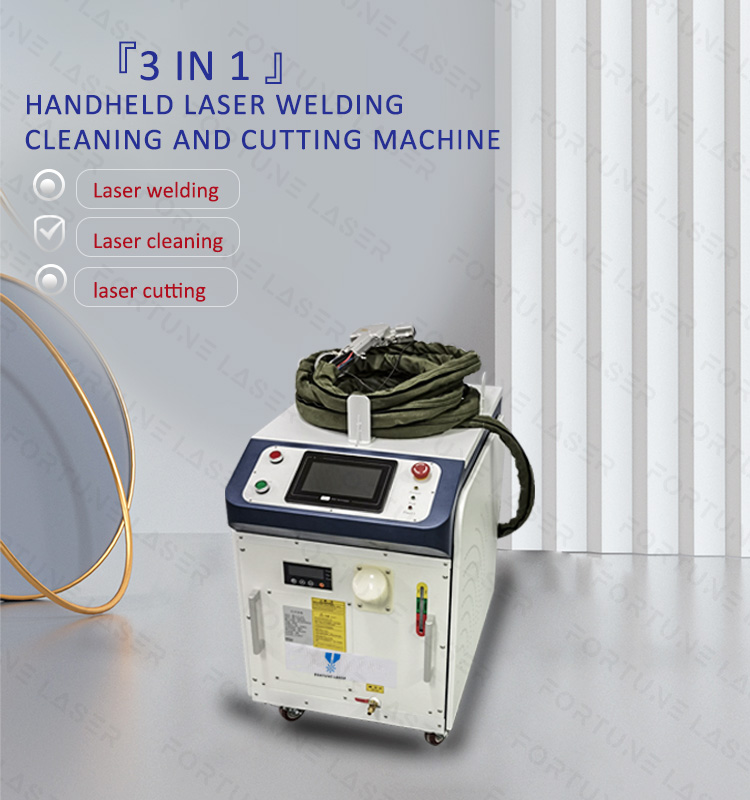

Umatshini wokucoca i-Laser Welding ophathwa ngesandla onama-3 kwi-1

Umatshini wokucoca i-Laser Welding ophathwa ngesandla onama-3 kwi-1

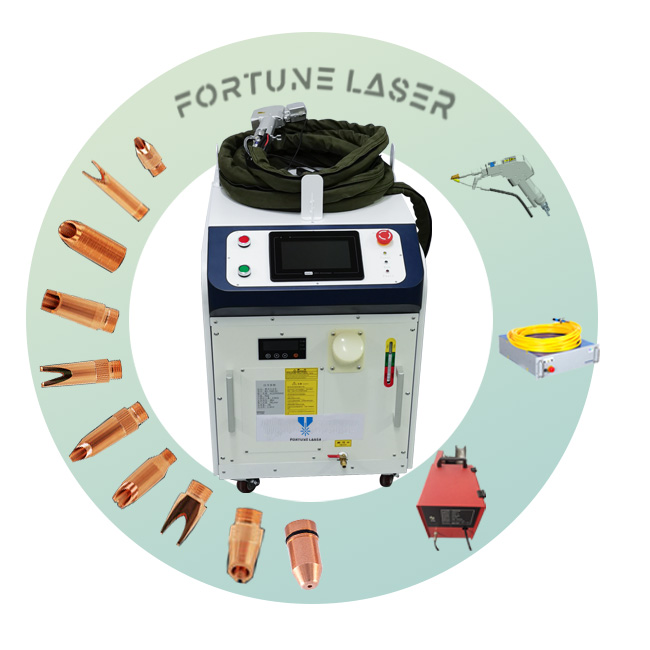

Iimpawu zomatshini zokusika i-laser eziphathwayo ezi-3 kwi-1, ukuwelda, kunye nokucoca

1. Njengeisicoci selaser, yindlela yokucoca "eluhlaza". Akufuneki kusetyenziswe nayiphi na into esetyenziselwa iikhemikhali kunye nesisombululo sokucoca. Inkunkuma ecociweyo ngokuyintloko yimpuphu eqinileyo. Incinci, kulula ukuyigcina kwaye inokuphinde isetyenziswe. Ingayisombulula lula ingxaki yongcoliseko lokusingqongileyo olubangelwa kukucocwa kweekhemikhali.

2. Njengeumthungi welaser, umthungo wokuwelda uthambile kwaye umhle, akukho mfuneko yokupolisha, akukho tshintsho okanye isilonda sokuwelda, ukuwelda okuqinileyo kwenxalenye. Gcina ixesha kwaye uphucule ukusebenza kakuhle.

