Usebenza njani umatshini wokuwelda nge-laser?

Umatshini wokuwelda nge-laser usebenzisa amandla amakhulu e-laser pulse ukufudumeza izinto eziza kucutshungulwa kuluhlu oluncinci, kwaye ekugqibeleni uyayinyibilikisa ukuze yenze ichibi elithile elinyibilikisiweyo, elinokwenza ukuwelda okucacileyo, ukuwelda kwe-butt, ukuwelda kwe-lap, ukuwelda kokuvala, njl. Iingenelo zayo ezikhethekileyo zivula indawo entsha yesicelo sokuwelda nge-laser, ebonelela ngokuwelda ngokuchanekileyo kwezinto ezixineneyo kunye neendawo ezincinci.

Yintoni esetyenziselwa umatshini wokuwelda nge-laser?

1. Ukuwelda

Eyona njongo iphambili yomatshini wokuwelda nge-laser ngokungathandabuzekiyo kukuwelda. Ayikwazi ukuwelda kuphela izinto zesinyithi ezibhityileyo ezifana neepleyiti zentsimbi engagqwaliyo, iipleyiti ze-aluminium, kunye neepleyiti ze-galvanized, kodwa ingasetyenziselwa ukuwelda iindawo zesinyithi, ezifana nezixhobo zasekhitshini. Ifanelekile kwi-flat, straight, arc kwaye ukuwelda kwayo nayiphi na imilo kusetyenziswa kakhulu kwimishini echanekileyo, ubucwebe, izinto ze-elektroniki, iibhetri, iiwotshi, unxibelelwano, imisebenzi yezandla kunye neminye imboni. Ingagqibezela ukuwelda kakuhle kwiindawo ezahlukeneyo ezintsonkothileyo kwaye inokusebenza kakuhle kwemveliso. Xa kuthelekiswa nokuwelda kwe-argon arc yendabuko kunye nokuwelda ngombane. Ezinye iinkqubo zinezibonelelo ezicacileyo ngakumbi.

Ukusebenzisa umatshini wokuwelda nge-laser, umthungo wokuwelda unobubanzi obuncinci, ubunzulu obukhulu, indawo encinci yokutshayiswa kobushushu, ukuguquguquka okuncinci, umthungo wokuwelda ogudileyo nomhle, umgangatho ophezulu wokuwelda, akukho mingxunya yomoya, ulawulo oluchanekileyo, umgangatho wokuwelda ozinzileyo, akukho mfuneko yonyango okanye unyango olulula emva kokuwelda.

2. Ukulungiswa

Ukusetyenziswa komatshini wokuwelda nge-laser akupheleli nje ekuwelda, kodwa kukwalungisa ukuguguleka, isiphene, ukukrweleka kwesikhunta, kunye nomngxuma wesanti, ukuqhekeka, ukuguquka kunye nezinye iziphene zesixhobo somsebenzi sesinyithi. Isikhunta siya kuguga emva kwexesha elide sisetyenziswa. Ukuba silahliwe ngokuthe ngqo, ilahleko iya kuba nkulu. Isikhunta esinengxaki singasetyenziswa ngokupheleleyo kwakhona ngokulungisa isikhunta esinengxaki ngomatshini wokuwelda nge-laser, ingakumbi xa kulungiswa umphezulu omncinci, kuthintelwe iingxaki ezimbini zoxinzelelo lobushushu kunye nonyango lwasemva kokuwelda. Inkqubo enye, isindisa kakhulu ixesha lemveliso kunye neendleko zemveliso.

Yeyiphi inkqubo yokuwelda eyenziwa ngumatshini wokuwelda nge-laser?

1. Ukuwelda phakathi kweziqwenga

Kubandakanya ukuwelda kweempundu, ukuwelda kokuphela, ukuwelda kokudibanisa phakathi, kunye nokuwelda kokudibanisa phakathi.

2. Ukuwelda ngocingo oluya kwintambo

Kubandakanya ukuwelda kweempundu zocingo, ukuwelda okunqamlezileyo, ukuwelda okuhamba ngaxeshanye, kunye nokuwelda okumile okwe-T.

