Lub tshuab laser vuam ua haujlwm li cas?

Lub tshuab laser vuam siv lub zog loj ntawm lub laser pulse los ua kom sov cov khoom siv uas yuav tsum tau ua tiav hauv ib qho me me, thiab thaum kawg yaj nws los ua ib lub pas dej ua ke tshwj xeeb, uas tuaj yeem paub qhov chaw vuam, vuam taub qab, vuam ceg, sealing vuam, thiab lwm yam. Nws cov txiaj ntsig tshwj xeeb qhib lub tshav pob tshiab ntawm kev vuam laser, muab kev vuam precision rau cov ntaub ntawv nyias-phab ntsa thiab cov khoom me me.

Lub tshuab laser welding siv rau dab tsi?

1. Kev vuam

Lub hom phiaj tseem ceeb ntawm lub tshuab laser vuam yog qhov tsis muaj qhov tsis ntseeg vuam. Nws tsis tsuas yog vuam cov khoom siv hlau nyias-phab ntsa xws li cov hlau tsis xeb, cov hlau txhuas, thiab cov hlau galvanized, tab sis kuj siv tau rau vuam cov hlau ntawv, xws li cov khoom siv hauv chav ua noj. Nws yog qhov tsim nyog rau kev vuam tiaj tus, ncaj, arc thiab vuam ntawm txhua yam duab yog siv dav hauv cov tshuab precision, hniav nyiaj hniav kub, cov khoom siv hluav taws xob, roj teeb, moos, kev sib txuas lus, tes ua thiab lwm yam lag luam. Nws tuaj yeem ua tiav vuam zoo hauv ntau qhov chaw nyuaj thiab muaj kev ua haujlwm siab. Piv nrog rau kev vuam argon arc ib txwm muaj thiab vuam hluav taws xob Thiab lwm cov txheej txheem muaj ntau qhov zoo dua.

Siv lub tshuab laser vuam, qhov vuam seam muaj qhov dav me me, qhov tob loj, thaj chaw thermal shock me me, deformation me me, du thiab zoo nkauj weld seam, vuam zoo, tsis muaj qhov cua, tswj tau zoo, vuam zoo ruaj khov, tsis tas yuav kho lossis kho yooj yim tom qab vuam.

2. Kho

Kev siv lub tshuab laser vuam tsis yog tsuas yog siv rau kev vuam xwb, tab sis kuj tseem siv tau los kho qhov hnav, qhov tsis zoo, khawb ntawm cov pwm, thiab qhov xuab zeb, tawg, deformation thiab lwm yam tsis zoo ntawm cov hlau ua haujlwm. Cov pwm yuav hnav tawm tom qab siv ntev. Yog tias nws raug pov tseg ncaj qha, qhov poob yuav loj heev. Cov pwm teeb meem tuaj yeem siv tau dua los ntawm kev kho cov pwm teeb meem los ntawm lub tshuab laser vuam, tshwj xeeb tshaj yog thaum kho qhov chaw zoo, zam ob qho teeb meem ntawm kev ntxhov siab thermal thiab kev kho tom qab vuam. Ib qho txheej txheem, txuag tau ntau lub sijhawm tsim khoom thiab cov nqi tsim khoom.

Lub tshuab laser welding muaj cov txheej txheem welding dab tsi?

1. Vuam ntawm cov khoom

Xws li kev vuam taub qab, kev vuam kawg, kev vuam sib xyaw ua ke hauv nruab nrab, thiab kev vuam sib xyaw ua ke hauv nruab nrab.

2. Hlau rau hlau vuam

Xws li kev vuam hlau-rau-hlau, kev vuam hla, kev vuam sib luag, thiab kev vuam zoo li T.

3. Vuam cov hlau hlau thiab cov khoom thaiv

Kev vuam laser tuaj yeem ua tiav qhov kev sib txuas ntawm cov hlau hlau thiab cov khoom thaiv, thiab qhov loj ntawm cov khoom thaiv tuaj yeem ua tau raws li qhov xav tau. Yuav tsum tau them sai sai rau qhov ntev ntawm cov ntsiab lus filamentary thaum vuam.

4. Vuam cov hlau sib txawv

Kev vuam ntawm ntau hom hlau sib txawv hais txog qhov sib txawv ntawm kev vuam thiab kev vuam. Kev vuam laser ntawm cov khoom sib txawv tsuas yog ua tau nrog qee cov khoom sib xyaw ua ke.

Yuav ua li cas xaiv qhov chaw laser zoo?

