Ukhuseleko nokusebenza kakuhle kweenkqubo zikaloliwe zanamhlanje kuxhomekeke kwizixhobo zokwenza izinto ngokwemigangatho ephezulu kakhulu yokuchaneka. Eyona nto iphambili kule nkqubo yemizi-mveliso kukusika nge-laser, iteknoloji esebenzisa ukukhanya okugxileyo ukwenza iindawo zesinyithi ngokuchanekileyo okungenakuthelekiswa nanto.

Esi sikhokelo sibonelela ngenkcazo eneenkcukacha kwimigaqo yobunjineli elawulayoumsiki welaser, ihlola usetyenziso lwayo olwahlukeneyo ukusuka kwizakhiwo zoololiwe ukuya kwizixhobo ezisecaleni kwendlela, kwaye ichaza isizathu sokuba ibe sisixhobo esisisiseko kushishino loololiwe.

Itekhnoloji: Indlela iLaser eyisika ngayo intsimbi

Asikuko nje "umsebe wokukhanya" oqhelekileyo.Le nkqubo yindlela elawulwa kakhulu yokusebenzisana phakathi kokukhanya, igesi kunye nesinyithi.

Nantsi inkqubo yenyathelo ngenyathelo:

1. Isizukulwana:Ngaphakathi kumthombo wamandla, uthotho lweediode “zipompa” amandla kwiintambo ze-fiber optic ezixutywe nezinto ezinqabileyo zomhlaba. Oku kuyavuselela iiathom kwaye kuvelise ukukhanya okunamandla kakhulu.

2. Ukugxila:Lo mqadi, udla ngokulinganiselwa phakathi kwee-kilowatts ezi-6 nezingama-20 (kW) xa isetyenziswa kakhulu kwimizi-mveliso, idluliselwa ngentambo ye-fiber optic ukuya entloko yokusika. Apho, uthotho lweelensi luyijolisa kwindawo encinci, enamandla kakhulu, ngamanye amaxesha ingaphantsi kwe-0.1 mm.

3. Ukusika kunye noNcedo lweGesi:Umqadi ojolisiweyo uyanyibilika kwaye uphelise isinyithi. Kwangaxeshanye, igesi yokuncedisa uxinzelelo oluphezulu idutyulwa nge-nozzle efanayo nomqadi we-laser. Le gesi ibalulekile kwaye isebenza iinjongo ezimbini: ivuthuza isinyithi esinyibilikisiweyo kakuhle siphume kwisiqwenga (esaziwa ngokuba yi-"kerf") kwaye ichaphazela umgangatho wesiqwenga.

I-nitrogen (N)2)yigesi engangeniyo esetyenziselwa ukusika intsimbi engagqwaliyo kunye ne-aluminium. Ivelisa umphetho ococekileyo, wesilivere, ongena-oxide olungele ukuwelda ngoko nangoko. Oku kubizwa ngokuba "kukusikwa okucocekileyo okunoxinzelelo oluphezulu".

Ioksijini (O2)2)isetyenziselwa ukusika intsimbi yekhabhoni. Ioksijini idala i-exothermic reaction (itsha ngamandla kunye nentsimbi), nto leyo evumela isantya sokusika esikhawulezayo. Umphetho ophumayo unomaleko omncinci we-oxide owamkelekileyo kwiindlela ezininzi zokusetyenziswa.