3. Njengeumsiki welaserKulula kakhulu ukuyisebenzisa ukusika zonke iintlobo zesinyithi.

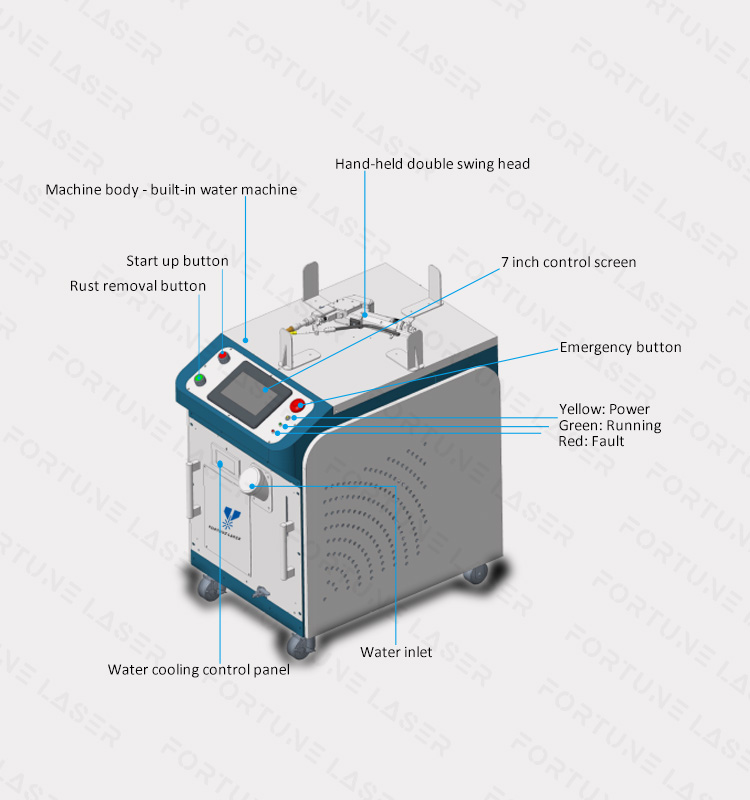

4. Isibhamu selaser esiphathwayo sinesakhiwo esilula esiphathwa ngesandla kwaye kulula ukusiphatha. Sixhotyiswe ngesikrini sokuchukumisa, esilungele ukutshintsha iiparameter ngexesha lomsebenzi kwaye senze lula umsebenzi. Ubunzima yi-0.8kg, elula ukuyisebenzisa ngaphandle kokudinwa.

5.Isebenzisa umthombo we-laser yefayibha yobungcali enesantya esiphantsi seempazamo, ukusetyenziswa kwamandla okuphantsi, akukho kugcinwa, kwaye kulula ukuyihlanganisa.

6. Isixhobo sokupholisa amanzi esisebenza ngobushushu obungaguqukiyo semizi-mveliso senzelwe ngokukodwa. Isixhobo sokupholisa amanzi sixhotyiswe ngesihluzo, esisebenza ngokukhuselekileyo, okuhlala ixesha elide, nokuzinzileyo kunye nobomi benkonzo ende. Inkqubo yokupholisa amanzi eqinileyo nezinzileyo iya kuqinisekisa ukuba umthombo we-fiber laser usebenza ngokugqibeleleyo.

7. Uyilo oluphathekayo: Uyilo oluncinci, olulungelelanisiweyo, olunamavili okuhamba ngokukhululekileyo.

| Umatshini wokucoca i-Laser ephathekayo ye-Fortune 3 kwi-1 ye-Laser Welding | |||

| Amandla eLaser | 1000W | 1500W | 2000W |

| Umthombo weLaser | I-laser yefayibha ye-GW 25um core diameter (ukhetho lweRaycus/JPT/MAX/IPG) | ||