Yg laser qhov chaw:

Cov ntawv hlau, cov txuas hniav kub, cov tshuab pacemakers titanium, cov hniav riam rau kev vuam nrog pulsed lasers.

Hom laser no tiv thaiv cov hlau los ntawm kev yaj lossis deforming.

Rau cov hlau nyias thiab sib dua.

CW laser qhov chaw:

Qhov no kim dua piv rau cov lasers pulsed. Nws kuj txo cov nqi khiav lag luam.

Zoo tshaj plaws rau cov hlau refractory.

Pom zoo rau kev vuam cov khoom tuab.

Nws tuaj yeem ua teeb meem yog tias siv rau ntawm cov hlau lossis cov khoom uas nyias dhau. Hauv qhov no, lub laser tuaj yeem ua puas, yaj lossis deform qhov khoom.

Muaj cov tshuab vuam hom twg tag nrho?

Cov tshuab vuam laser kuj tseem hu ua cov tshuab vuam laser thiab cov tshuab vuam laser. Cov kev faib tawm tshwj xeeb yog raws li nram no:

1. Lub tshuab vuam laser tes:

Qhov no yog hom khoom siv vuam uas siv ntau tshaj plaws hauv khw. Feem ntau siv rau vuam ntau yam ntawv hlau.

2. Lub tshuab vuam laser:

Nws siv tau rau cov hniav nyiaj hniav kub thiab nyiaj, txhaws qhov ntawm cov khoom siv hluav taws xob, vuam cov pob zeb me me, vuam inlays, thiab lwm yam.

3. Tshuab vuam laser tsis siv neeg:

Nws yog qhov tsim nyog rau kev vuam tsis siv neeg ntawm cov kab ncaj thiab cov voj voog ntawm cov hlau workpieces, thiab feem ntau yog siv rau hauv kev lag luam xws li roj teeb xov tooj ntawm tes, hniav nyiaj hniav kub, cov khoom siv hluav taws xob, sensors, moos thiab watches, precision machinery, kev sib txuas lus, thiab handicrafts.

4. Tshuab vuam pwm laser:

Nws feem ntau yog siv rau kev kho pwm hauv kev tsim pwm thiab kev lag luam molding xws li xov tooj ntawm tes, cov khoom digital, tsheb thiab maus taus, thiab kuj tseem siv rau kev vuam tes.

5. Lub tshuab vuam laser fiber ntau optical:

Rau cov khoom uas nyuaj rau kev vuam, kev sib kis yooj ywm tsis sib cuag tau siv, uas muaj kev ywj pheej ntau dua. Lub teeb laser tuaj yeem paub lub sijhawm thiab lub zog faib, thiab tuaj yeem ua ntau lub teeb tib lub sijhawm, uas muab cov xwm txheej rau kev vuam raug.

6. Lub tshuab fiber ntau optical galvanometer laser vuam tshuab:

Kev sib xyaw ua ke zoo meej ntawm galvanometer txav system thiab laser vuam system. Txuag tau lub sijhawm tso qhov khoob thaum lub sijhawm vuam ib qho, thiab txhim kho kev ua haujlwm zoo los ntawm 3 ~ 5 zaug piv rau lub rooj ua haujlwm hluav taws xob ib txwm muaj.

Kev Taw Qhia Txog Cov Hom Tshuab Vuam Tshwj Xeeb:

Tshuab vuam laser tes tuav

Cov khoom siv ua hlau laser feem ntau muaj nyob rau hauv kev ua lag luam yog lub tshuab vuam laser tes. Hauv cov khoom siv vuam ib txwm muaj, kev sib xyaw ua ke ntawm kev paub txog kev vuam thiab thev naus laus zis yog qhov yuav tsum tau ua kom tau raws li kev tsim khoom txhua hnub, thiab qhov ceev qeeb, thiab qhov tsos ntawm kev vuam xav tau kev txhuam tom qab. Kev ua tiav yog siv sijhawm thiab siv zog.

Kev taw qhia txog qauvSiv cov fiber optic los xa cov laser, thiab tsom lub teeb laser ncaj qha rau ntawm qhov chaw vuam los ntawm rab phom txau tes. Nws muaj cov yam ntxwv ntawm kev ua haujlwm siab, kev ua haujlwm siab thiab thaj chaw kub tsawg, thiab tsim nyog rau kev vuam cov khoom me me, nyuaj lossis nyuaj rau ncav cuag.

