Muchina we laser welding unoshanda sei?

Muchina wekuisa laser unoshandisa simba guru rekupisa kwelaser kupisa zvinhu zvinofanira kugadziriswa munzvimbo diki, uye pakupedzisira unonyungudutsa kuti ugadzire dziva rakanyungudutswa, rinogona kuita kuti pave nekuisa spot welding, kuisa butt welding, kuisa lap welding, kuisa sealing welding, nezvimwewo. Zvakanakira zvawo zvakasiyana zvinovhura nzvimbo itsva yekushandisa laser welding, ichipa welding chaiyo yezvinhu zvakatetepa uye zvikamu zvidiki.

Chii chinoshandiswa muchina we laser welding?

1. Kushongedza

Chinangwa chikuru chemuchina we laser welding hapana mubvunzo kuti ndeyekushongedza. Haugone kungoshongedza simbi dzakatetepa dzakadai semaplate esimbi asina ngura, maplate ealuminium, nemaplate egalvanized chete, asiwo unogona kushandiswa pakushongedza sheet metal, senge midziyo yekicheni. Yakakodzera kune yakatsetseka, yakatwasuka, arc uye Welding yemhando ipi zvayo inoshandiswa zvakanyanya mumichina yakanyatsogadzirwa, zvishongo, zvikamu zvemagetsi, mabhatiri, mawachi, kutaurirana, mabasa emaoko nemamwe maindasitiri. Inogona kupedzisa welding zvakanaka munzvimbo dzakasiyana-siyana dzakaoma uye ine kushanda kwakanaka kwekugadzira. Kana ichienzaniswa ne welding yeargon arc yechinyakare uye welding yemagetsi, mamwe maitiro ane zvakanakira zviri pachena.

Uchishandisa muchina we welding we laser, musono we weld une upamhi hudiki, kudzika kukuru, nzvimbo diki yekupisa, deformation diki, musono we weld wakatsetseka uye wakanaka, mhando yepamusoro ye welding, hapana maburi emhepo, kutonga kwakarurama, mhando ye welding yakagadzikana, hapana chikonzero chekurapa kana kurapwa kuri nyore mushure mekuwelding Can.

2. Kugadzirisa

Kushandiswa kwemuchina we laser welding hakungogumiri pakuwelda, asiwo kugadzirisa kupera, kuremara, kukwenya kwemould, uye gomba rejecha, kutsemuka, kuchinjika nezvimwe zvikanganiso zvebasa resimbi. Mould ichapera mushure menguva yakareba yekushandiswa. Kana ikarasirwa zvakananga, kurasikirwa kwayo kuchave kukuru. Mould ine dambudziko inogona kushandiswa zvizere zvakare nekugadzirisa mould ine dambudziko kuburikidza nemuchina we laser welding, kunyanya pakugadzirisa nzvimbo yakanaka, kudzivirira matambudziko maviri ekupisa uye kurapwa mushure mekuwelda. Maitiro mamwe chete, anochengetedza zvikuru nguva yekugadzira nemari yekugadzira.

Ndeipi nzira yekushongedza ine muchina we laser welding?

1. Kusundira pakati pezvidimbu

Kusanganisira kupinza mabutt, kupinza end, kupinza centre penetration fusion, uye kupinza centre penetration fusion.

2. Kubatanidza waya newaya

Kusanganisira welding kubva pawaya kuenda pawaya, welding inochinjika, welding inochinjika pamativi ese, uye welding yakaita seT.

3. Kubatanidza waya dzesimbi nemidziyo yebhuroko

Kuwedera nelaser kunogona kuita kuti waya dzesimbi nezvikamu zvemabhuroko zvibatanidzwe, uye saizi yezvikamu zvemabhuroko inogona kunge isina kurongeka. Kutarisirwa kunofanirwa kupihwa kune zviyero zvejometri zvezvinhu zvemafilamentary panguva yekuwedera.

4. Kubatanidza simbi dzakasiyana

Kubatanidza simbi dzakasiyana-siyana kunotarisa huwandu hwezvinhu zvinogona kuchinjika uye zvinogona kuchinjika. Kubatanidza nelaser pakati pezvinhu zvakasiyana kunogoneka chete nekusanganiswa kwezvinhu zvakasiyana.

Ungasarudza sei sosi ye laser yakakodzera?

