Umatshini wokusika i-fiber laser sisixhobo esibalulekileyo sokusika ngokuchanekileyo kwishishini lokuvelisa. Nangona kunjalo, ukuze kufezekiswe umgangatho wokusika ofunekayo, iiparameter ezithile kufuneka ziqwalaselwe. Iiparameter ezichaphazela umgangatho wokusika ziquka ukuphakama kokusika, uhlobo lwe-nozzle, indawo yokugxila, amandla, i-frequency, umjikelo womsebenzi, uxinzelelo lomoya, kunye nesantya. Xa umgangatho wokusika womatshini wokusika i-fiber laser uphantsi, kucetyiswa ukuba kwenziwe uhlolo olupheleleyo kuqala. Eli nqaku liza kwazisa indlela yokuphucula iiparameter kunye neemeko zehardware zomatshini wokusika i-fiber laser ukuphuculaumgangatho wokusika.

Enye yeeparameter ezisisiseko ekufuneka ziqwalaselwe xa kusenziwa ngcono iiparameter zomatshini wokusika i-fiber laser kukuphakama kokusika. Ukuphakama kokusika ngumgama ophakathi kwe-nozzle yokusika kunye ne-workpiece. Ukuphakama kokusika okufanelekileyo kuxhomekeke kwizixhobo ezisikiweyo. Ukuseta ukuphakama kokusika okuchanekileyo kuqinisekisa ukuba umqadi we-laser ugxile kwizixhobo zokusika ngokuchanekileyo. Ngaphezu koko, uhlobo lwe-nozzle yokusika ludlala indima ebalulekileyo kwinkqubo yokusika. Ukukhetha uhlobo lwe-nozzle kuxhomekeke kwizixhobo ezisikiweyo kwaye kuchaphazela umgangatho wemveliso yokugqibela.

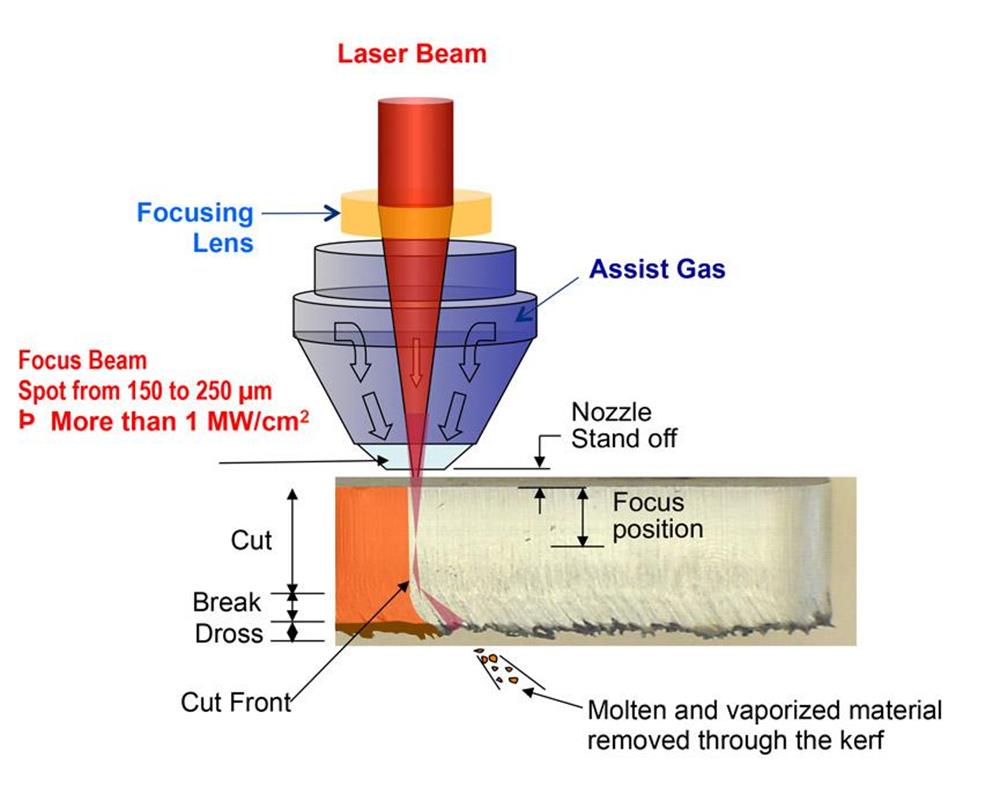

Enye iparameter ephambili yindawo yokugxila. Indawo yokugxila ngumgama ophakathi kwelensi kunye nendawo yokusebenza. Indawo yokugxila imisela ubungakanani kunye nokuma komqadi welaser. Indawo yokugxila ebekwe ngokufanelekileyo inegalelo ekucoceni imiphetho yokusika kwaye inciphisa isidingo sokuphathwa emva kokusika.

