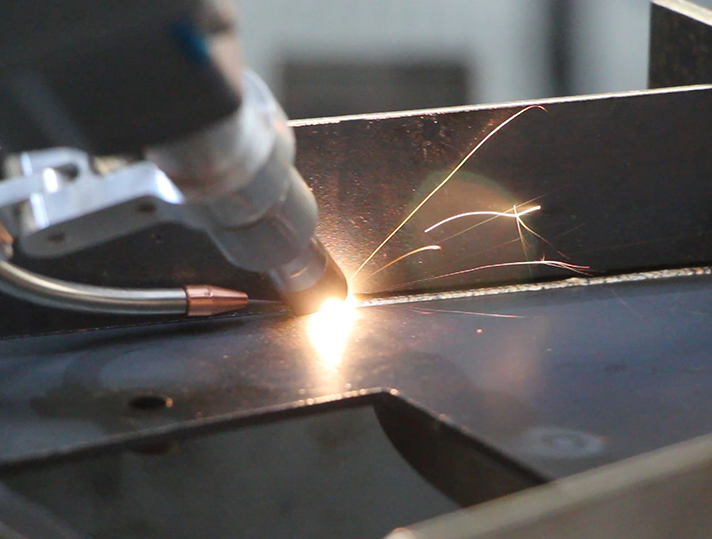

Oomatshini bokuwelda nge-laser abaphathwa ngesandla bathandwa kakhulu kumashishini ahlukeneyo ngenxa yokuguquguquka nokusebenza kakuhle kwabo. Ukongeza kwizakhono zabo eziphambili zokuwelda, aba matshini bakwabonelela ngezakhono zokusika, nto leyo eyongeza kuluncedo lwabo. Kweli nqaku, siza kuhlola umatshini wokuwelda nge-laser ophathwa ngesandla ongu-3-in-1 kwaye sifunde indlela yokusebenzisa ngokufanelekileyo izakhono zawo zokusika.

Iintloko zokuwelda zezixhobo eziphathwayooomatshini bokuwelda nge-laserZihlala zisebenza ngeendlela ezininzi kwaye zibonelela ngezinto ezingaphezulu kwemisebenzi yokuwelda. Ukongeza ekuwelding, zingasetyenziselwa ukusika nokucoca. Olu tshintsho lwenza oomatshini bokuwelda be-laser abaphathwa ngesandla babe lukhetho lokuqala kumashishini amaninzi. Ukukwazi ukwenza imisebenzi emininzi ngomatshini omnye akugcini nje ngokusindisa ixesha kodwa kwandisa imveliso iyonke.

Ukuze kusetyenziswe umsebenzi wokusika womatshini wokuwelda we-laser ophathwa ngesandla, kufuneka kutshintshwe umlomo wobhedu wentloko yokuwelda. Iintloko zokuwelda zezi matshini zihlala zixhotyiswe ngemilomo yobhedu yokuwelda. Nangona kunjalo, ukuze kusetyenziswe umsebenzi wokusika, umlomo wobhedu odibanisayo kufuneka utshintshwe ngomlomo wobhedu wokusikela. Eli nyathelo lilula livumela abasebenzisi ukuba batshintshe ngaphandle kokuphazamiseka phakathi kwemisebenzi yokuwelda kunye nemisebenzi yokusikela ngokweemfuno zabo.

Emva kokutshintsha umlomo wobhedu, inyathelo elilandelayo kukuseta iiparameter zokusika kwiphaneli yokusebenza. Ngokungafaniyo nokuwelda, okufuna useto oluthile, ukusika kubandakanya iseti eyahlukileyo yeeparameter. Ezi parameter zimisela isantya, ubunzulu kunye nokuchaneka kwenkqubo yokusika. Ngokufaka amaxabiso achanekileyo kwiphaneli yomsebenzisi, umsebenzisi unokuqinisekisa ukusebenza kakuhle kokusika.

Ngaphambi kokuba uqale inkqubo yokusika, kubalulekile ukuthatha amanyathelo okuzikhusela. Oku kuquka ukunxiba iiglasi, iiglavu, kunye nezinye izixhobo ezifunekayo ukuqinisekisa ukhuseleko xa usebenzisa i-laser welder ephathwayo. Kwakhona, ungaze uyichukumise loo nto emva kokusika kuba isenokuba shushu kwaye inokubangela ukutsha. Ukulandela la manyathelo kuya kunceda ukuthintela naziphi na iingozi kunye nokwenzakala okunokwenzeka.

Amandla okusika ephathwa ngesandlaoomatshini bokuwelda nge-laserziluncedo kakhulu kumashishini ahlukeneyo. Zingasika izinto ezahlukeneyo ngokuchanekileyo nangokufanelekileyo, kuquka isinyithi, iplastiki. Nokuba zenza uyilo oluntsonkothileyo okanye zisika ngokuchanekileyo kwizicelo zoshishino, amandla okusika abawelda be-laser abaphathwayo anika ubuchule obungenakuthelekiswa nanto.

Ukongeza kwizakhono zokusika, eziphathwa ngesandlaoomatshini bokuwelda nge-laserKwakhona zibalasele kwimisebenzi yokuwelda. Ukuguquguquka nokuchaneka kwezi matshini kuzenza zifunwe kakhulu. Nokuba zikwimizi-mveliso yeemoto, yeenqwelo moya, oomatshini bokuwelda be-laser abaphathwa ngesandla bazisa iziphumo ezigqwesileyo.

Lilonke, umatshini wokuwelda we-laser ophathwa ngesandla ongu-3-in-1 utshintsha umdlalo kwiinkampani ezahlukeneyo. Ngenxa yezakhono zawo zokusika, lo matshini uvumela abasebenzisi ukuba banqumle ngokuchanekileyo nangokufanelekileyo kwiindidi ezahlukeneyo zezinto. Ngokutshintsha umlomo wobhedu, ukuseta iiparameter zokusika, kunye nokubeka phambili ukhuseleko lomntu, abasebenzisi banokusebenzisa ngokufanelekileyo nangokukhuselekileyo amandla okusika esandla.umatshini wokuwelda nge-laserUkongeza, amandla okuwelda nokusika ala matshini awenza abe zizixhobo ezibalulekileyo zokuhlangabezana neemfuno ezahlukeneyo zamashishini ahlukeneyo. Ngoko ke, ukuba ufuna isisombululo sokuwelda esisebenziseka lula nesisebenzisekayo, cinga ngokutyala imali kumatshini wokuwelda we-laser ophathwa ngesandla oneubuchule bokusika.

Ixesha lokuthumela: Sep-27-2023