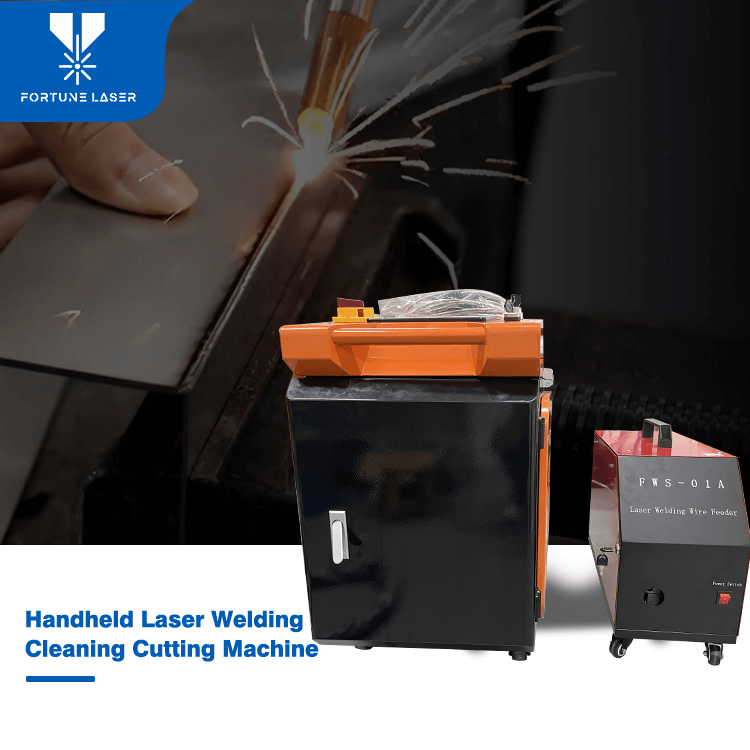

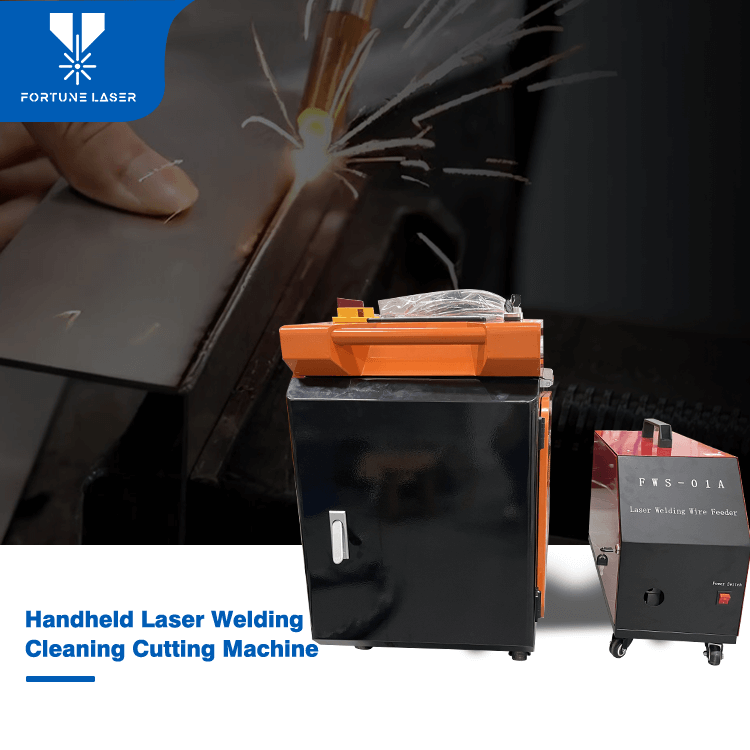

Na'urar Yanke Laser Mai Zafi ta Fortune Laser 1000W-3000W Injin Yanke Laser Mai Hannu 3-In-1

Na'urar Yanke Laser Mai Zafi ta Fortune Laser 1000W-3000W Injin Yanke Laser Mai Hannu 3-In-1

