Intloko eWobble 3 kwi-1 ye-Handheld Laser Welder Cleaner Cutter

Intloko eWobble 3 kwi-1 ye-Handheld Laser Welder Cleaner Cutter

Iimpawu zoMshini weLaser we-3 IN 1

1. Uluhlu olubanzi lokuwelda: intloko yokuwelda ephathwa ngesandla ixhotyiswe nge-10M original optical fiber, eyoyisa umda wendawo yokusebenza kwaye ingasetyenziselwa ukuwelda ngaphandle kunye nokuwelda umgama omde;

2. Ukusetyenziswa okulula nokuguquguqukayo:Ukuwelda nge-laser ephathwa ngesandlaIxhotyiswe ngee-pulleys ezihambayo, ezikhululekileyo ukubamba kwaye zinokulungisa isikhululo nangaliphi na ixesha ngaphandle kwezikhululo ezinendawo ezinzileyo. Ikhululekile kwaye iguquguquka, kwaye ifanelekile kwiimeko ezahlukeneyo zemeko yokusebenza.

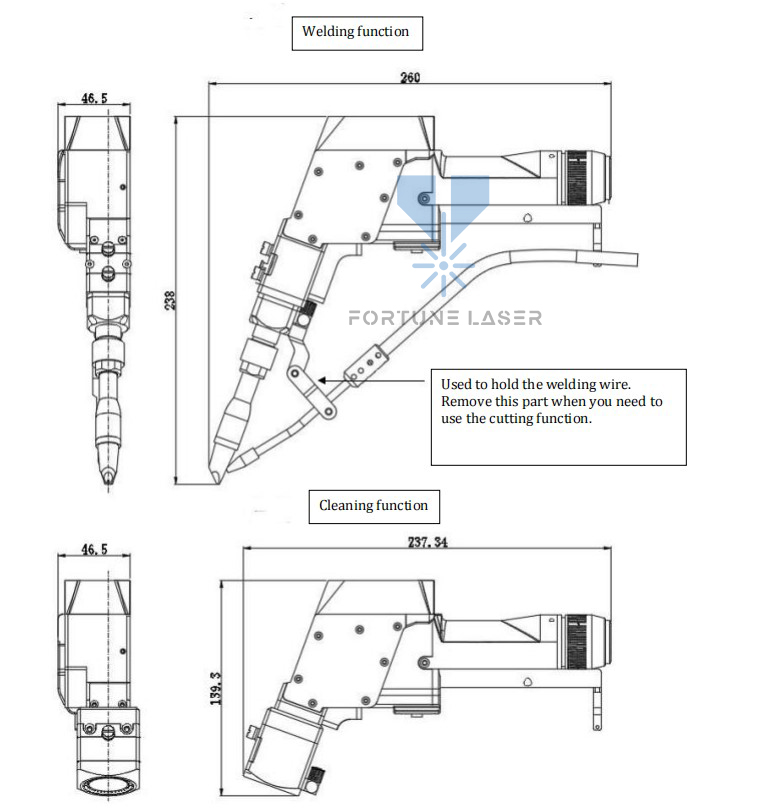

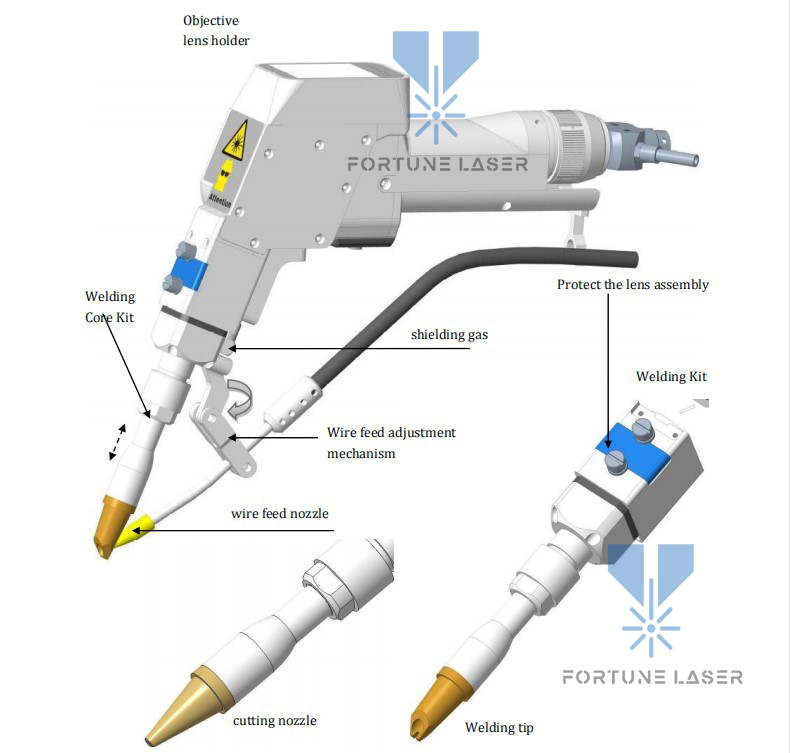

3. Iindlela ezahlukeneyo zokuwelda: ukuwelda nangayiphi na i-engile zinokufezekiswa: ukuwelda kwelap, ukuwelda kwe-butt, ukuwelda ngokuthe nkqo, ukuwelda kwe-flat fillet, ukuwelda kwe-inner fillet, ukuwelda kwe-outer fillet, njl.njl., kwaye kungasetyenziselwa izinto zokusebenza ezinee-welds ezahlukeneyo ezintsonkothileyo kunye neemilo ezingaqhelekanga zokuwelda kwe-workpieces ezinkulu. Qaphela ukuwelda nangayiphi na i-engile. Ukongeza, ingagqibezela ukusika, ukuwelda kunye nokusika kungatshintshwa ngokukhululekileyo, tshintsha nje i-welding copper nozzle ibe yi-cutting copper nozzle, ekulula kakhulu.

4. Ukusika, ukuwelda, kunye nokucoca kudla ngokudibana kakhulu neenkqubo eziphezulu nezisezantsi kwimisebenzi yokucubungula isinyithi. Indlela yokusebenza yendabuko idla ngokufuna izixhobo zokusebenza ezintathu ezahlukeneyo ukuze kuqhutywe iinkqubo ezintathu. Ukuphendula le ngxaki, sibonelela abathengi ngesisombululo esidibeneyo kwaye siqalise umatshini wokusika nokuwelda we-laser ophathwa ngesandla! Esi sisixhobo esinemisebenzi emithathu yokwelda, ukucoca kunye nokusika nge-laser.

