Umatshini wakho wokuwelda nge-laser uyinto enamandla kwaye utyalo-mali olukhulu. Kodwa ixesha lokungasebenzi elingalindelekanga, ukusebenza okungaguqukiyo, kunye nokungaphumeleli kwangaphambi kwexesha kunokuguqula loo nto ibe yingxaki enkulu. Iindleko zokutshintsha umthombo we-laser okanye i-critical optics zinokuba nzima kakhulu.

Kuthekani ukuba ungayandisa kakhulu ubomi bayo obuvelisayo, uqinisekise umgangatho ohambelanayo kwaye uphucule imbuyekezo yakho kutyalo-mali? Ayisiyonto ibalulekileyo kwithamsanqa; imalunga neqhinga. Esi sikhokelo sibonelela ngesakhelo esibanzi sokwandisa ubomi bomatshini wakho wokuwelda nge-laser, sigubungela yonke into ukusuka kulondolozo lwemihla ngemihla ukuya kucwangciso lwesicwangciso sexesha elide.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

Ixesha Eliqhelekileyo Lobomi: Umatshini ogcinwe kakuhle uhlala iiyure ezili-10,000 ukuya kwezingama-30,000, kodwa oku kunokwandiswa kakhulu ngononophelo olufanelekileyo.

Iintsika Eziphambili Zokuphila Ixesha Elide: Ubomi bomatshini buxhomekeke kwiindawo ezine ezibalulekileyo: Indawo yokusebenza, Iipateni Zokusetyenziswa, Ukuqina Kokugcinwa, kunye Nesakhono Sokusebenza.

Ezona Zisongelo Zinkulu Kumatshini Wokuwelda NgeLaser: Iintshaba eziphambili zomatshini wakho bubushushu obugqithisileyo, uthuli, ukufuma okuphezulu, amandla angaguqukiyo, kunye nokusebenza rhoqo ngaphaya kwamandla awo alinganiselweyo.

Ingakanani I-Avareji Yobomi Bomatshini Wokuwelda Nge-Laser?

Umatshini wokuwelda we-laser ogcinwe kakuhle ngokubanzi unobomi benkonzo obuqikelelwayo beeyure ezili-10,000 ukuya kwezingama-30,000 zokusebenza. Nangona kunjalo, olu luqikelelo olubanzi. Njengoko sele sixoxile, izinto ezifana nokugcinwa ngononophelo kunye neemeko ezifanelekileyo zokusingqongileyo zinokuchaphazela kakhulu ukuba umatshini wakho usebenza kwinqanaba elisezantsi okanye eliphezulu kolu luhlu—okanye ude udlule kakhulu kulo.

Ngenxa yokuqhubela phambili kwezobuchwepheshe, imithombo emininzi ye-fiber laser yanamhlanje nesemgangathweni ophezulu ngokwayo idla ngokuphila ubomi obumangalisayo obumalunga neeyure ezili-100,000. Kodwa ubude bomatshini buxhomekeke kwimpilo esebenzayo yazo zonke izinto zayo ezidityanisiweyo, kungekuphela nje komthombo.

Izinto ezi-6 ezichaphazela ngokuthe ngqo ubude bomatshini

Ukuqonda izinto ezibangela uxinezeleko kukunika amandla okusebenzisa amanyathelo okuthintela asebenzayo.

1. Indawo yokusebenza

Ii-elektroniki ezibuthathaka kunye ne-optics ezithambileyo zichaphazeleka kakhulu yindawo ezikuyo.

Ubushushu kunye nokufuma: Amaqondo obushushu agqithisileyo abangela uxinzelelo kumacandelo, ngelixa ukufuma okuphezulu kunokubangela ukufuma okubolayo. Umzekelo, ukwehla ngequbuliso kobushushu kunokubangela ukufuma kwi-optics yangaphakathi, okukhokelela kumonakalo ongunaphakade.

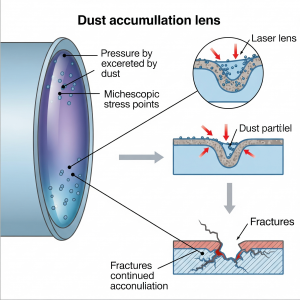

Ucoceko: Uthuli kunye nenkunkuma ephuma emoyeni zizinto ezibulala abantu ngaphandle kwelizwi. Zinokuhlala kwiilensi, nto leyo ebangela ukuba umqadi welaser uphelelwe ngamandla, okanye uvale amaphiko okupholisa, nto leyo ekhokelela ekutshiseni kakhulu nasekungasebenzini kwenxalenye.