| Ubude bamaza (nm) | 1064 - 1080 | ||

| Imo yeLaser | Ukuwelda ngeLaser/ Ukusika ngeLaser/ Ukucoca ngeLaser | ||

| Ubude beFiber | 10M (ingenziwa ngokwezifiso) | ||

| Indlela Yokusebenza | Ukuqhubekeka / Ukuguqulwa | ||

| Intloko yelaser | I-Axis ephindwe kabini | ||

| Ujongano | I-QBH | ||

| Ububanzi bokuWelda | 0.2-0.5mm (iyalungiseka) | ||

| Umboniso weLaser | Imbonakalo Yokukhanya Okubomvu Edibeneyo | ||

| Iimfuneko zesithuba sokuwelda | ≤1.2mm | ||

| Ubukhulu beWelding | 0.5-3mm | ||

| Isantya sokuWelda | 0-120mm/s (iyalungiseka) | ||

| Ubude befocal edibeneyo | 75mm | ||

| Ukugxila/Ukucoca Ubude beFokasi | F150mm/F500mm | ||

| Uluhlu lokujika | 0.1—5mm | ||

| Isantya sokujika | 0—300Hz | ||

| Ukupholisa | I-Integrated Water Chiller | ||

| Ulwimi | IsiTshayina/isiNgesi/isiRashiya/isiKorea/kunye nezinye iilwimi njengoko kufuneka. | ||

| Ukunikezwa Amandla | I-AC 220V, 50Hz/60Hz | I-AC 380V, 50Hz/60Hz | |

| Useto lweParamitha | Iphaneli yokuchukumisa | ||

| Izixhobo zokuWelda | Intsimbi yeCarbon, iStainless Steel, iAluminiyam, iBrass, iAlloy njl. | ||

| Ubushushu obugciniwe | 10~40°C | ||

| Umswakama kwiNdalo | <70% Ngaphandle koKufunxwa | ||

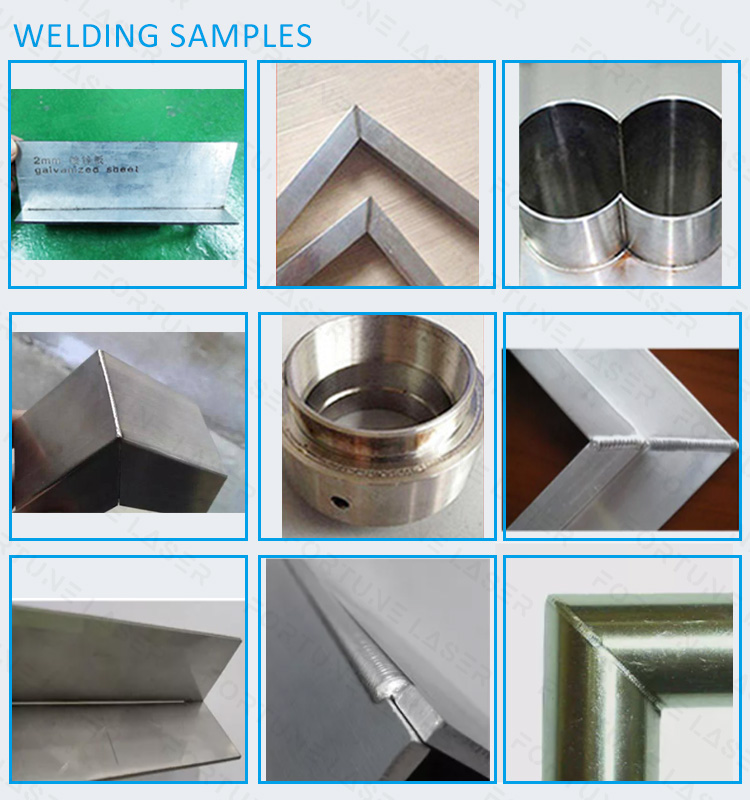

| IIPARAMETHA ZOKUWELDA NGELASER | ||

| Izinto eziphathekayo | Amandla eLaser(watt) | Ukungena okuphezulu (mm) |

| Yenziwe ngentsimbi eshayinayo | 1000 | 0.5-3 |

| Yenziwe ngentsimbi eshayinayo | 1500 | 0.5-4 |

| Intsimbi yeCarbon | 1000 | 0.5-2.5 |

| Intsimbi yeCarbon | 1500 | 0.5-3.5 |

| I-Aluminium Alloy | 1000 | 0.5-2.5 |

| I-Aluminium Alloy | 1500 | 0.5-3 |

| Iphepha lesinyithi | 1000 | 0.5-1.2 |

| Iphepha lesinyithi | 1500 | 0.5-1.8 |

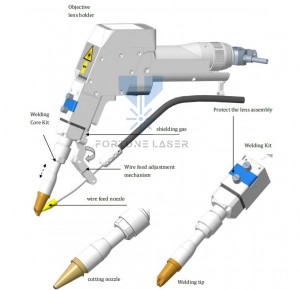

Isibhamu selaser esiphathwa ngesandla singenza ukuwelda, ukucoca, kunye nokusika ngesilawuli esikrelekrele, kulula ukusisebenzisa kwi-machining eguquguqukayo, siphathwa kancinci, singabizi kakhulu ngaphandle kwezinto ezisetyenziswayo. Abasebenzisi banokuseta iiparameter ngesikrini sokuchukumisa kwisibhamu selaser, esilula kakhulu kwaye kulula ukusisebenzisa.