Fasali na na'urar walda ta Fortune Laser

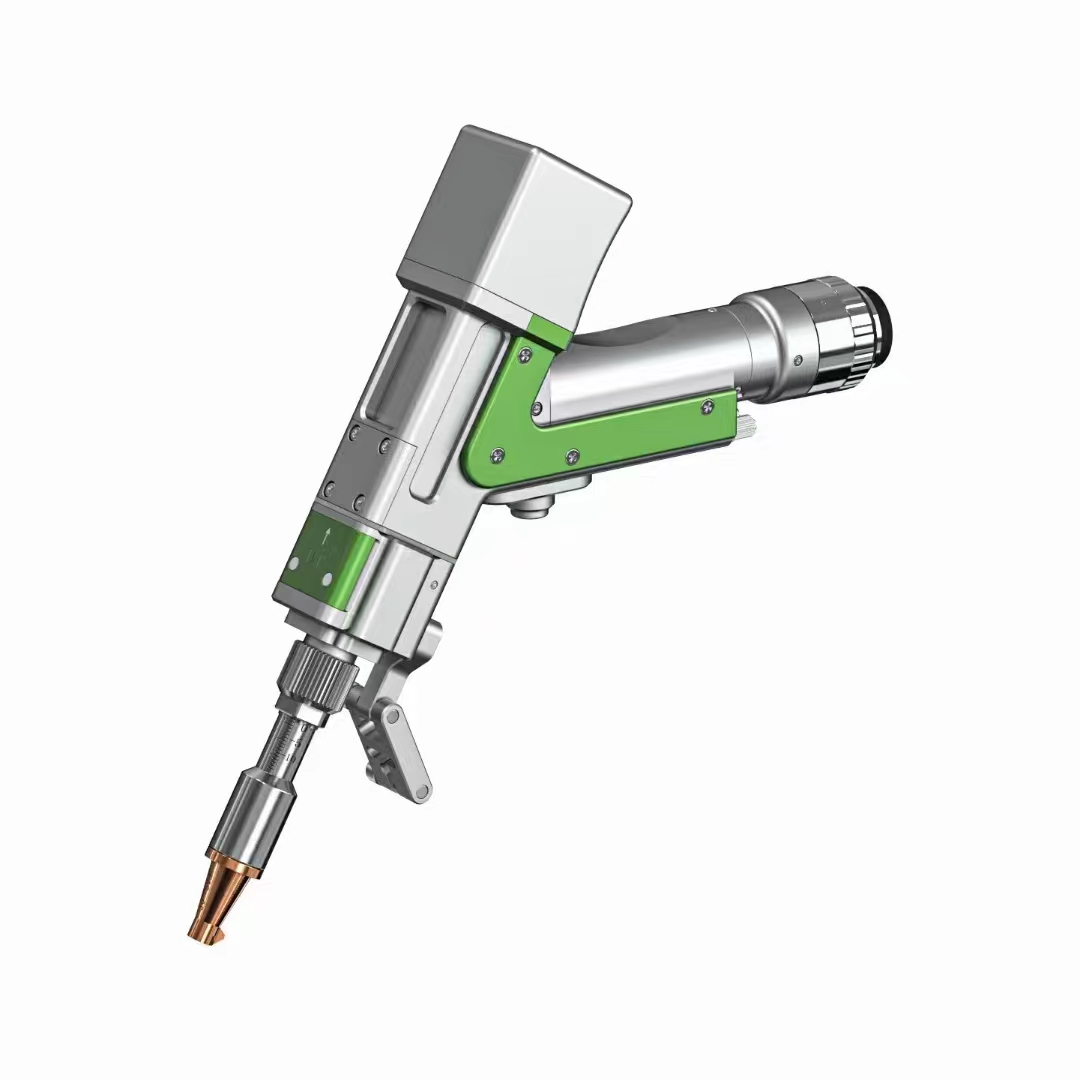

1. Tsarin tsarin da aka haɗa na dukkan na'urar, kayan aikin suna ɗauke da ƙaramin sarari, kuma an sanye su da manyan na'urori masu ɗaukar kaya na duniya, waɗanda suke da sauƙin ɗauka da ɗauka;

2. An tanadar da nau'ikan na'urorin haɗin walda iri-iri a matsayin mizani don biyan buƙatun walda iri-iri, kuma suna iya cimma walda mai inganci. Dinkin walda ƙarami ne, kyakkyawa kuma mai ƙarfi;

3. Manhajar walda ta laser ƙwararriya ce, mai ƙarfi kuma mai sauƙin koyo da amfani, ana iya ɗaukar ma'aikata gabaɗaya bayan horo, babu buƙatar ƙwararrun masu walda;

4. Kayan aikin suna da ƙarfin faɗaɗawa, kuma ana iya haɗa su da na'urorin ciyar da waya, robot, da sauransu, kuma ana iya sanya su da haɗin walda mai ɗaurewa ɗaya ko haɗin walda mai ɗaurewa biyu;

5. An sanya wa yankin sarrafa wutar lantarki fanka mai sanyaya a matsayin misali, wanda zai iya inganta daidaiton walda yadda ya kamata a yanayin zafi mai yawa (zaɓin na'urar sanyaya iska ta kabad);

