Iirobhothi zokuwelda nge-laserziye zaguqula icandelo lokuwelda ngokwazisa iimpawu eziphambili ezonyusa ukusebenza kakuhle kunye nemveliso. Ezi robhothi zibonelela ngemisebenzi eyahlukeneyo eyenza lula inkqubo yokuwelda, yonyusa ukuchaneka kwaye iqinisekise ukhuseleko oluphezulu. Eli nqaku lijolise ekujongeni amandla eerobhothi zokuwelda nge-laser, ligxininisa indima yazo ekwandiseni ukusebenza kakuhle kokuwelda kunye nokuzisebenzela ngokuzenzekelayo ngokupheleleyo. Siza kuphinda sihlolisise iinkcazo ezahlukeneyo zemveliso ezifana nomsebenzi wokujika, umsebenzi wokuzikhusela, umsebenzi wokuva ukuwelda, umsebenzi wokulwa nokungqubana, umsebenzi wokufumanisa iimpazamo, umsebenzi wokuwelda onamathelayo woqhagamshelwano lwentambo, umsebenzi wokuqalisa kwakhona ukuqhekeka kwe-arc.

1. Umsebenzi wokujika:

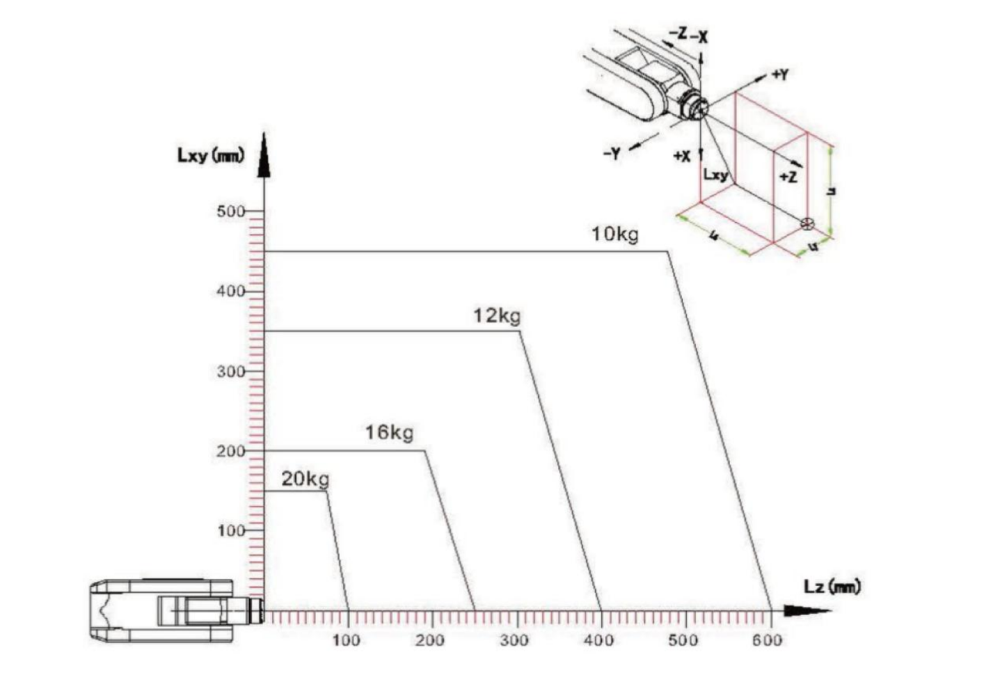

Enye yezona zinto zibalulekileyo zeirobhothi yokuwelda nge-laserngumsebenzi wayo wokushukuma. Olu phawu luvumela irobhothi ukuba ihambe ngentshukumo yokushukuma, igubungela indawo enkulu kuneendlela zemveli zokushukuma. Olu phawu lokushukuma luqinisekisa ukuba umqadi welaser ugubungela indawo ebanzi yomphezulu, nto leyo enciphisa ixesha lokushukuma elifunekayo kwiiprojekthi ezinkulu. Ngokwandisa indawo yokugubungela, uphawu lokushukuma lunceda ekufezekiseni imveliso ephezulu kunye nokusebenza kakuhle kwizicelo zokushukuma.

2. Umsebenzi wokuzikhusela:

Iirobhothi zokuwelda nge-laser zixhotyiswe ngeempawu zokuzikhusela ukuqinisekisa ukuba zihlala ixesha elide kwaye zithintele umonakalo onokubakho. Olu phawu lusebenza njengomqobo wokukhusela kwiimeko ezimbi ezifana nokushisa kakhulu, ukuphambuka kwevolthi okanye ukutshintsha kwamandla. Iimpawu zokuzikhusela zerobhothi azikhuseli nje kuphela izinto zayo zangaphakathi, kodwa zikwathintela nawuphi na umonakalo wangaphandle ovela kwiintlantsi zokuwelda okanye inkunkuma. Ngokugcina ukuthembeka kwayo, irobhothi inokubonelela rhoqo ngeziphumo zokuwelda ezisemgangathweni ophezulu kwaye yandise ubomi bayo.