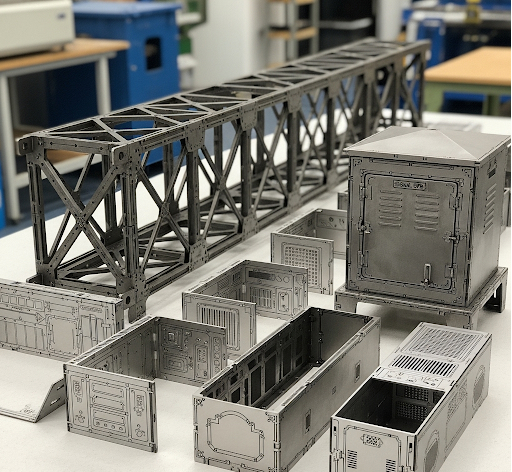

Isicelo: Ukusuka kwiifreyimu eziphambili ukuya kwii-Micro-Components

Itekhnoloji yokusika i-laser isetyenziswa kuyo yonke inkqubo yokwenziwa koololiwe, ukusuka kwizakhelo ezinkulu zesakhiwo eziqinisekisa ukhuseleko lwabakhweli ukuya kwizinto ezincinci nezintsonkothileyo zangaphakathi. Ukuguquguquka kobu buchwepheshe kuvumela ukuba busetyenziswe kwiindawo ezininzi ezahlukeneyo, bubonisa indima yalo ebalulekileyo ekwakheni oololiwe banamhlanje kunye neziseko ezibaxhasayo.

Izinto eziyinxalenye yoLwakhiwo:Le yeyona ndawo ibalulekileyo. Iilaser zisetyenziselwa ukusika iibhloko zokwakha eziphambili zesitimela, kuquka iigobolondo zomzimba wemoto, ii-underframes ezinzima ezixhasa umgangatho, kunye nezinto ezibalulekileyo zokhuseleko ezifana neefreyimu ezisecaleni, imiqadi enqamlezileyo, kunye nee-bolsters. Ezi zihlala zenziwe ngezinto ezikhethekileyo ezifana nentsimbi enamandla aphezulu, intsimbi ye-corten yokumelana nokugqwala, okanye ii-aluminium alloys ze-5000 kunye ne-6000 zothotho lwee-trains ezikhaphukhaphu ezihamba ngesantya esiphezulu.

Iinkqubo zangaphakathi nezeSub-systems:Ukuchaneka kubalulekile nalapha. Oku kuquka imibhobho ye-HVAC yentsimbi engagqwaliyo ekufuneka ilingane kwiindawo ezixineneyo, iiphaneli zophahla lwe-aluminiyam kunye nodonga ezineziqwenga ezichanekileyo zezibane kunye nezithethi, iifreyimu zokuhlala, kunye nezivalo zentsimbi ezigqunyiweyo ze-elektroniki ezinobuthathaka.

Iziseko zophuhliso kunye nezikhululo:Ukusetyenziswa kwayo kudlulela ngaphaya koololiwe ngokwabo. Iilaser zisika iipleyiti zentsimbi enzima zeemasti ze-catenary, ii-housing zezixhobo zokubonisa ecaleni kwendlela, kunye neepaneli zokwakha ezintsonkothileyo ezisetyenziselwa ukuphucula iifacade zesikhululo.

Inzuzo Echanekileyo: Ukuntywila Okunzulu

Igama elithi "ukuchaneka" linezibonelelo zobunjineli ezibonakalayo ezingaphaya "kokulingana kakuhle".