2. Ukuphindaphinda kokusetyenziswa kunye nomthwalo wokusebenza

Indlela oyisebenzisa ngayo le matshini ngamandla iyayichaphazela ngokuthe ngqo isantya sokuguguleka kwayo.

Ukusetyenziswa Kakhulu: Ukusebenzisa umatshini rhoqo ngaphandle kokuphazamiseka ngokwaneleyo kukhokelela kuxinzelelo olukhulu lobushushu kunye nokuguguleka okukhawulezileyo komthombo welaser kunye nenkqubo yokupholisa.

Imithwalo Egqithisileyo: Ukusebenza rhoqo kumthamo ophezulu okanye kufutshane nomthamo ophezulu kubeka uxinzelelo olukhulu loomatshini kwiindawo ezihambayo. Yiyo loo nto ukuqonda umjikelo womsebenzi womatshini wakho—ixesha eliphezulu lokusebenza kumandla athile okukhupha—kubalulekile.

3. Uzinzo lweCandelo le-elektroniki

Ukuthembeka kokusebenza kwenkqubo yokuwelda nge-laser kunxulunyaniswa nokuzinza kwezinto zayo ze-elektroniki. Iibhodi zolawulo, izixhobo zamandla, kunye neesekethe zomqhubi ziphantsi kokonakala ngenxa yezinto ezininzi ezinokuchaphazela ngokuthe ngqo ukusebenza, ukuchaneka, kunye nobomi benkqubo.

Uxinzelelo lobushushu: Ukujikeleza kobushushu kunye nobushushu obuhlala buhleli kubangela uxinzelelo kwiindawo zokudibanisa kwaye kukhawulezise ukonakala kwezinto ezifana nee-capacitors, okuphazamisa uzinzo lwenkqubo kunye nolawulo lwamandla.

Ukuphela koBomi kweCandelo: Zonke izinto zinobomi obungapheliyo. Ukonakala kwezinto okungenakuphepheka kukhokelela ekutshintsheni kokusebenza, iimpazamo ezingapheliyo, kunye nokusilela kwenkqubo ekugqibeleni, okufuna icebo lokutshintsha elisebenzayo.

4. Amandla oMbane angaZinzanga

Izixhobo zakho ze-elektroniki ezibuthathaka zomshiseli we-laser azikwazi ukuzikhusela kumbane ongaguqukiyo. Ukunyuka kwamandla, ukuwohloka, kunye nokunye ukuguquguquka kombane kunokubangela umonakalo kwiibhodi zolawulo kunye nomthombo wamandla, okukhokelela ekuqhekekeni ngequbuliso okanye kumonakalo ofihlakeleyo onciphisa ubomi bazo. Ukubonelela ngombane ozinikeleyo nocwangcisiweyo ngobuchwephesha akuyonto yongezelelweyo—yimfuneko esisiseko yokukhusela impahla yakho kunye nokuqinisekisa ukusebenza okuthembekileyo.

5. Yamkela icebo lokulungisa elisebenzayo

Indlela "yokulungisa xa iphukile" yenye yezona ndlela zikhawulezayo zokunciphisa ubomi bomshiseli wakho. Isicwangciso sokulungisa esicwangcisiweyo nesisebenzayo senzelwe ukubamba nokusombulula iingxaki ezincinci, njengesihluzo esingcolileyo okanye isitywina esigugileyo, ngaphambi kokuba zingene kwintlekele enkulu. Oku kuqikelela kwangaphambili akuthinteli nje kuphela ukulungiswa okubizayo, okungxamisekileyo kunye nexesha lokungasebenzi elicwangcisiweyo kodwa kunciphisa kakhulu iindleko zizonke zobunini bomatshini ebomini bawo.