Chitubu che laser cheYg:

Simbi yesimbi, zvishongo zvegoridhe, ma "pacemakers" e "titanium", mapanga e "razor" ekuwedera ne "pulsed lasers".

Rudzi urwu rwelaser runodzivirira simbi kuti isanyungudike kana kushata.

Kune simbi dzakatetepa uye dzakareruka.

CW laser sosi:

Izvi zvinodhura zvakanyanya kana tichienzanisa nema-pulsed lasers. Zvinoderedzawo mari yekushandisa.

Inonyanya kushanda pasimbi dzinoramba kushanda.

Zvinokurudzirwa pakusondera zvikamu zvikobvu.

Zvinogona kukonzera matambudziko kana zvikashandiswa pasimbi kana zvikamu zvakatetepa zvakanyanya. Panyaya iyi, laser inogona kukuvadza, kunyungudutsa kana kukanganisa chikamu chacho.

Mhando dzipi dzemichina yekuwedera dziripo?

Michina yekuisa laser inozivikanwawo semichina yekuisa laser uye michina yekuisa laser. Mapoka chaiwo ndeaya anotevera:

1. Muchina wekunamira we laser unobatwa nemaoko:

Iyi ingangove ndiyo mhando yemidziyo yekunamira inowanikwa zvakanyanya pamusika. Inowanzo shandiswa pakunamira machira esimbi akasiyana-siyana.

2. Muchina wekunamira weLaser spot:

Inogona kushandiswa pazvishongo zvegoridhe nesirivha, kuzadza maburi ezvigadzirwa zvemagetsi, mablister ekuputira mavanga, mainlays ekuputira, nezvimwewo.

3. Muchina wekushongedza we laser otomatiki:

Yakakodzera kusungirirwa otomatiki kwemitsetse yakatwasuka uye yakatenderera yesimbi, uye inowanzoshandiswa mumaindasitiri akadai semabhatiri efoni, zvishongo, zvikamu zvemagetsi, masensa, mawachi, michina chaiyo, kutaurirana, uye mabasa emaoko.

4. Muchina wekunamira weLaser mold:

Inonyanya kushandiswa kugadzirisa chakuvhuvhu mumaindasitiri ekugadzira nekuumba chakuvhuvhu akadai semafoni, zvigadzirwa zvedhijitari, mota nemidhudhudhu, uye inonyanya kushandiswa pakushongedza nemaoko.

5. Muchina we laser welding we optical fiber transmission:

Kune zvikamu zvakaoma kuwana zvekuwedera, welding inochinjika inochinjika isingabatanidzi chinhu inoiswa, iyo ine flexible transmission non-contact, iyo ine flexible yakakura. Beam relaser rinogona kupatsanura nguva nesimba, uye rinogona kugadzirisa matanda akawanda panguva imwe chete, izvo zvinopa mamiriro ekuwedera kwakanyatsonaka.

6. Muchina wekubatanidza we laser we optical fiber galvanometer:

Musanganiswa wakakwana we galvanometer motion system uye laser welding system. Zvinobudirira kuchengetedza nguva yekumira isina chinhu panguva yekuwelda kwe single-point, uye kuvandudza mashandiro ne3-5 times zvichienzaniswa nebhenji remagetsi rekare.

Nhanganyaya kumhando dzakasiyana dzemichina yekuwedera:

Muchina wekunamira we laser unobatwa nemaoko

Midziyo ye laser processing metal inowanikwa zvakanyanya pamusika muchina we laser welding unobatwa nemaoko. Mumichina ye welding yechinyakare, musanganiswa weruzivo rwakakura rwe welding netekinoroji zvinonyanya kudiwa kuti zvizadzise kugadzirwa kwezuva nezuva, uye kumhanya kwacho kunononoka, uye kuoneka kwe welding kunoda kukweshwa. Kugadzirisa kunotora nguva uye kunonetsa.

Sumo yemuenzaniso: Shandisa fiber ye optical kutumira laser, uye isa laser beam zvakananga pachikamu chekuwelda kuburikidza nepfuti inopfapfaidza inobatwa nemaoko. Ine hunhu hwekuita nemazvo, kushanda zvakanaka uye nzvimbo inoderedza kupisa, uye yakakodzera kuwelda zvikamu zvidiki, zvakaoma kana zvakaoma kusvika.