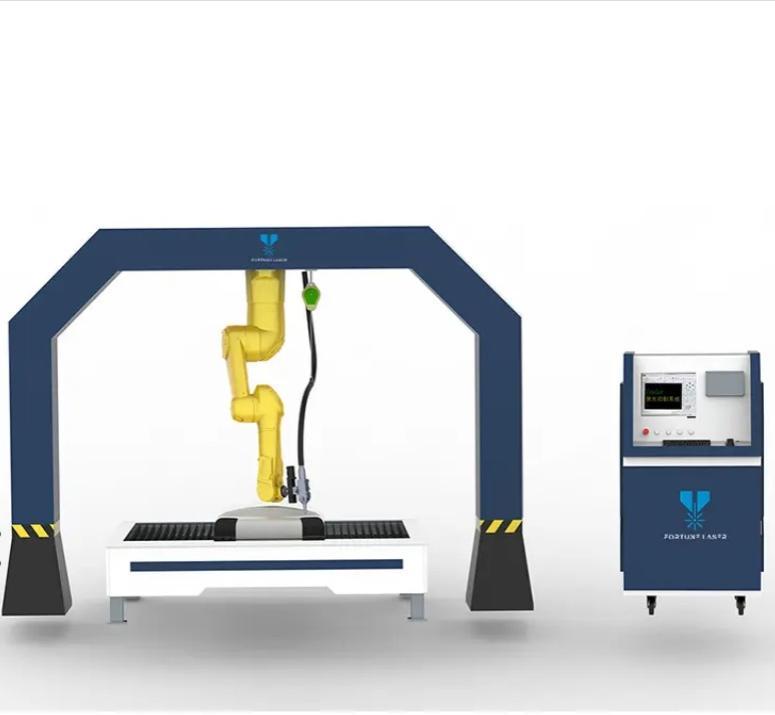

Ukuvumela iRobotic Automation:Ukuhambelana okungaqhelekanga kweendawo ezisikiweyo nge-laser yikona okwenza ukuba i-robotic welding ekhawulezayo ibe yinyani. I-robot ye-welding ilandela indlela echanekileyo, ecwangcisiweyo kwangaphambili kwaye ayinakuziqhelanisa notshintsho phakathi kweendawo. Ukuba inxalenye ingekho kwindawo yayo, yonke i-weld inokungaphumeleli. Ngenxa yokuba i-laser cutting ivelisa iindawo ezifanayo ngokobukhulu bexesha ngalinye, inika ukuthembeka okungagungqiyo okufunekayo kwiinkqubo ezizenzekelayo ukuze zisebenze ngokungenamthungo nangokufanelekileyo.

Ukunciphisa Indawo Echaphazeleka Bubushushu (HAZ):Xa usika isinyithi ngobushushu, indawo ejikeleze isiqwenga nayo iyashushu, nto leyo enokutshintsha iimpawu zayo (njengokuyenza ibe buthathaka ngakumbi). Le yiNdawo echaphazeleka bubushushu (HAZ). Ngenxa yokuba i-laser igxile kakhulu, ingenisa ubushushu obuncinci kakhulu kwinxalenye, nto leyo eyenza i-HAZ encinci. Oku kubalulekile kuba kuthetha ukuba ukuqina kwesakhiwo sesinyithi ecaleni kwesiqwenga akutshintshi, ukuqinisekisa ukuba izinto zisebenza kanye ngendlela eziyilwe ngayo ziinjineli.

Ityala leShishini: Ukulinganisa iiNzuzo

Iinkampani azityali izigidi kule teknoloji kuba nje ichanekileyo. Inzuzo yemali kunye neyothutho ibalulekile.

Ukusetyenziswa kwezinto eziPhambili:Isoftware ekrelekrele "yokwenza izidleke" ibalulekile. Ayizihlanganisi nje kuphela iindawo njengephazili kodwa ikwasebenzisa iindlela eziphambili ezifana nokusika umgca oqhelekileyo, apho iindawo ezimbini ezikufutshane zisikwa ngomgca omnye, nto leyo esusa ngokupheleleyo ukungcola phakathi kwazo. Oku kunokunyusa ukusetyenziswa kwezinto ukusuka kwi-75% eqhelekileyo ukuya kwi-90%, nto leyo egcina imali eninzi kwiindleko zezinto eziluhlaza.

Ukuveliswa "kokukhanya":Izicucu ze-laser zanamhlanje zihlala zidityaniswa neenqaba zokulayisha/zokukhulula izinto ngokuzenzekelayo. Ezi nkqubo zinokubamba amaphepha amaninzi ezinto eziluhlaza kwaye zigcine iindawo ezigqityiweyo. Oku kuvumela umatshini ukuba usebenze ngokuqhubekayo ubusuku bonke neempelaveki ngaphandle kokubekwa esweni ngumntu—ingcamango eyaziwa ngokuba yimveliso “yokucima izibane”—inyusa kakhulu imveliso.

Ukulungelelanisa uMsebenzi Opheleleyo:Iingenelo ziyanda ngokwanda.

1. Akukho kurhoxiswa kwenkunkuma:Ukusika kokuqala okucocekileyo kususa imfuneko yesikhululo sokugaya sesibini ukuze kususwe imiphetho ebukhali. Oku kusindisa ngokuthe ngqo iindleko zabasebenzi, kuphucula ukhuseleko lwabasebenzi ngokususa iingozi zokugaya, kwaye kukhawulezise umsebenzi wemveliso iyonke.