3. Umsebenzi wokuva ukuwelda:

Amandla okubona ukuwelda yinxalenye ebalulekileyoiirobhothi zokuwelda nge-laser, ebanceda ukuba babone kwaye baphendule kutshintsho olukwimeko yokuwelda. Olu phawu lusebenzisa izinzwa eziphambili ukulinganisa ngokuchanekileyo izinto eziguquguqukayo ezifana nobukhulu bentsimbi, ulungelelwaniso lwamalungu kunye nobushushu bemozulu. Ngokuziqhelanisa nolu tshintsho ngexesha langempela, irobhothi yokuwelda iqinisekisa ukuwelda ngokuchanekileyo kwindlela efunekayo, nto leyo ekhokelela kumgangatho wokuwelda ongenasiphako kwaye inciphise isidingo sokulungiswa ngesandla.

4. Umsebenzi wokulwa nokungqubana:

Ukhuseleko lubaluleke kakhulu kuyo nayiphi na imeko-bume yemizi-mveliso, kwayeiirobhothi zokuwelda nge-laserzixhotyiswe ngeempawu zokulwa nokungqubana ukuze kuthintelwe ukungqubana okungabangela iingozi okanye umonakalo. Olu phawu lusebenzisa indibaniselwano yeenzwa, iikhamera, kunye ne-algorithms zesoftware ukubona imiqobo endleleni yerobhothi. Nje ukuba ifunyenwe, irobhothi ilungisa ngokuzenzekelayo indlela yayo ukuze iphephe ukungqubana. Olu phawu alukhuseli nje kuphela irobhothi ekonakaleni, kodwa lukwaqinisekisa ukhuseleko lwabasebenzi kunye nezixhobo ezikufutshane, lususa umngcipheko weengozi kunye nokulungiswa okubizayo.

5. Umsebenzi wokufumanisa iimpazamo:

Ukuze kuqinisekiswe ukusebenza kwe-welding okuqhubekayo nokungaphazanyiswa, irobhothi ye-laser welding inomsebenzi wokufumanisa iimpazamo. Olu phawu luhlala lujonga ukusebenza kwerobhothi, kuquka izinto ezifana neentambo, izixhobo zombane, kunye neenkqubo zokupholisa. Ngokuchonga ukungasebenzi kakuhle okanye ukungaphumeleli kwasekuqaleni, iirobhothi zingathatha amanyathelo okuthintela okanye zazise abaqhubi ngengxaki. Ukufumanisa kunye nokusombulula ukungaphumeleli kwangethuba kunokunceda ukwandisa ukusebenza kakuhle, ukunciphisa ixesha lokungasebenzi kunye nokunyusa imveliso.

6. Umsebenzi wokudibanisa ucingo olunamathelayo kunye nomsebenzi wokuqalisa kwakhona emva kokuqhekeka kwe-arc:

Uphawu olwahlukileyo lweerobhothi zokuwelda nge-laser kukukwazi ukuphatha oonxibelelwano beentambo ezinamathelayo kunye nokuqalisa kwakhona inkqubo yokuwelda ngaphandle kokuphazamiseka emva kokuqhekeka kwe-arc. Umsebenzi woqhagamshelwano lweentambo ezinamathelayo zokuwelda uvumela irobhothi ukuba iva kwaye ilungise unxibelelwano nocingo lokuwelda, iqinisekisa iziphumo ezilungileyo zokuwelda nakwiimathiriyeli ezinzima. Ukongeza, umsebenzi wokuqalisa kwakhona ukuqhekeka kwe-arc uvumela irobhothi ukuba iqalise ngokuzenzekelayo ukuwelda emva kokuphazamiseka okwethutyana ngaphandle kokungenelela komntu. Ezi mpawu zivumela ukuwelda okusemgangathweni ophezulu rhoqo, zinciphisa iziphene kwaye ziphucule ukusebenza kakuhle kokuwelda.

Ukuququmbela:

Iirobhothi zokuwelda nge-laserInika uninzi lweempawu eziphambili ezonyusa ukusebenza kakuhle kokuwelda kwaye ivumela ukwenziwa kwezinto ngokuzenzekelayo ngokupheleleyo kwiindlela ezahlukeneyo zokusebenza. Isici sokujika silungiselela ukugubungela okuchanekileyo nokukhawulezayo, ukwandisa imveliso. Ukuzikhusela, ukuva ukuwelda, ukulwa nokungqubana, ukufunyanwa kweempazamo kunye neminye imisebenzi kuqinisekisa ukusebenza okukhuselekileyo, okuchanekileyo nokuqhubekayo. Ukongeza, ukuwelda ucingo olunamathelayo kunye nemisebenzi yokuqalisa kwakhona ukuqhekeka kwe-arc kunceda ukuphucula umgangatho wokuwelda kunye nokusebenza kakuhle ngokubanzi. Ngokusebenzisa ezi zakhono ziphambili, iirobhothi zokuwelda nge-laser zitshintshe kakhulu intsimi yokuwelda, zenza abavelisi bakwazi ukufumana iziphumo eziphezulu zokuwelda ngokwandisa ukuwelda kunye nemveliso.

Ixesha lokuthumela: Agasti-03-2023