3. Ukuwelda kweentsimbi zesinyithi kunye nezixhobo zeebhloko

Ukuwelda nge-laser kunokwenza ngempumelelo uqhagamshelo lwentsimbi yesinyithi kunye neenxalenye zebhloko, kwaye ubungakanani beenxalenye zebhloko bunokuba yinto engacwangciswanga. Kufuneka kuqwalaselwe ubukhulu bejometri yezinto ze-filamentary ngexesha lokuwelda.

4. Ukuwelda kweentsimbi ezahlukeneyo

Ukuwelda kweentlobo ezahlukeneyo zesinyithi kujongana noluhlu lweeparamitha zokuwelda kunye nokuwelda. Ukuwelda nge-laser phakathi kwezinto ezahlukeneyo kunokwenzeka kuphela ngokudibanisa izinto ezithile.

Ungakhetha njani umthombo we-laser ofanelekileyo?

Umthombo we-Yg laser:

Isinyithi sephepha, iikhonkco zobucwebe begolide, izixhobo zokunciphisa isantya setitanium, ii-razor blades zokuwelda ngee-laser ezishukumayo.

Olu hlobo lwelaser luthintela isinyithi ekunyibilikeni okanye ekuguquguqukeni.

Kwizinyithi ezincinci nezikhaphukhaphu.

Umthombo weleza yeCW:

Oku kubiza kakhulu xa kuthelekiswa ne-pulsed lasers. Kukwanciphisa iindleko zokusebenza.

Eyona nto isebenzayo kwiintsimbi ezinganyangekiyo.

Kucetyiswa ukuwelda iindawo ezityebileyo.

Ingabangela iingxaki xa isetyenziswa kwisinyithi okanye kwiindawo ezincinci kakhulu. Kwimeko enjalo, i-laser inokonakalisa, inyibilikise okanye iguqule indawo.

Zeziphi iintlobo zoomatshini bokutywina ezikhoyo xa zizonke?

Oomatshini bokuwelda nge-laser baziwa ngokuba ngoomatshini bokuwelda nge-laser kunye noomatshini bokuwelda nge-laser. Uhlu oluthile lolu hlobo lulandelayo:

1. Umatshini wokuwelda we-laser ophathwa ngesandla:

Mhlawumbi olu lolona hlobo luqhelekileyo lwezixhobo zokuwelda ezithengiswayo. Zisetyenziswa rhoqo ekuwelding amaphepha esinyithi ahlukeneyo.

2. Umatshini wokuwelda we-laser spot:

Ingasetyenziselwa ubucwebe begolide nesilivere, ukuzaliswa kwemingxunya yezinto ze-elektroniki, ama-blister okuwelda amabala, izinto zokuwelda, njl.njl.

3. Umatshini wokuwelda we-laser ozenzekelayo:

Ifanelekile ukuwelda ngokuzenzekelayo imigca ethe tye kunye nezangqa zezinto zokusebenza zesinyithi, kwaye idla ngokusetyenziswa kumashishini afana neebhetri zefowuni eziphathwayo, ubucwebe, izinto ze-elektroniki, izinzwa, iiwotshi kunye neewotshi, oomatshini abachanekileyo, unxibelelwano, kunye nemisebenzi yezandla.

4. Umatshini wokuwelda we-laser mold:

Isetyenziswa kakhulu ekulungiseni isikhunta kwimizi-mveliso yesikhunta kunye nemizi-mveliso yokubumba efana neefowuni eziphathwayo, iimveliso zedijithali, iimoto kunye neebhayisekile, kwaye ikwasetyenziswa kakhulu ekudibaniseni ngesandla.

5. Umatshini wokuwelda we-laser transmission laser:

Kwiindawo ezinzima ukufikelela kuzo ukuze zifakwe i-welding, kusetyenziswa i-flexible transmission non-contact welding, enokuguquguquka okukhulu. Umqadi we-laser unokwahlulahlula ixesha namandla, kwaye unokucubungula imiqadi emininzi ngaxeshanye, nto leyo ebonelela ngeemeko zokufakelela ngokuchanekileyo.