5. Isusa ngokukhawuleza nangokulula ioyile, umhlwa kunye neengubo ngaphambi kokuwelda, kwaye isusa inkunkuma kunye nokutshintsha kombala emva kokuwelda, ngelixa isenza iinkqubo zokusika kwiipleyiti ezahlukeneyo. Inokunceda abathengi ngokulula nangokufanelekileyo ukuba bafezekise ukusebenza kakuhle kwaye bahlangabezane neemeko ezininzi zomsebenzi. Ububanzi bokujija kwe-welding buphezulu njenge-5mm, kwaye ubude bokujija kokucoca bufikelela kwi-100mm. Ingasika iipleyiti zentsimbi engagqwaliyo ngaphantsi kwe-6mm. Isalathisi senkqubo siqinile, ingakumbi isalathisi sokucoca asifani nanto!

Iiparamitha zoBugcisa eziSiseko zeLaser yeFortune yeLaser encinci

Iiparamitha zokungena kweWelding (Uluhlu lweWelding lweZinto kunye noBungqingqwa) ukuze kubhekiselwe kuzo

| Izinto eziphathekayo | Amandla okukhupha (W) | Ukungena okuphezulu (mm) |

| Yenziwe ngentsimbi eshayinayo | 1000 | 0.5-3 |

| Yenziwe ngentsimbi eshayinayo | 1500 | 0.5-4 |

| Yenziwe ngentsimbi eshayinayo | 2000 | 0.5-5 |

| Intsimbi yekhabhoni | 1000 | 0.5-2.5 |

| Intsimbi yekhabhoni | 1500 | 0.5-3.5 |

| Intsimbi yekhabhoni | 2000 | 0.5-4.5 |

| I-alloy ye-aluminiyam | 1000 | 0.5-2.5 |

| I-alloy ye-aluminiyam | 1500 | 0.5-3 |

| I-alloy ye-aluminiyam | 2000 | 0.5-4 |

| Ishidi lesinyithi | 1000 | 0.5-1.2 |

| Ishidi lesinyithi | 1500 | 0.5-1.8 |

| Ishidi lesinyithi | 2000 | 0.5-2.5 |

[Imibala emibini yomatshini enombala o-orenji/omnyama nomhlophe/oluhlaza okwesibhakabhaka (iboniswe njengakumfanekiso) yeyokhetho.]

1. Le ntloko yokuwelda ineengenelo ezinkulu kwintsimbi engagqwaliyo, ukuwelda kwe-aluminium alloy, kunye nokusetyenziswa kwe-welding enamandla amancinci naphakathi. Yintloko yokuwelda engabizi kakhulu.