6. Izakhono zoMsebenzi kunye noQeqesho

Kwanomatshini oqinileyo kakhulu usengozini yeempazamo zabantu. Umsebenzisi osebenzisa rhoqo iiparameters ezingalunganga, ongazinaki izilumkiso zenkqubo, okanye ophatha kakubi izinto ezibonakalayo ezibuthathaka anokubangela ngokuthe ngqo ukuguguleka okukhawulezileyo okanye kwanokonakala kwangoko. Uqeqesho olufanelekileyo lokusebenza kunye nokunamathela kwiMigqaliselo yokuSebenza eMigangatho (ii-SOP) kubalulekile. Uqeqesho olupheleleyo luguqula abasebenzi bakho babe ngumgca wokuqala wokuzikhusela, lubanika amandla okuqhuba umatshini ngokufanelekileyo nangokukhuselekileyo ngelixa bekhulisa ubomi bawo benkonzo.

Isikhokelo seNyathelo ngeNyathelo sokwandisa ixesha lobomi bakho bokuWelda ngeLaser

Inyathelo 1: Yenza Indawo Efanelekileyo Yokusebenza

Ubushushu boLawulo kunye nokufuma: Gcina imeko-bume izinzile, ngesiqhelo phakathi kwe-15℃ kunye ne-30℃ (59℉ kunye ne-86℉), kunye nokufuma okungaphantsi kwe-70%.

Qinisekisa ukuba umoya ucocekile: Sebenzisa umoya ococekileyo kwaye ucinge ngeenkqubo zokucoca umoya eziphucukileyo, ingakumbi kwiindawo zoshishino, ukukhusela izinto ezibonakalayo kunye ne-elektroniki eluthulini.

Inyathelo lesi-2: Phumeza uCwangciso loSetyenziso oluCwangcisiweyo

Kuphephe Ukusebenza Ngamandla Aphezulu Okuqhubekayo: Vumela amaxesha okuphola acwangcisiweyo okanye imisebenzi enamandla kakhulu ukuze unciphise uxinzelelo lobushushu. Cinga ngayo njengokulungisa injini yemoto—ayenzelwanga ukusebenza kakuhle okuqhubekayo.

Sebenzisa Ngokusebenza Okulinganiselweyo: Soloko uhlonipha iiparameters eziyilwe ngumatshini kunye nomjikelo womsebenzi ukuze uthintele uxinzelelo olugqithisileyo kwiindawo zoomatshini nezombane.

Inyathelo lesi-3: Zibophelele kwiShedyuli yoLondolozo oluQhubekekileyo

Ukucocwa nokuthambisa rhoqo: Coca rhoqo izinto ezibonakalayo (iilensi, izibuko) ngezisombululo ezivunyiweyo kwaye uthambise iindawo ezihambayo (iireyili ezikhokelayo, iibheringi) ukuze unciphise ukungqubana.

Ukutshintshwa kweCandelo eliSebenzayo: Musa ukulinda ukuba iindawo ziqhekeke. Misela ishedyuli yokutshintsha izinto ezisetyenziswayo ezisengozini njengezihluzo kunye nezitywino ngokusekelwe kwiingcebiso zomenzi. Ixabiso lokutshintsha rhoqo inxalenye esetyenziswayo, nokuba yifestile ekhanyayo okanye isihluzo samanzi, lincinci kakhulu xa lithelekiswa nexabiso lokusilela okukhulu elilungiselelwe ukuthintela.

Inyathelo lesi-4: Tyala imali kuQeqesho lwabaSebenzi kunye neNkxaso yeeNgcali

Uqeqesho Olupheleleyo Lomqhubi: Abaqhubi abanezakhono abaziqondayo izakhono zomatshini, useto olufanelekileyo lweeparameter, kunye nokusombulula iingxaki ezisisiseko babaluleke kakhulu. Banciphisa uxinzelelo kumatshini kwaye bathintele umonakalo ongalindelekanga.

Sebenzisa uLondolozo lweeNgcali: Ukuze ufumane uxilongo oluntsonkothileyo, ulungelelwaniso, kunye nokulungiswa, thembela kwiingcali ezingoochwephesha. Ukulungiswa rhoqo kobuchwephesha kunokuchonga iingxaki ezincinci ngaphambi kokuba zibe ziingxaki ezinkulu.

Inyathelo lesi-5: Jonga rhoqo impilo yoomatshini

Sebenzisa ukuBeka esweni ukusebenza: Sebenzisa izixhobo ezikhoyo ukulandelela izalathisi ezibalulekileyo zempilo ezifana nombane we-laser, uzinzo lobushushu be-chiller, kunye neekhowudi zeempazamo. Iimatshini ezininzi zanamhlanje zibonelela ngoxilongo olusebenzisa i-IoT ukuze kugcinwe kwangaphambili.