Chinhu chikuru chakanakira:

1 Kushanda kuri nyore, hapana ruzivo rwehunyanzvi rwekushongedza simbi runodiwa, uye kushanda kunogona kutanga mushure memaawa maviri ekudzidziswa kuri nyore.

2 Kumhanya kwekuwelda kunokurumidza zvikuru, uye welder yelaser inobatwa nemaoko inogona kutsiva kubuda kwewelders dzakajairika nhatu kusvika kushanu.

3 Kuwedera kunogona kusava nezvinhu zvinodyiwa, zvichideredza mari yekugadzira.

4 Mushure mekunge welding yapera, weld seam inopenya uye yakachena, uye inogona kuitwa pasina kukuya.

5. Simba remuchina we laser welding rakanyanya kusimba, huwandu hwekupisa hushoma, uye chigadzirwa chacho hachina kuomarara.

6 Simba remuchina we laser welding rakanyanya kusimba, uye simba rewelding rakanyanya kusimba.

7. Simba remuchina we laser welding zvinodzorwa nedhijitari, izvo zvinogona kusangana nezvinodiwa zvakasiyana-siyana zve welding, zvakaita sekupinda zvachose, kupinda, kupinza panzvimbo nezvimwe zvakadaro.

Zvinhu zvinoshanda uye mashandisirwo eindasitiri: zvinonyanya kushandiswa muzvikamu zvemagetsi, zvikamu zvemotokari, zviridzwa, michina chaiyo, michina yekutaurirana nemamwe maindasitiri simbi isingatsvi, simbi yekabhoni, simbi yesilicon, aruminiyamu alloy, titanium alloy, jira regalvanized, jira regalvanized, mhangura, nezvimwewo. Kukurunga nekukurumidza kwezvinhu zvakasiyana-siyana zvesimbi uye kukwesha pakati pezvimwe zvinhu zvakasiyana.

Muchina wekuisa we laser otomatiki-muchina wekuisa we laser otomatiki une mativi maviri

Nhanganyaya yeModhero:

Muchina uyu unoshandisa madziro ekuisa ceramic ane mwenje miviri inotorwa kubva kuUK, nesimba rayo guru, pulse inorongwa uye manejimendi yehurongwa hwemagetsi. Z-axis yebhenji rebasa inogona kufamba ichikwira nekudzika nemagetsi kuti ikwanise kutarisisa, uye inodzorwa nePC yeindasitiri. Yakashongedzerwa netafura yekufambisa otomatiki yeX/Y yakaparadzana. Imwe tambo inotenderera (80mm kana p 125mm isingada) kuti iwane welding ye laser otomatiki ine mativi maviri. Sisitimu yekutarisa inoshandisa maikorosikopu, mwenje mutsvuku uye CCD. Yakashongedzerwa nesisitimu yekutonhodza mvura yekunze.

Chinhu chikuru chakanakira:

1. Chigadziko checeramic concentrator chine mwenje miviri chakatorwa kubva kuUK chinoshandiswa, icho chinodzivirira ngura uye chinodzivirira kupisa kwakanyanya, uye hupenyu hwechigadziko makore 8-10.

2. Kubudirira kwekugadzira kwakanyanya, kumhanya kwekunamira kwesimbi kunokurumidza, uye kugadzirwa kwemutsetse wekugadzira otomatiki kunogona kuitika.

3. Musoro welaser unogona kutenderedzwa 360°, uye nzira yese yekutarisa inogona kufambiswa 360° uye kutatamurwa kuenda mberi nekudzoka.

4. Saizi yenzvimbo ine chiedza inogona kugadziriswa nemagetsi.

5. Puratifomu yekushanda inogona kufambiswa nemagetsi muzvikamu zvitatu.

Zvinhu zvinoshanda uye mashandisirwo eindasitiri:

Yakakodzera makettle, ma vacuum cup, ndiro dzesimbi dzisina ngura, masensa, waya dzetungsten, ma diode ane simba guru (transistors), alloys dzealuminium, macasing elaptop, mabhatiri efoni, mibato yemusuwo, mamold, zvishandiso zvemagetsi, mafirita, nozzles, zvigadzirwa zvesimbi dzisina ngura, golf Ball head, zinc alloy crafts nezvimwe zvekuwelda. Mifananidzo inowelda inosanganisira: mapoinzi, mitsetse yakatwasuka, madenderedzwa, masikweya kana chero mifananidzo yeplane yakadhirowewa neAutoCAD software.