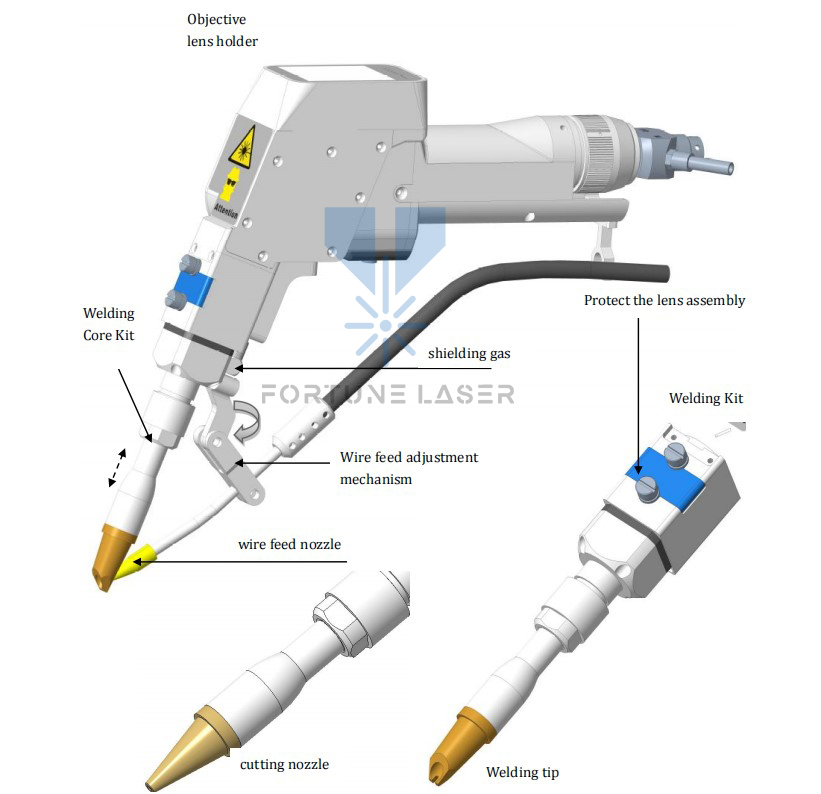

Intloko yokuwelda ephathwa ngesandla ye-pendulum kabini Iimpawu:

A. Le ntloko yokuwelda ineengenelo ezinkulu kwintsimbi engagqwaliyo, ukuwelda kwe-aluminium alloy, kunye nokusetyenziswa kwe-welding enamandla amancinci naphakathi. Yintloko yokuwelda engabizi kakhulu.

B. Intloko yokufakelwa kwentsimbi isebenzisa ilensi yokungcangcazela ye-X eqhutywa yimoto, ene-Y-axis, eneendlela ezininzi zokufakelwa kwentsimbi, kwaye ukufakwa kwentsimbi yokufakelwa kwentsimbi kuvumela ukuba indawo yokusebenza ibe nokufakelwa kwentsimbi ngendlela engaqhelekanga, izikhewu ezinkulu kunye nezinye iiparameter zokucubungula, ezinokuphucula kakhulu umgangatho wokufakelwa kwentsimbi.

C. Ulwakhiwo lwangaphakathi lwentloko yokuwelda luvaliwe ngokupheleleyo, nto leyo enokuthintela inxalenye ye-optical ukuba ingcoliswe luthuli.

D. Iikiti zokuwelda/zokusika kunye neekiti zokucoca ezikhethwayo zinokufezekisa imisebenzi emithathu yokuwelda, ukusika kunye nokucoca.

E. Ilensi ekhuselayo isebenzisa isakhiwo sedrowa, esilula ukusitshintsha.

Ingaxhotyiswa ngee-laser ezahlukeneyo ezinezihlanganisi ze-QBH.

G. Incinci, ibukeka kakuhle kwaye ivakala kakuhle.

Isikrini sokuchukumisa se-HA asinyanzelekanga ukuba sisetyenziswe entlokweni yokuwelda, esinokudityaniswa nesikrini seqonga ukuze ufumane amava angcono okulawula umatshini womntu.

