Umatshini wokuwelda we-Fortune Laser ozenzekelayo we-1000W/1500W/2000W Fiber Laser oqhubekayo

Umatshini wokuwelda we-Fortune Laser ozenzekelayo we-1000W/1500W/2000W Fiber Laser oqhubekayo

Imigaqo esisiseko yoMatshini weLaser

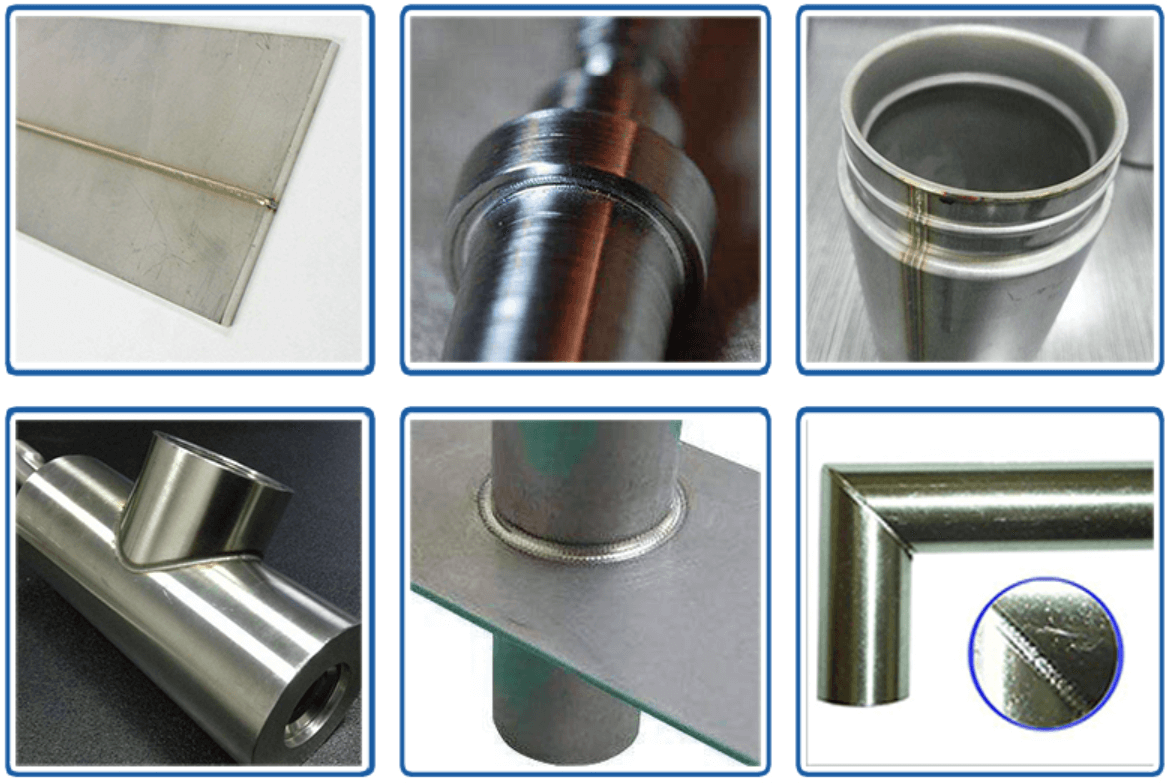

Umatshini wokuwelda we-laser yefayibha eqhubekayo luhlobo olutsha lwendlela yokuwelda. Ngokuqhelekileyo yenziwe "ngumsingathi wokuwelda" kunye "nebhentshi yokusebenza yokuwelda". Umqadi we-laser udityaniswe nefayibha ye-optical. Emva kokudluliselwa komgama omde, icutshungulwa ibe yi-parallel light focus. Ukuwelda okuqhubekayo kwenziwa kwindawo yokusebenza. Ngenxa yokuqhubeka kokukhanya, isiphumo sokuwelda siqina kwaye umthungo wokuwelda ulungile kwaye umhle. Ngokweemfuno ezahlukeneyo zamashishini ahlukeneyo, izixhobo zokuwelda ze-laser zinokuhambelana nohlobo kunye nebhentshi yokusebenza ngokwendawo yemveliso kwaye zenze umsebenzi ozenzekelayo, onokuhlangabezana ngokupheleleyo neemfuno zabasebenzisi kumashishini ahlukeneyo.

Uninzi lweemashini zokuwelda ze-fiber laser eziqhubekayo zisebenzisa ii-laser ezinamandla aphezulu ezinamandla angaphezu kwama-watts angama-500. Ngokubanzi, ezi laser kufuneka zisetyenziswe kwiipleyiti ezingaphezu kwe-1mm. Umatshini wazo wokuwelda yi-deep penetration welding esekelwe kwisiphumo semingxuma emincinci, enomlinganiselo omkhulu wobunzulu nobubanzi, onokufikelela ngaphezu kwe-5:1, isantya sokuwelda esikhawulezayo, kunye nokuguquguquka okuncinci kobushushu.

Uphawu lomatshini wokuwelda we-laser oqhubekayo we-1000W 1500w 2000w

Iiparamitha zobugcisa zomatshini wokuwelda we-Laser eqhubekayo ye-Fortune Laser

Izixhobo

1. Umthombo welaser

2. Intambo yeLaser yeFayibha

3. Intloko yokuwelda ye-laser ye-QBH

4. Isitshizi se-1.5P

5. I-PC kunye nenkqubo yokuwelda

6. I-500*300*300 Linear Rail Servo Electric Translation Stage

7. Inkqubo yolawulo ye-3600 ene-axis ezine

8. Inkqubo yekhamera yeCCD

9. Ikhabhathi ye-Mainframe