Umatshini wokuwelda we-LASER we-Fortune Laser 200W wegolide wesilivere yobhedu kunye ne-YAG ene-Microscope

Umatshini wokuwelda we-LASER we-Fortune Laser 200W wegolide wesilivere yobhedu kunye ne-YAG ene-Microscope

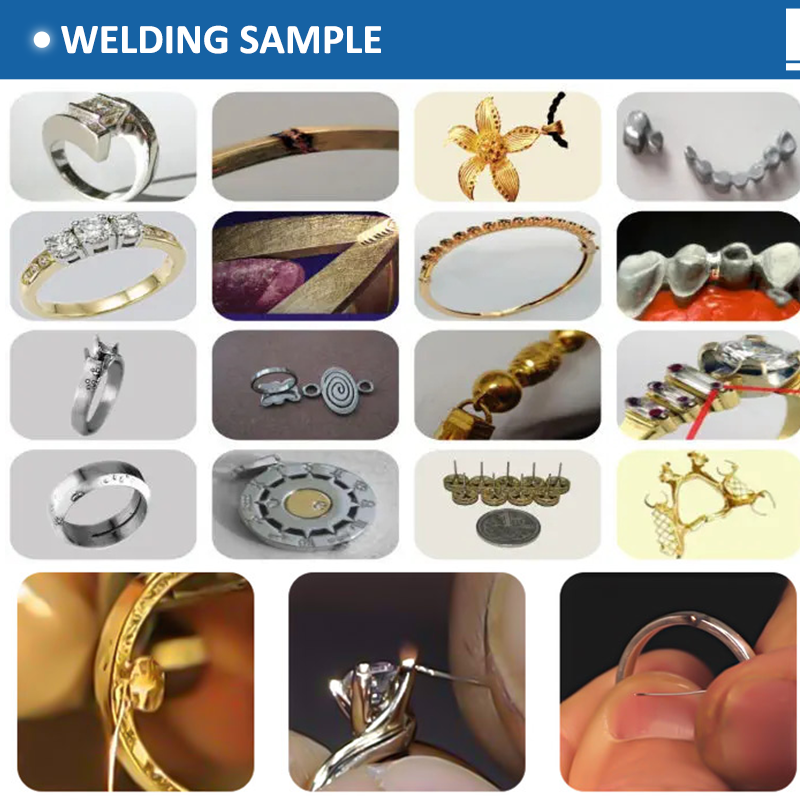

Umgaqo wokusebenza komatshini wokuwelda ubucwebe

Ubucwebe busoloko bulishishini elihlala lihleli. Ukufuna kwabantu ubucwebe bekusoloko kukuphucula, kodwa ubucwebe obuhle budla ngokuba yingxaki enkulu ukwenza. Ngokuhambela phambili kwetekhnoloji, iingcibi zobucwebe zemveli ziyalahleka kancinci kancinci. Ngenxa yenkqubo yayo enzima, kunzima ukuyifumana. Indlela yokugaya yenza iindleko zokucubungula zibe phezulu kwaye ukusebenza kube phantsi, kwaye ukubonakala komatshini wokuwelda we-laser kunciphisa inkqubo yokucubungula kwishishini lobucwebe, okwenza ukucubungula ubucwebe kube yinto efanelekileyo.

Umatshini wokuwelda we-laser spot luhlobo lwezixhobo zokucubungula izinto ze-laser. Umatshini wokuwelda we-laser usebenzisa ii-laser pulses ezinamandla aphezulu ukufudumeza izinto kwindawo encinci. Amandla emitha ye-laser ayasasazeka kancinci aye ngaphakathi kwezinto ngokuqhuba ubushushu. Emva kokufikelela kubushushu obuthile, idama elithile elinyibilikisiweyo lenziwa ukufezekisa injongo yokuwelda.

Ubucwebe buyinxalenye encinci kakhulu kwinkqubo yokucubungula nokupolisha. Isibane se-xenon somatshini wokuwelda welaser ubucwebe sikhanyiswa kakhulu ngumbane welaser kwaye sikhanyisa intonga yekristale ye-YAG. Kwangaxeshanye, ipompo yomatshini wokuwelda welaser ubucwebe inokuba namandla athile e-laser ngesipili esisiqingatha nesipili esipheleleyo, ize emva koko iphucule umgangatho we-laser nge-beam expander kwaye ibonise i-output laser nge-galvanometer, enokuwelda ngqo kwicandelo lezinto.

Iimpawu zoMatshini zokuwelda zeLaser zobucwebe ze-200W

● Ibhentshi yokusebenzela elula, isantya sokuwelda esikhawulezayo kunye nokusebenza kakuhle okuphezulu.

● Umgodi wokugxila we-ceramic ongeniswe kwamanye amazwe, ukumelana nokugqwala, ukumelana nobushushu obuphezulu, ukusebenza kakuhle kokuguqulwa kwe-photoelectric, ubomi besibane se-xenon obungaphezulu kwezigidi ezisi-8.

● Ubungakanani, ububanzi be-pulse, i-frequency, ubungakanani bebala, njl.njl. bunokulungiswa ngaphakathi koluhlu olukhulu ukuze kufezekiswe iziphumo ezahlukeneyo zokuwelda. Iiparameter zilungiswa ngentonga yokulawula kwigumbi elivaliweyo, elula nesebenzayo.

● Inkqubo yokufunxa ngokuzenzekelayo ephucukileyo isusa ukurhawuzelelwa kwamehlo ngexesha lomsebenzi.

● Ngobuchule bokusebenza obuqhubekayo beeyure ezingama-24, umatshini wonke usebenza ngokuzinzileyo kwaye awudingi kugcinwa kwiiyure ezili-10,000.

● Uyilo olunobuntu, i-ergonomics, ukusebenza ixesha elide ngaphandle kokudinwa.