Igwe ịgbado ọkụ laser bụ ụdị ngwa ịgbado ọkụ a na-ejikarị eme ihe n'ụlọ ọrụ mmepụta ihe, ọ bụkwa igwe dị mkpa maka nhazi ihe laser. Site na mmalite nke igwe ịgbado ọkụ laser ruo na teknụzụ ugbu a etoola nwayọ nwayọ, e nwetala ọtụtụ ụdị igwe ịgbado ọkụ, gụnyere igwe ịgbado ọkụ laser ejiri aka mee, onye enyemaka dị ike maka ọrụ ịgbado ọkụ.

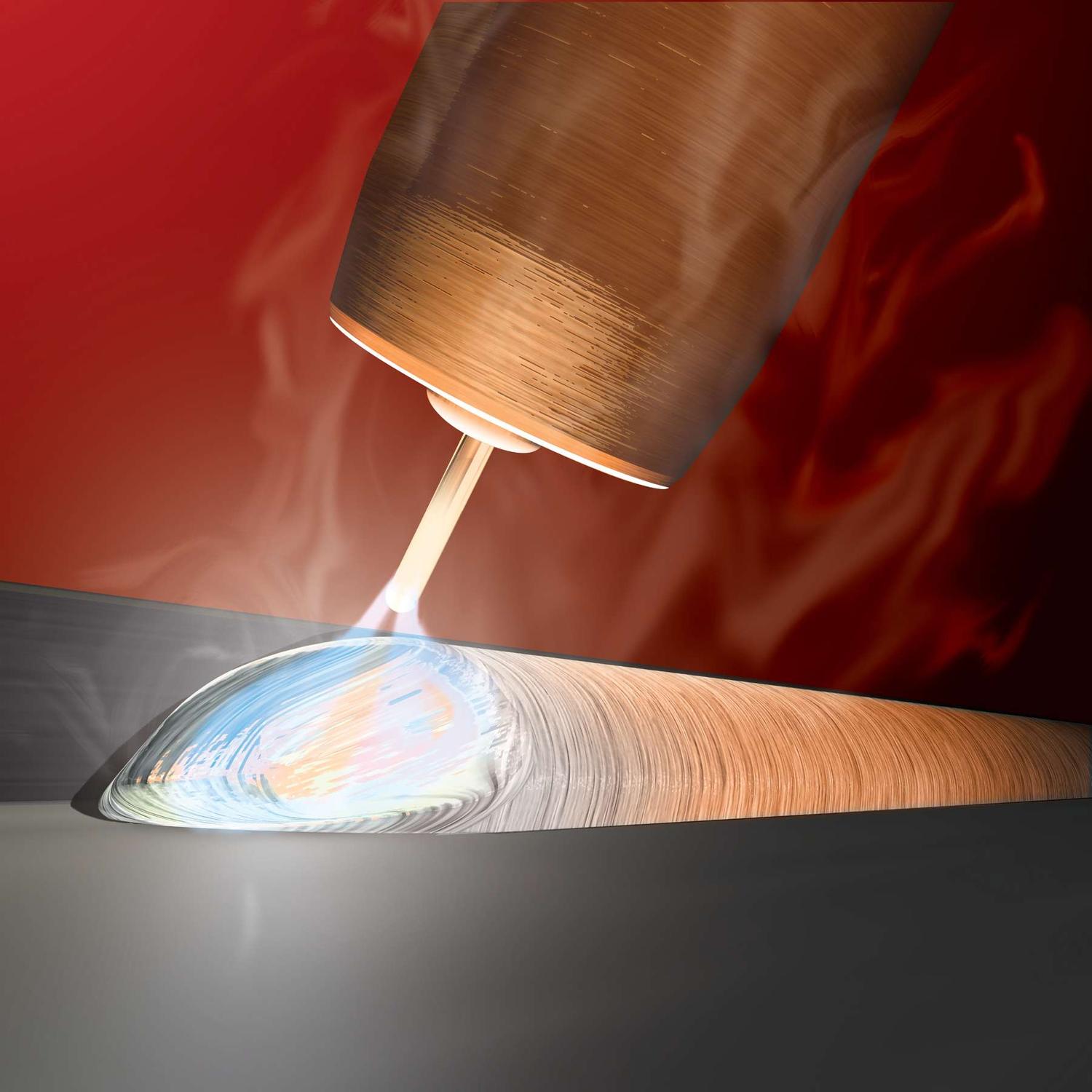

Gịnị mere e ji eji gas echebe mgbe a na-eji igwe ịgbado ọkụ laser aka? Igwe ịgbado ọkụ laser aka bụ ụdị ụzọ ịgbado ọkụ ọhụrụ, ọkachasị maka ihe ndị dị gịrịgịrị na akụkụ ziri ezi, nke nwere ike ime ka ịgbado ọkụ dị nro, ịgbado ọkụ n'ubu, ịgbado ọkụ n'apata ụkwụ, ịgbado ọkụ n'apata ụkwụ, ịgbado ọkụ n'apata ụkwụ, wdg, nwere oke omimi dị elu, obere obosara ịgbado ọkụ, na okpomọkụ. Ebe ahụ emetụtara nke ukwuu, obere mgbanwe, ọsọ ịgbado ọkụ ngwa ngwa, akwa ịgbado ọkụ dị nro ma mara mma, ọ dịghị mkpa ka a gwọọ ya ma ọ bụ naanị mkpa ọgwụgwọ dị mfe mgbe a gbadochara ya, akwa ịgbado ọkụ dị elu, enweghị porosity, njikwa ziri ezi, obere ebe a na-elekwasị anya, izi ezi dị elu, na akpaaka dị mfe ịghọta.

1. Ọ nwere ike ichebe oghere anya site na mmetọ ígwè na nsị nke mmiri mmiri

Gas nchekwa nwere ike ichebe lenzi anya nke igwe ịgbado ọkụ laser site na mmetọ uzuoku ígwè na mmụba nke mmiri mmiri, ọkachasị na ịgbado ọkụ ike dị elu, n'ihi na mwepụ ahụ na-adị ike nke ukwuu, ọ dịkwa mkpa karị ichebe lenzi ahụ n'oge a.

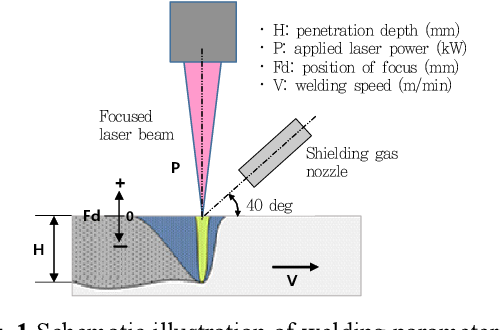