Amandla okusikakwaye i-frequency zezinye iiparameter ezichaphazela kakhulu umgangatho wokusika. Amandla okusika abhekisa kubungakanani bamandla aziswa kwizinto nge-laser beam. I-frequency, kwelinye icala, ibhekisa kwinani lee-laser pulses ezisiwa kwizinto ngeyunithi yexesha. Amandla okusika kunye ne-frequency kufuneka zilungiswe ngokufanelekileyo ukuze kufezekiswe ukusika okufunekayo. Amandla aphezulu kunye ne-frequency zinokubangela ukunyibilika okugqithisileyo kwezinto, ngelixa amandla aphantsi kunye ne-frequency zinokubangela ukusika okungaphelelanga.

Umjikelo womsebenzi ukwangumlinganiselo obalulekileyo ekufuneka uqwalaselwe xa kusenziwa ngcono iiparameters zeumatshini wokusika ifayibha nge-laserUmjikelo womsebenzi umisela umlinganiselo wexesha elivuliweyo yilaser kunye nexesha elivaliweyo yilaser. Umjikelo womsebenzi uchaphazela ubushushu bomqadi welaser kwaye kufuneka umiselwe ngokuchanekileyo ukuze kufezekiswe umgangatho wokusika ofunekayo. Umjikelo womsebenzi ophezulu ubangela ukwanda kokuveliswa kobushushu, okungagcini nje ngokunciphisa umgangatho wokusika, kodwa kunokonakalisa umatshini.

Ukunciphisa uxinzelelo lomoya yenye ipharamitha edla ngokungajongwa xa kulungiselelwaumatshini wokusika ifayibha nge-laserIiparameters. Uxinzelelo lomoya olusikiweyo luxinzelelo apho umoya ocinezelweyo uthunyelwa khona kwi-nozzle yokusika. Uxinzelelo lomoya olusikiweyo olufanelekileyo luqinisekisa ukuba inkunkuma yezinto ezisetyenzisiweyo iyaphephuka, nto leyo enciphisa amathuba omlilo kwaye iphucula umgangatho wokusika.

Okokugqibela, isantya sokusika sisantya apho umqadi welaser uhamba khona kwizinto. Ukulungisa isantya sokusika kunokuchaphazela kakhulu umgangatho wokusika. Isantya sokusika esiphezulu siya kubangela ukunqunyulwa okungaphelelanga, ngelixa isantya sokusika esiphantsi siya kubangela ukuba izinto zinyibilike.

Iimeko zehardware nazo zibalulekile ekufezekiseni umgangatho ogqwesileyo wokusika. Ii-optics ezikhuselayo, ubumsulwa begesi, umgangatho weplate, ii-condenser optics, kunye nee-collimating optics zezinye zeemeko zehardware ezinokuchaphazela kakhulu umgangatho wokusika.

Iilensi zokukhusela ziqinisekisa umgangatho wokuphuma komqadi welaser kwaye kufuneka zihlolwe rhoqo ukuba azinamonakalo okanye zingcoliseko. Ubunyulu begesi bubalulekile ekufezekiseni ukunqunyulwa okuchanekileyo. Ubunyulu begesi obuphezulu bunciphisa amathuba okungcoliseka kwaye kunciphisa isidingo seenkqubo ezongezelelweyo emva kokusika.

Umgangatho wephepha unefuthe kumgangatho wokusikwa. Amaphepha acwebezelayo adla ngokubonisa umqadi welaser nto leyo ebangela ukugqwetheka, ngelixa amaphepha arhabaxa enokubangela ukunqunyulwa okungaphelelanga. Iilensi zeCondenser kunye ne-collimator ziqinisekisa ukuba umqadi welaser ugxile ngokufanelekileyo kwizinto ezisetyenziswayo.ukusika okuchanekileyo.

Ukuqukumbela, ukuphucula iiparameter zomatshini wokusika i-fiber laser kunye neemeko zehardware kubalulekile ukuze kufezekiswe umgangatho ofanelekileyo wokusika. Ukuphakama kokusika, uhlobo lwe-nozzle, indawo yokugxila, amandla, i-frequency, umjikelo womsebenzi, uxinzelelo lomoya kunye nesantya zezinye zeparameter ekufuneka ziphuculwe. Iimeko zehardware ezifana neelensi zokukhusela, ubumsulwa begesi, umgangatho wepleyiti yokuprinta, iilensi zokuqokelela, kunye neelensi ze-collimating nazo kufuneka ziqwalaselwe. Ngokuphucula iiparameter ngokufanelekileyo, abavelisi banokuphucula umgangatho wokusika, banciphise imisebenzi yasemva kokusika kwaye bonyuse imveliso.

Ukuba ufuna ukufunda okungakumbi malunga nokusika nge-laser, okanye ufuna ukuthenga umatshini wokusika nge-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuthumela: Juni-09-2023