Incwadi Yokusebenza Yerobhothi Yokuwelda NgeLaser isebenza njengesikhokelo esibanzi esinika ulwazi olusisiseko malunga nokusetyenziswa kunye nokusebenza kwezixhobo ezizenzekelayo ezisebenzisa imiqadi yelaser ukuwelda. Le ncwadi yenzelwe ukunceda abasebenzisi baqonde amanyathelo okufakela, iinkqubo zokulungisa iingxaki kunye neenkqubo zokusebenza ezifunekayo ukuze kusetyenziswe iirobhothi zokuwelda ngelaser ngokufanelekileyo nangokukhuselekileyo. Ngenxa yeenzuzo zayo zokusebenza kakuhle, ukuchaneka okuphezulu, kunye nomgangatho ophezulu, iirobhothi zokuwelda ngelaser zamkelekile kakhulu kumashishini ahlukeneyo afana nokuvelisa iimoto, i-aerospace, kunye ne-elektroniki.

Ingcaciso yeMveliso

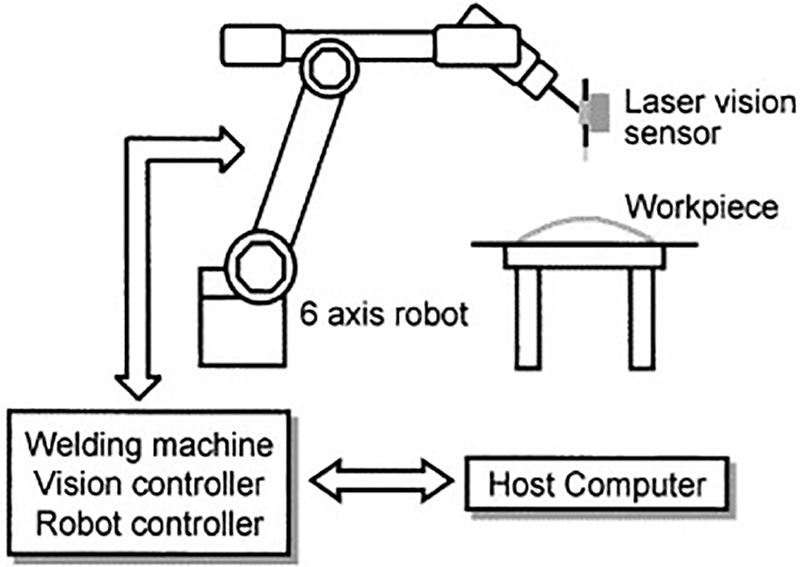

Irobhothi yokuwelda nge-laser sisixhobo esisebenzisa umqadi we-laser ukwenza imisebenzi yokuwelda. Eyona njongo iphambili yokuwelda nge-laser kukufudumala nokunyibilikisa iindawo eziweldayo, ukubopha ngempumelelo nokudibanisa izinto kunye. Le nkqubo ivumela ukuwelda ngokuchanekileyo, nto leyo ephumela kwimveliso esemgangathweni ophezulu. Iirobhothi zokuwelda nge-laser ziyaziwa ngokukwazi kwazo ukunika iziphumo zokuwelda ezigqwesileyo, nto leyo ezenza zibe zilungele amashishini afuna ukugqibelela nokuthembeka.

Amanyathelo okufaka

Ukufakwa ngokufanelekileyo kwerobhothi yokuwelda nge-laser kubalulekile ekusebenzeni kwayo kakuhle nasekuhlaleni ixesha elide. La manyathelo alandelayo achaza inkqubo yokufaka:

1. Ukufakelwa kwesakhiwo soomatshini: Okokuqala hlanganisa uze ufake isakhiwo soomatshini serobhothi yokuwelda nge-laser. Qinisekisa ukuba zonke izinto ziqhagamshelwe ngokukhuselekileyo kwaye zilungelelaniswe ukuze zinike uzinzo ngexesha lokusebenza.

2. Ukufakelwa kwenkqubo yokulawula: Faka inkqubo yolawulo yerobhothi yokuwelda nge-laser. Le nkqubo inoxanduva lokulawula iintshukumo kunye nemisebenzi yerobhothi kwaye idlala indima ebalulekileyo ekufezekiseni iziphumo ezichanekileyo zokuwelda.

3. Uqhagamshelo lombane kunye nomgca wesignali: Qhagamshela ngokuchanekileyo umbane kunye nomgca wesignali werobhothi yokuwelda nge-laser ukuqinisekisa umbane othembekileyo nongaphazanyiswayo. Landela ngononophelo umzobo wocingo onikiweyo kwaye uqinisekise ukuba zonke iintambo zichanekile.

Amanyathelo okulungisa iingxaki

Emva kokuba irobhothi yokuwelda nge-laser ifakiwe, kufuneka ilungiswe kakuhle ukuze isebenze kakuhle. La manyathelo alandelayo achaza inkqubo yokulungisa iimpazamo:

1. Ukugxila kunye nokulungiswa kobukhali be-laser beam: Lungisa ukugxila kunye nobukhali be-laser beam ukuze ufumane isiphumo esifanelekileyo sokuwelda. Eli nyathelo lifuna ukulinganiswa okuchanekileyo nokucokisekileyo ukuqinisekisa ukuwelda okuchanekileyo.