6. Umatshini wokuwelda we-laser welding we-optical fiber galvanometer:

Indibaniselwano egqibeleleyo yenkqubo yokuhamba ye-galvanometer kunye nenkqubo yokwelda nge-laser. Yonga ngokufanelekileyo ixesha lokubeka izinto ezingenanto ngexesha lokwelda nge-single-point, kwaye uphucule ukusebenza kakuhle ngokuphindwe ka-3-5 xa kuthelekiswa nebhentshi yombane yendabuko.

Intshayelelo kwiintlobo ezithile zoomatshini bokuwelda:

Umatshini wokuwelda we-laser ophathwa ngesandla

Izixhobo zokucubungula isinyithi se-laser ezixhaphakileyo kwimarike yi-handheld laser welding machine. Kwizixhobo zokudibanisa zemveli, indibaniselwano yamava atyebileyo kunye netekhnoloji iyafuneka ukuze kuhlangatyezwane nemveliso yemihla ngemihla, kwaye isantya sihamba kancinci, kwaye ukubonakala kwe-welding kufuna ukupholishwa okulandelayo. Ukucubungula kuthatha ixesha kwaye kudinisa.

Intshayelelo yomzekelo: Sebenzisa i-optical fiber ukuhambisa i-laser, kwaye ugxile umqadi we-laser ngqo kwindawo yokuwelda ngesibhamu sokutshiza esiphathwa ngesandla. Ineempawu zokuchaneka okuphezulu, ukusebenza kakuhle kunye nendawo echaphazeleka bubushushu obuphantsi, kwaye ifanelekile ukuwelda iindawo ezincinci, ezinzima okanye ezinzima ukufikelela kuzo.

Inzuzo ephambili:

1 Lo msebenzi ulula, akukho mava obuchwephesha bobuchwephesha bokuwelda afunekayo, kwaye lo msebenzi ungaqaliswa emva kweeyure ezi-2 zoqeqesho olulula.

2 Isantya sokuwelda sikhawuleza kakhulu, kwaye i-laser welder ephathwayo inokutshintsha imveliso yaba-welder abaqhelekileyo aba-3 ukuya kwaba-5.

3 Ukuwelda akunakusetyenziswa kakhulu, nto leyo egcina iindleko zokuvelisa.

4 Emva kokuba ukuwelda kugqityiwe, umthungo wokuwelda uyakhanya kwaye ucocekile, kwaye ngokusisiseko ungenziwa ngaphandle kokusila.

5. Amandla omatshini wokuwelda nge-laser axineneyo, uluhlu lokubonakalisa ubushushu luncinci, kwaye imveliso ayilula ukuyiguqula.

6 Amandla omatshini wokuwelda nge-laser axineneyo, kwaye amandla okuwelda aphezulu kakhulu.

7. Amandla kunye namandla omatshini wokuwelda nge-laser alawulwa ngedijithali, nto leyo enokwanelisa iimfuno ezahlukeneyo zokuwelda, ezinje ngokungena ngokupheleleyo, ukungena, ukuwelda kwindawo ethile njalo njalo.

Izixhobo ezisebenzayo kunye nokusetyenziswa kwemizi-mveliso: zisetyenziswa kakhulu kwizixhobo ze-elektroniki, iinxalenye zeemoto, izixhobo, oomatshini abachanekileyo, izixhobo zonxibelelwano kunye neminye imimandla yentsimbi engatyiwayo, intsimbi yekhabhoni, intsimbi yesilicon, i-aluminium alloy, i-titanium alloy, i-galvanized sheet, i-galvanized sheet, i-copper, njl. Ukuwelda ngokukhawuleza kwezixhobo ezahlukeneyo zesinyithi kunye nokuwelda phakathi kwezixhobo ezithile ezahlukeneyo.