Kubatanidza Desktop, kwakaparadzana, mini laser spot welding

Nhanganyaya yeModhero:

Muchina wekushongedza weLaser unonyanya kushandiswa kugadzirisa maburi nemabhurugwa ekushongedza ezvishongo zvegoridhe nesirivha. Kushongedza weLaser ndeimwe yezvinhu zvakakosha pakushandisa tekinoroji yekugadzirisa zvinhu zvelaser. Maitiro ekushongedza wespot ndeemhando yekupisa, kureva kuti, mwaranzi yelaser inopisa pamusoro pechinhu chebasa, uye kupisa kwepadenga kunopararira mukati kuburikidza nekudzora kupisa. Nekudzora hupamhi, simba, simba repamusoro uye kudzokorora kwekupisa kwelaser, maParameter akaita sefrequency anoita kuti chinhu chebasa chinyunguduke uye chigadzire dziva rakanyungudutswa. Nekuda kwezvakanaka zvaro zvakasiyana, rakashandiswa zvinobudirira mukugadzirisa zvishongo zvegoridhe nesirivha uye kushongedza zvikamu zvidiki-diki.

Zvimiro zveModhero:

Kumhanya nekukurumidza, kushanda zvakanaka, kudzika kukuru, kuchinja kudiki, nzvimbo diki inokanganiswa nekupisa, mhando yepamusoro yekuwedera, hapana kusvibiswa kwemajoini ekusonesa, kushanda zvakanaka uye kuchengetedzwa kwezvakatipoteredza.

Chinhu chikuru chakanakira:

1. Simba, upamhi hwepulse, frequency, saizi yenzvimbo, nezvimwewo zvinogona kugadziriswa mukati mehuwandu hwakakura kuti zviwane mhedzisiro dzakasiyana-siyana dzewelding. Maparamita anodzorwa uye anogadziriswa mugomba rakavharwa, izvo zviri nyore uye zvinoshanda.

2. Nzvimbo yekuisa ceramic concentrating cavity inotorwa kubva kuUnited Kingdom inoshandiswa, iyo inodzivirira ngura, inodzivirira kupisa kwakanyanya, uye ine simba rekushandura photoelectric zvakanyanya.

3. Shandisa sisitimu yekudzikisa mumvuri yemhando yepamusoro pasi rose, iyo inobvisa kushatirwa kwemaziso panguva yebasa.

4. Inokwanisa kushanda nguva dzose kwemaawa makumi maviri nemana, muchina wese une mashandiro akasimba, uye hauna kugadziriswa mukati memaawa zviuru gumi.

5. Dhizaini yakagadzirwa nevanhu, inoenderana ne ergonomics, inogona kushanda kwenguva yakareba isina kuneta.

Muchina weLaser Mould Welding

Nhanganyaya yeModhero:

Muchina we laser mold welding muchina wakagadzirirwa indasitiri yemold. Muchina uyu unoshandiswa zvakanyanya kutsiva muchina we argon arc welding wekare wekugadzirisa mamold akanyatsogadzirwa. Zvikamu zvakakosha zvemuchina uyu zvese zvigadzirwa zvinotengeswa kunze kwenyika. Iyo software operation interface inoshandisa large-screen liquid crystal display, uye interface yacho iri nyore uye yakajeka, uye mushandisi ari nyore kudzidza nekushandisa. Mhando dzakasiyana dzemaoperation akachengetwa kare dzinogonawo kurongwa newe pachako, uye permanent memory function inogona kushandiswa pazvinhu zvakasiyana-siyana.

Zvimiro zveModhero:

1. Nzvimbo inokanganiswa nekupisa idiki uye haizokonzere kushanduka kwemafungiro akanyatsojeka;

2. Kudzika kwewelding kwakakura uye welding yakasimba. Yakanyunguduka zvizere, isingasiyi mavanga ekugadzirisa. Hapana kudzika kwenzvimbo iri pakati pechikamu chakasimudzwa chedziva rakanyungudutswa ne substrate;