2. Ukulungiswa kokuchaneka kokushukuma kwesakhiwo soomatshini: Lungisa ukuchaneka kokushukuma kwesakhiwo soomatshini ukuze kupheliswe ukungangqinelani okanye ukungachaneki. Eli nyathelo libalulekile ekufezekiseni ukushintshwa okuchanekileyo nokulinganayo.

Inkqubo yokusebenza

Ukuqinisekisa ukusebenza okukhuselekileyo nokufanelekileyo, kufuneka kulandelwe iinkqubo zokusebenza ezichanekileyo. La manyathelo alandelayo achaza indlela eqhelekileyo yokusebenza kwerobhothi yokuwelda nge-laser:

1. Qala ukulungiselela: Ngaphambi kokuba uqalise irobhothi yokuwelda nge-laser, yenza uhlolo olucokisekileyo lwazo zonke izinto kunye noqhagamshelo ukuqinisekisa ukuba zisebenza kakuhle. Jonga naziphi na iingozi okanye ukungasebenzi kakuhle.

2. Ukulungiswa komqadi welaser: Lungisa ngononophelo iiparameter zomqadi welaser ngokweemfuno zomqadi welaser. Qinisekisa ukuba ukugxila, ubunzulu, kunye nezinye izicwangciso ziyahambelana nemigaqo yomqadi welaser efunekayo.

3. Ulawulo lwenkqubo yokuwelda: qalisa inkqubo yokuwelda ngokweemfuno ezithile. Jonga kwaye ulawule iiparameter zokuwelda kulo lonke ixesha lokusebenza ukuze ufumane ukuwelda okuchanekileyo nokungaguquguqukiyo.

4. Ukucima: Emva kokugqiba inkqubo yokudibanisa, sebenzisa uthotho lweenkqubo zokuvala ukucima ngokukhuselekileyo amandla erobhothi yokudibanisa i-laser. Oku kuquka ukuqinisekisa iinkqubo ezifanelekileyo zokupholisa kunye nokulawula ukucima.

Izinto eziqwalaselwayo kukhuseleko

Xa usebenzisa irobhothi yokuwelda nge-laser, ukhuseleko kufuneka lube phambili ukuthintela ukonakala kubasebenzi nakwizixhobo. Umqadi we-laser osetyenziswa kule nkqubo unokuba yingozi ukuba awuphathwanga kakuhle. Ke ngoko, kubalulekile ukunamathela kule migaqo yokhuseleko ilandelayo:

1. Izixhobo zokuzikhusela zobuqu (PPE): Qinisekisa ukuba bonke abasebenzi ababandakanyekayo kulo msebenzi banxiba iiPPE ezifanelekileyo, kuquka neeglasi zokhuseleko ezine-laser ethile kunye nezinye izixhobo ezifunekayo.

2. Ikhaka lelaser beam: Nika indawo yokusebenza evalekileyo ngokufanelekileyo yerobhothi yokuwelda ngelaser enezinto ezifanelekileyo zokukhusela ukuthintela ukuvezwa ngengozi kwelaser beam.

3. Ukuma kwiNgxamiseko: Faka iqhosha lokuma kwingxamiseko elilula ukulisebenzisa kwaye ulenze liqheleke kubo bonke abaqhubi. Oku kungasetyenziswa njengenyathelo lokhuseleko xa kukho ingozi okanye ukuphazamiseka kwengxamiseko.

4. Ukugcinwa kwezixhobo rhoqo: Misela isicwangciso sokugcinwa kwemihla ngemihla ukuqinisekisa ukuba irobhothi yokuwelda nge-laser ikwimeko yokusebenza eqhelekileyo. Jonga kwaye ucoce zonke iindawo zerobhothi rhoqo, kuquka iinkqubo ze-laser, izakhiwo zoomatshini, iinkqubo zolawulo, njl.

Ukuququmbela

Incwadi Yokusebenza Yerobhothi YokuWela NgeLaser sisixhobo esibalulekileyo kubasebenzisi bezixhobo ezizenzekelayo ezisebenzisa imisebe yelaser kwimisebenzi yokuwela echanekileyo nesebenzayo. Ngokunika ingqalelo kumanyathelo okufakela, iinkqubo zokugunyazisa kunye neenkqubo zokusebenza ezichazwe kule ncwadi, abasebenzisi banokwandisa amandla eerobhothi zokuwela ngelaser kumashishini ahlukeneyo. Ukubeka phambili ukhuseleko kunye nokulandela isikhokelo esibonelelwe kule ncwadi kubalulekile kwimpilo-ntle yabasebenzi kunye nexesha elide lezixhobo. Ngezibonelelo zokusebenza kakuhle, ukuchaneka okuphezulu kunye nokuwela okusemgangathweni ophezulu, iirobhothi zokuwela ngelaser ziyaqhubeka nokuvelisa iinkqubo zokuwela kwaye zinegalelo kwinkqubela phambili yokwenziwa kweemoto, i-aerospace, i-elektroniki kunye nezinye iinkalo.

Ixesha lokuthumela: Novemba-22-2023