Ukuwelda nge-laser yindlela ethandwa kakhulu kwimveliso ngenxa yokuchaneka kwayo nokusebenza kwayo kakuhle. Enye yezona zinto ziphambili kumatshini wokuwelda nge-laser yinkqubo yokulandelela umthungo, eqinisekisa indawo echanekileyo ye-laser. Kweli nqaku, siza kuhlalutya iingenelo zokulandelela umthungo kwiimashini zokuwelda nge-laser kunye nendlela enokuphucula ngayo imveliso kunye nomgangatho wokuwelda. Siza kuxoxa nangeengenelo zokusebenzisa irobhothi enenkqubo yokulandelela umthungo nge-laser.

Indawo echanekileyo ixhomekeke kwi-laser

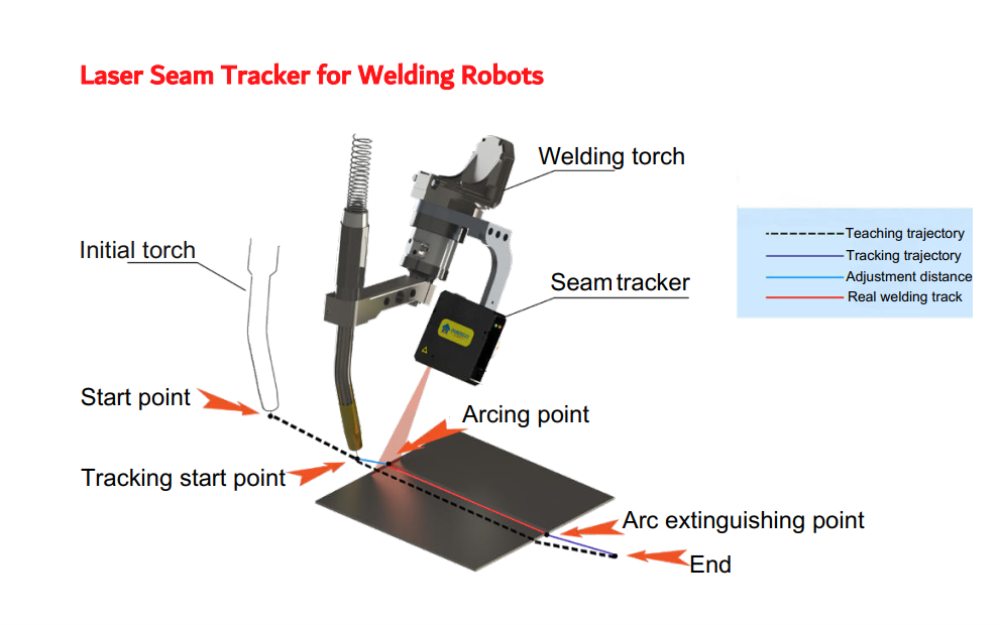

Ukuchaneka kweukuwelda nge-laserIxhomekeke kakhulu kwindawo echanekileyo yokubeka umqadi welaser. Iinkqubo zokulandelela umthungo kwiimashini zokufaka ilaser zidlala indima ebalulekileyo ekufezekiseni olu chanekileyo. Ngokusebenzisa iteknoloji yokuva ephucukileyo, inkqubo inokulandelela rhoqo kwaye ilungise indawo yelaser njengoko ihamba ecaleni komthungo ukuze ifakelwe i-weld. Oku kuqinisekisa ukuphambuka okuncinci xa i-laser idutyulwa. Ngenxa yoko, abavelisi banokufikelela kwii-welds ezihambelanayo nezichanekileyo eziqinisekisa umgangatho wemveliso yokugqibela.

Umgangatho olungileyo kunye nexabiso eliphantsi

Xa bekhetha umatshini wokuwelda nge-laser, abathengi badla ngokuxhalaba ngokuchitha imali eninzi kakhulu. Nangona kunjalo, ngenkqubo yokulandelela umthungo, akufuneki bancame umgangatho ukuze bahlale ngaphakathi kohlahlo-lwabiwo mali. Ngokubeka ngokuchanekileyo umqadi we-laser, inkqubo yokulandelela umthungo iqinisekisa ukuba yonke i-weld ikumgangatho ophezulu kwaye ihlangabezana nemigangatho efunekayo. Oku kususa isidingo sokulungiswa kwakhona okubiza kakhulu kwaye kunciphisa iindleko zizonke zomenzi. Ukudibanisa umgangatho olungileyo kunye nexabiso eliphantsi kwenza umatshini wokuwelda nge-laser kunye nokulandelela umthungo kube lutyalo-mali oluhle kakhulu kuyo nayiphi na indawo yemveliso.