3. Mwero wekudzikiswa kweokisijeni wakaderera, workpiece haizochinje ruvara;

4. Hapazovi negomba remhepo kana maburi ejecha mushure mekunamira;

5. Weld inogona kugadziriswa, kunyanya yakakodzera kugadzirisa chakuvhuvhu nezvinodiwa zvekupukuta;

6. Chishandiso chebasa chinogona kusvika pakuomarara kweRockwell kusvika 50~60 mushure mekunamira.

Mashandisirwo:

Mould, precision injection molding, die-casting, stamping, stamping steel nezvimwe zvinhu zvakaoma zvakaita sekutsemuka, chipping, edge grinding machine wear and sealing edge repair, welding; high accuracy, laser welding spot dayameter inongova 0.2nm ~ 1.5nm; heating area idiki, processing. Workpiece haizokanganiswe; inogona kuchekwa mushure mekuwelding pasina kukanganisa mhedzisiro.

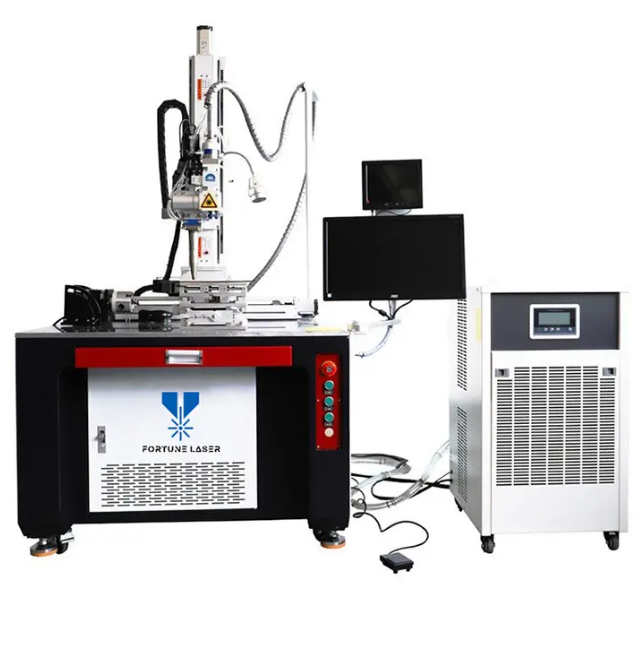

Muchina wekutapurirana kwefiber otomatiki we laser welding

Nhanganyaya yeModhero:

Muchina we laser welding welding we optical fiber transmission imhando yemuchina we laser welding unobatanidza laser beam ine simba rakawanda mu optical fiber, mushure mekutumirwa kure, unounganidza chiedza chakafanana kuburikidza negirazi re collimating, uye unoisa welding pa workpiece. Unosunga mapundu makuru nezvikamu zvisingawanikwe, uye unoisa transmission inochinjika isingabatanidzi welding, iyo ine flexible transmission non-contact welding, iyo ine flexible yakakura. Laser beam inogona kupatsanura nguva nesimba, uye inogona kugadzirisa matanda akawanda panguva imwe chete, zvichipa mamiriro ari nyore ekushongedza.

Chinhu chikuru:

1.Sarudzo yekutarisa kamera yeCCD, yakakodzera kutariswa uye kuiswa kwakarurama;

2. Kugoverwa kwesimba kwenzvimbo yekuwelding kwakafanana, uye ine nzvimbo yechiedza chakanakisa chinodiwa pahunhu hwekuwelding;

3. Chinjana nemidziyo yakasiyana-siyana yakaoma, welding yenzvimbo dzakasiyana dzemidziyo, uye welds dzemaplate matete ari mukati me1mm;

4. Chigadziko checeramic chinopinzwa kunze chinoshandiswa, chinodzivirira ngura, hachipise kupisa kwakanyanya, uye hupenyu hwechigadziko makore 8 kusvika ku10), uye hupenyu hwerambi reargon hunopfuura mamiriyoni 8; maturusi akasarudzika uye zvigadziriso zvinogona kugadziriswa kuti zvigadzirwa zvigadzirwe zvakawanda.

Mashandisirwo:

Inoshandiswa zvakanyanya mukugadzira michina yekutaurirana ye optical, zvikamu zvemagetsi, michina yekurapa, wachi, magirazi, zvigadzirwa zvekutaurirana zve digital, zvikamu zve precision, hardware nedzimwe indasitiri, pamwe nekugadzirisa hombe mold welding, die casting uye injection molding.

Nguva yekutumira: Chikumi-02-2023