2. Gas nchekwa dị irè n'iwepụ ihe nchebe plasma site na ịgbado ọkụ laser dị elu

Uzu ígwè ahụ na-amịkọrọ oghere laser ahụ ma mee ka ọ ghọọ ion ka ọ ghọọ ígwé ojii plasma, a na-emekwa ka gas nchebe gbara uzu ígwè ahụ gburugburu ion ka ọ bụrụ ion n'ihi okpomọkụ. Ọ bụrụ na plasma dị oke, plasma ahụ na-eri obere oghere laser ahụ. Plasma dị n'elu ọrụ dị ka ike nke abụọ, nke na-eme ka ntinye ahụ ghara ịdị omimi ma elu nke ọdọ mmiri weld ahụ gbasaa.

A na-amụba ọsọ njikọta nke elektrọn site n'ịbawanye nkpọkọ ahụ atọ nke elektrọn na ion na atọm na-anọpụ iche iji belata njupụta elektrọn na plasma. Ka atọm na-anọpụ iche dị mfe, otú ahụ ka ugboro nkpọkọ na-adị elu ma ọnụego njikọta na-adị elu; n'aka nke ọzọ, naanị gas nchebe nwere ike ionization dị elu agaghị eme ka njupụta elektrọn dịkwuo elu n'ihi ionization nke gas ahụ n'onwe ya.

3. Gas nchebe nwere ike ichebe workpiece site na oxidation n'oge ịgbado ọkụ

Igwe ịgbado ọkụ laser ga-eji ụdị gas maka nchekwa, a ga-edozi mmemme ahụ n'ụzọ ga-eme ka gas nchebe ahụ buru ụzọ pụta wee wepụta laser ahụ, ka o wee gbochie oxidation nke laser pulsed n'oge nhazi na-aga n'ihu. Gas inert nwere ike ichebe ọdọ mmiri gbazere agbaze. Mgbe a na-agbakọta ụfọdụ ihe n'agbanyeghị oxidation elu, a gaghị atụle nchebe ahụ, mana maka ọtụtụ ojiji, a na-ejikarị helium, argon, nitrogen na gas ndị ọzọ eme ihe dị ka nchekwa iji gbochie workpiece ịgbado ọkụ n'oge ịgbado ọkụ. nke a na-etinye na oxidation.