2. Intloko yokufakelwa kwentsimbi isebenzisa ilensi yokungcangcazela ye-X eqhutywa yimoto, ene-Y-axis, eneendlela ezininzi zokufakelwa kwentsimbi, kwaye ukufakwa kwentsimbi yokufakelwa kwentsimbi kuvumela ukuba indawo yokusebenza ibe nokufakelwa kwentsimbi ngendlela engaqhelekanga, izikhewu ezinkulu kunye nezinye iiparameter zokucubungula, ezinokuphucula kakhulu umgangatho wokufakelwa kwentsimbi.

3. Ulwakhiwo lwangaphakathi lwentloko yokudibanisa luvaliwe ngokupheleleyo, nto leyo enokuthintela inxalenye ye-optical ukuba ingcoliswe luthuli.

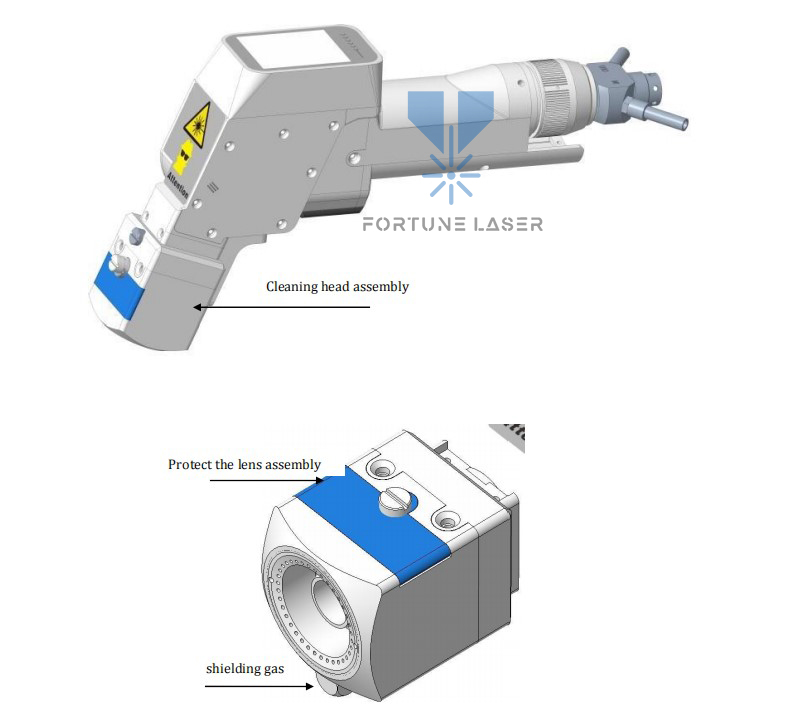

4. Iikiti zokuwelda/zokusika kunye neekiti zokucoca ezikhethwayo zinokufezekisa imisebenzi emithathu yokuwelda, ukusika kunye nokucoca.Sikwanayo nomatshini wokucoca omncinci onomsebenzi owahlukileyo wokucoca)

5. Ilensi ekhuselayo isebenzisa isakhiwo sedrowa, esilula ukusitshintsha.

6. Ingaxhotyiswa ngee-laser ezahlukeneyo ezinezihlanganisi ze-QBH.

7. Ubungakanani obuncinci, imbonakalo entle kunye nokuziva kakuhle.

8. Isikrini sokuchukumisa asinyanzelekanga ukuba sisetyenziswe entlokweni yokuwelda, esinokudityaniswa nesikrini seqonga ukuze ufumane amava angcono olawulo loomatshini bomntu.

| I-voltage yokubonelela (V) | 220V±10% AC 50/60Hz |

| Amandla alinganisiweyo | 1500W |

| Ubude befocal edibeneyo | 75mm |

| Indawo yokusebenza yokufuma (%) | <70 |

| Ukugxila/Ukucoca Ubude beFokasi | F150mm/F500mm |

| Uluhlu lokujika | 0.1-5mm |

| Indlela yokupholisa | Isixhobo sokupholisa amanzi |

| Isantya sokujika | 0—300Hz |

| Ubunzima | 0.8kg |

| Ukhetho | Intloko yokucoca / iSongezo seeNtambo / iNgcebiso yokusika / iKiti yokuWelda |

| Ubungakanani besikrini | Isikrini esikhulu esiqhelekileyo + isikrini esincinci esinganyanzelekanga se-intshi ezi-2 |

