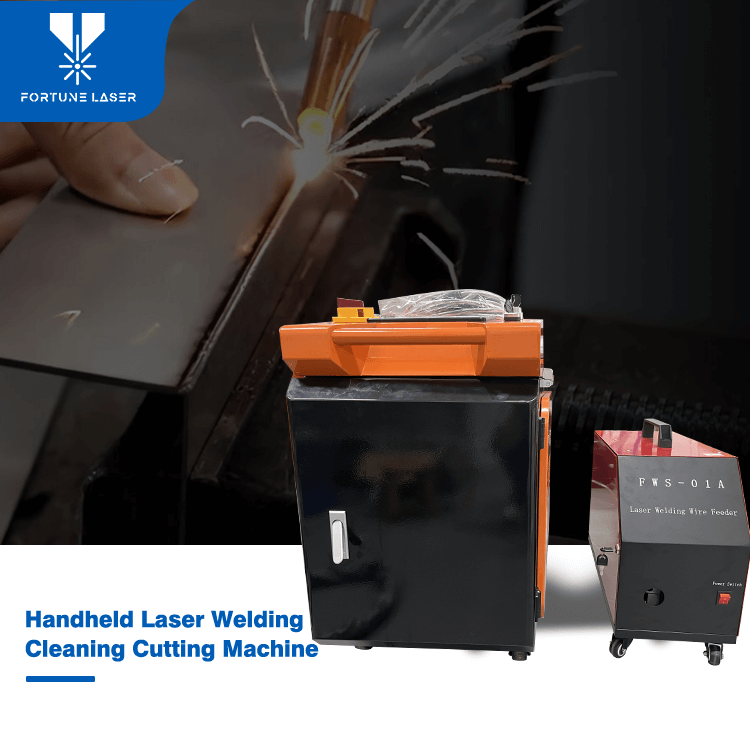

Njengoko itekhnoloji yesandlaoomatshini bokuwelda nge-laseriyaqhubeka iphucuka, amashishini amaninzi asebenzisa le ndlela ukuze ahlangabezane neemfuno zawo zokuwelda. Uluhlu olubanzi lweenzuzo ezibonelelayo, kubandakanya amandla ayo okuwelda ngaphandle nakude, luyenza ibe lukhetho oludumileyo kumashishini amaninzi. Oko kuthethiweyo, ukugcinwa ngokufanelekileyo kubalulekile ekuqinisekiseni ukusebenza kakuhle komatshini wakho wokuwelda we-laser kunye ne-cooler.

Enye yezona nzuzo ziphambili zesixhobo esiphathwayoumthungi welaseryindlela enokusetyenziselwa ngayo ukuwelda ngaphandle kunye nokuwelda kumgama omde. Olu phawu lwenza ukuba ibe sisixhobo esifanelekileyo sokuwelda kwiindawo ezinzima nezikude. Nangona kunjalo, ukuze umatshini wakho usebenze kakuhle, kubalulekile ukuba ugcinwe kakuhle. Ukucoca rhoqo kunye nokuthambisa kuyimfuneko ukuze umatshini usebenze kakuhle.

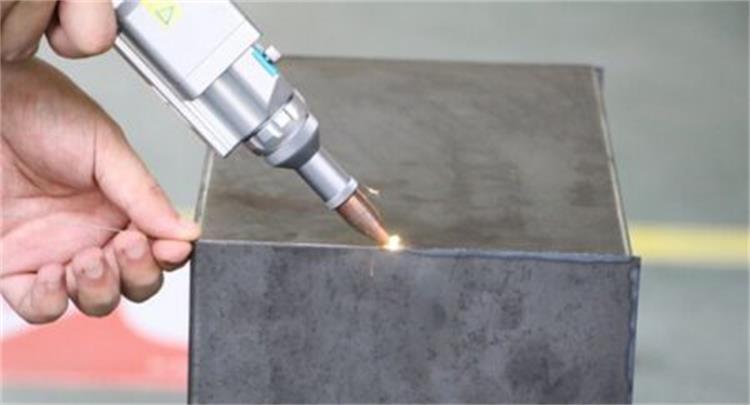

Elinye ixabiso leumatshini wokuwelda we-laser ophathwa ngesandlayindlela yayo yokuwelda eguquguqukayo, enokusetyenziselwa ukugqibezela iintlobo ngeentlobo zezicelo zokuwelda. Ezi ziquka ukugquma, ukuwelda kwebutt kunye nokuwelda kwe-fillet okuthe nkqo, okuthe tyaba, okungaphandle nangaphakathi. Nokuba zisebenza kwiindawo ezixineneyo okanye kwii-engile ezinzima, oomatshini bokuwelda be-laser abaphathwa ngesandla bafanelekile kwimisebenzi eyahlukeneyo yokuwelda.

Ngenxa yokuba i-handheldumatshini wokuwelda nge-laserAkukho mfuneko yokusebenzisa izinto ezisetyenzisiweyo, ii-welds azidingi kugaywa. Le yinzuzo ebalulekileyo njengoko inciphisa ixesha lokusebenza kwaye ikhokelela kwinkqubo yokugaywa esebenza kakuhle. Ukongeza, olu phawu lwenza ii-welds zifane ngakumbi kwaye zibukeke zintle, nto leyo ebangela inkangeleko ecocekileyo necolekileyo.

Ukugcina i-chiller yakho kubaluleke kakhulu njengokugcina umatshini wakho wokuwelda we-laser ophathwa ngesandla. I-cooler inceda ukugcina ubushushu bokuwelda we-laser buzinzile, ngaloo ndlela yenza inkqubo yokuwelda ihambelane. Ukugcinwa ngokufanelekileyo kwe-cooler kuqinisekisa ukuba ubushushu buhlala buzinzile kwaye kuthintela i-laser ekutshiseni kakhulu. Imisebenzi elula efana nokujonga amanqanaba e-coolant kunye nokucoca ii-coolers kunokunceda ukwandisa ubomi bomatshini wakho.

Ukuseka inkqubo yokulungisa kufanele kube yeyona nto iphambili ukuba ufuna ukuphucula ubomi bomatshini wakho wokuwelda we-laser kunye nenkqubo yokupholisa. Ukuhlolwa rhoqo, ukuthambisa, ukucoca kunye nokulinganisa kuya kunceda ukuqinisekisa ukuba umatshini uyaqhubeka nokusebenza kakuhle. Ukwenza njalo kunceda ukuthintela ukusilela okubiza kakhulu kwaye kugcina oomatshini besebenza kwinqanaba eliphezulu.

Ukuququmbela,oomatshini bokuwelda be-laser abaphathwa ngesandlaZizixhobo ezibalulekileyo kumashishini amaninzi, kwaye ngokugcinwa kakuhle, zinokwenza umsebenzi wazo ngaphandle kokuphazamiseka. Nokuba usebenzisa umatshini wakho ukuwelda ngaphandle okanye ukuwelda kumgama omde, ukuwugcina kakuhle kuya kunceda ukuqinisekisa ukuba uyaqhubeka nokusebenza kakuhle, uvelisa ukuwelda okucocekileyo nokusebenzayo ngalo lonke ixesha. Khumbula ukuba ukugcina umatshini wakho ngokufanelekileyo kufanelekile ixesha kunye nomgudu wokuwugcina usebenza kakuhle iminyaka ezayo.

Ukuba ufuna ukufunda okungakumbi malunga nokuwelda nge-laser, okanye ufuna ukuthenga umatshini wokuwelda we-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuthumela: Epreli-15-2023