Misela Uxilongo Lwempazamo Olukhawulezileyo: Yenza inkqubo ecacileyo yokuchonga nokulungisa iingxaki ngokukhawuleza. Isenzo esikhawulezileyo sinokuthintela iingxaki ukuba zingabi yingozi enkulu kwaye zingabi naxesha lokuphumla elaneleyo.

Inyathelo lesi-6: Cwangcisa uHlaziyo oluCwangcisiweyo kunye noPhuculo

Hlala Unolwazi Ngobuchwepheshe: Uhlaziyo lwesoftware lunokuphucula ukusebenza kakuhle nokusebenza, ngamanye amaxesha lwandise ubomi becandelo ngokusebenzisa ii-algorithms zolawulo ezilungisiweyo.

Vavanya Ukuphuculwa Kwezixhobo: Kufika ixesha apho ukuphucula umatshini omdala kubiza kakhulu kunokulungisa rhoqo. Cinga ngoku xa iindleko zokulungisa ziba nzima okanye iteknoloji entsha inika i-ROI enkulu.

Isiphelo: Khusela utyalo-mali lwakho kwiminyaka ezayo

Ukwandisa ubomi benkonzo yomatshini wakho wokuwelda nge-laser akungomsebenzi omnye womlingo; kukuthatha icebo elibanzi nelisebenzayo. Ngokulawula ngononophelo indawo yokusebenza kwawo, ukucwangcisa ukusetyenziswa kwawo ngononophelo, ukuzibophelela ekugcinweni kwawo ngononophelo, nokuqinisekisa ukuba abaqhubi bakho banobuchule obuphezulu, unokwandisa utyalo-mali lwakho, unciphise kakhulu ixesha lokungasebenzi elibizayo, kwaye uqinisekise ukuba umatshini wakho unikezela ngeziphumo ezisemgangathweni iminyaka emininzi enemveliso.

Imibuzo Ebuzwa Rhoqo (Imibuzo Ebuzwa Rhoqo)

Umbuzo 1: Umatshini wokuwelda nge-laser ufanele ulungiswe kangaphi?

A: Oku kuxhomekeke ekusetyenzisweni kwayo kunye nemeko yokusebenza. Umgaqo jikelele kukulandela amaxesha eenkonzo acetyiswayo ngumvelisi. Ukuhlolwa okubonakalayo kwemihla ngemihla ngumqhubi kubalulekile, ngenkonzo yobungcali ecokisekileyo eqhutywa rhoqo ngekota, kabini ngonyaka, okanye ngonyaka.

Umbuzo 2: Yeyiphi eyona nto ibiza kakhulu ukuyitshintsha kumatshini wokuwelda nge-laser?

A: Umthombo welaser uhlala uyinto enye ebiza kakhulu, idla ngokuba yinxalenye enkulu yexabiso lilonke lomatshini. Yiyo loo nto ukuyikhusela ekutshiseni kakhulu nasekungcoleni kubaluleke kakhulu.

Umbuzo 3: Ngaba uthuli lungonakalisa ngokwenene umthungi we-laser?

A: Ngokuqinisekileyo. Uthuli oluhlala kwilensi okanye kwisibuko esijongileyo lunokufunxa amandla elaser, okubangela ukuba ifudumale kwaye iqhekeke, itshise, okanye iqhekeke. Oku konakalisa i-optic ngokusisigxina kwaye kunciphisa kakhulu ukusebenza komatshini.

Umbuzo 4: Ngaba ukusebenzisa i-laser ngamandla aphantsi kuyandisa ubomi bayo?

A: Ewe. Ukusebenzisa umatshini rhoqo ngaphantsi komthamo wawo ophezulu kunciphisa uxinzelelo lobushushu nombane kuzo zonke izinto, ingakumbi umthombo welaser kunye nombane, nto leyo enokuba negalelo kwixesha elide lokusebenza.

Ngaba ufuna uncedo lokwenza isicwangciso sokulungisa izixhobo zakho? Nxibelelana neqela lethu leengcali zenkonzo namhlanje ukuze ufumane ingcebiso.

Ixesha leposi: Julayi-29-2025