| Uluhlu lohlengahlengiso oluthe nkqo olugxile | ±10mm |

| Uluhlu lohlengahlengiso lweendawo (imo yokuwelda ebanjwe ngesandla) | 0~6mm |

| Uluhlu lohlengahlengiso lweendawo (imo yokucoca) | 0~50mm |

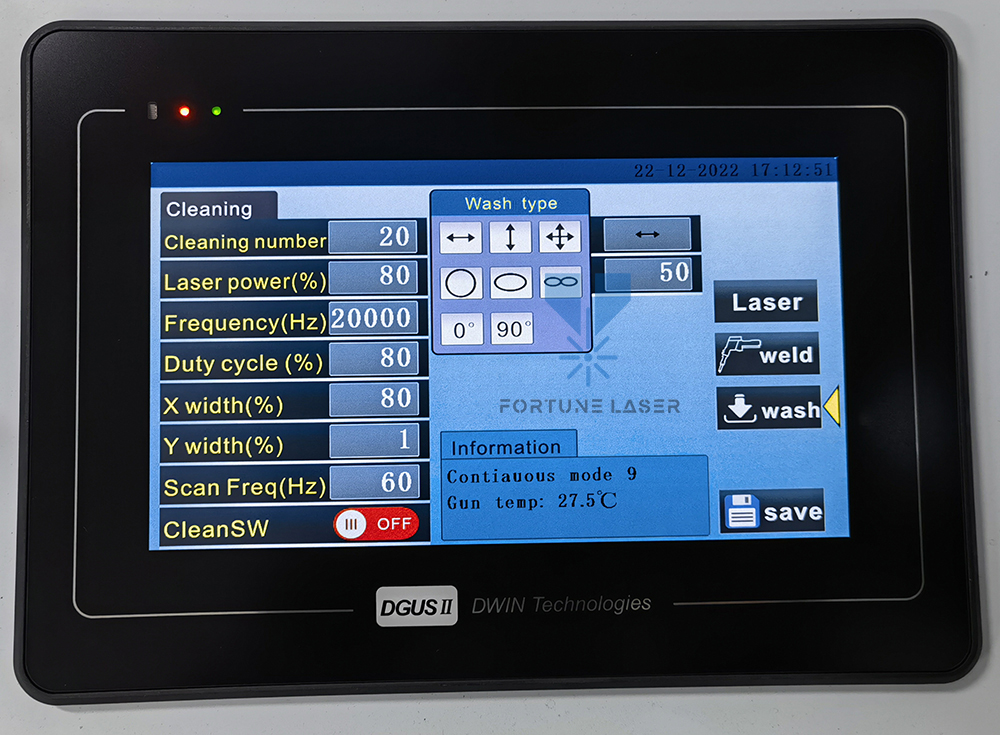

Zonke iindlela zokusebenza koomatshini bethu zilula kwaye kulula ukuziqonda. Khetha iiparameter ofuna ukuzitshintsha ngesikrini sokuchukumisa uze uzigcine. Imisebenzi yokucoca kunye nokuwelda kulula ukuyitshintsha. Khetha nje ukhetho olukumatshini kwaye luya kutshintshela kwimo oyifunayo.

Kwaye abahlobo abaninzi abangazange bayisebenzise baya kuzibuza ukuba bangazilungisa njani iiparameter. Siza kuseta iiparameter ezifanelekileyo kuwe xa sithumela imveliso. Xa uyisebenzisa, kufuneka utshintshe amandla okusebenzisa yona kuphela. Ukuba usaziva ungakhululekanga, sikwanayo neseti yophando. Itheyibhile yeeparameter ezifanelekileyo zokuwelda izinto ezahlukeneyo zenzelwe abathengi bethu.

Indlela ye-optical, inkqubo, i-hardware, njl.njl. zonke ziphuhliswe ngokuzimeleyo. Ujongano lokusebenza lulula kwaye lucacile, kwaye ukusebenza kulula. Iiyure zoqeqesho zinokukwenza uzive ngathi ungumwelda onobuchule. Nciphisa iindleko zomsebenzi ngelixa uphucula umgangatho, ukuhambelana, kunye nemveliso.