2. Akukho kuphinda kusetyenziswe:Izixhobo ezisikwe ngokuchanekileyo ziqinisekisa ukulingana ngokugqibeleleyo, zisusa uhlengahlengiso oluchitha ixesha ngesandla ngexesha lokuhlanganiswa. Oku kukhawulezisa ngokuthe ngqo isantya semveliso, kwandisa imveliso, kwaye kuphumela kwimveliso yokugqibela ekumgangatho ophezulu.

3. Uthotho lweenkonzo olulula:Ukususa iinxalenye xa zifunwa kwiifayile zedijithali kunciphisa isidingo sokugcina impahla enkulu, kunciphisa iindleko zokugcina, kunciphisa inkunkuma, kunye nokwandisa ubuchule bokusebenza.

Isixhobo Esifanelekileyo Somsebenzi: Uthelekiso Olubanzi

Ukukhethwa kwezixhobo ezifanelekileyo kwindawo yokwenziwa kobuchwephesha kugqitywa luhlalutyo oluguquguqukayo oluninzi lwesantya semveliso, ukunyamezelana ngokuchanekileyo, iindleko zokusebenza, kunye neempawu zezinto. Ngenxa yoko, i-laser ayisosisombululo esifanelekileyo kwihlabathi liphela.

| Indlela | Eyona ilungileyo | Inzuzo ephambili | Ingxaki Ephambili |

| Ukusika iFayibha ngeLaser | Ukusika ngokuchanekileyo kumashiti ukuya kuthi ga kwi-~25mm (1 intshi) ubukhulu. Ilungele intsimbi engagqwaliyo kunye ne-aluminium. | Ukuchaneka okungenakuthelekiswa, imiphetho ecocekileyo, i-HAZ encinci kakhulu, kunye nesantya esiphezulu kwizinto ezincinci. | Ixabiso lokuqala lenkunzi liphezulu. Ayisebenzi kangako kwiipleyiti ezityebileyo kakhulu. |

| Iplasma | Ukusika iipleyiti zentsimbi ezityebileyo (>25mm) ngokukhawuleza apho umgangatho ogqibeleleyo womphetho ungeyonto iphambili. | Isantya esiphezulu kakhulu sokusika kwizinto ezixineneyo kwaye ixabiso lokuqala liphantsi kuneleza enamandla aphezulu. | I-HAZ enkulu, ayichanekanga kangako, kwaye ivelisa umphetho ogobileyo odla ngokufuna ukugaywa. |

| Ijethi yamanzi | Ukusika nayiphi na into (isinyithi, ilitye, iglasi, izinto ezidityanisiweyo) ngaphandle kobushushu, ingakumbi ii-alloys ezibuthathaka kubushushu okanye isinyithi esityebileyo kakhulu. | Akukho HAZ konke konke, ukugqitywa komphetho okugudileyo kakhulu, kunye nokuguquguquka okumangalisayo kwezinto. | Icotha kakhulu kuneleser okanye iplasma, kwaye ineendleko eziphezulu zokusebenza ngenxa yezixhobo zokurhawuzelela kunye nokugcinwa kwepompo. |

Ukuqukumbela, ukusika i-fiber laser kungaphezulu kakhulu kunendlela yokubumba isinyithi; bubuchwepheshe obusisiseko kwinkqubo yokuvelisa yedijithali yeshishini likaloliwe lanamhlanje. Ixabiso layo likwindibaniselwano enamandla yokuchaneka okugqithisileyo, imveliso ekhawulezayo, kunye nokuhlanganiswa okunzulu neenkqubo zomzi-mveliso wonke.

Ngokuvumela ukuzisebenzela okuphucukileyo okufana nokuwelda kwerobhothi, ukunciphisa indawo echaphazeleka bubushushu ukuze kulondolozwe amandla ezinto, kunye nokubonelela ngomgangatho ogqibeleleyo ofunekayo ukuhlangabezana nemigangatho yokhuseleko engqongqo njenge-EN 15085, iye yaba sisixhobo esingenakuxoxiswana ngaso.

Ekugqibeleni, ukusika nge-laser kubonelela ngoqiniseko lobunjineli kunye nokuqinisekiswa komgangatho ofunekayo ukwakha iinkqubo zikaloliwe ezikhuselekileyo, ezithembekileyo, neziphucukileyo zobuchwepheshe zanamhlanje.

Ixesha lokuthumela: Agasti-22-2025