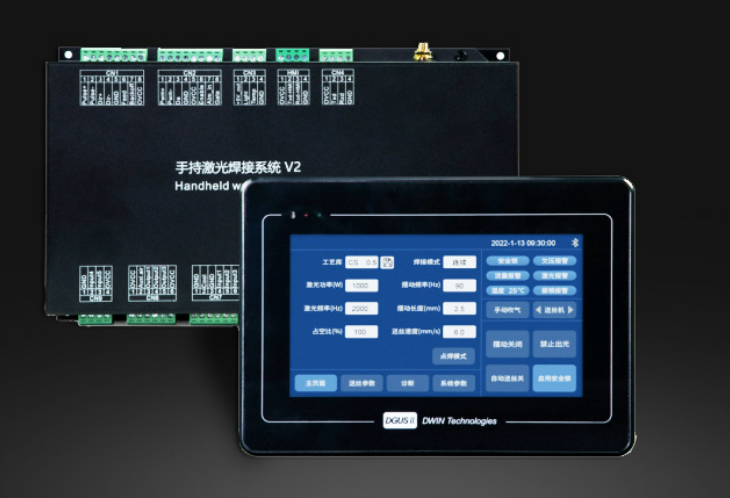

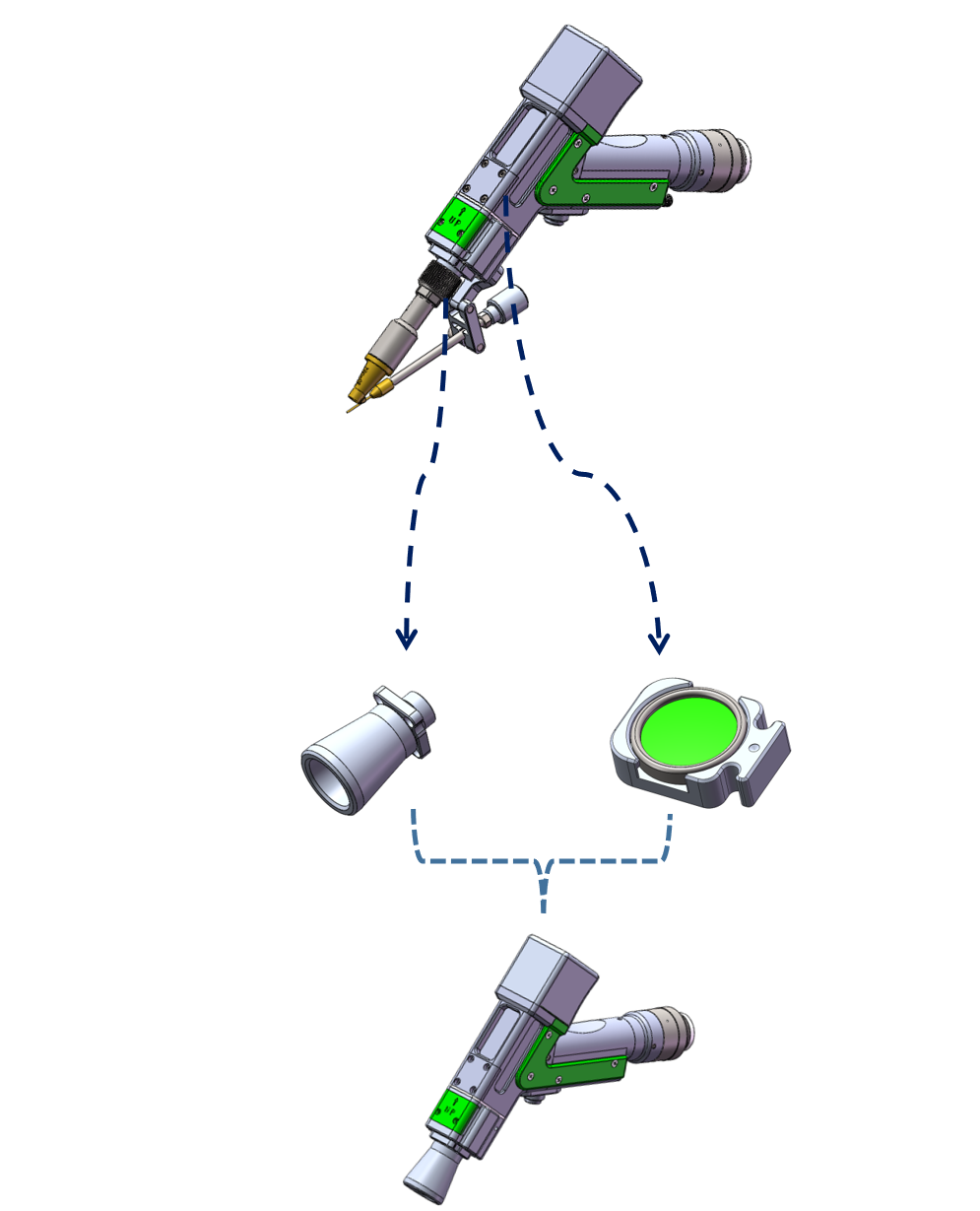

6. Ana iya lura da kayan aiki na gani da tashar allurar ruwa a kowane lokaci yayin amfani, kuma ana amfani da allon kula da allon taɓawa a lokaci guda don gyara sigogin aikin cikin sauƙi da sauƙi;

7. Tsarin zai iya adana nau'ikan sigogi daban-daban na aiki, waɗanda za a iya canzawa a kowane lokaci ta allon taɓawa bisa ga buƙatun sarrafawa, wanda hakan ke rage lokacin gyara sigogin sosai.

Shin kai ma kana da waɗannan matsalolin?

1. Walda ba ta da lafiya

2. Walda ba ta da kyau

3. Babban kuɗin aiki

Injinan mu na iya ba ku cikakkiyar mafita.

Aiki mai ƙarfi, ƙarin aiki mai wayo, gargaɗi mai zaman kansa, kariyar kai da gyara matsala cikin sauri

