Muchina wekugadzira weYag Laser Welding weFortune Laser 200W Gold Sirivha Yemhangura Yegoridhe ine Maikorosikopu

Muchina wekugadzira weYag Laser Welding weFortune Laser 200W Gold Sirivha Yemhangura Yegoridhe ine Maikorosikopu

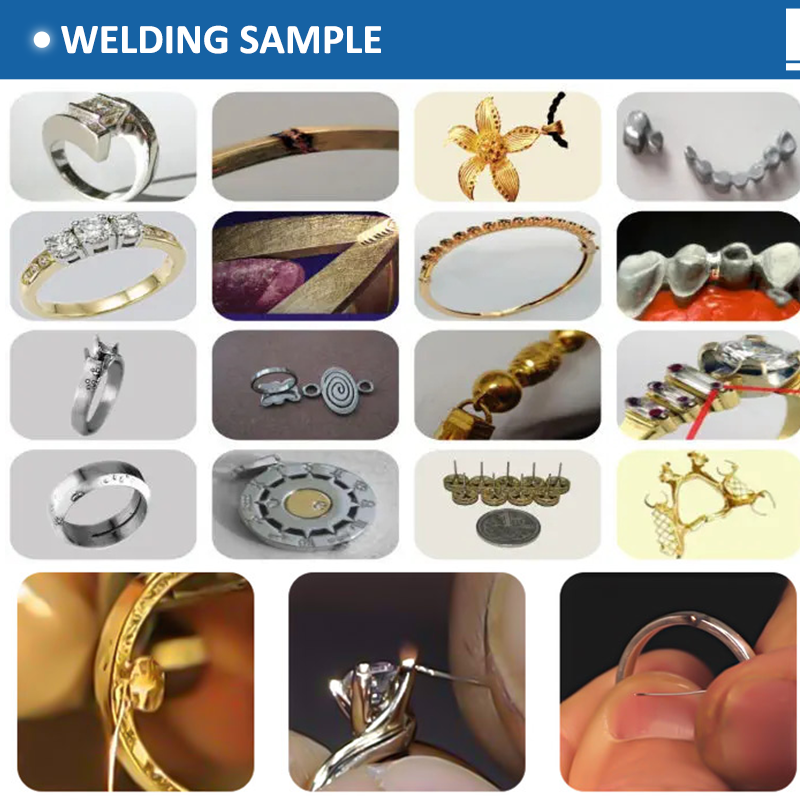

Musimboti wekushanda kwemuchina wekushongedza zvishongo

Zvishongo zvagara zviri indasitiri inogara iripo. Kutsvaga zvishongo kwagara kuri kwevanhu kuti zvirambe zvichivandudzwa, asi zvishongo zvakanaka zvinowanzova zvinonetsa kugadzira. Nekufambira mberi kwetekinoroji, mhizha dzezvishongo zvechinyakare dziri kushaikwa zvishoma nezvishoma. Nekuda kwemaitiro ayo akaoma, zvakaoma kugaya. Nzira yekugaya inoita kuti mari yekugadzira ive yakakwira uye kushanda kwayo kuve kwakaderera, uye kutaridzika kwemuchina we laser spot welding kunoderedza maitiro ekugadzirisa zvishongo muindasitiri yezvishongo, zvichiita kuti kugadzirisa zvishongo kuve chinhu chakakosha.

Muchina wekushongedza weLaser spot imhando yemuchina wekugadzirisa zvinhu zvelaser. Muchina wekushongedza weLaser unoshandisa malaser pulses ane simba guru kupisa zvinhu munzvimbo diki. Simba remwaranzi yelaser rinopararira zvishoma nezvishoma mukati mechinhu kuburikidza nekupisa. Mushure mekusvika patembiricha yakati, dziva rakanyungudutswa rinoumbwa kuti riwane chinangwa chekushongedza.

Zvishongo chikamu chidiki kwazvo mukugadzirisa nekupukuta. Rambi rexenon remuchina wekucheka welaser rinobatidzwa zvakanyanya nemagetsi elaser uye rinovhenekera tsvimbo yekristaro yeYAG. Panguva imwe chete, pombi yemuchina wekucheka welaser inogona kuva nesimba relaser kuburikidza nehafu yegirazi negirazi rakazara, uye yobva yagadzirisa kunaka kwelaser nebeam expander uye inoratidza laser inobuda kuburikidza negalvanometer, iyo inogona kusungirirwa zvakananga pane chikamu chezvinhu.

200W Zvishongo zveLaser welding Machine Features

● Bhenji rebasa rakareruka, kumhanya kwekushongedza nekukurumidza uye kushanda zvakanaka kwazvo.

● Ceramic concentrating cavity inotorwa kubva kunze kwenyika, inodzivirira ngura, inodzivirira kupisa kwakanyanya, inodzivirira kushanduka kwemagetsi zvakanyanya, ine hupenyu hwemwenje wexenon hunopfuura ka8 miriyoni.

● Huwandu, upamhi hwepulse, frequency, saizi yenzvimbo, nezvimwewo zvinogona kugadziriswa mukati mehuwandu hwakakura kuti zviwane mhedzisiro dzakasiyana-siyana dzewelding. Maparamita anogadziriswa netambo yekudzora iri mukamuri rakavharwa, iri nyore uye inoshanda.

● Sisitimu yemhando yepamusoro yekudzikisa mumvuri inobvisa kutsamwa kwemaziso panguva yebasa.

● Nekugona kushanda kwemaawa makumi maviri nemana, muchina wese une mashandiro akasimba uye hauna kugadziriswa mukati memaawa zviuru gumi.

● Dhizaini yakagadzirwa nevanhu, ergonomics, kushanda kwenguva yakareba pasina kuneta.