Ii-alloy ze-aluminium zisetyenziswa kakhulu kumashishini e-semiconductor kunye ne-microelectronics ngenxa yeempawu zazo ezilungileyo zomzimba nezekhemikhali kunye neempawu ezibalaseleyo zoomatshini. Njengoko iimveliso zanamhlanje zoshishino ziphuhliswa zisiya kumandla aphezulu, zikhaphukhaphu, kwaye zisebenza kakuhle, iindlela zokusika i-laser ye-aluminium alloy nazo ziyaphuhliswa zisiya kuchanekileyo, ukusebenza kakuhle, kunye nokuguquguquka. Ukusika i-laser kuneenzuzo zomngxuma omncinci wokusika, indawo encinci echaphazeleka bubushushu, ukusebenza kakuhle, kunye nokungabikho koxinzelelo loomatshini kwimiphetho yokusika. Ibe yindlela ebalulekileyo yokucubungula ngokuchanekileyo ii-alloy ze-aluminium.

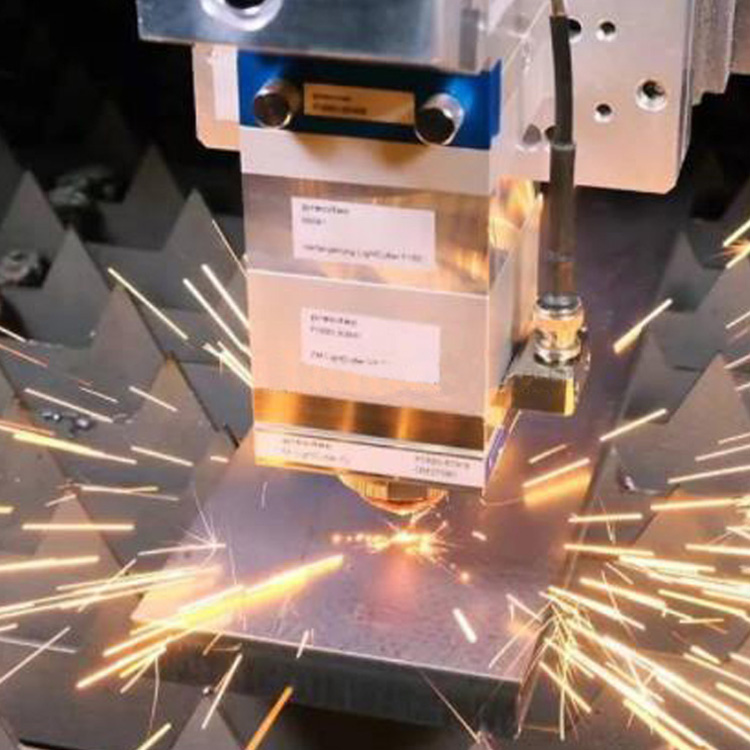

Ukusika i-laser ye-aluminium alloy ekhoyo ngokubanzi kusebenzisa intloko yokusika kunye negesi encedisayo. Indlela esebenza ngayo kukuba i-laser igxile ngaphakathi kwe-aluminium alloy, i-gasification enamandla aphezulu iyanyibilikisa i-aluminium alloy, kwaye i-high-pressure assistant gas ivuthulula izinto ezinyibilikisiweyo.

Le ndlela yokusika isebenzisa ikakhulu iilaser ezimbini ezinamaza obude obumalunga ne-10640nm kunye ne-1064nm, zombini ezikwinqanaba le-infrared wavelength. Ukuze kunqunyulwe ngokuchanekileyo amaphepha e-aluminium alloy anobungakanani bokusika obuchanekileyo kwinqanaba le-micron, ngenxa yendawo yayo enkulu yokukhanya kunye nendawo enkulu echaphazeleka bubushushu, kulula ukuba kubekho i-Slag kwaye kubekho imifantu emincinci kumphetho wokusika, nto leyo ekugqibeleni ichaphazela ukuchaneka kunye nesiphumo sokusika.

Inkqubo yokusika i-laser ye-aluminium alloy kunye nendlela yokwenziwa kwayo yenza ukuba isikwe isikwe ngendlela engeyiyo eyokuchukumisa ngokusebenzisa ububanzi obuncinci be-pulse kunye nobude obufutshane be-laser beam, kuthintelwe ukulahleka koxinzelelo lokunxibelelana kwesikwe esiza kunqunyulwa ngeendlela zoomatshini, kwaye ngexesha lokusika. Ngexesha lokucubungula, iingxaki ezifana nokuqhekeka okuncinci kunye nokuxhonywa kwe-slag zibangelwa yindlela yokucubungula ubushushu; ngokusebenzisa isixhobo esithile ukulungisa isikwe esiza kunqunyulwa ngokuthe tye, ngelixa sigcina indawo yokuqhekeka emoyeni, indawo yokusika yesikwe esiza kunqunyulwa ixhaswa ngasemva ukuthintela ukuba ingawi ngexesha lokusika. Ivelisa uxinzelelo lokutshabalalisa isiphumo sokusika; isebenzisa amanzi okupholisa ajikelezayo kwisixhobo setanki yamanzi ukupholisa isikwe esiza kunqunyulwa, inciphisa impembelelo yobushushu kwizinto ezijikelezileyo, kwaye iphucula ngakumbi umgangatho wokusika; inqumla ngokudibeneyo kweendlela ezininzi zokusika ukwandisa umthungo wokusika. Ububanzi buphucula ukusebenza kakuhle kokusika.

Ezi ndlela zingentla zezona zikhethwayo, kodwa ukuphunyezwa akuthintelwanga ziindlela ezingentla. Naluphi na olunye utshintsho, utshintsho, utshintsho, indibaniselwano, kunye nokulula okungaphambuki kumoya kunye nemigaqo kufuneka kwenziwe ngolu hlobo lulandelayo. Iindlela zokutshintshwa ezisebenzayo zonke zibandakanyiwe kuluhlu lokukhusela iindlela zokusika i-aluminiyam alloy laser.

Ixesha leposi: Meyi-23-2024