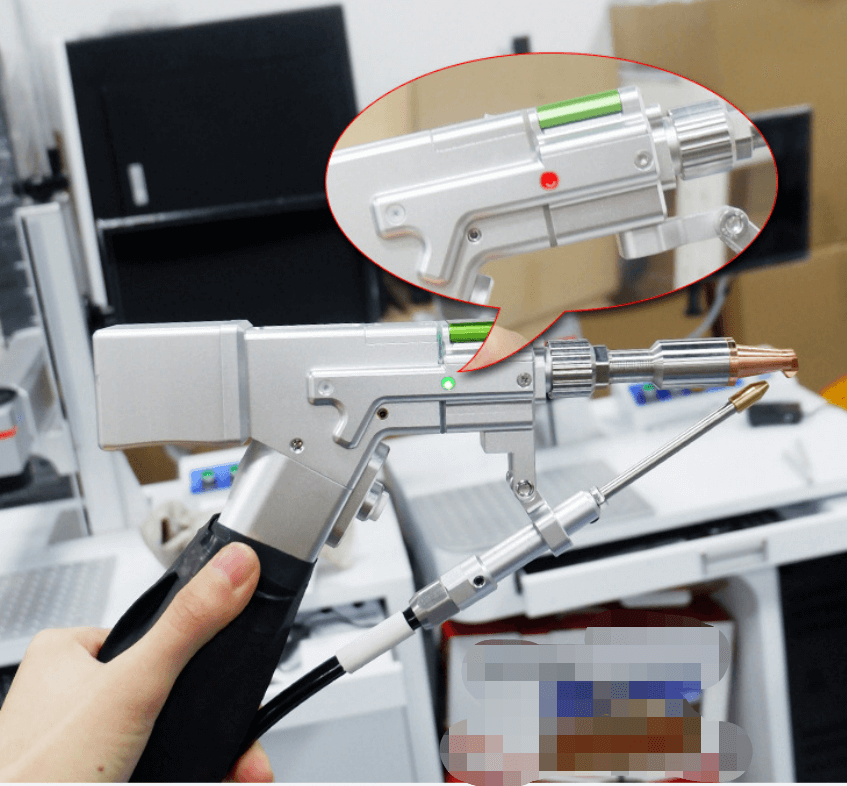

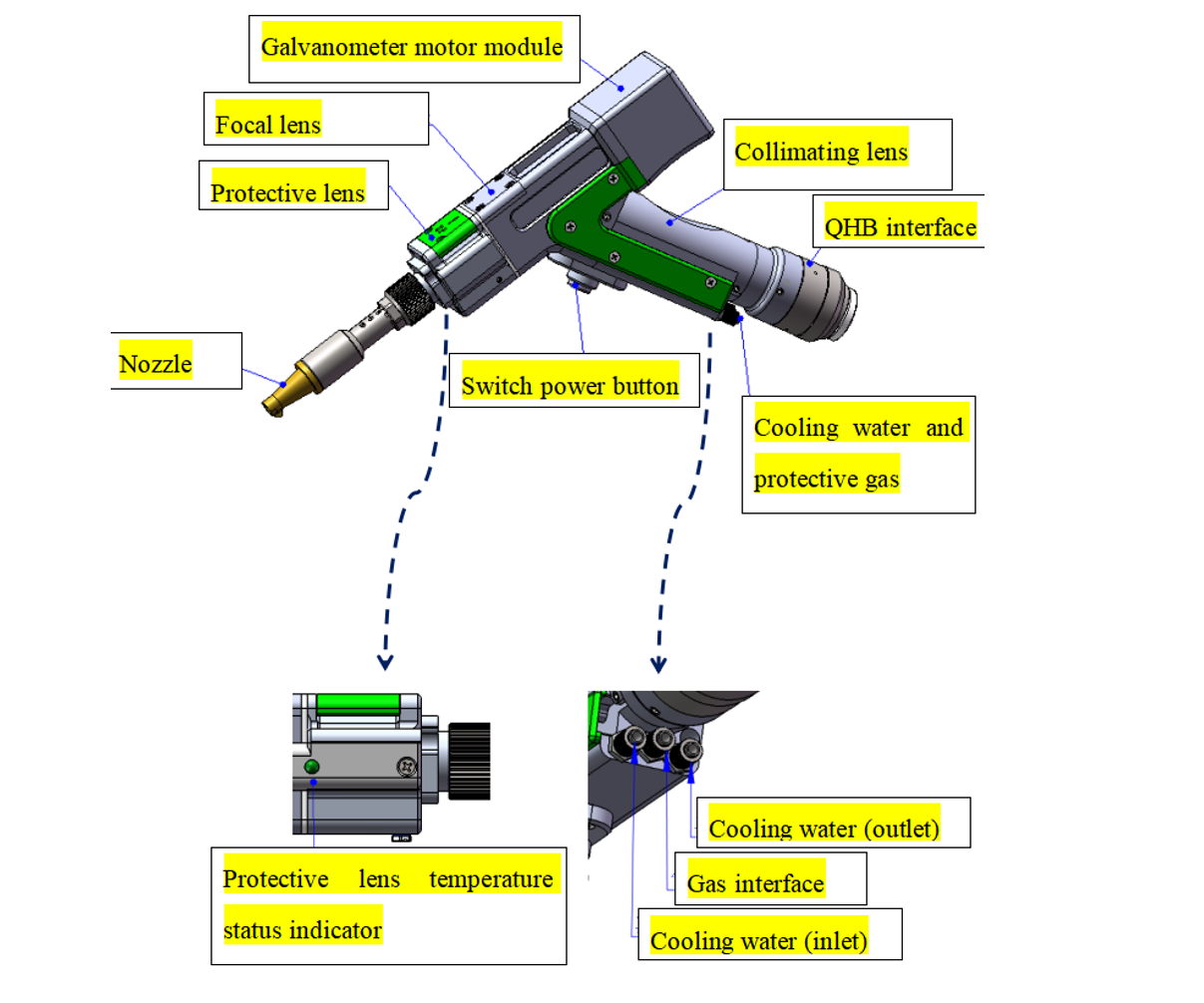

Na'urar ganowa mai hankali, sa ido da kariya: ƙimar saita zafin ruwan tabarau, lokacin da zafin ruwan tabarau ya wuce ƙimar saitawa, ƙararrawa za ta bayyana akan babban shafin don tunatar da gefen kan laser na hannu kuma hasken mai nuna alama zai yi ja a lokaci guda

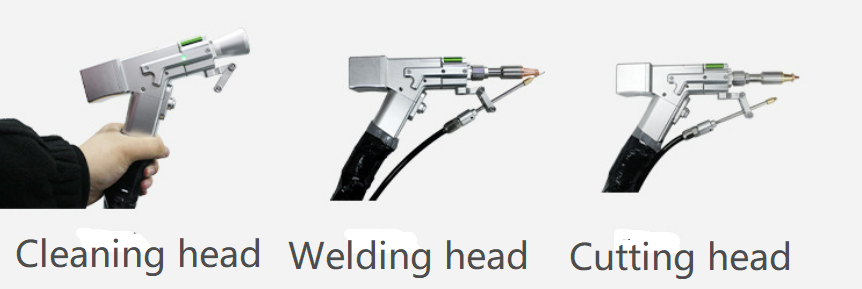

Sauƙin aiki, ana iya canza ayyuka uku a kowane lokaci

Sigogi na Fasaha na Injin Walda na Laser na Fortune

Sigogin shigar walda

Game da Fa'idodin Kan Laser na Fortune RelFar 3 In 1

Cikakkun bayanai kan Laser

Siga na shugaban Laser

Cikakkun Bayanan Mai Ciyar da Waya