kamannin yake da mahimmanci.

-

Ramin Maɓalli (Zurfin Shiga Cikin Gida) Walda:A lokacin da ƙarfinsa ya yi yawa (kimanin 1.5 MW/cm²), laser ɗin yana tururi ƙarfen nan take, yana ƙirƙirar rami mai zurfi da ake kira "hole na maɓalli." Wannan ramin maɓalli yana kama ƙarfin laser ɗin, yana tura shi cikin kayan don yin walda mai ƙarfi da cikakken shiga cikin sassa masu kauri.

Na'urorin Laser Masu Ci gaba (CW) da Na'urorin Pulsed

-

Ci gaba da Raƙuman Ruwa (CW):Laser ɗin yana isar da hasken kuzari mai ɗorewa, wanda ba a katse shi ba. Wannan yanayin ya dace da ƙirƙirar dogayen ɗinki masu ci gaba a cikin babban gudu a cikin samarwa ta atomatik.

-

Laser mai juyawa:Laser ɗin yana ba da kuzari a cikin ɗan gajeren lokaci mai ƙarfi. Wannan hanyar tana ba da cikakken iko akan shigar zafi, rage HAZ kuma yana sa ya zama mafi dacewa don walda sassa masu laushi, masu saurin amsawa ga zafi ko ƙirƙirar walda masu haɗuwa don cikakken hatimi.

Jagorar Mataki-mataki don Shiri Mara Aibi

A walda ta laser, ana tantance nasara kafin a kunna hasken. Daidaiton aikin yana buƙatar shiri mai kyau.

Mataki na 1: Tsarin Haɗaka da Daidaitawa

Ba kamar walda ta baka ba, walda ta laser ba ta da juriya sosai ga gibba ko rashin daidaito.

-

Nau'in Haɗin gwiwa:Haɗaɗɗun duwawu sune mafi inganci amma suna buƙatar tazara kusan sifili (yawanci ƙasa da 0.1 mm ga sassa masu siriri). Haɗaɗɗun duwawu sun fi gafartawa ga bambancin daidaitawa.

-

Sarrafa Gilashi:Gibin da ya wuce kima zai hana ƙaramin wurin narkakken najasa ya haɗa haɗin, wanda hakan zai haifar da haɗakar da ba ta cika ba da kuma raunin walda. Yi amfani da hanyoyin yankewa masu inganci da kuma mannewa mai ƙarfi don tabbatar da daidaito mai kyau.

Mataki na 2: Tsaftace saman ƙasa da Cire Gurɓataccen abu

Ƙarfin wutar lantarkin laser zai tururi duk wani gurɓataccen abu a saman, ya kama su a cikin walda kuma yana haifar da lahani kamar porosity.

-

Tsafta Yana da Muhimmanci:Dole ne saman ya kasance babu mai, mai, ƙura, da sauran abubuwan da suka rage a manne gaba ɗaya.

-

Hanyar Tsaftacewa:A goge wurin haɗin da kyalle mara lint wanda aka jika a cikin wani sinadari mai canzawa kamar acetone ko 99% isopropyl barasa nan da nan kafin a yi walda.

Kwarewa a Injin: Inganta Maɓallan Walda Masu Maɓalli

Samun cikakkiyar walda yana buƙatar daidaita ma'auni da dama da suka haɗa kai.

Triad na Sigogi: Ƙarfi, Gudu, da Matsayin Mai da Hankali

Waɗannan saituna guda uku tare suna ƙayyade shigarwar makamashi da bayanin martabar walda.

-

Ƙarfin Laser (W):Ƙarfin iko mafi girma yana ba da damar shiga cikin zurfi da sauri. Duk da haka, ƙarfin da ya wuce kima na iya haifar da ƙonewa akan siraran kayan.

-

Gudun Walda (mm/s):Saurin gudu yana rage shigar zafi da karkacewarsa. Idan gudun ya yi yawa fiye da yadda ake tsammani, zai iya haifar da rashin shigar da shi.

