Ukukhetha phakathi kwesixhobo sokuwelda esiphathwa ngesandla kunye nesixhobo sokuwelda serobhothi sisigqibo esibalulekileyo esiya kuchaza icebo lakho lokusebenza. Oku akusiyo nje ukukhetha phakathi kwezixhobo; kukutyala imali kwifilosofi yemveliso. Impendulo echanekileyo ixhomekeke ngokupheleleyo kwinjongo yakho ephambili yeshishini: Ngaba ufuna ukuguquguquka okungenakuthelekiswa nanto kumsebenzi owenziwe ngokwezifiso, okanye ufuna isantya esingaguqukiyo kunye nokuchaneka kwemveliso yobuninzi ezenzekelayo?

Esi sikhokelo sibonelela ngesikhokelo esicacileyo sokukunceda wenze utyalo-mali oluphambili olucwangcisiweyo kwikamva lenkampani yakho.

Impendulo emfutshane: Ukuguquguquka kunye nomlinganiselo

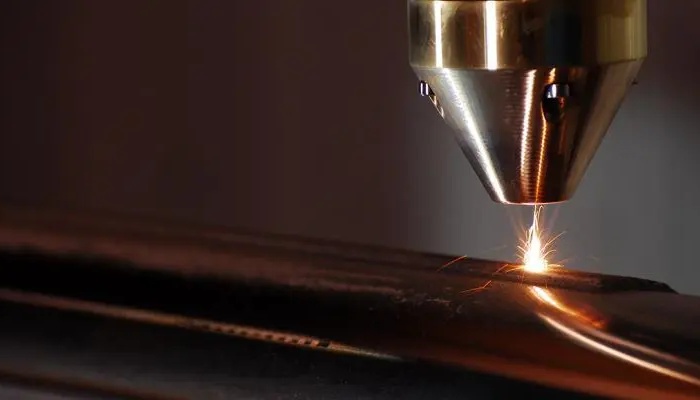

Abawelda beLaser abaphathwa ngesandlalukhetho oluchanekileyo kwiivenkile zemisebenzi, iinkonzo zokulungisa, kunye nabenzi bezinto ezenziwe ngokwezifiso. Ukuba umsebenzi wakho wemihla ngemihla ubandakanya umxube ophezulu wezinto ezahlukeneyo, imveliso ephantsi, okanye izinto ezinkulu nezinzima, ubuchule benkqubo ephathwayo bubalulekile.