Qhov zoo tshaj plaws:

1 Kev ua haujlwm yooj yim, tsis tas yuav muaj kev paub txog kev siv tshuab vuam, thiab kev ua haujlwm tuaj yeem pib tom qab 2 teev ntawm kev cob qhia yooj yim.

2 Qhov ceev ntawm kev vuam yog ceev heev, thiab lub tshuab vuam laser tes tuav tuaj yeem hloov qhov tso zis ntawm 3 txog 5 tus neeg vuam ib txwm muaj.

3 Kev vuam tuaj yeem tsis muaj cov khoom siv tau, txuag cov nqi hauv kev tsim khoom.

4 Tom qab vuam tiav lawm, qhov vuam seam yog ci thiab huv si, thiab nws tuaj yeem ua tiav yam tsis tau sib tsoo.

5. Lub zog ntawm lub tshuab laser vuam yog concentrated, qhov ntau ntawm kev cuam tshuam cua sov yog me me, thiab cov khoom tsis yooj yim rau deform.

6 Lub zog ntawm lub tshuab laser vuam yog concentrated, thiab lub zog vuam yog siab heev.

7. Lub zog thiab lub zog ntawm lub tshuab laser vuam yog tswj los ntawm digitally, uas tuaj yeem ua tau raws li ntau yam kev xav tau vuam, xws li kev nkag mus tag nrho, kev nkag mus, qhov chaw vuam thiab lwm yam.

Cov ntaub ntawv siv tau thiab kev siv hauv kev lag luam: feem ntau yog siv rau hauv cov khoom siv hluav taws xob, cov khoom siv tsheb, cov twj paj nruag, cov tshuab ua kom raug, cov khoom siv sib txuas lus thiab lwm yam kev lag luam stainless hlau, carbon hlau, silicon hlau, txhuas alloy, titanium alloy, galvanized ntawv, galvanized ntawv, tooj liab, thiab lwm yam. Vuam sai ntawm ntau yam khoom siv hlau thiab vuam ntawm qee cov ntaub ntawv sib txawv.

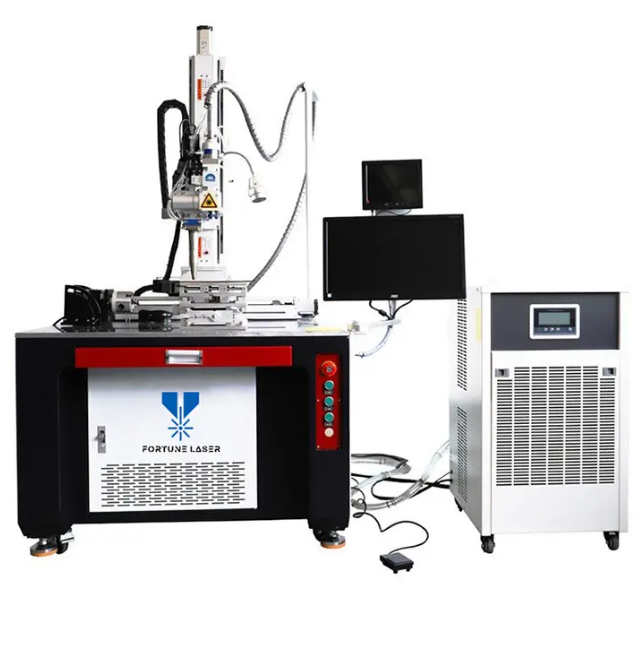

Tshuab vuam laser tsis siv neeg-ob sab nraud tshuab vuam laser tsis siv neeg

Qauv Taw Qhia:

Lub tshuab siv ob lub teeb ceramic concentrating qhov uas xa tuaj ntawm UK, nrog lub zog muaj zog, programmable pulse thiab kev tswj hwm lub kaw lus ntse. Lub Z-axis ntawm lub rooj ua haujlwm tuaj yeem txav mus rau saum thiab nqis hluav taws xob kom tsom mus rau, thiab tswj hwm los ntawm lub PC kev lag luam. Nruab nrog tus qauv sib cais X/Y axis peb-seem tsis siv neeg txav lub rooj. Lwm lub rotary fixture xaiv tau (80mm lossis p 125mm xaiv tau) kom ua tiav ob-seem tsis siv neeg laser vuam. Lub kaw lus saib xyuas siv lub tshuab microscope, lub teeb liab thiab CCD. Nruab nrog lub kaw lus dej txias sab nraud.

Qhov zoo tshaj plaws:

1. Lub qhov cub ob lub teeb uas siv los ntawm UK yog siv, uas yog corrosion-resistant thiab high-temperature resistant, thiab lub neej ntawm qhov cub yog 8-10 xyoo.