-

Matsayin Mai da Hankali:Wannan yana daidaita girman tabo na laser da yawan ƙarfinsa. Mayar da hankali kan saman yana ƙirƙirar walda mafi zurfi da kunkuntar. Mayar da hankali kan saman (mai da hankali kan mai da hankali) yana ƙirƙirar walda mai faɗi da zurfi fiye da kima. Mayar da hankali a ƙarƙashin saman (mai da hankali kan mai da hankali) na iya haɓaka shigar kayan da suka yi kauri.

Zaɓin Iskar Gas Mai Kariya: Argon vs. Nitrogen

Iskar gas mai kariya tana kare wurin walda mai narkewa daga gurɓatar yanayi kuma tana daidaita aikin.

-

Argon (Ar):Zaɓin da aka fi sani, yana samar da kariya mai kyau da kuma samar da walda mai tsabta da kwanciyar hankali.

-

Nitrogen (N2):Sau da yawa ana fifita shi da bakin karfe, domin yana iya ƙara juriya ga tsatsa a haɗin gwiwa na ƙarshe.

-

Yawan Guduwar:Dole ne a inganta yawan kwararar ruwa. Ƙarancin ruwa ba zai iya kare walda ba, yayin da yawan ruwa zai iya haifar da hayaniya da kuma jawo gurɓatattun abubuwa. Yawan kwararar ruwa daga lita 10 zuwa 25 a minti ɗaya (L/min) shine matsakaicin lokacin farawa.

Ma'aunin Farawa: Teburin Shaida

Ga wasu daga cikin abubuwan da za a fara amfani da su wajen walda ƙarfe mai siffar austenitic 304/316. Koyaushe a yi gwaje-gwaje kan tarkacen kayan da za a yi amfani da su don daidaita takamaiman aikin da ake yi.

| Kauri na Kayan Aiki (mm) | Ƙarfin Laser (W) | Gudun Walda (mm/s) | Matsayin Mai da Hankali | Iskar Gas Mai Kariya |

| 0.5 | 350 – 500 | 80 – 150 | A saman | Argon ko Nitrogen |

| 1.0 | 500 – 800 | 50 – 100 | A saman | Argon ko Nitrogen |

| 2.0 | 800 – 1500 | 25 – 60 | Ɗan ƙasa da saman ƙasa | Argon ko Nitrogen |

| 3.0 | 1500 - 2000 | 20 – 50 | A ƙasan saman | Argon ko Nitrogen |

| 5.0 | 2000 – 3000 | 15 – 35 | A ƙasan saman | Argon ko Nitrogen |

Kula da Inganci: Jagorar Shirya Matsaloli ga Lalacewar da Aka Fi Sani

Ko da an yi cikakken tsari, lahani na iya faruwa. Fahimtar musabbabin su shine mabuɗin rigakafi.

Gano Lalacewar Laser da Aka Fi Sani

-

Rarrabuwa:Ƙananan kumfa na iskar gas da aka makale a cikin walda, galibi suna faruwa ne sakamakon gurɓatar saman ko kwararar iskar gas mara kyau.

-

Fashewa Mai Zafi:Tsagewar tsakiyar layi da ke samuwa yayin da walda ke tauri, wani lokacin saboda abubuwan da ke cikin kayan ko kuma matsanancin matsin lamba na zafi.

-

Shigarwa Ba Tare Da Kammalawa Ba:Walda ba ta haɗuwa ta cikin zurfin haɗin gwiwa gaba ɗaya ba, yawanci saboda rashin ƙarfi ko saurin gudu mai yawa.

-

An yanke ƙasa:Wani rami ya narke a cikin ƙarfen da ke gefen walda, wanda galibi yakan faru ne sakamakon saurin gudu ko babban gibi.

-

Shafawa:Digon da aka narke daga wurin walda, yawanci saboda yawan ƙarfi ko gurɓatar saman.

