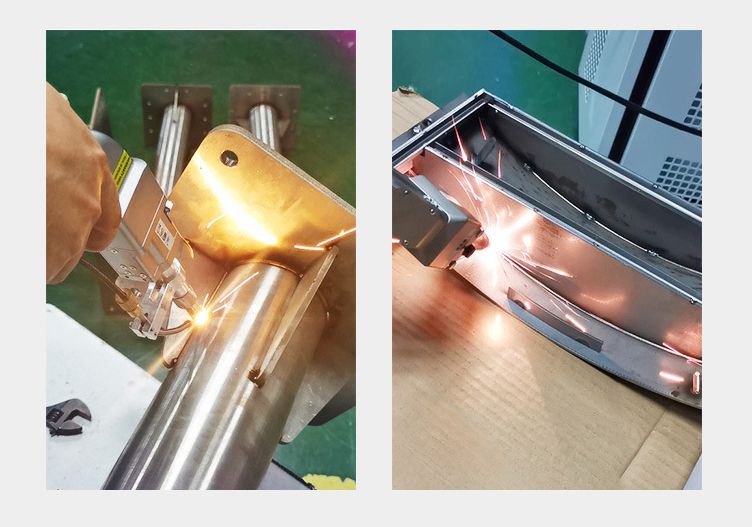

Pakadali pano, pankhani yolumikiza zitsulo, makina olumikizirana a laser ogwiritsidwa ntchito ndi manja amagwiritsidwa ntchito kwambiri. Kwenikweni, zitsulo zomwe zingalumikizidwe ndi kuwotcherera kwachikhalidwe zimatha kulumikizidwa ndi laser, ndipo mphamvu ndi liwiro la kuwotcherera zidzakhala bwino kuposa njira zachikhalidwe zolumikizira. Kulumikiza kwachikhalidwe kumakhala kovuta kuwotcherera zinthu zachitsulo zopanda chitsulo monga aluminiyamu, koma kuwotcherera kwa laser kuli ndi ntchito zambiri, ndipo aluminiyamu ndi zipangizo zina zimatha kuwotcherera mosavuta.

Kuwala kwa laser kuli ndi mphamvu yokwanira, ndipo kumaonekera pa chinthucho kudzera mu ulusi wowala, womwe umayamwa ndi kuwunikira, ndipo mphamvu ya kuwala yomwe imayamwa idzamaliza kusintha kutentha koyenera, kufalikira, kupititsa patsogolo, kutumiza ndi kuwala, ndipo chinthucho chidzakhudzidwa ndi kuwalako kuti chipange kutentha kofanana - Kusungunuka - Kutulutsa nthunzi - Kusintha kwa ma microfacets achitsulo.

Mitundu yosiyanasiyana ya makina ochapira a laser omwe amagwiritsidwa ntchito ndi manja ikukulirakulira. Amagwiritsidwa ntchito m'makabati a kukhitchini ndi bafa, mipando yachitsulo chosapanga dzimbiri, mabokosi ogawa, zitseko zosapanga dzimbiri ndi zotchingira mawindo, komanso masitepe ndi ma elevator. Mukamagwiritsa ntchito, muyenera kuyang'anira kwambiri chitetezo.

Ndiye kodi njira zodzitetezera zogwiritsira ntchito makina owotcherera a laser ogwiritsidwa ntchito m'manja ndi ziti?

1. Pogwiritsa ntchito makina ochapira a laser ogwiridwa ndi manja, wogwiritsa ntchito ayenera kuphunzitsidwa bwino asanagwire ntchito. Laser singathe kugunda anthu kapena zinthu zozungulira, apo ayi ikhoza kubweretsa zotsatirapo zoopsa kwambiri. , monga kupsa, kapena moto, izi ndi zoopsa kwambiri, aliyense ayenera kusamala kwambiri za chitetezo.

2. Ngakhale kuti njira yowotcherera ya makina ochapira a laser ogwiritsidwa ntchito m'manja imayendetsedwa motsutsana ndi ntchito, imapangabe kuwala kowala kwambiri. Chifukwa chake, wogwiritsa ntchitoyo ayenera kukhala ndi magalasi apadera oteteza maso awo. Ngati savala magalasi, saloledwa kugwiritsa ntchito makina ochapira a laser ogwiritsidwa ntchito m'manja.

3. Mukamagwiritsa ntchito makina ochapira a laser ogwiritsidwa ntchito m'manja, yang'anani nthawi zonse gawo la mawaya amagetsi. Pamalo omwe ali mbali yolowera ndi mbali yotulutsira, komanso magawo a mawaya akunja ndi magawo a mawaya amkati, ndi zina zotero, ndikofunikira kuyang'ana mosamala ngati pali kusasunthika kulikonse kwa zomangira mawaya. Ngati dzimbiri lapezeka, dzimbiri liyenera kuchotsedwa mwachangu. Chotsani kuti magetsi aziyenda bwino komanso kupewa ngozi zamagetsi.

