Iteknoloji yokucoca nge-laser yiteknoloji entsha yokucoca eye yaphuhliswa ngokukhawuleza kwiminyaka eli-10 edlulileyo. Iye yathatha indawo yeenkqubo zokucoca zemveli kwiindawo ezininzi ngeenzuzo zayo kunye nokungathathelwa indawo. Ukucoca nge-laser kungasetyenziselwa ukucoca ukungcola kwezinto eziphilayo kuphela, kodwa nokucoca izinto ezingaphiliyo, kubandakanya umhlwa wesinyithi, amasuntswana esinyithi, uthuli, njl. Ezinye zezicelo ezisebenzayo zichazwe ngezantsi. Ezi teknoloji zivuthiwe kakhulu kwaye zisetyenziswa kakhulu.

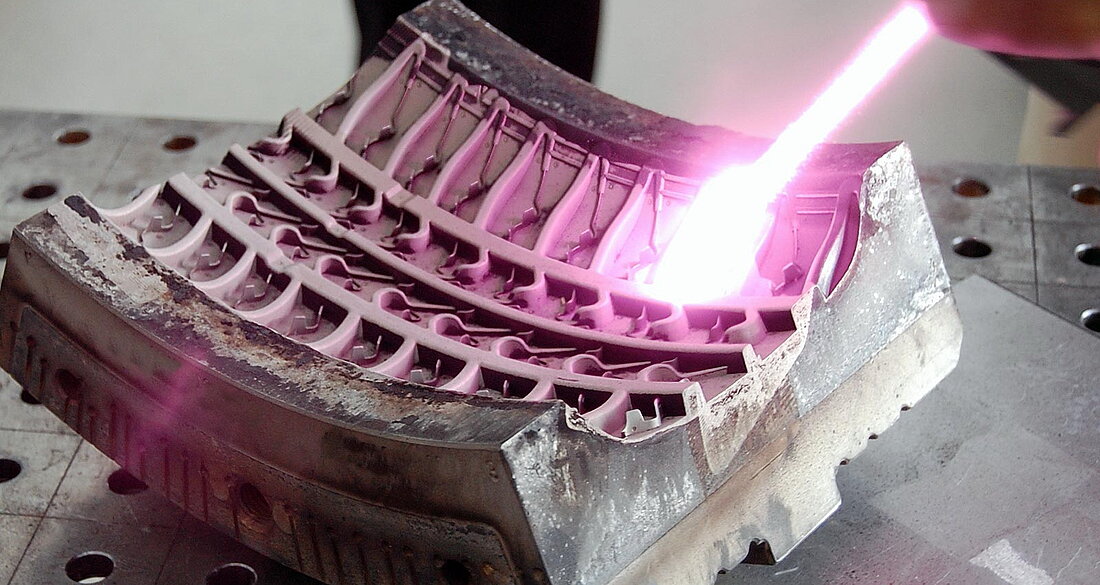

Abavelisi bamathayi kwihlabathi liphela benza amakhulu ezigidi zamatayara minyaka le, kwaye ukucocwa kweenkuni zamatayara ngexesha lenkqubo yemveliso kufuneka kukhawuleze kwaye kuthembeke ukuze kongiwe ixesha lokungasebenzi. Iindlela zokucoca zemveli ziquka ukuqhumisa isanti, ukucoca nge-ultrasound okanye nge-carbon dioxide, njl.njl., kodwa ezi ndlela zihlala kufuneka zifuduselwe kwizixhobo zokucoca emva kokuba inkuni eshushu kakhulu ipholile iiyure ezininzi, nto leyo ethatha ixesha elide kwaye yonakalisa ngokulula ukuchaneka kwenkuni. , izinyibilikisi zeekhemikhali kunye nengxolo nazo ziya kubangela iingxaki ezifana nokhuseleko kunye nokukhuselwa kwendalo.

Ukusebenzisa indlela yokucoca nge-laser, kuba i-laser inokudluliselwa yi-optical fiber, iguquguquka kakhulu xa isetyenziswa; kuba indlela yokucoca nge-laser inokudityaniswa ne-optical fiber ukukhokela ukukhanya kwikona efileyo yesikhunta okanye kwiindawo ezingelula ukuzicoca, ngoko ke kulula ukuzisebenzisa; Akukho gasification, ngoko ke akukho gesi inetyhefu iya kuveliswa, nto leyo eya kuchaphazela ukhuseleko lwendawo yokusebenza.

Itekhnoloji yokucoca ii-molds zamatayara nge-laser isetyenziswa kakhulu kwishishini lamatayara eYurophu nase-United States. Nangona iindleko zokuqala zotyalo-mali ziphezulu, iingenelo ezifumaneka ekongeni ixesha lokulinda, ukuphepha umonakalo we-mold, ukhuseleko lokusebenza kunye nokonga izinto eziluhlaza zinokubuyiselwa ngokukhawuleza.

