Kwimarike eqhutywa bubuchule kunye nokusebenza kakuhle,ukuwelda nge-laserInika iinkampani zefenitshala yesinyithi inzuzo ekhethekileyo ngokuphucula inzuzo, ukuqina, kunye nomgangatho wokubonakala.

Le teknoloji ivelisa ii-welds ezichanekileyo kangangokuba azidingi ukugqitywa okuncinci, nto leyo engundoqo kolu phuculo. Oku kukhokelela kwimijikelo yemveliso ekhawulezayo, iindleko eziphantsi zomsebenzi, kunye nenkululeko enkulu yoyilo, okuvumela ukudalwa kwefenitshala eqinileyo necociweyo ngelixa kuphucula ukusebenza kakuhle kwemveliso.

Uyilo Olungenamida: Impembelelo Yokuwelda NgelaserIfenitshala

Iindlela zemveli zokuwelda zazidla ngokunyanzela abayili ukuba bavumelane. Iiweld ezibonakalayo nezinkulu kwakufuneka zifihlwe okanye zamkelwe njengenxalenye yembonakalo. Iiweld zelaser ziyazitshabalalisa ezo mingcele.

Ukufezekisa iphupha elincinci nge-Invisible Welds

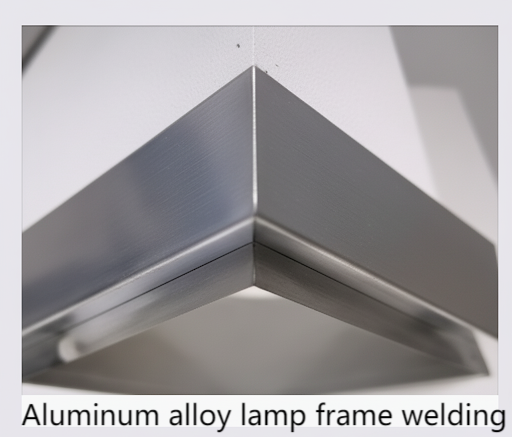

Uyilo lwefenitshala yanamhlanje luphumelela xa kufikwa kwimigca ecocekileyo kunye nobuhle obuncinci. Ukuwelda nge-laser liqabane elifanelekileyo kule ndlela. Kwenza iindawo ezigudileyo nezingenamthungo ezilungele ifenitshala yexabiso eliphezulu apho ukuwelda okubonakalayo kungamkelekanga. Isiphumo yimveliso ebonakala ngathi yenziwe ngentsimbi enye.

Ukwakha iipateni ezintsonkothileyo kunye neejometri

Ngaba wakha wafuna ukwenza izinto zokuhombisa ezithambileyo nezintsonkothileyo? Ukuchaneka komqadi welaser kwenza kube nokwenzeka. Le teknoloji ivumela ukwenziwa kweepateni ezintsonkothileyo kunye neemilo zejiyometri ebezingenakwenzeka ngeendlela zemveli, ezidla ngokubangela ukuphazamiseka kobushushu kwaye zonakalise iinkcukacha ezincinci.

Ukuvelisa izinto ezintsha ngefenitshala yezinto ezixutyiweyo

Ingeniso ephantsi yenkqubo yokuwelda nge-laser yenye inzuzo enkulu. Oku kuvumela isinyithi ukuba sifakwe kufutshane kakhulu nezinye izinto ezifana nomthi, iglasi, okanye i-upholstery ngaphandle kokubangela umonakalo. Oku kuvula ihlabathi elitsha loyilo lwefenitshala oluyintsha, oluxutyiweyo.

Ukhetho Olucacileyo: Kutheni Ukuwelda Ngelaser Kuphumelela Kwiindlela Zemveli

Xa kufikwa kwimveliso yefenitshala yesinyithi, ukhetho phakathi kokuwelda nge-laser kunye neendlela zemveli ze-MIG okanye ze-TIG luya lucaca ngakumbi.

Isantya kunye noPhumezo

Ixesha liyimali kumgangatho wefektri. Ukuwelda nge-laser kukhawuleza ngokuphindwe kalishumi kuneendlela zemveli. Esi santya simangalisayo sinciphisa kakhulu ixesha lokuvelisa ngeqhekeza ngalinye, sinyusa imveliso yakho iyonke, kwaye senza iimveliso zithengiswe ngokukhawuleza.

