Sida aan wada ognahay, mashiinnada jarista fiber laser-ka waa khubaro ku xeel dheer jarista xaashida birta waxaana si weyn loo isticmaalaa. Haddaba maxay yihiin saameynta jarista xaashida birta aan dhammaystirnayn - xaashida birta ee miridhku ka muuqdo iyo dhinacyada ay tahay in fiiro gaar ah loo yeesho?

1. Jarjaridda saxannada miridhku waxay yareyn doontaa hufnaanta farsamaynta, tayada jarista ayaa sidoo kale ka sii dari doonta, heerka qashinka badeecadduna sidoo kale wuu kordhi doonaa si waafaqsan. Sidaa darteed, haddii xaaladdu saamaxdo, inta lagu jiro habka farsamaynta birta xaashida ah, isku day inaad isticmaasho saxanno yar yar oo miridhku ku badan yahay intii suurtagal ah ama aad daaweyso saxannada miridhku ku badan yahay ka hor intaadan farsamayn. Isticmaal.

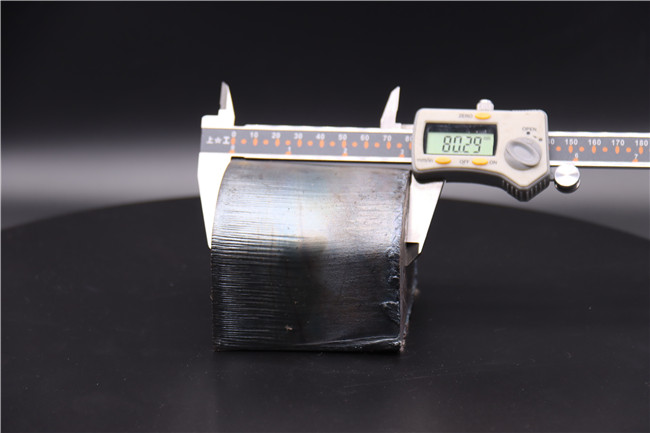

2. Inta lagu jiro habka jarista saxanka, gaar ahaan marka la feerayo oo la jarayo, godadku way qarxi karaan, taas oo wasakhayn doonta muraayadda ilaalinta. Tani waxay naga rabtaa inaan marka hore wax ka qabano saxanka miridhku ka baxay, sida isticmaalka mishiinka wax lagu shiido si looga saaro miridhku. Dabcan, saxannada ka hooseeya 5MM Saameyntu ma weyna, inta badan waxaa sabab u ah saxannada qaro weyn ee miridhku ka baxayo, laakiin tayada jarista ayaa wali saameyn doonta, taas oo aan la mid ahayn tayada jarista saxannada u qalma.

3. Isku mid ahaanshaha guud ee saamaynta jarista ayaa ka wanaagsan saxanka miridhku aanu sinnayn. Isku mid ahaanshaha guud ee saxanka miridhku wuxuu si siman u nuugaa laser-ka, sidaa darteed si fiican ayaa loo jari karaa. Birta xaashida ah ee aan sinnayn, waxaa lagu talinayaa in dusha sare la daweeyo si dusha sare ee xaashida looga dhigo mid siman ka dibna la sameeyo jarista laser-ka birta ah.

Waqtiga boostada: Abriil-10-2024