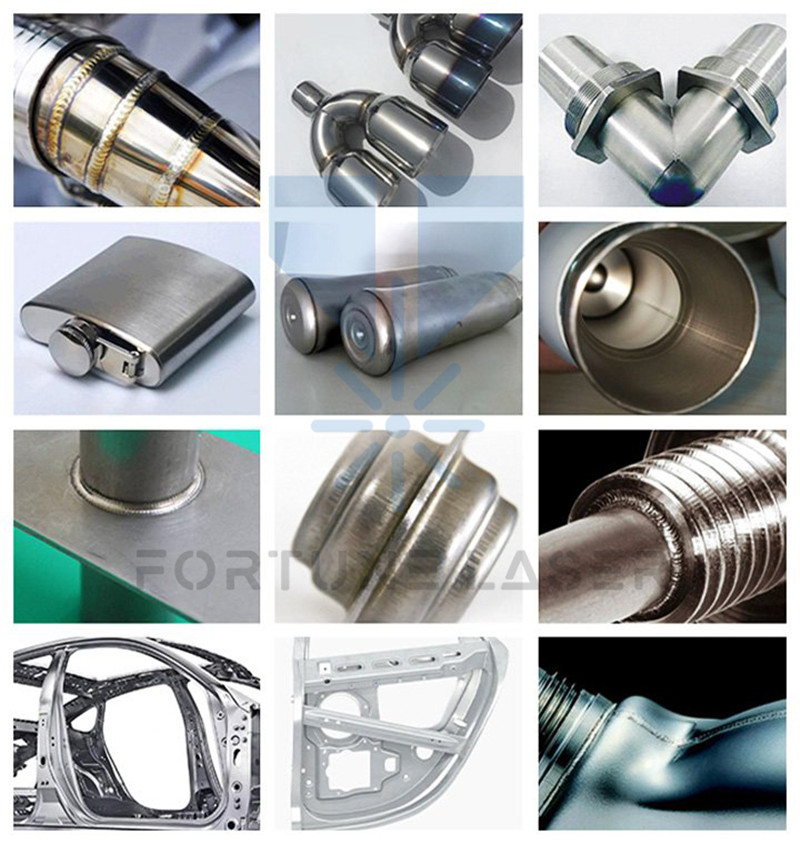

Abawelda beLaser yeRoboticzenzelwe ukwenziwa ngobuninzi obuphezulu, obuphindaphindwayo. Ukuba imodeli yeshishini lakho ixhomekeke kwisantya, ukuhambelana okugqibeleleyo, kunye nokwandisa imveliso kumashishini afana neemoto, i-aerospace, okanye izixhobo zonyango, inkqubo yerobhothi yindlela ebalulekileyo eya phambili.

Ukushwankathela: Inkqubo yesandla kunye neyerobhothi

| Uphawu | Umshiseli weLaser ophathwa ngesandla | Umthungi weRobotic Laser |

| Eyona ilungileyo | Ukwenziwa ngokwezifiso, iiprototypes, ukulungiswa, iindawo ezinkulu nezingaqhelekanga. | Imigca yemveliso enomthamo ophezulu, ephindaphindwayo kakhulu. |

| Inzuzo engundoqo | Ukuguquguquka Okugqibeleleyo kunye nokuThuthwa | Isantya esingalinganiyo, ukuchaneka kunye nokuphindaphinda |

| Uchaneko | Iphezulu, kodwa ixhomekeke kwisakhono somsebenzisi. | Iphezulu kakhulu kwaye ihambelana ngokugqibeleleyo. |

| Isantya | Khawuleza kwimisebenzi yabantu abangatshatanga. | Ukusebenza iiyure ezingama-24 ngosuku, iintsuku ezisixhenxe ngeveki. |

| Ixabiso lokuqala | Ephantsi ukuya kwePhakathi | Phezulu |

| Indima yoMsebenzi | Umqhubi onobuchule osebenza ngezandla. Kulula ukufunda iziseko, kunzima ukuzazi kakuhle. | Ingcali yeenkqubo kunye nengcali yeenkqubo enobuchule obuphezulu. |

| Utshintsho lomsebenzi | Kwangoko | Ingathabatha ixesha kwaye ifuna uhlengahlengiso lwenkqubo. |

Ityala Lokuguquguquka: Nini Ukukhetha I-Handheld Laser Welder

Umthungi we-laser ophathwa ngesandla unika amandla umqhubi onobuchule ngobuchule nangobuchule, nto leyo eyenza ukuba abe yintshatsheli yobuchule kwiworkshop yanamhlanje. Lukhetho olufanelekileyo xa imodeli yeshishini lakho yakhelwe phezu kokuguquguquka.

Imveliso yomxube ophezulu, enomthamo ophantsi:Iinkqubo eziphathwa ngesandla zisisiseko seevenkile zemisebenzi apho yonke iprojekthi yahlukile. Umsebenzisi angatshintsha ukusuka ekudibaniseni ikhawuntara yentsimbi engagqwaliyo eyenziwe ngokwezifiso ukuya ekulungiseni isikhunta esintsonkothileyo okanye enze iprototype ngaphandle kokutshintsha zobugcisa ngexesha.

Iijometri ezinkulu okanye ezintsonkothileyo:Inkululeko yetotshi ephathwayo iyimfuneko xa usebenza kwiindawo ezingenakungena kwindawo evalekileyo yerobhothi. Oku kuquka iiprojekthi ezinkulu ezifana neetanki zoshishino, itshasi yezithuthi ezenziwe ngokwezifiso, okanye umsebenzi wesinyithi woyilo.

Ukulungiswa nokufakelwa kwindawo:Ukuphatheka lula kweeyunithi ezininzi eziphathwayo kukuvumela ukuba ukwazi ukuzisa amandla okuwelda ngqo kwindawo yomsebenzi. Oku kutshintsha umdlalo xa kulungiswa oomatshini abanzima endaweni okanye kufakwa izinto zokwakha, kunciphisa ixesha lokungasebenzi kwabathengi kunye nemingeni yempahla.