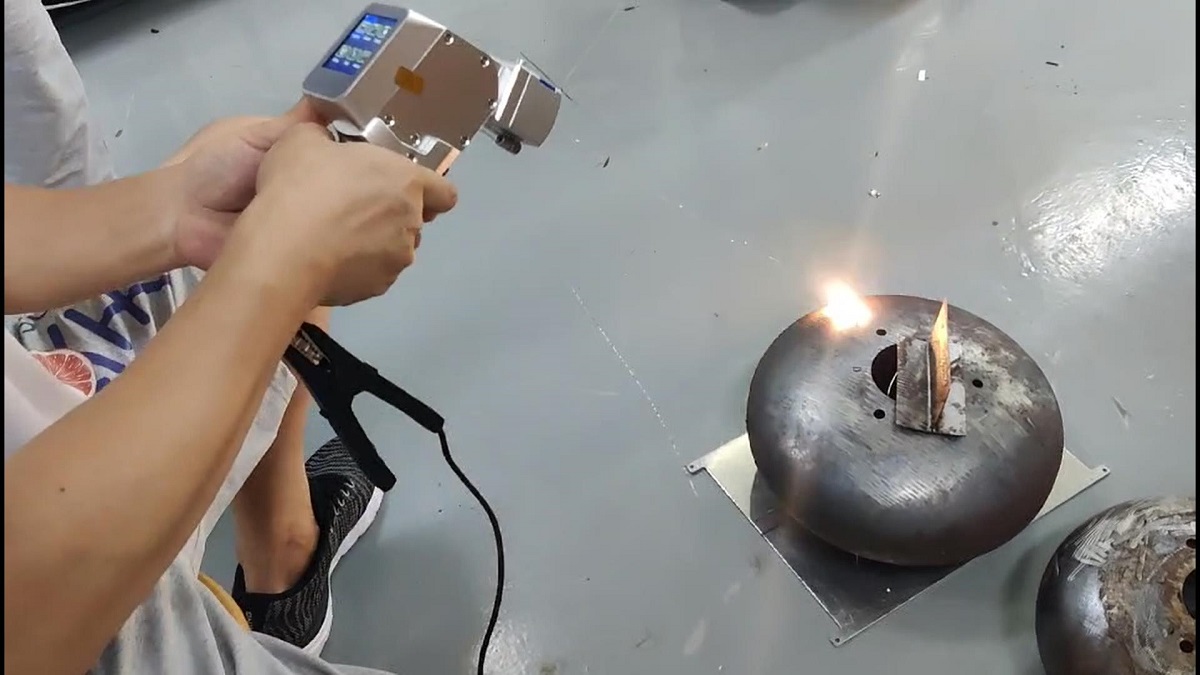

Njengokuba kunjalo ngokucoca iintsimbi, ukususwa kwelaser kwiiseramikhi kusebenza ngokukhanyisela ungcoliseko lomphezulu ngamawaka eepulses zelaser ngomzuzwana. Le nkqubo ikhuselekile kumaleko weseramikhi we-substrate kwaye ayidali nkunkuma ingako - edla ngokubanjwa yi-nozzle ye-suction eyakhelwe ngaphakathi yelaser.

Njengakwezinye iindlela zokucoca nge-laser, isitshixo sempumelelo yokucoca nge-ceramic sisisombululo se-laser esilinganiswe kakuhle. Ufuna inkqubo ye-laser enokufikelela kumda wokukhupha ofunekayo ekucoceni iileya ezingcolisayo ngaphandle kokonakalisa iimveliso ozicocayo. Ke ngoko, ukukhetha i-laser eneinqanaba lamandla elifanelekileyo, useto, i-optics, kunye nenkqubo yokuhambisa izinto zibalulekile. Ngethamsanqa,iingcali zethu zelaserYiba nolwazi lokuqinisekisa ukuba uhlala une-laser efanelekileyo kulo msebenzi.

3. Ukucocwa kwepeyinti yeenqwelo-moya ezindala

Iinkqubo zokucoca nge-laser bezisetyenziswa ixesha elide kushishino lweenqwelo moya eYurophu. Umphezulu wenqwelo moya kufuneka upeyintwe kwakhona emva kwexesha elithile, kodwa ipeyinti endala yokuqala kufuneka isuswe ngokupheleleyo ngaphambi kokuba ipeyintwe. Indlela yendabuko yokususa ipeyinti ngoomatshini kulula ukuyonakalisa umphezulu wesinyithi wenqwelo moya, nto leyo ebangela iingozi ezifihlakeleyo ekubhabheni ngokukhuselekileyo. Ukusebenzisa iinkqubo ezininzi zokucoca nge-laser, ipeyinti ingasuswa ngokupheleleyo kwi-A320 Airbus kwiintsuku ezimbini ngaphandle kokonakalisa umphezulu wesinyithi.