Inzuzo yesicelo

Ukongeza ekuchanekeni okwandisiweyo kunye nokusebenza kakuhle kweendleko, iinkqubo zokulandelela umthungo zizisa iingenelo ezibalulekileyo kwinkqubo yokuthunga. Umzekelo, inokufezekisa uhlengahlengiso olukrelekrele lwenkqubo yokuthunga, ngaloo ndlela iphucula kakhulu ukusebenza kakuhle kwemveliso kunye nomgangatho wokuthunga. Inkqubo inokwamkela utshintsho kwisixhobo somsebenzi, njengemithungo engacwangciswanga okanye ukungalungelelani okuncinci. Olu kuguquguquka lwenza inkqubo yokuthunga ibe lula kwaye ithembeke ngakumbi, iqinisekisa ukuthungwa okulinganayo nokumgangatho ophezulu ngalo lonke ixesha.

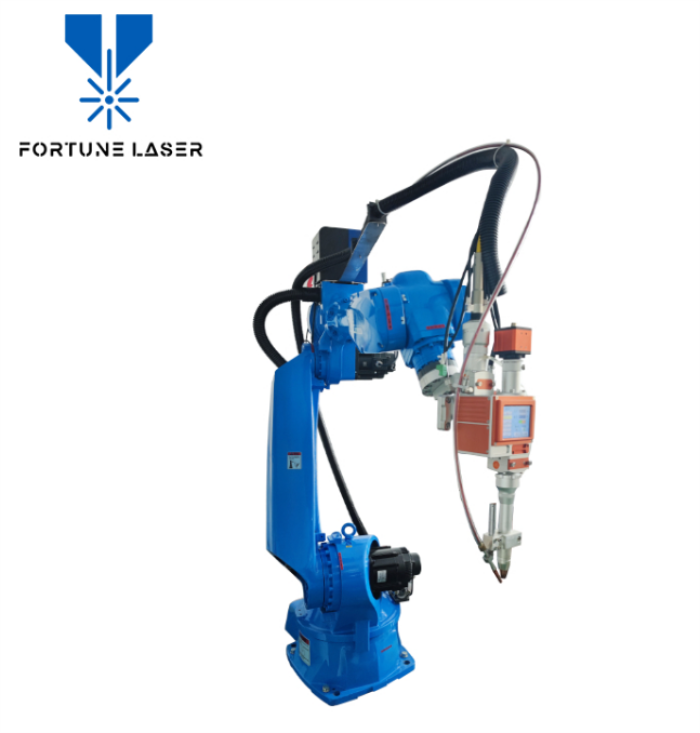

Enye inzuzo yenkqubo yokulandelela umthungo kukukwazi kwayo ukusebenza neerobhothi. Ngokudibanisa iinkqubo zokulandelela umthungo nge-laser kwiukuwelda kwerobhothiNgokusebenzisa iindlela zokuseta, abavelisi banokuwuphucula kakhulu umgangatho we-weld kunye nemveliso. Phantsi kwesikhokelo senkqubo yokulandelela umthungo, irobhothi inokulandelela ngokuchanekileyo umthungo kwaye ibeke ngokuchanekileyo umqadi welaser, ukuze ifezekise ukuwelda okusemgangathweni ophezulu rhoqo. Ukongeza, ukusetyenziswa kweerobhothi kususa isidingo somsebenzi wezandla kwaye kunciphisa umngcipheko weempazamo zomntu, nto leyo enyusa ngakumbi ukusebenza kakuhle kwenkqubo yokuwelda.