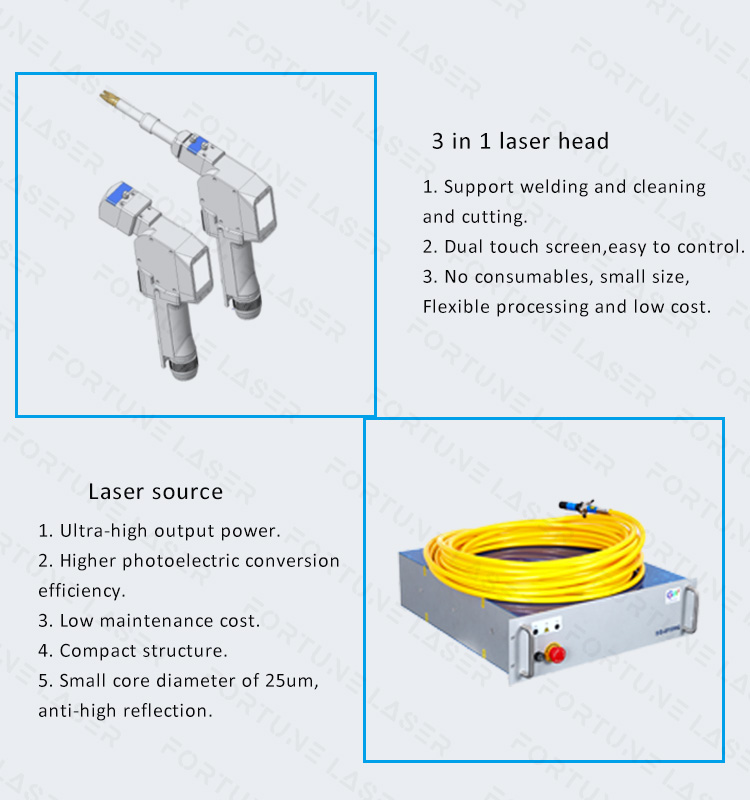

Ijeneretha yeLaser yeFayibha

Iijenereyitha ze-laser ze-GW (JPT, Raycus, MAX, RECI kunye ne-IPG azinyanzelekanga) zinokusebenza okuphezulu kokuguqula i-photoelectric, izinga eliphantsi leempazamo, ukusetyenziswa kwamandla okuphantsi, akukho kugcinwa, kunye nolwakhiwo oluncinci.

Uyilo lweChiller yamanzi eyakhelwe ngaphakathi

Ingakuphepha ukuxinana kweentambo ukuze ikwazi ukuziqhelanisa neendawo ezininzi, kwaye inemiphumo emihle yokuthintela uthuli kunye nokuchasana nokufuma. Iphaneli yoLawulo oluHlakaniphileyo Uluhlu lohlengahlengiso lweeparameter ezakhelwe ngaphakathi lukhulu, kwaye isiqalo sesitshixo esinye silula kwaye kulula ukusisebenzisa.

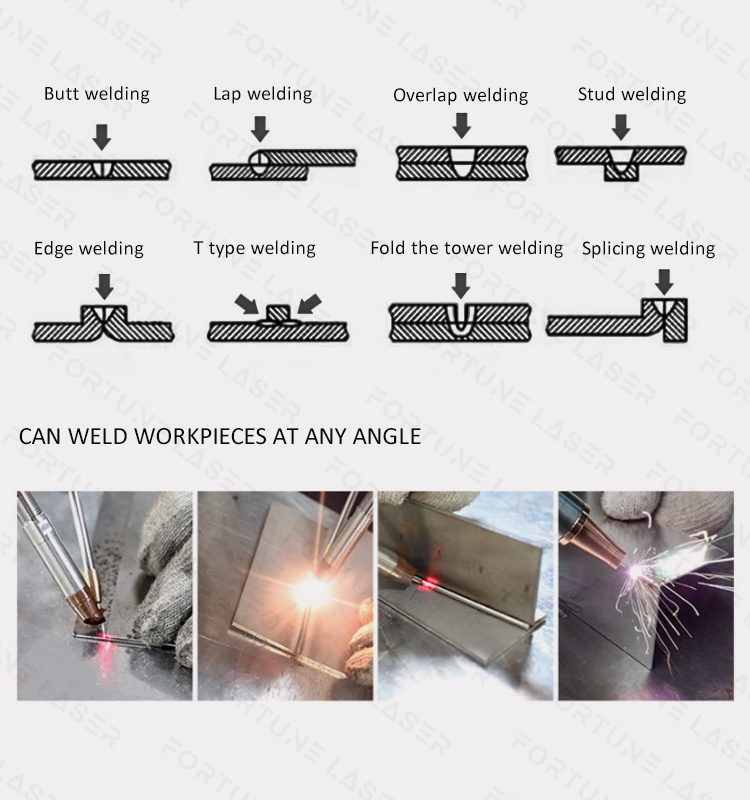

Ukucoca ngeLaser okubanjwe ngesandla oku-3 kwi-1, ukuWelda, kunye nokufaka izicelo zomatshini wokusika

