Impumelelo yesinyithi kunyeukuwelda nge-laserixhomekeke kwiimpawu zayo eziphambili zomzimba. Umzekelo, ukubonakalisa okuphezulu kunokuphambukisa amandla e-laser, ngelixa ubushushu obuphezulu bususa ubushushu ngokukhawuleza kwindawo ye-weld. Ezi mpawu, kunye nendawo yokunyibilika, zimisela indlela ephumelela ngayo into efunxa amandla ukuze yenze i-weld enamandla nechanekileyo.

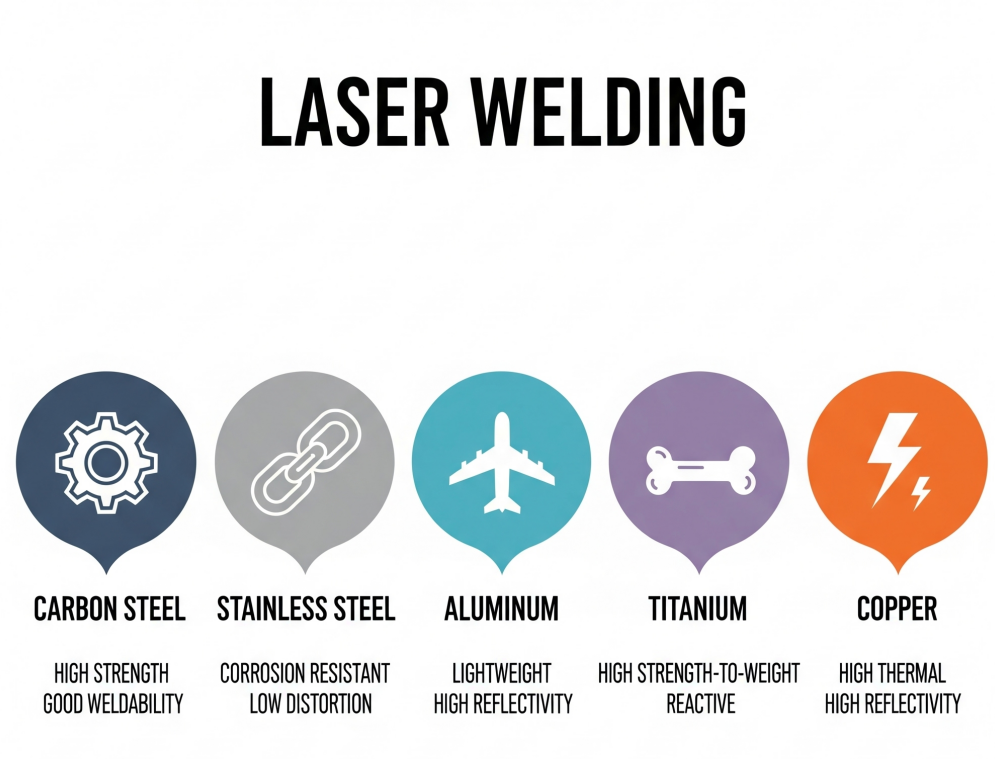

Nantsi inkcazo yesinyithi esiqhelekileyo kunye nendlela iimpawu zazo ezisebenza ngayo.

Ukuwelda ngeLaser Intsimbi yeCarbon

Intsimbi yekhabhoni yintsimbi-khabhoni equlathe i-carbon efikelela kwi-2.1% yomxholo wekhabhoni. Umxholo wekhabhoni ngowona uphambili ochaza iimpawu zayo.

Intsimbi ekhabhoni ephantsi(ikhabhoni engaphantsi kwe-0.25%) ayiguquki, iqinile, kwaye kulula ukuyilungisa kwaye iyaxutywa. Ihlala isetyenziselwa iiphaneli zomzimba, ucingo, kunye nemibhobho.

Intsimbi ephakathi nekhabhoni(ikhabhoni eyi-0.25% ukuya kwi-0.60%) inamandla kwaye inzima kunentsimbi engenakhabhoni ininzi. Oku kuyenza ifaneleke kwizinto ezifuna amandla angakumbi kunye nokumelana nokuguguleka, njengeegiya, iishafti, kunye namavili kaloliwe.

Intsimbi enekhabhoni ephezulu(ngaphezulu kwe-0.60% yekhabhoni) yeyona inamandla kwaye inzima kwezi zintathu, kodwa ikwayeyona incinci kakhulu kwaye ibuthathaka kakhulu. Ubulukhuni bayo buyenza ilungele izixhobo zokusika, izipringi, kunye neengcingo ezinamandla aphezulu, kodwa ifuna ukuphathwa ngononophelo ngexesha lokuwelda ukuthintela ukuqhekeka.