4. Valani chotetezera kutentha. Kugwiritsa ntchito makina ochapira a laser ogwiritsidwa ntchito m'manja kumafunanso chotetezera kutentha, kuti mpweya utuluke mofanana, apo ayi tochi yochapira imatha kuyaka chifukwa cha short circuit.

Mukagwiritsa ntchito makina ochapira laser ogwiritsidwa ntchito m'manja, mutha kugwiritsa ntchito njira yomwe ili pamwambapa kuti mugwiritse ntchito, kuti muwonetsetse kuti kugwiritsa ntchito kuli kotetezeka komanso kupewa ngozi momwe mungathere. Zipangizo za laser zidzayambitsa kutayika kwina panthawi yogwiritsa ntchito, ndipo kukonza bwino kungachepetse kutayika ndi kulephera. Izi zimafuna kuyang'aniridwa pafupipafupi kwa zida za laser.

Kodi njira zodzitetezera zosamalira makina ochapira ndi zoziziritsira a laser ogwiritsidwa ntchito m'manja ndi ziti?

1. Yang'anani nthawi zonse magetsi a chipangizocho. Kaya mawaya ndi otayirira, ngati chotetezera mawaya ndi chotayirira kapena chochotsedwa.

2. Yeretsani fumbi nthawi zonse. Malo ogwirira ntchito a makina opachikira ndi fumbi, ndipo fumbi lomwe lili mkati mwa makina opachikira likhoza kutsukidwa nthawi zonse. Mipata pakati pa coil ya reactance ndi coil ya coil, ndi ma semiconductor amphamvu iyenera kutsukidwa makamaka. Chotenthetsera chimayenera kuyeretsa fumbi pa chinsalu cha fumbi ndi zipsepse za condenser.

3. Tochi yolumikizira ndi gawo lofunika kwambiri la makina olumikizira, lomwe liyenera kuyang'aniridwa ndikusinthidwa nthawi zonse. Chifukwa cha kuwonongeka, kutsegula kwa nozzle kumakula, zomwe zimapangitsa kuti arc isakhazikike, kuwonongeka kwa mawonekedwe a weld kapena waya womata (kuwotcha kumbuyo); kumapeto kwa nsonga yolumikizira kumamatira ku matope, ndipo waya wolumikizira udzakhala wosagwirizana; nsonga yolumikizira siimangika mwamphamvu. , kulumikizana kwa ulusi kudzatentha ndikuwotchedwa. Tochi yowonongeka iyenera kusinthidwa nthawi zonse. Choziziritsira chimayenera kusintha madzi ozungulira pafupifupi kamodzi pamwezi.

4. Samalani kutentha kwa malo ozungulira. Kutentha kwa malo ogwirira ntchito a tochi yowotcherera ndi chowotcherera sikuyenera kukhala kokwera kwambiri, chimodzi chidzakhudza kutayika kwa kutentha ndi kuzizira kwa chowotcherera, ndipo china chidzakhudza magwiridwe antchito abwinobwino a makina owotcherera. Makamaka nthawi yachilimwe yotentha, chisamaliro chachikulu chiyenera kuperekedwa ku kutentha kwa chipinda, ndipo zida ziyenera kugwiritsidwa ntchito pamalo opumira mpweya momwe zingathere. Kutentha kwa nthawi yozizira sikuyenera kukhala kotsika kwambiri, ngati kutentha kwa madzi ozungulira kuli kotsika kwambiri, chowotcherera sichingayambitsidwe.

Pambuyo pokonza tsiku ndi tsiku, makina ochapira a laser ogwiritsidwa ntchito m'manja amakhala abwino, mphamvu yozizira ya chiller imakhala yabwino, ndipo nthawi yogwira ntchito imatha kukulitsidwa.

Mfundo yofunika kwambiri yokhudza momwe mungasamalire makina ochapira laser ogwiritsidwa ntchito m'manja tsiku ndi tsiku. Tiyenera kudziwa kuti akamagwiritsa ntchito makina ochapira laser ogwiritsidwa ntchito m'manja, wogwiritsa ntchito ayenera kuphunzitsidwa bwino kuti amvetse bwino momwe kuwala kulikonse kwa chizindikiro cha dongosolo kumagwiritsidwira ntchito komanso batani lililonse, komanso kuti adziwe bwino zida zonse zofunika.

Ngati mukufuna kudziwa zambiri zakuwotcherera ndi laser, kapena mukufuna kugula makina abwino kwambiri odulira zitsulo pogwiritsa ntchito laser, chonde lembani uthenga patsamba lathu ndipo titumizireni imelo mwachindunji!

Nthawi yotumizira: Januwale-10-2023