Ityala lesikali: Ixesha lokukhetha iRobotic Laser Welder

I-robotic laser welder ayisiyonto nje yesixhobo—yinkqubo yemveliso edibeneyo eyenzelwe imveliso yomgangatho wemizi-mveliso. Yinjini yabavelisi ababeka phambili ukusebenza kakuhle, ukuhambelana, kunye nomthamo.

Ukuchaneka Okungaguqukiyo Nokuphindaphindwa:Kwimizi-mveliso apho ukusilela kungeyondlela ifanelekileyo, iinkqubo zerobhothi zibalulekile. Ngokususa ukuguquguquka kwabantu, zibonelela ngee-welds ezifanayo nezingenasiphako ngalo lonke ixesha. Oku kubalulekile kwii-implants zonyango, izinto ze-aerospace, kunye neendawo ze-elektroniki ezinobuthathaka.

Isantya esiphezulu:Irobhothi yenzelwe ukwenziwa “kwezibane ezicimayo” iiyure ezingama-24 ngosuku, iintsuku ezisi-7 ngosuku. Isebenza ngaphandle kokuphazamiseka okanye ukudinwa, inciphisa kakhulu amaxesha okujikeleza kwaye iphucula imveliso, nto leyo ibalulekileyo kwiindlela zokubonelela ngezixhobo ezininzi ezifana neemoto (iitreyi zebhetri ze-EV, iifreyimu) kunye nezixhobo ze-elektroniki zabathengi.

Ukunyaniseka kweWeld okuphezulu:Irobhothi inokugcina i-engile yetotshi ifanelekile, isantya sokuhamba, kunye nomgama wokuma, into engenakwenzeka ukuba umntu oyisebenzisayo ayenze rhoqo. Oku kubangela ukuba kubekho ii-welds ezinamandla, ezinzulu, nezifanayo ezineempawu ezingcono ze-metallurgical.

Ukuntywila Okunzulu: Iinyani Zezemali Nezobuchwephesha

Ukuze wenze isigqibo esinolwazi olupheleleyo, kufuneka ujonge ngaphaya kwesicatshulwa sokuqala kwaye uhlalutye impembelelo iyonke yezemali kunye nokusebenza.

Ukuqonda Ixabiso Elipheleleyo Lobunini (i-TCO)

Ixabiso lesitikha sisiqalo nje. I-TCO inika umfanekiso opheleleyo wexabiso lempahla ebomini bayo, ityhila inzuzo yayo yokwenyani.

1.Utyalo-mali Lokuqala (Inkcitho Yemali – CapEx)

Lo ngumahluko ocacileyo kwezemali.

Umthungi obanjwa ngesandla:Olu lungeniso olunexabiso eliphantsi kwi-laser welding, njengoko ngokuyintloko uthenga isixhobo esizimeleyo. Ixabiso libandakanya umthombo wamandla we-laser kunye nentloko ye-welding ephathwayo. Eli xabiso liphantsi kakhulu kwangaphambili lenza kube lukhetho olufikelelekayo kwiivenkile ezincinci, iinkampani ezintsha, okanye amashishini anebhajethi encinci yemali afuna ukongeza amandla amatsha.

Umthungi weRobhothi:Olu lutyalo-mali olukhulu kuba uthenga inkqubo yemveliso epheleleyo nedibeneyo. Ixabiso liphezulu kakhulu kuba alibandakanyi nje umthombo welaser, kodwa kunye nengalo yerobhothi ene-axis ezininzi, indawo yokhuseleko enyanzelekileyo, izixhobo zamalungu ezenziwe ngokwezifiso, kunye nobunjineli obuntsonkothileyo obufunekayo ukucwangcisa nokudibanisa zonke izinto zecandelo lakho elithile. Oku kwenza ukuba ibe sisigqibo esibalulekileyo sezemali esifanelekileyo kwimveliso ezinikeleyo neyimveliso eninzi.

2.Iindleko Zokusebenza (Iindleko Zokusebenza – OpEx)

Ezi ndleko ziqhubekayo zibalulekile ukuze kubekho inzuzo yexesha elide.