2. Kev ua haujlwm tau zoo yog siab, qhov vuam ceev ceev, thiab kev tsim cov kab sib dhos tuaj yeem ua tiav.

3. Lub taub hau laser tuaj yeem tig tau 360 °, thiab txoj kev kho qhov muag tag nrho tuaj yeem txav tau 360 ° thiab ncab rov qab thiab tawm.

4. Qhov loj ntawm lub teeb pom kev tuaj yeem hloov kho tau los ntawm hluav taws xob.

5. Lub platform ua haujlwm tuaj yeem txav mus los ntawm hluav taws xob hauv peb qhov ntev.

Cov ntaub ntawv siv tau thiab kev siv hauv kev lag luam:

Haum rau cov hwj kais dej, khob nqus tsev, tais stainless hlau, sensors, xov hlau tungsten, diodes muaj zog (transistors), txhuas alloys, laptop casings, roj teeb xov tooj ntawm tes, qhov rooj kov, pwm, khoom siv hluav taws xob, lim dej, nozzles, cov khoom siv hlau stainless, golf pob taub hau, zinc alloy tes ua thiab lwm yam vuam. Cov duab kos vuam tau suav nrog: cov ntsiab lus, cov kab ncaj, voj voog, plaub fab lossis txhua daim duab kos los ntawm AutoCAD software.

Kev sib xyaw ua ke ntawm lub desktop, sib cais, mini laser spot welding

Qauv Taw Qhia:

Lub tshuab laser spot welding feem ntau yog siv rau kev kho cov qhov thiab cov pob hlwv ntawm cov hniav nyiaj kub thiab nyiaj. Laser spot welding yog ib qho tseem ceeb ntawm kev siv cov thev naus laus zis ua cov khoom siv laser. Cov txheej txheem spot welding yog hom kev xa cua sov, uas yog, lub teeb laser ua rau qhov chaw ua haujlwm sov, thiab qhov kub ntawm qhov chaw sib kis mus rau sab hauv los ntawm kev xa cua sov. Los ntawm kev tswj qhov dav, lub zog, lub zog siab tshaj plaws thiab kev rov ua dua ntawm lub laser pulse. Cov kev ntsuas xws li zaus ua rau lub workpiece yaj thiab tsim ib lub pas dej molten tshwj xeeb. Vim nws cov txiaj ntsig tshwj xeeb, nws tau siv tau zoo hauv kev ua cov hniav nyiaj kub thiab nyiaj thiab kev xa cua sov ntawm cov khoom me me.

Cov Qauv Nta:

Kev ceev ceev, kev ua haujlwm siab, qhov tob loj, kev hloov pauv me me, thaj chaw cuam tshuam los ntawm cua sov me me, qhov zoo ntawm kev vuam, tsis muaj kuab paug rau cov pob qij txha solder, kev ua haujlwm siab thiab kev tiv thaiv ib puag ncig.

Qhov zoo tshaj plaws:

1. Lub zog, qhov dav ntawm lub zog, zaus, qhov loj ntawm qhov chaw, thiab lwm yam tuaj yeem hloov kho tau hauv ntau qhov ntau kom ua tiav ntau yam kev vuam. Cov kev teeb tsa raug tswj thiab kho hauv qhov kaw, uas yooj yim thiab ua haujlwm tau zoo.

2. Lub qhov ua kom muaj zog ceramic uas xa tawm los ntawm tebchaws United Kingdom yog siv, uas yog corrosion-resistant, high-temperature resistant, thiab muaj high photoelectric conversion efficiency.

3. Txais yuav lub ntiaj teb txoj kev tswj hwm ntxoov ntxoo zoo tshaj plaws, uas tshem tawm qhov khaus rau lub qhov muag thaum lub sijhawm ua haujlwm.

4. Nws muaj peev xwm ua haujlwm tas mus li rau 24 teev, tag nrho lub tshuab muaj kev ua haujlwm ruaj khov, thiab tsis tas yuav saib xyuas hauv 10,000 teev.

