Njengoko sonke sisazi, itshiphu ye-LED njengeyona nto iphambili kwisibane se-LED sisixhobo se-semiconductor esiqinileyo, intliziyo ye-LED yitshiphu ye-semiconductor, elinye icala letshiphu linamathele kwi-bracket, elinye icala yi-electrode engalunganga, elinye icala liqhagamshelwe kwi-electrode elungileyo yombane, ukuze yonke itshiphu igqunywe yi-epoxy resin. Xa i-sapphire isetyenziswa njengesixhobo se-substrate, isetyenziswa kakhulu kwimveliso yeetshiphu ze-LED, kwaye isixhobo sokusika sendabuko asisakwazi ukuhlangabezana neemfuno zokusika. Ngoko ke uyisisombulula njani le ngxaki?

Umatshini wokusika i-laser ye-picosecond ene-wavelength emfutshane ungasetyenziselwa ukusika ii-wafers ze-sapphire, nto leyo esombulula ngempumelelo ubunzima bokusika i-sapphire kunye neemfuno zeshishini le-LED ukwenza i-chip ibe ncinci kwaye indlela yokusika ibe mxinwa, kwaye inika ithuba kunye nesiqinisekiso sokusika ngokufanelekileyo kwimveliso enkulu ye-LED esekwe kwi-sapphire.

Iingenelo zokusika nge-laser:

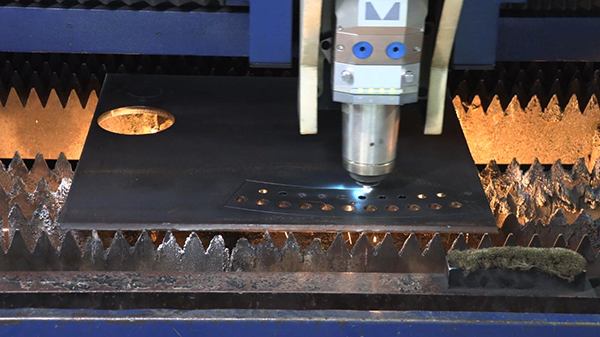

1, umgangatho wokusika olungileyo: ngenxa yendawo encinci yelaser, uxinano lwamandla aphezulu, isantya sokusika, ngoko ke ukusika ngelaser kunokufumana umgangatho wokusika ongcono.

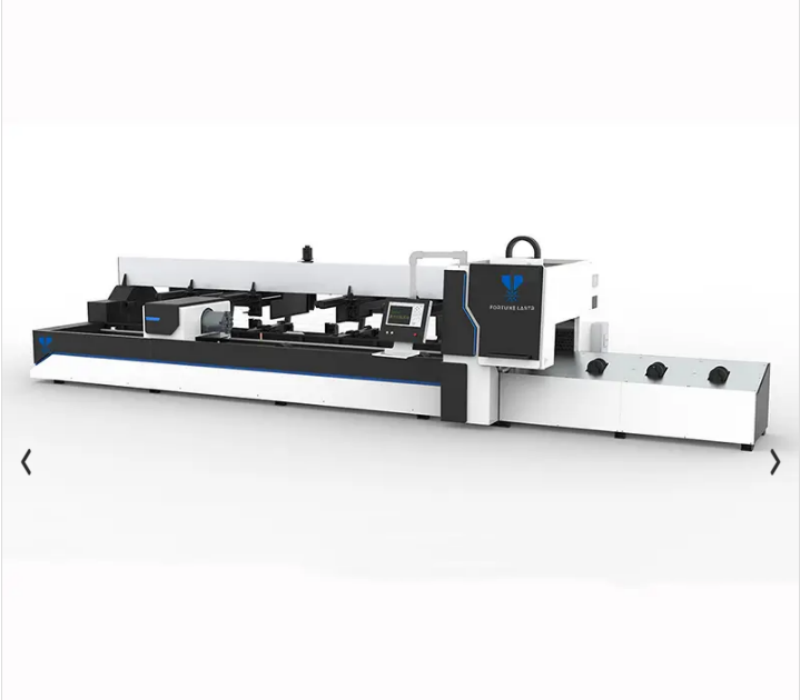

2, ukusebenza kakuhle kokusika: ngenxa yeempawu zokudlulisa ze-laser, umatshini wokusika i-laser ngokubanzi uxhotyiswe ngeetafile ezininzi zokulawula amanani, kwaye yonke inkqubo yokusika inokuba yi-CNC ngokupheleleyo. Xa usebenza, tshintsha nje inkqubo yokulawula amanani, ingasetyenziswa ekusikeni iindawo zemilo eyahlukeneyo, zombini ukusika okunemilinganiselo emibini kunye nokusika okunemilinganiselo emithathu kunokufezekiswa.

3, isantya sokusika siyakhawuleza: izinto azidingi ukulungiswa kwi-laser cutting, nto leyo enokonga isixhobo kwaye igcine ixesha elincedisayo lokulayisha nokukhupha impahla.

4, ukusika okungadibaniyo: itotshi yokusika nge-laser kunye ne-workpiece akukho kudibana, akukho zixhobo zigugileyo. Ukucubungula iindawo zeemilo ezahlukeneyo, akufuneki kutshintshwe "isixhobo", tshintsha nje iiparameter zemveliso ye-laser. Inkqubo yokusika nge-laser inengxolo ephantsi, ukungcangcazela okuphantsi kwaye akukho ngcoliseko.

5, kukho iintlobo ngeentlobo zezinto zokusika: kwizixhobo ezahlukeneyo, ngenxa yeempawu zazo zomzimba ezishushu kunye namazinga ahlukeneyo okufunxa kwelaser, zibonisa ukuguquguquka kokusika kwelaser okwahlukileyo.

Ixesha leposi: Disemba-02-2024