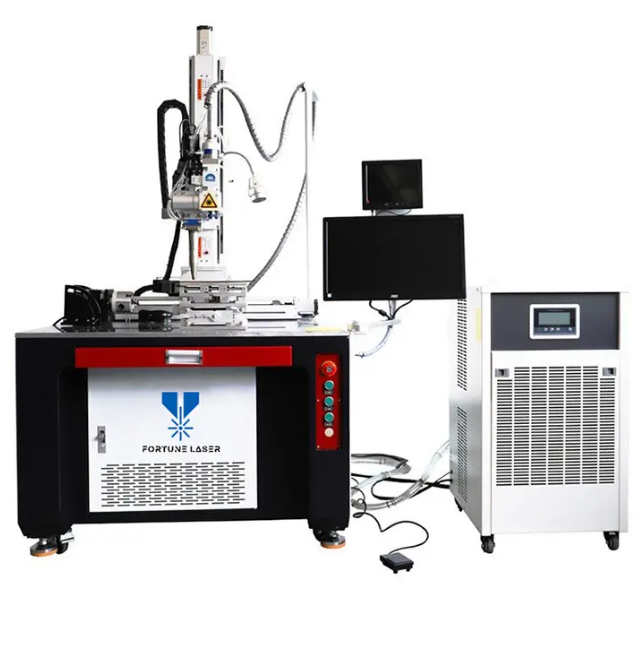

Umatshini wokuwelda we-laser ozenzekelayo-umatshini wokuwelda we-laser ozenzekelayo onemilinganiselo emibini

Intshayelelo yoMzekelo:

Lo matshini usebenzisa umgodi wokugxila we-ceramic onezibane ezimbini ongeniswe e-UK, ngamandla anamandla, i-pulse ecwangcisiweyo kunye nolawulo lwenkqubo olukrelekrele. I-Z-axis yebhentshi yokusebenzela inokunyuka nokuhla ngombane ukuze igxile, kwaye ilawulwa yiPC yemizi-mveliso. Ixhotyiswe ngetafile yokuhamba ezenzekelayo ye-X/Y axis eqhelekileyo eyahlukileyo enemilinganiselo emithathu. Enye into ejikelezayo ekhethwayo (80mm okanye i-p 125mm ekhethwayo) ukuze kufezekiswe ukuwelda kwe-laser ezenzekelayo enemilinganiselo emibini. Inkqubo yokubeka iliso isebenzisa imakroskopu, isibane esibomvu kunye ne-CCD. Ixhotyiswe ngenkqubo yokupholisa amanzi yangaphandle.

Inzuzo ephambili:

1. Kusetyenziswa umngxuma we-ceramic concentrator onesibane esiphindwe kabini ongeniswe e-UK, omelana nokugqwala kwaye umelana nobushushu obuphezulu, kwaye ubomi bomngxuma buyiminyaka esi-8 ukuya kweli-10.

2. Ukusebenza kakuhle kwemveliso kuphezulu, isantya sokuwelda siyakhawuleza, kwaye ukuveliswa kobunzima obuzenzekelayo bomgca wokuhlanganisana kunokufezekiswa.

3. Intloko yelaser ingajikeleziswa ngama-360°, kwaye indlela iyonke ye-optical ingashukunyiswa ngama-360° ize yolulwe iye phambili nangasemva.

4. Ubungakanani bendawo yokukhanya bunokulungiswa ngombane.

5. Iqonga lokusebenza lingashukunyiswa ngombane ngokwemilinganiselo emithathu.

Izixhobo ezisebenzayo kunye nezicelo zoshishino:

Ifanelekile kwiiketile, iikomityi zevacuum, izitya zentsimbi engagqwaliyo, izinzwa, iingcingo ze-tungsten, ii-diode ezinamandla aphezulu (ii-transistors), ii-alloy ze-aluminium, ii-casing zelaptop, iibhetri zefowuni ephathwayo, iziphatho zeminyango, ii-molds, izixhobo zombane, izihluzi, ii-nozzles, iimveliso zentsimbi engagqwaliyo, intloko yebhola yegalufa, ubugcisa be-zinc alloy kunye nezinye izinto zokuwelda. Imizobo enokuwelda ibandakanya: amanqaku, imigca ethe tye, izangqa, izikwere okanye nayiphi na imizobo yeplane edwetshwe yisoftware ye-AutoCAD.