Jadawalin Shirya Matsaloli: Dalilai da Magani

| Lalacewa | Dalilan da Zasu Iya Faru | Shawarar Ayyukan Gyara |

| Porosity | Gurɓatar saman ƙasa; kwararar iskar gas mara kyau. | Aiwatar da tsaftace iskar gas mai tsafta kafin walda; tabbatar da ingantaccen iskar gas da kuma inganta yawan kwararar iska. |

| Fashewa Mai Zafi | Kayan da ke jure wa sanyi; matsanancin matsin lamba na zafi. | Yi amfani da wayar cikawa mai dacewa; kunna kayan don rage girgizar zafi. |

| Shigarwa Ba Tare Da Kammalawa Ba | Rashin ƙarfi; saurin gudu; rashin mayar da hankali sosai. | Ƙara ƙarfin laser ko rage saurin walda; tabbatar da daidaita matsayin mai da hankali. |

| An yanke ƙasa | Gudu mai yawa; babban gibin haɗin gwiwa. | Rage saurin walda; inganta daidaita sassan don rage gibin. |

| Spatter | Yawan ƙarfi; gurɓatar saman. | Rage ƙarfin laser ko amfani da na'urar cire hankali mai kyau; tabbatar da cewa saman yana da tsafta sosai. |

Matakai na Ƙarshe: Tsaftacewa Bayan Walda da kuma Tausasawa

Tsarin walda yana lalata kaddarorin da ke sa bakin karfe ya zama "bakin karfe." Mayar da su mataki ne na ƙarshe da ya zama dole.

Dalilin da yasa ba za ku iya tsallake maganin bayan walda ba

Zafin da ke fitowa daga walda yana lalata layin chromium-oxide mara ganuwa, mai kariya a saman ƙarfen. Wannan yana barin walda da HAZ da ke kewaye su cikin haɗarin tsatsa da tsatsa.

An Bayyana Hanyoyin Passivation

Passivation magani ne na sinadarai wanda ke kawar da gurɓatattun abubuwa a saman fata kuma yana taimakawa wajen gyara wani tsari mai ƙarfi, iri ɗaya na chromium-oxide.

-

Tsaftace sinadarai:Hanya ta gargajiya da ke amfani da sinadarai masu haɗari kamar nitric da hydrofluoric acid don tsaftacewa da kuma kawar da gurɓataccen ruwa.

-

Tsaftace Wutar Lantarki:Hanya ta zamani, mafi aminci, kuma mafi sauri wadda ke amfani da ruwa mai laushi na electrolytic da kuma ƙaramin ƙarfin lantarki don tsaftacewa da kuma sarrafa walda a mataki ɗaya.

Tsaro Na Farko: Muhimman Kariya Don Walda Na Laser

Yanayin walda mai ƙarfin gaske na laser yana haifar da manyan haɗurra a wurin aiki waɗanda ke buƙatar tsauraran ƙa'idoji na tsaro.

Hatsarin da Ya Boye: Hayakin Hexavalent Chromium (Cr(VI))

Idan aka dumama bakin karfe zuwa yanayin walda, sinadarin chromium da ke cikin hadin zai iya samar da sinadarin hexavalent chromium (Cr(VI)), wanda ke zama iska a cikin hayakin.

-

Hadarin Lafiya:Cr(VI) wani sanannen nau'in cutar kansa ne da ke da alaƙa da ƙaruwar haɗarin kamuwa da cutar kansar huhu. Hakanan yana iya haifar da matsanancin kumburin numfashi, fata, da idanu.

-

Iyakokin Fuskantar Fuska:OSHA ta kafa ƙa'idar iyaka mai izini ta fallasa (PEL) na microgram 5 a kowace mita mai siffar cubic na iska (5 µg/m³) ga Cr(VI).

Matakan Tsaro Masu Muhimmanci

-

Sarrafa Injiniya:Hanya mafi inganci don kare ma'aikata ita ce gano haɗarin daga tushensa. Ingantaccen aikitsarin cire hayakitare da matattarar HEPA mai matakai da yawa yana da mahimmanci don kama ƙwayoyin ultrafine da aka samar ta hanyar walda ta laser.

-

Kayan Kariyar Kai (PPE):Duk ma'aikatan da ke yankin dole ne su sanya gilashin kariya na laser wanda aka kimanta shi daidai da tsawon laser ɗin. Idan cire hayaki ba zai iya rage fallasa ba a ƙasa da PEL, ana buƙatar na'urorin numfashi da aka amince da su. Dole ne a kuma gudanar da aikin walda a cikin wani wuri mai hana haske tare da makullan tsaro don hana fallasa haske ba da gangan ba.