Umgangatho kunye nokuGqiba

Libala ngamanyathelo athatha ixesha elide okugaya, ukusanta, kunye nokupolisha. Ukuwelda nge-laser kuvelisa ukuwelda okunokusasaza okuncinci kunye nendawo encinci kakhulu echaphazeleka bubushushu (HAZ). Oku kuthetha ukuba imveliso egqityiweyo iphuma ecaleni komgca phantse igqibelele, isusa iindleko ezibizayo nezifuna umsebenzi omninzi emva kokucutshungulwa.

Amandla kunye nokuchaneka

Musa ukuvumela inkangeleko ecocekileyo ikulahlekise; ezi weld zinamandla kakhulu. Iiweld ezinzulu nezimxinwa ezenziwe yilaser zihlala zinamandla kunezinto eziphambili. Le nkqubo ichaneke kakhulu, nto leyo enciphisa ukugqwetheka kwezinto kunye nenkunkuma.

Uthelekiso lweNdlela yokuWelda: I-Laser vs. MIG vs. TIG

| I-Metric | Ukuwelda ngeLaser | Ukuwelda kwe-MIG | Ukuwelda kweTIG |

| Isantya | Phezulu kakhulu | Phezulu | Icotha |

| Uchaneko | Ingaqhelekanga | Iphakathi | Phezulu |

| Umgangatho Wokugqiba | Igqwesile (Ingenamthungo) | Ilungile (Ifuna Ukusila) | Kulungile (Kufuneka Ucoceke) |

| Ukucutshungulwa emva | Okuncinci ukuya kokungafumanekiyo | Olubanzi | Iphakathi |

| Izakhono zoMsebenzil | Kulula Ukuyifunda | Iphakathi | Phezulu |

| Ixabiso lokuqala | Phezulu | Iphantsi | Iphantsi |

Ukusuka kwiFrames ukuya kwiFiligree: Izicelo zokuWelda ngeLaser zeHlabathi lokwenyani

Ngoko ke, obu buchwephesha busebenza njani kwiimveliso zakho zokwenyani? Nazi ezinye zemizekelo esebenzayo:

Izinto eziyinxalenye yoLwakhiwo:Hlanganisa ngokulula iifreyimu, imilenze, kunye nezixhaso zeetafile nezitulo ngamandla agqwesileyo kunye nokuhambelana okugqibeleleyo ngalo lonke ixesha.

Imisebenzi yesinyithi yokuhombisa:Yenza ii-welds ezintle nezineenkcukacha kwiziqwenga zokuhombisa, njengee-backs zezihlalo ezineepatheni okanye iziseko zeetafile zobugcisa, ezigcina ixabiso elipheleleyo lobuhle.

Izinto ezibhityileyo kunye neekhabhathi:Hlanganisa isinyithi esincinci kwiikhabhathi, iilokha, kunye neephaneli ngaphandle kokugoba okanye ukutshiza okuqhelekileyo kwezinye iindlela.

Ezi zicelo zibonisa ukuba nokuba umsebenzi ufuna ukuqina kwesakhiwo okanye iinkcukacha zokuhombisa ezintsonkothileyo, ukuwelda nge-laser sisisombululo esiguquguqukayo. Kuvula ithuba loyilo olutsha kunye nomgangatho ophezulu, kuqinisekisa ukuba iimveliso zakho azakhelwe ukuhlala ixesha elide kuphela kodwa zenziwe ngendlela egqibeleleyo.

Vula Amandla e-Laser Welding: Izitshixo Ezintathu Zokuqala Okungenasiphako

Ukusebenzisa i-laser welding kukuphucula amandla akho emveliso. Ukuze usebenzise amandla ayo apheleleyo ukususela ngomhla wokuqala, dibanisa le migaqo isisiseko kumsebenzi wakho.