Idityaniswe kwidesktop, eyahlukileyo, kunye ne-mini laser spot welding

Intshayelelo yoMzekelo:

Umatshini wokuwelda amabala elaser usetyenziswa kakhulu ekulungiseni imingxunya kunye namabala okuwelda amabala enziwe ngezinto zokuhombisa zegolide nezesilivere. Ukuwelda amabala elaser yenye yezinto ezibalulekileyo ekusetyenzisweni kwetekhnoloji yokucubungula izinto zelaser. Inkqubo yokuwelda amabala iluhlobo lokuqhuba ubushushu, oko kukuthi, imitha yelaser ifudumeza umphezulu wento yokusebenza, kwaye ubushushu bomphezulu buyasasazeka ngaphakathi ngokuqhuba ubushushu. Ngokulawula ububanzi, amandla, amandla aphezulu kunye nokuphindaphinda kwe-laser pulse Iiparameter ezifana nokuphindaphinda kwenza into yokusebenza inyibilike kwaye yenze ichibi elithile elinyibilikisiweyo. Ngenxa yeenzuzo zayo ezikhethekileyo, isetyenziswe ngempumelelo ekucubungulweni kwezinto zokuhombisa zegolide nezesilivere kunye nokuwelda kwiindawo ezincinci.

Iimpawu zeModeli:

Isantya esikhawulezayo, ukusebenza kakuhle okuphezulu, ubunzulu obukhulu, ukuguqulwa okuncinci, indawo encinci echaphazeleka bubushushu, umgangatho ophezulu wokuwelda, akukho ngcoliseko lwamalungu e-solder, ukusebenza kakuhle kunye nokukhuselwa kwendalo.

Inzuzo ephambili:

1. Amandla, ububanzi be-pulse, i-frequency, ubungakanani bebala, njl.njl. zinokulungiswa ngaphakathi koluhlu olukhulu ukuze kufezekiswe iziphumo ezahlukeneyo ze-welding. Iiparameter zilawulwa kwaye zilungiswe kwindawo evaliweyo, elula nesebenzayo.

2. Kusetyenziswa umngxuma oqulathe i-ceramic ongeniswe e-United Kingdom, omelana nokugqwala, omelana nobushushu obuphezulu, kwaye osebenza kakuhle ekuguquleni i-photoelectric.

3. Sebenzisa inkqubo yokufunxa ngokuzenzekelayo ephucukileyo ehlabathini, ephelisa ukurhawuzelelwa kwamehlo ngexesha lomsebenzi.

4. Iyakwazi ukusebenza ngokuqhubekayo iiyure ezingama-24, umatshini wonke usebenza ngokuzinzileyo, kwaye awudingi kugcinwa kwiiyure ezili-10,000.

5. Uyilo olusekelwe kubuntu, oluhambelana ne-ergonomics, lunokusebenza ixesha elide ngaphandle kokudinwa.

Umatshini wokuwelda we-laser mold

Intshayelelo yoMzekelo:

Umatshini wokuwelda we-laser mold ngumzekelo okhethekileyo owenzelwe ishishini lokuwelda. Lo matshini usetyenziselwa ngokukodwa ukuthatha indawo yomatshini wokuwelda we-argon arc wendabuko wokulungisa ii-molds ezichanekileyo. Izinto eziphambili zomatshini zonke ziimveliso ezingenisiweyo. I-interface yokusebenza kwesoftware isebenzisa isibonisi sekristale yolwelo esikhulu, kwaye i-interface ilula kwaye icacile, kwaye umqhubi kulula ukuyifunda nokusebenzisa. Iindlela ezahlukeneyo zokusebenza ezigcinwe kwangaphambili nazo zinokucwangciswa nguwe, kwaye umsebenzi wememori osisigxina ungasetyenziswa kwizixhobo ezahlukeneyo.