Intsimbi yekhabhoni inzima kakhulu kwimveliso, kwaye kufuneka ukuwelda nge-laser kakuhle.

Iingenelo: Ufumana ii-welds eziqinileyo nezinzulu ngocoselelo olumangalisayo kunye nokugqwetheka okuncinci kakhulu. Isantya siluncedo olukhulu, sinyusa imveliso kumgangatho wefektri.

Izinto ekufuneka ziqwalaselwe: Ukupholisa ngokukhawuleza kwenkqubo yelaser kunokwenza i-weld ibe buthathaka kwaye ithambekele ekuqhekekeni. Ngamanye amaxesha, ukufudumeza kwangaphambili inxalenye kuyimfuneko ukuze kuncitshiswe ukupholisa nokuthintela iingxaki.

Ukuwelda ngeLaser Intsimbi Engagqwaliyo

Le yinto efanayo eyenziwe ezulwini. Ukuwelda nge-laser yinkqubo efanelekileyo yentsimbi engagqwaliyo, ingakumbi kumashishini afuna ucoceko.

Iingenelo: Ukufakwa kobushushu obuphantsi, obugxile kakhulu kukuphumelela okukhulu. Kugcina iipropati zentsimbi engagqwaliyo ezingamelani nokugqwala ngokuthintela into ebizwa ngokuba yi-"carbide precipitation." Oku kuphumela kwii-welds ezicocekileyo nezichanekileyo ngotyando, yiyo loo nto ithandwa kakhulu kumashishini ezonyango nawokutya.

Izinto ekufuneka ziqwalaselwe: Iintsimbi ezixhaphakileyo ezingenasici, ezifana nothotho lwe-300 (umz., 304, 316), zidityaniswa kakuhle kakhulu. Nangona kunjalo, ezinye iintlobo, ezifana nothotho lwe-400, zinokuba buthathaka kwindawo echaphazelekileyo bubushushu.

I-Aluminiyam yokuWelda ngeLaser

Ukuwelda i-aluminiyam bekusoloko kunzima, kodwa ukuwelda nge-laser kuyawutshintsha umdlalo.

Iingenelo: I-Aluminium yi-heat conductor entle kakhulu, oko kuthetha ukuba xa usebenzisa i-welding yendabuko, ubushushu buyasasazeka bubangele ukuba yonke inxalenye igobe. Amandla agxile kwi-laser kunye nokufakwa kobushushu obuphantsi kusombulula le ngxaki, kunciphisa kakhulu ukugqwetheka.

Izinto ekufuneka ziqwalaselwe: I-aluminiyam ikhanya kakhulu. Umphezulu okhazimlayo ungawutsiba umqadi we-laser kwangoko. Impumelelo ixhomekeke kwizinto ezimbalwa ezibalulekileyo: ukucoca umphezulu ococekileyo, igesi yokukhusela efanelekileyo, kunye nokusebenzisa uhlobo olufanelekileyo lwe-laser (ii-fiber lasers zihlala zikhethwa) ukuqinisekisa ukuba amandla ayafunxwa.

Ukuwelda kweLaser Titanium

Ukuba ufuna ukuwelda i-titanium, i-laser yenye yezona zixhobo zakho zibalaseleyo kulo msebenzi.

Iingenelo: I-Titanium yintsimbi esabelayo, oko kuthetha ukuba ingcoliswa lula yioksijini emoyeni xa inyibilika, nto leyo ekhokelela kwi-weld ebuthathaka neqhekekayo. Isantya kunye nokuchaneka kwelaser kunciphisa ixesha isinyithi esinyibilikayo nesivezwa ngalo, kunciphisa umngcipheko wongcoliseko kunye nokuqhekeka.

Izinto ekufuneka ziqwalaselwe: Njengakwi-TIG welding titanium, kusafuneka ulumke kakhulu. Ucoceko olupheleleyo kunye nokukhusela okugqibeleleyo ngegesi engangenisi (njenge-argon) akunakuxoxiswana ngako.

Ukuwelda ngeLaser Ubhedu kunye nezinye iiMetal eziKhazimlayo

Kulapho ukuwelda nge-laser kutyhala khona imida yoko kunokwenzeka.

Iingenelo: Umatshini wokuwelda nge-laser unokudibanisa izinto ezikhanyayo kakhulu ezifana nobhedu, ezinzima kakhulu ukuzihlanganisa phantse nangayiphi na enye indlela. Oku kubaluleke kakhulu kwiimveliso ezifana neebhetri zezithuthi zombane (EV), apho ubhedu kunye ne-aluminium kufuneka zidityaniswe.

Izinto ekufuneka ziqwalaselwe: Le yinto ekumgangatho ophezulu. Ukukhanya okuphezulu kunye nokuqhuba kobushushu kunokonakalisa i-optics yelaser ukuba ayilawulwa ngokuchanekileyo. Idla ngokufuna izixhobo ezikhethekileyo, kunye neendlela eziphambili.