Umsebenzi:Le yeyona nto iphambili eyenza umahluko. Inkqubo ephathwayo ifuna umntu ozinikeleyo kuyo yonke imizuzu esebenza ngayo. Iseli yerobhothi, yakuba icwangcisiwe, inokusebenza ngononophelo oluncinci, nto leyo enciphisa kakhulu iindleko zomsebenzi ngenxalenye nganye.

Izinto ezisetyenziswayo kunye nezixhobo:Zombini ezi nkqubo zisebenzisa igesi yokukhusela, ii-nozzles, kunye nombane. Nangona kunjalo, inkqubo yerobhothi esebenza ngokuqhubekayo ngamandla aphezulu ngokwemvelo iya kuba namazinga aphezulu okusetyenziswa kune-welder ephathwayo esetyenziswa ngamaxesha athile.

3.Imbuyekezo yoTyalo-mali (i-ROI) kunye ne-"Crossover Point"

Olu balo luchaza ukuba xa umatshini obiza kakhulu uba ngowona unenzuzo ngakumbi.

Kwimisebenzi ephantsi, ixabiso eliphantsi lomatshini wokuwelda ophathwayo lenza ukuba kube nenzuzo engakumbi.

Njengoko umthamo wemveliso unyuka, "indawo yokudibanisa" ifikelelwa apho ukonga okuqokelelweyo emsebenzini kwinkqubo yerobhothi kudlula utyalo-mali lwayo lokuqala oluphezulu. Ngaphaya kweli nqanaba, yonke inxalenye eyenziwe kumgca werobhothi inenzuzo enkulu kakhulu. Kufuneka uqikelele ngokuchanekileyo umthamo wemveliso yakho ukuze ubone ukuba ungafikelela na kweli nqanaba lokudibanisa ngexesha elifanelekileyo.

Ukuhambelana kwezinto kunye neemfuno zamandla

Inzuzo ephambili ye-fiber lasers yanamhlanje—ephathwa ngesandla neyirobhothi—kukuba iyakwazi ukuwelda iintlobo ngeentlobo zesinyithi, kuquka:

Intsimbi Engagqwaliyo Intsimbi Yekhabhoni I-Aluminiyam I-Copper Titanium

Eyona nto ibalulekileyo kukulinganisa amandla elaser nohlobo lwezinto kunye nobukhulu bazo. Ilaser eyi-1 kW ukuya kwi-1.5 kW ilungile kakhulu kwiintsimbi ezinciphileyo, ngelixa iindawo ezityebileyo, ngakumbi kwiintsimbi ezikhanyayo ezifana ne-aluminium kunye nobhedu, zifuna amandla aphezulu kuluhlu lwe-2 kW ukuya kwi-3 kW okanye ngaphezulu ukuze isantya kunye nokungena kusebenze kakuhle.

Isiphelo: Ukwenza eyakhoSUkhetho olufanelekileyo

Isigqibo phakathi kwe-handheld laser welder kunye ne-robotic laser welder sisisombululo esibalulekileyo phakathi kokuguquguquka kunye nokuphindaphinda.

Khetha i-Handbald ukuba:Ishishini lakho lichazwa ngokwahluka, umsebenzi owenziwe ngokwezifiso, kunye nokuguquguquka. Kufuneka ulungelelanise ngokukhawuleza imisebenzi eyahlukeneyo kwaye ulawule ngononophelo utyalo-mali lwakho lokuqala lwemali.

Khetha iRobotic ukuba:Ishishini lakho ligxile ekwandiseni imveliso yezixhobo ezithile. Iinjongo zakho eziphambili kukufikelela kwisantya esiphezulu, ukuhambelana okugqibeleleyo, kunye nokunciphisa iindleko zomsebenzi zexesha elide.

Ngokuhlalutya ngononophelo ubunzima becandelo lakho, ubungakanani bemveliso, uhlahlo-lwabiwo mali, kunye neenjongo zeshishini lakho zexesha elide, ungenza utyalo-mali olunamandla oluya kuqhuba ukusebenza kakuhle kwenkampani yakho, umgangatho, kunye nokukhula kwayo iminyaka ezayo.

Ixesha lokuthumela: Agasti-04-2025