Iimpawu zeModeli:

1. Indawo echaphazeleka bubushushu incinci kwaye ayizukubangela ukuguquka kwesikhunta esichanekileyo;

2. Ubunzulu bokuwelda bukhulu kwaye ukuwelda kuqinile. Kunyibilike ngokupheleleyo, akushiyi zimpawu zokulungiswa. Akukho kuxinana kwindawo edibeneyo phakathi kwenxalenye ephakanyisiweyo yedama elinyibilikisiweyo kunye nesiseko;

3. Izinga eliphantsi le-oxidation, umsebenzi awuyi kutshintsha umbala;

4. Akuyi kubakho mingxunya yomoya okanye imingxuma yesanti emva kokuwelda;

5. I-weld ingacutshungulwa, ifaneleke ngakumbi ukulungiswa kwesikhunta ngeemfuno zokupolisha;

6. Umsebenzi ungafikelela kwi-50~60 Rockwell hardness emva kokuwelda.

Izicelo:

Ukubumba, ukubumba ngenaliti ngokuchanekileyo, ukuphosa nge-die-casting, ukunyathela, intsimbi engatyiwayo kunye nezinye izinto eziqinileyo ezifana neentanda, ukuqhekeza, ukulungiswa komatshini wokusila onqenqemeni kunye nokutywina, ukuwelda; ukuchaneka okuphezulu, ububanzi bendawo yokuwelda nge-laser yi-0.2nm ~ 1.5nm kuphela; indawo yokufudumeza incinci, ukucutshungulwa. Indawo yokusebenza ayizukuba naso; inokukrolwa emva kokuwelda ngaphandle kokuchaphazela isiphumo.

Umatshini wokuwelda we-laser ozenzekelayo wokudlulisa ifayibha ye-optical

Intshayelelo yoMzekelo:

Umatshini wokuwelda welaser othunyelelwa ngefayibha ye-optical luhlobo lwezixhobo zokuwelda zelaser ezidibanisa umqadi welaser onamandla aphezulu kwifayibha ye-optical, emva kothunyelelwa kumgama omde, zidibanisa ukukhanya okulinganayo ngesibuko esijikelezayo, kwaye zenze ukuwelda kwindawo yokusebenza. Ziwelda iimold ezinkulu kunye neendawo ezichanekileyo ezingafikelelekiyo, kwaye zisebenzise ukuwelda okuguqukayo okungenakunxibelelana, okunokuguquguquka okukhulu. Umqadi welaser unokufikelela ekuqhekekeni kwexesha namandla, kwaye unokucubungula imiqadi emininzi ngaxeshanye, ukubonelela ngeemeko ezilula ngakumbi zokuwelda.

Uphawu oluphambili:

1. Inkqubo yokujonga ikhamera ye-CCD ekhethiweyo, efanelekileyo yokujonga kunye nokubeka indawo ngokuchanekileyo;

2. Ukusasazwa kwamandla kwendawo yokuwelda kuyafana, kwaye ineyona ndawo ilungileyo yokukhanya efunekayo kwiimpawu zokuwelda;

3. Ziqhelanise nee-welds ezahlukeneyo ezintsonkothileyo, ii-spot welding zezixhobo ezahlukeneyo, kunye nee-welds zeepleyiti ezincinci ngaphakathi kwe-1mm;

4. Kusetyenziswa umngxuma oqokelelweyo weceramic ongeniswe kwamanye amazwe, omelana nokugqwala, omelana nobushushu obuphezulu, kwaye ubomi bomngxuma buyiminyaka esi-8 ukuya kweli-10), kwaye ubomi besibane se-argon bungaphezulu kwezigidi ezisi-8; izixhobo ezizodwa ezizenzekelayo kunye nezixhobo zinokwenziwa ngokwezifiso ukuze kufezekiswe imveliso enkulu yeemveliso.

Izicelo:

Isetyenziswa kakhulu kwimveliso enkulu yezixhobo zonxibelelwano lwe-optical, izinto ze-elektroniki, oomatshini bezonyango, iiwotshi, iiglasi, iimveliso zonxibelelwano lwedijithali, iindawo ezichanekileyo, izixhobo zekhompyutha kunye nezinye izimboni, kunye nokulungiswa kwe-mold welding enkulu, i-die casting kunye ne-injection molding.

Ixesha lokuthumela: Juni-02-2023