4. Ukucocwa kweendonga zangaphandle zesakhiwo

Ngenxa yophuhliso olukhawulezileyo loqoqosho lwelizwe lethu, kuye kwakhiwa izakhiwo ezinde ezinde, kwaye ingxaki yokucoca iindonga zangaphandle zezakhiwo iye yanda kakhulu. Inkqubo yokucoca nge-laser inika isisombululo esilungileyo sokucoca iindonga zangaphandle zezakhiwo ngokusebenzisa iifayibha ze-optical. Ingakwazi ukucoca ngokufanelekileyo ukungcola okuhlukeneyo kwilitye ezahlukeneyo, isinyithi kunye neglasi, kwaye ukusebenza kakuhle kuphezulu kakhulu kunokucoca okuqhelekileyo. Ingasusa namabala amnyama kunye namabala kwizinto ezahlukeneyo zelitye zezakhiwo.

Ishishini le-elektroniki lifuna ukucoca ngokucokisekileyo, kwaye lifanelekile ngokukodwa ekucoceni nge-laser. Iiphini zecandelo kufuneka zisuswe ngokupheleleyo ngaphambi kokuba kufakwe i-solder yebhodi ukuqinisekisa unxibelelwano olufanelekileyo lombane ngaphandle kokonakalisa iiphini ngexesha lenkqubo yokucoca. Ukucocwa nge-laser kunokuhlangabezana neemfuno zokusetyenziswa, kwaye ukusebenza kakuhle kuphezulu kakhulu, kwaye iphini enye kuphela ekufuneka ikhanyiswe nge-laser.

6. Ukucocwa ngokuchanekileyo kwe-desterification kwishishini lezixhobo ezichanekileyo

Ishishini loomatshini abachanekileyo lidla ngokufuna ukususa ii-esters kunye neeoyile zeminerali ezisetyenziselwa ukuthambisa kunye nokumelana nokugqwala kwiindawo ezithile, ngokuqhelekileyo ngokweekhemikhali, kwaye ukucoca ngeekhemikhali kudla ngokushiya amasalela. Ukususwa kwee-ester nge-laser kunokususa ngokupheleleyo ii-esters kunye neeoyile zeminerali ngaphandle kokonakalisa umphezulu weendawo. Ukususwa kwezinto ezingcolisayo kwenziwa ngamaza othuko, awenziwa yi-gasification eqhumayo yomaleko we-oxide obhityileyo kumphezulu weendawo, nto leyo ebangela ukususwa kwezinto ezingcolisayo endaweni yokusebenzisana kweendawo. Izinto zisuswa ngokupheleleyo ukuze kucocwe iindawo zemishini kwishishini leenqwelo-moya. Ukucoca nge-laser kungasetyenziselwa ukususwa kweoyile kunye nee-ester ekucutshungulweni kweendawo zemishini.

7. Ukucocwa kwemibhobho yereactor yesikhululo samandla enyukliya

Iinkqubo zokucoca nge-laser zikwasetyenziswa ekucoceni imibhobho kwii-reactors zesityalo samandla enyukliya. Isebenzisa iifayibha ze-optical ukufaka imisebe ye-laser enamandla aphezulu kwi-reactor ukususa ngokuthe ngqo uthuli olune-radioactive, kwaye izinto ezicociweyo kulula ukuzicoca. Kwaye ngenxa yokuba isebenza kude, ukhuseleko lwabasebenzi lunokuqinisekiswa.

Ngamafutshane, ukucocwa nge-laser kudlala indima ebalulekileyo kwiinkalo ezininzi, kwaye kusetyenziswa ekuveliseni iimoto, ekucoceni ii-wafer ze-semiconductor, ekucutshungulweni nasekuveliseni iindawo ezichanekileyo, ekucoceni izixhobo zomkhosi, ekucoceni udonga lwangaphandle lwesakhiwo, ekukhuseleni iintsalela zenkcubeko, ekucoceni iibhodi zesekethe, ekucutshungulweni nasekuveliseni iindawo ezichanekileyo, ekucoceni nasekuboniseni izinto ezibonisa ulwelo, ekususeni intsalela yetshungama kunye nezinye iindawo kunokudlala indima ebalulekileyo.

Ukusetyenziswa kokucoca nge-laser kwizixhobo zokhuselo lwesizwe nezomkhosi: njengokukrazula ipeyinti kunye nokususa umhlwa kwiinqwelo-moya ezahlukeneyo, izixhobo ezahlukeneyo zeenqanawa, ukususwa komhlwa kwezixhobo zezixhobo ezahlukeneyo, ukususwa komhlwa kweenqwelo-moya ezahlukeneyo kunye nee-artillery, ukususwa komhlwa kweendawo ezahlukeneyo, njl. njl., ngamathuba abanzi, umkhwa wophuhliso unamandla amakhulu. Ngokukodwa, ukucoca nge-laser kuneengenelo ezicacileyo ezifana nokukhuselwa kwendalo, ukulula, ukhuseleko, kunye nokusetyenziswa ngexabiso eliphantsi. Yiteknoloji entsha, esebenzayo nekhuselekileyo yenkqubo.

Ukuba unezicelo ezininzi ofuna ukuzivavanya ukuba umatshini wokucoca nge-laser ungasetyenziswa na, nceda unxibelelane nathi nge-WhatsApp okanye nge-imeyile! I-Fortune laser iya kukunika inkxaso yobugcisa kunye noomatshini ababalaseleyo.

Ixesha lokuthumela: Agasti-26-2022