5. Kev tsim qauv tib neeg, ua raws li ergonomics, tuaj yeem ua haujlwm tau ntev yam tsis muaj kev qaug zog.

Tshuab Vuam Laser Pwm

Qauv Taw Qhia:

Lub tshuab laser pwm vuam yog ib qho qauv tshwj xeeb uas tsim los rau kev lag luam pwm. Lub tshuab no yog siv tshwj xeeb los hloov lub tshuab argon arc vuam ib txwm muaj rau kev kho cov pwm precision. Cov khoom tseem ceeb ntawm lub tshuab yog cov khoom xa tuaj txawv teb chaws. Lub software ua haujlwm interface siv lub vijtsam loj, thiab lub interface yooj yim thiab meej, thiab tus neeg teb xov tooj yooj yim kawm thiab siv. Ntau yam hom kev ua haujlwm uas tau khaws cia ua ntej kuj tuaj yeem programmed los ntawm koj tus kheej, thiab lub cim xeeb tas mus li tuaj yeem siv rau ntau yam khoom siv.

Cov Qauv Nta:

1. Thaj chaw uas raug cua sov cuam tshuam me me thiab yuav tsis ua rau cov pwm raug hloov pauv;

2. Qhov tob ntawm qhov vuam yog loj thiab qhov vuam ruaj khov. Yaj tag, tsis muaj qhov kho. Tsis muaj qhov nyuaj ntawm qhov sib koom ua ke ntawm qhov siab ntawm lub pas dej yaj thiab lub substrate;

3. Tus nqi oxidation qis, qhov workpiece yuav tsis hloov xim;

4. Yuav tsis muaj qhov cua lossis qhov xuab zeb tom qab vuam;

5. Lub weld tuaj yeem ua tiav, tshwj xeeb tshaj yog rau kev kho pwm nrog kev xav tau polishing;

6. Cov khoom ua haujlwm tuaj yeem ncav cuag 50 ~ 60 Rockwell hardness tom qab vuam.

Cov ntawv thov:

Pwm, kev txhaj tshuaj molding, die-casting, stamping, stainless hlau thiab lwm yam khoom siv tawv xws li tawg, chipping, ntug sib tsoo tshuab hnav thiab sealing ntug kho, vuam; qhov tseeb siab, laser vuam qhov chaw txoj kab uas hla tsuas yog 0.2nm ~ 1.5nm; thaj chaw cua sov me me, ua cov haujlwm yuav tsis raug deformed; nws tuaj yeem raug etched tom qab vuam yam tsis cuam tshuam rau cov nyhuv.

Tshuab laser vuam siv lub tshuab fiber ntau optical

Qauv Taw Qhia:

Lub tshuab vuam laser kis tau los ntawm fiber ntau yog ib hom khoom siv vuam laser uas txuas cov teeb laser muaj zog siab rau hauv fiber ntau, tom qab kis tau deb, sib sau ua ke lub teeb sib luag los ntawm daim iav sib sau ua ke, thiab ua vuam rau ntawm qhov chaw ua haujlwm. Vuam cov pwm loj thiab cov khoom siv tsis raug, thiab siv cov vuam kis tau yooj yim uas tsis sib cuag, uas muaj kev ywj pheej ntau dua. Lub teeb laser tuaj yeem ua tiav lub sijhawm thiab lub zog faib, thiab tuaj yeem ua ntau lub teeb tib lub sijhawm, muab cov xwm txheej yooj yim dua rau kev vuam.

Lub ntsiab feature:

1. Xaiv tau lub koob yees duab CCD saib xyuas, yooj yim rau kev soj ntsuam thiab qhov chaw tseeb;

2. Lub zog faib ntawm qhov chaw vuam yog sib xws, thiab nws muaj qhov chaw teeb pom kev zoo tshaj plaws uas xav tau rau cov yam ntxwv vuam;

3. Hloov kho rau ntau yam kev sib txuas ua ke, qhov chaw vuam ntawm ntau yam khoom siv, thiab kev sib txuas ntawm cov phaj nyias nyias hauv 1 hli;

4. Siv cov khoom siv ceramic concentrating qhov, uas yog corrosion-resistant, high-temperature resistant, thiab lub neej ntawm qhov yog 8 txog 10 xyoo), thiab lub neej ntawm lub teeb argon yog ntau tshaj 8 lab; cov cuab yeej tshwj xeeb thiab cov khoom siv tuaj yeem hloov kho kom ua tiav cov khoom loj.

Cov ntawv thov:

Nws yog dav siv rau hauv kev tsim khoom loj ntawm cov khoom siv sib txuas lus kho qhov muag, cov khoom siv hluav taws xob, cov tshuab kho mob, moos, tsom iav, cov khoom sib txuas lus digital, cov khoom siv precision, kho vajtse thiab lwm yam lag luam, nrog rau kev kho cov pwm loj vuam, tuag casting thiab txhaj tshuaj molding.

Lub sijhawm tshaj tawm: Lub Rau Hli-02-2023