Umatshini we-laser osetyenziselwa izinto ezininzi usetyenziswa kwimveliso, kwiimoto, kwiimpahla zasekhitshini, kwiishelufu, kwiilifti, kwiibhokisi zokusasaza, kwii-oveni, kwifenitshala yesinyithi, kwizixhobo ze-elektroniki, kunxibelelwano lwe-optical, kwi-sensor, kwizixhobo zeemoto, kwiimazinyo ze-porcelain, kwiiglasi, kumandla elanga, nakwimveliso yezixhobo ezichanekileyo.

1. Ngompu wokuwelda nge-laser, sisixhobo sokuwelda esiphathwayo se-laser ukuwelda i-aluminiyam, intsimbi engatyiwayo, i-titanium, igolide, isilivere, i-copper, i-nickel, i-chromium, kunye nezinye iintsimbi okanye ii-alloys, singasetyenziswa nakwiindidi ezahlukeneyo ze-welds phakathi kweentsimbi ezahlukeneyo, ezifana ne-titanium–igolide, i-copper–brass, i-nickel-copper, i-titanium–molybdenum njalo njalo.

2. Ngompu wokucoca nge-laser, sisicoci se-laser esiphathwayo sokususa umhlwa, i-resin, i-coating, ioyile, amabala, ipeyinti, ukungcola ukuze kusetyenzwe ngayo umphezulu ngabantu abathanda izinto zokuzonwabisa kunye nemveliso yemizi-mveliso, sinokunciphisa ngokufanelekileyo iindleko zokugcinwa komatshini kwaye siphucule isiphumo sokucoca kwimizi-mveliso.

3.Nge-laser cutting gun, sisixhobo esinye esiphathwayo sokusika i-laser esiphathwayo kuzo zonke iintlobo zokusika iintsimbi.

(Ifanele kuphela ipleyiti yesinyithi ebhityileyo.)

Ulwazi lokupakisha umatshini wokusika we-Laser welding oluphathwayo olunezintlu ezintathu kwi-One

Iingcaliumatshini wokusika wokucoca i-fiber laser weldingumenzi weenkonzo zoshishino lokuvelisa isinyithi. Umtshisi we-laser, umcoci we-laser kunye nomsiki we-laser uthengiswa eAlgeria, eArmenia, eArgentina, eAustria, eOstreliya, eAzerbaijan, eBangladesh, eBelgium, eBulgaria, eBolivia, eBrazil, eBelarus, eKhanada, eChile, eTshayina, eColombia, eCzech, eCyprus, eJamani, eDenmark, , eEcuador, eEstonia, eYiputa, eSpain, eFinland, eFransi, eGeorgia, eGrisi, eHungary, eIndonesia, eIreland, eIsrael, eIndiya, eItali, eJordan, eJapan, eKorea, eKuwait, eKazakhstan, eLebhanon, eLatvia, eMorocco, eMalta, eMexico, eMalaysia, eNetherlands, eNorway, eNew Zealand, eOman, ePeru, ePhilippines, ePoland, ePortugal, eParaguay, eQatar, eRomania, eRashiya, eSaudi Arabia, eSwitzerland, eSweden, eSingapore, eSlovenia, eSlovakia, eSwaziland, eMzantsi Afrika, eThailand, eTunisia, eTurkey, eUnited Kingdom, eUAE, e-USA, eUruguay, eUzbekistan, eVenezuela, eVietnam.

Ii-laser welders eziphathekayo kunye nee-laser cleaners zithandwa kakhulu. Nokuba ufuna umatshini wokuwelda okanye isixhobo sokucoca oza kusisebenzisa, okanye uceba ukuqala ishishini lenkonzo yokuwelda kunye nenkonzo yokucoca, lo matshini we-laser we-3 kwi-1 lukhetho olufanelekileyo kakhulu. Nceda unxibelelane nathi namhlanje ukuze ufumane iinkcukacha ezithe vetshe.