Phucula umgangatho wokuwelda kwaye unciphise ixesha lokuphinda usebenze kwakhona

Esinye sezona ziphumo zinqwenelekayo kuyo nayiphi na inkqubo yokuwelda kukufezekisa ukuwelda okusemgangathweni ophezulu okungadingi ukuphinda kusetyenzwe. Iinkqubo zokulandelela umthungo zidlala indima ebalulekileyo koku. Ngokuqinisekisa indawo echanekileyo yelaser, inkqubo inciphisa umngcipheko wokuphinda kusetyenzwe ngenxa yeziphene zokuwelda. Oku akugcini nje ngokusindisa ixesha, kodwa kunciphisa neendleko ezinxulumene nokuphinda kusetyenzwe, njengomsebenzi owongezelelweyo kunye nezixhobo. Ngoncedo lweenkqubo zokulandelela umthungo, abavelisi banokunciphisa iziphene zokuwelda, ngaloo ndlela baphucule umgangatho wokuwelda ngokubanzi.

Ukongeza, iinkqubo zokulandelela umthungo zinceda ekunciphiseni ixesha elifunekayo lokuphinda usebenze. Ekubeni ivelisa ii-welds ezichanekileyo nezihambelanayo, akukho hlengahlengiso okanye zilungiso ezifunekayo emva kokuba i-weld yokuqala igqityiwe. Oku kusindisa ixesha nomgudu, okuvumela abavelisi ukuba babelane ngezixhobo ngokufanelekileyo kwaye bahlangabezane neeshedyuli zemveliso ezixineneyo. Inkqubo yokulandelela umthungo yenza lula inkqubo yokudibanisa, isuse ukulibaziseka okungeyomfuneko, kwaye yonyusa imveliso.

Yandisa imveliso

Ukudibanisa inkqubo yokulandelela umthungo we-laser kunye nokuseta i-robotic welding kunokunyusa kakhulu imveliso.ukuzenzekela kwerobhothikunye nokubekwa ngokuchanekileyo kwelaser akunciphisi nje kuphela ixesha elifunekayo lokuphinda usebenze, kodwa kwandisa isantya senkqubo yokuwelda. Ngokususa umsebenzi wezandla, abavelisi banokufikelela kwimigca yemveliso ekhawulezayo nesebenzayo ngakumbi.

Ukongeza, inkqubo yokulandelela umthungo iqinisekisa ukuwelda okulinganayo nokusemgangathweni kuyo yonke inkqubo yokuvelisa. Oku kususa isidingo sokujonga nokulungisa rhoqo, njengoko inkqubo iqhubeka nokulandelela nokulungisa umqadi welaser ngexesha langempela. Oku kuvumela abaqhubi ukuba bagxile kweminye imisebenzi, nto leyo eyonyusa imveliso ngakumbi. Ngoomatshini bokuwelda ngelaser abaxhotyiswe ngeenkqubo zokulandelela umthungo, abavelisi banokwenza ngcono izixhobo, bandise imveliso kwaye bahlangabezane neemfuno zabathengi ngokufanelekileyo.

Ukuqukumbela, inkqubo yokulandelela umthungo yomatshini wokuwelda nge-laser ineenzuzo ezininzi, ezinokuphucula ukusebenza kakuhle kwemveliso kunyeukuweldaumgangatho. Ukususela ekubekweni ngokuchanekileyo kwelaser ukuya kwiinkqubo zemveliso eziphuculweyo, inkqubo iqinisekisa ukuwelda okuchanekileyo nokungaguquguqukiyo ngelixa inciphisa ixesha lokuphinda usebenze kunye neendleko. Xa zidityaniswe neeyunithi zokuwelda zerobhothi, iinkqubo zokulandelela umthungo welaser zinokuphucula ngakumbi ukusebenza kakuhle, zivumele abavelisi ukuba bandise imveliso kwaye bahlangabezane neemfuno zabathengi ngokufanelekileyo. Ngokutyala imali kumatshini wokuwelda welaser onenkqubo yokulandelela umthungo, abavelisi banokulindela ukuphucula umgangatho wokuwelda, bandise ukusebenza kakuhle kweendleko, kwaye baphucule imveliso iyonke.

Ukuba ufuna ukufunda okungakumbi malunga nokuwelda nge-laser, okanye ufuna ukuthenga umatshini wokuwelda we-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuthumela: Julayi-08-2023