Zithini ii-Lukulinganisa ukuWelda ngeLaser?

Nangona ivakala ngathi sisixhobo esingummangaliso, ayilungelanga wonke umsebenzi. Kubalulekile ukuqonda umahluko phakathi kwayo.

1.Ixabiso Eliphezulu Lokuqala: Umatshini wokuwelda we-laser ochwephesha lutyalo-mali olukhulu, lubiza kakhulu kune-MIG okanye i-TIG setups zemveli.

2.Iimfuno eziNgqongileyo zoManyanoNjengoko kutshiwo, iilaser zifuna ukulingana okufanelekileyo. Ukuba iindawo zakho zinezikhewu okanye azinqunyulwanga ngokuchanekileyo, ilaser ayizukukwazi ukuzidibanisa ngokufanelekileyo.

3.Imiba yokubonakalisa ubunzulu bengqondoIzinto ezikhazimlayo ezifana ne-aluminium kunye nobhedu zinokuba nzima ukuzihlanganisa ngaphandle kwe-laser kunye neendlela ezikhethekileyo.

4.Iingxaki zoKhuseleko: Umqadi welaser onamandla kakhulu uyingozi kakhulu kwaye unokubangela ukwenzakala okukhulu kwamehlo kunye nokutsha kwesikhumba, nokuba kuvela ekukhanyeni. Izivalo ezifanelekileyo zokhuseleko kunye nezixhobo zokuzikhusela (PPE) ziyimfuneko ngokupheleleyo.

Iindlela ezilungileyo zokusebenzisa ii-Welds zeLaser ezingenasiphako

Ukuze ufumane okuninzi kwinkqubo yakho yokuwelda nge-laser, kufuneka uqonde izinto ezisisiseko.

Ukulungiselela yinto yonke

Ukulingana Kwamalungu: Asinakutsho ngokwaneleyo: iindawo zakho mazilingane kakuhle. Jonga ukuba kukho isithuba esingaphantsi kwe-10% yobukhulu bezinto ukuze ufumane iziphumo ezilungileyo.

Ukucoca Umphezulu: Lahla yonke into engeyontsimbi. Oku kuthetha ukususa zonke iioyile, amafutha, ii-oxides, kunye nazo naziphi na ezinye izinto ezingcolisayo. Umphezulu ococekileyo ubalulekile ukuthintela iimbobo kunye nezinye iziphene kwi-weld yakho.

Lawula Inkqubo Yakho

Igesi yokukhusela: Njenge-TIG kunye ne-MIG, i-laser welding isebenzisa igesi engangenisi mandla (ngesiqhelo i-argon okanye i-helium) ukukhusela ichibi le-weld elinyibilikisiweyo kwi-oksijini kunye ne-nitrogen emoyeni, ukuqinisekisa i-weld eqinileyo necocekileyo.

Ukwenziwa ngcono kweParameter: Kuya kufuneka ucofe useto lwakho. Amandla elaser, isantya sokuwelda, kunye nomgama wokugxila kufuneka ulinganiswe ngokugqibeleleyo ukuze ulungelelaniswe nezinto ezithile kunye nobukhulu osebenza ngabo.

Ukhuseleko Kuqala, Ngalo Lonke Ixesha

Ukuwelda nge-laser akuyonkqubo onokuthi uyithathe lula. Ukukhanya okujolisiweyo kunamandla kakhulu. Nabani na okufutshane nomsebenzi kufuneka anxibe iiglasi zokhuseleko ze-laser ezikhethekileyo ezilinganiswe ngokwe-wavelength ethile ye-laser yakho.

Ngaba umatshini wokuwelda nge-laser yeyona ndlela ifanelekileyo kuwe?

Ngoko ke, ngaba kufuneka utyale imali kwi-laser welding?

Masiphinde siwuchaze. Ukuwelda nge-laser sisixhobo sokuvelisa esiphucukileyo esibonelela ngesantya, ukuchaneka, kunye nomgangatho ongenakuthelekiswa nanto. Ixabiso lokuqala liphezulu kunye neemfuno ezingqongqo zezixhobo ezicocekileyo nezifanelekileyo.

Ingcinga yethu yokugqibelaUkuba umsebenzi wakho ufuna ivolumu ephezulu, ukuzenzekela, kunye nokuchaneka okucacileyo—ingakumbi kwizinto ezibuthathaka okanye ezinzima—ngoko ke ukuwelda nge-laser akuyondlela nje enye. Sisisombululo esibalaseleyo esinokuguqula imveliso yakho.

Ixesha leposi: Agasti-15-2025