Ukuchaneka sisiseko seNtsebenzo

Ukuchaneka okumangalisayo kokuwelda nge-laser kuqala kudala ngaphambi kokuba umqadi usebenze. Kuxhomekeke ekudibaneni okugqibeleleyo phakathi kwezinto. Ngokucokisa iinkqubo zakho zokusika nokwenza izinto ezisezantsi ukuze uvelise iindawo ezinezikhewu ezincinci, ubeka inqanaba lee-welds eziqinileyo, ezicocekileyo, nezihambelanayo.

Ubumsulwa Buvula Amandla

Umphezulu ococekileyo ubalulekile ukuze kubekho ukuwelda okugqibeleleyo. Naluphi na uhlobo lweoyile, ukungcola, okanye umaleko we-oxide wendalo kwi-aluminiyam unokufaka iziphene kwaye wonakalise ukuthembeka kwejoyinti. Ukumisela inyathelo lokucoca nokulungiselela eliyimfuneko kuqinisekisa ukuba i-laser idala umthungo ococekileyo, onamandla, nogqibeleleyo ngalo lonke ixesha.

Inkcubeko Yokhuseleko Iqhuba Impumelelo

Iilaser ezinamandla aphezulu zifuna indlela yokuziqhelanisa nokhuseleko. Ukukhusela iqela lakho yeyona nto iphambili kuwe. Oku kuthetha ukuyila indawo ekhuselekileyo eneendawo zokusebenza ezizinikeleyo nezivaliweyo, ukulawula umgangatho womoya ngokukhupha umsi ngokufanelekileyo, kunye nokuxhobisa wonke umntu kuloo ndawo ngee-eyewear eziqinisekisiweyo ezikhuselekileyo kwilaser. Ukusebenza ngokukhuselekileyo kuyasebenza kwaye kuyaqhubeka.

Ukuhlala Uphambili Kwigophe: Ikamva Lokuwelda Okuzenzakalelayo

Le teknoloji isatshintsha, ityhala imida yoko kunokwenzeka kwimveliso yefenitshala yesinyithi.

Ukunyuka kweeRobotics kunye neeCobots

Ukwenziwa kwezinto ngokuzenzekelayo kwenza ukuwelda nge-laser kube nempumelelo ngakumbi. Ukudibanisa abawelda nge-laser neengalo zerobhothi kunye neerobhothi ezisebenzisanayo (ii-cobots) kuvumela imveliso yeeyure ezingama-24/7 kunye nokuhambelana okungenakuthelekiswa nanto, okwenza ubuchwepheshe bufikeleleke ngakumbi kubavelisi bayo yonke imilinganiselo.

Ukwenziwa kweMveliso ekrelekrele nge-AI kunye nokufunda koomatshini

Ikamva likrelekrele. Ngokweengxelo zakutshanje zoshishino, i-AI kunye nokufunda koomatshini zidityaniswe kwiinkqubo zokuwelda ukuze kulawulwe umgangatho ngexesha langempela, izilumkiso zokugcinwa kwangaphambili, kunye nokwenza ngcono inkqubo ngokuzenzekelayo, ukuqinisekisa ukuba yonke i-weld igqibelele.

Isahluko esitsha kwiMveliso yeFenitshala

Ukushwankathela, ukuwelda nge-laser kungaphezulu nje kwesixhobo esitsha. Lutyalo-mali olucwangcisiweyo olubonelela ngomgangatho wobuhle ongenakuthelekiswa nanto, isantya semveliso, kunye nenkululeko yoyilo. Ikunika amandla okuhambisa iimveliso ezintle ezibonakalayo ezineemithungo ezingabonakaliyo, uzenze ngesantya esidlula abakhuphisana nabo, kwaye unike abayili bakho inkululeko yokuyila yokuvelisa izinto ezintsha ngaphandle kokuthintelwa. Eli lithuba lakho lokufumana isikhundla esiphambili kushishino lwefenitshala.

Masikubonise iingenelo ezibonakalayo kumgca wemveliso yakho. Nxibelelana neengcali zethu zokwenza izinto ukuze ufumane ingcebiso eyenzelwe wena kwaye uthathe inyathelo lokuqala eliya kwikamva lefenitshala.

Ixesha lokuthumela: Agasti-28-2025