Tambayoyin da Ake Yawan Yi (FAQ)

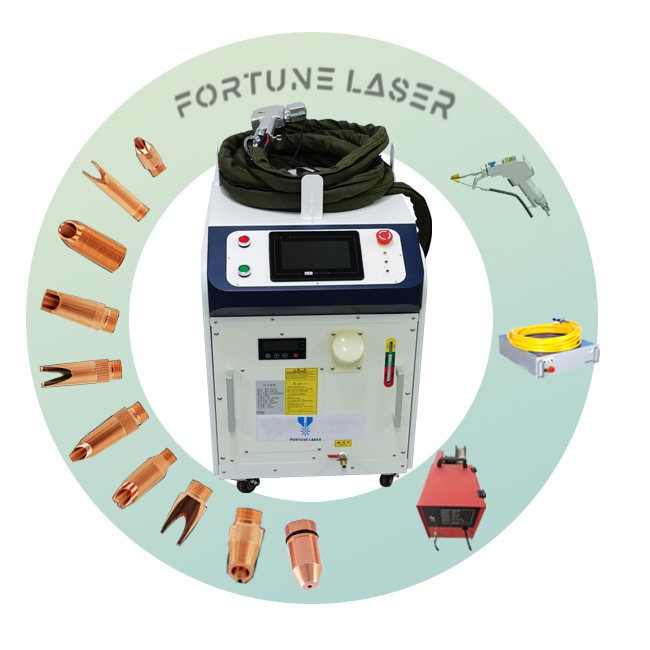

Menene mafi kyawun nau'in laser don walda bakin ƙarfe?

Fiber lasers galibi shine mafi kyawun zaɓi saboda gajeriyar tsawonsu, wanda bakin ƙarfe ke sha cikin sauƙi, da kuma kyakkyawan ingancin haskensu don sarrafa shi daidai.

Za ku iya haɗa kauri daban-daban na bakin ƙarfe tare da laser?

Haka ne, walda ta laser tana da matuƙar tasiri wajen haɗa kauri daban-daban ba tare da wata matsala ba kuma ba tare da ƙonewa a kan siraran ɓangaren ba, aiki ne mai matuƙar wahala da walda ta TIG.

Shin waya mai cikewa tana da mahimmanci don walda ta laser bakin karfe?

Sau da yawa, a'a. Walda ta Laser na iya samar da walda mai ƙarfi da ke shiga cikin jiki ba tare da kayan cikawa ba (ta atomatik), wanda ke sauƙaƙa aikin. Ana amfani da wayar cikawa lokacin da ƙirar haɗin gwiwa ke da babban gibi ko kuma lokacin da ake buƙatar takamaiman halayen ƙarfe.

Menene matsakaicin kauri na bakin karfe da za a iya walda da laser?

Tare da tsarin da ke da ƙarfi sosai, yana yiwuwa a yi walda da bakin ƙarfe har zuwa 1/4" (6mm) ko ma kauri a cikin hanya ɗaya. Tsarin laser-arc na haɗaka na iya haɗa sassa sama da inci ɗaya.

Kammalawa

Fa'idodin walda ta Laser a cikin sauri, daidaito, da inganci sun sa ta zama zaɓi mafi kyau ga ƙera ƙarfe na zamani. Tana samar da haɗin gwiwa masu ƙarfi da tsafta tare da ɓarna mara kyau, tana kiyaye mutuncin kayan da kuma kamanninsa.

Duk da haka, cimma waɗannan sakamako na duniya ya dogara ne da tsarin da aka tsara. Nasara ita ce ƙarshen sarkar masana'antu mai inganci - daga shiri mai kyau na haɗin gwiwa da kuma sarrafa sigogi na tsari zuwa tilastawa bayan walda da kuma jajircewa mai ƙarfi ga aminci. Ta hanyar ƙwarewa a wannan tsari, za ku iya buɗe sabon matakin inganci da inganci a cikin ayyukanku.

Lokacin Saƙo: Oktoba-08-2025