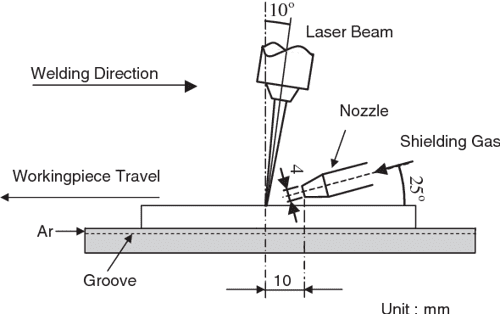

4. Nhazi nke oghere nozzle

A na-etinye gas nchekwa ahụ n'otu nrụgide site na nozzle ahụ iji ruo n'elu ihe eji arụ ọrụ ahụ. Ọdịdị hydrodynamic nke nozzle ahụ na dayameta nke ihe na-esi na ya pụta dị oke mkpa. Ọ ga-abụrịrị nnukwu nke na ọ ga-eme ka gas nchekwa ahụ gbazee kpuchie elu njikọta ahụ, mana iji chebe lenzi ahụ nke ọma ma gbochie uzuoku ígwè ka ọ ghara imerụ ahụ ma ọ bụ ịgbasa ígwè ka ọ ghara imebi lenzi ahụ, nha nke nozzle ahụ kwesịkwara ịkpa oke. A kwesịkwara ijikwa ọnụego mmiri ahụ, ma ọ bụghị ya, mmiri laminar nke gas nchekwa ahụ ga-aghọ ọgba aghara, ikuku ga-etinyekwa aka na ọdọ mmiri ahụ gbazere agbaze, na-emesịa mepụta pores.

N'ịkwado ọkụ laser, gas nchekwa ga-emetụta ọdịdị ịgbado ọkụ, ịdị mma ịgbado ọkụ, ntinye ịgbado ọkụ na obosara ịbanye n'ime. N'ọtụtụ oge, gas nchekwa ọkụ ga-enwe mmetụta dị mma na ịgbado ọkụ, mana ọ nwekwara ike ibute mmetụta ọjọọ.

Ọrụ Dị Mma:

1) Ịfụ gas nchebe ziri ezi ga-echebe ọdọ mmiri weld nke ọma iji belata ma ọ bụ ọbụna zere oxidation;

2) Ịfụ gas nchebe ziri ezi nwere ike ibelata mgbasa nke a na-emepụta n'oge ịgbado ọkụ nke ọma;

3) Ịfụ gas nchebe ziri ezi nwere ike ịkwalite mgbasa nke otu ọdọ mmiri ịgbado ọkụ mgbe ọ siri ike, na-eme ka ọdịdị ịgbado ọkụ ahụ dị otu ma maa mma;

4) Ịfụ gas nchebe ziri ezi nwere ike ibelata mmetụta nchebe nke plume ígwè ma ọ bụ igwe ojii plasma na laser nke ọma, ma mee ka ọnụego ojiji dị irè nke laser dịkwuo elu;

5) Ịfụ gas nchebe nke ọma nwere ike ibelata porosity nke weld.

Ma ọ bụrụhaala na ụdị gas, ọsọ gas, na nhọrọ ụdị ịfụfụ ziri ezi, nwere ike nweta mmetụta kacha mma. Agbanyeghị, ojiji na-ezighi ezi nke gas nchebe ga-ewetakwa mmetụta ọjọọ na ịgbado ọkụ.

Mmetụta Ọjọọ:

1) Njupụta na-ezighi ezi nke gas na-echebe nwere ike ibute njikọ na-adịghị mma:

2) Ịhọrọ ụdị gas na-ezighi ezi nwere ike ibute mgbawa na weld ahụ, ọ nwekwara ike ibute mbelata na njirimara igwe nke weld ahụ;

3) Ịhọrọ ọnụego mgbasa ikuku gas na-ezighi ezi nwere ike ibute oke oxidation nke weld (ma ọnụego mmiri ahụ buru ibu ma ọ bụ pere mpe), ma nwee ike ime ka ígwè weld pool ghara inwe nnukwu nsogbu site na ike mpụga, na-ebute ọdịda weld ma ọ bụ ọdịdị na-adịghị mma;

4) Ịhọrọ ụzọ e si etinye gas n'ime ihe na-ezighi ezi ga-eme ka ihe e ji agbaze ahụ ghara inweta mmetụta nchebe ma ọ bụ ọbụna ghara inwe mmetụta nchebe ma ọ bụ nwee mmetụta ọjọọ na nhazi ihe e ji agbaze ahụ;

5) Mkpọchi nke gas nchebe ga-enwe mmetụta ụfọdụ na mkọchi nke weld, ọkachasị mgbe a na-agbado efere dị gịrịgịrị, ọ ga-ebelata mkọchi nke weld.

N'ozuzu, a na-eji helium eme ihe dị ka gas nchebe, nke nwere ike igbochi plasma ruo n'ókè kachasị, si otú a na-eme ka omimi ịbanye n'ime ahụ dịkwuo elu ma na-eme ka ọsọ ịgbado ọkụ dịkwuo elu; ọ dịkwa obere ibu ma nwee ike ịpụ apụ, ọ dịghịkwa mfe ịkpata pores. N'ezie, site na mmetụta ịgbado ọkụ anyị n'ezie, mmetụta nke iji nchekwa argon adịghị njọ.

Ọ bụrụ na ịchọrọ ịmatakwu gbasara ịgbado ọkụ laser, ma ọ bụ ịchọrọ ịzụta igwe ịgbado ọkụ laser kacha mma maka gị,biko hapụ ozi na weebụsaịtị anyị wee zitere anyị ozi ozugbo na email!

Oge ozi: Feb-04-2023