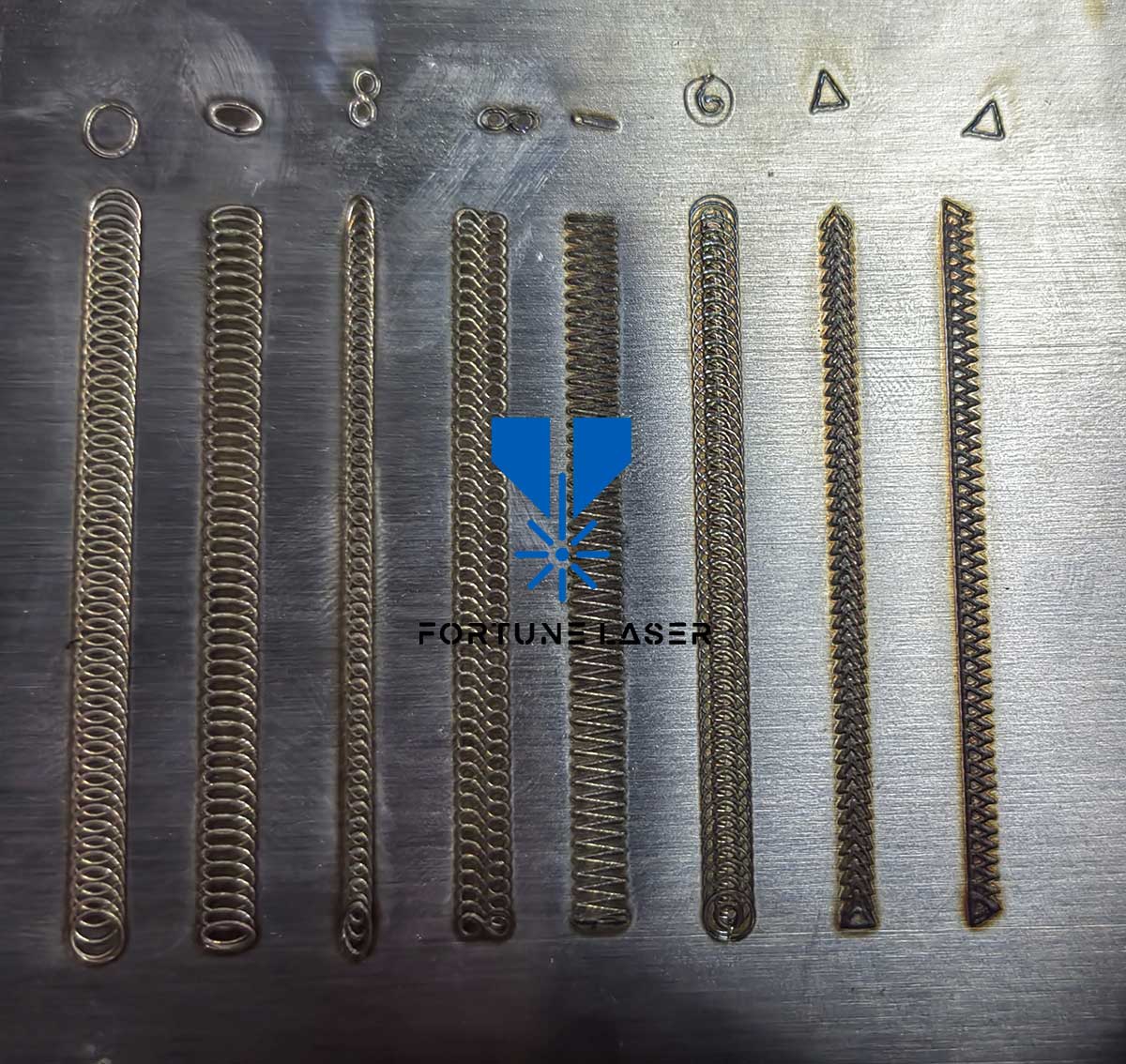

Ngokusekelwe ku-3 no-1, umatshini wethu unokutshintsha iintlobo ezahlukeneyo zeemilo zamabala njengoko kubonisiwe kumfanekiso ongezantsi.

Iipateni ezidityaniswe yimilo nganye yebham zahlukile. Imilo yethu yebham ibandakanya umgca othe tye, isangqa, unxantathu, umfanekiso 8, i-ellipse, i-90° kunye nezinye iimilo eziqhelekileyo.

1. Le ntloko yelaser yimveliso yethu ekhethekileyo eyenzelwe wena, phantse akukho efanayo kwimarike;

2. Sinamaqonga amaninzi okuthenga e-B2B, anokuqinisekisa ukhuseleko lokuthenga kwakho;

3. Sinenkxaso yobugcisa ezinikeleyo kunye nenkonzo yasemva kokuthengisa iiyure ezingama-24 ukuphucula amava abathengi;

4. Zonke iimatshini zethu zinewaranti yonyaka omnye.

5. Sigxila ekuphuhliseni iimveliso zethu ngobuchule kwaye sinikezela ngemigaqo yokhuphiswano.

6. Sineqela elinobuchule kakhulu nelithembekileyo elikunika inkonzo, elizimisele ukubonelela ngenkonzo yabathengi eyenzelwe wena kubo bonke abathengi bethu.