Sida aan wada ognahay, jajabka LED-ka oo ah qaybta ugu muhiimsan ee laambadda LED-ka waa qalab semiconductor ah oo adag, wadnaha LED-ku waa jajab semiconductor ah, dhinac ka mid ah jajabka waxaa lagu dhejiyay bir, dhinac ka mid ah waa elektroodh taban, dhinaca kalena waxaa lagu xiray elektroodh togan oo korontada ku shaqeeya, si jajabka oo dhan loogu xiro resin epoxy. Marka safayr loo isticmaalo sida walxaha substrate-ka, si weyn ayaa loogu isticmaalaa soo saarista jajabyada LED-ka, qalabka jarista dhaqameedna ma buuxin karo shuruudaha jarista. Haddaba sidee baad u xallin kartaa dhibaatadan?

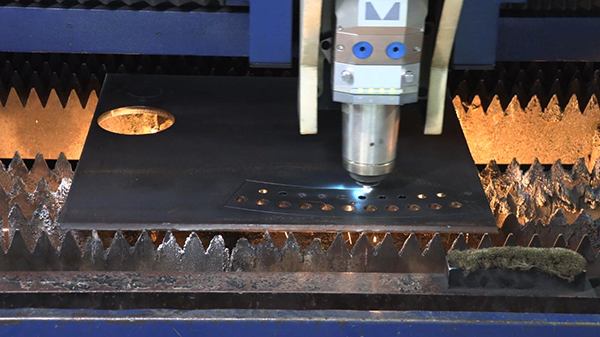

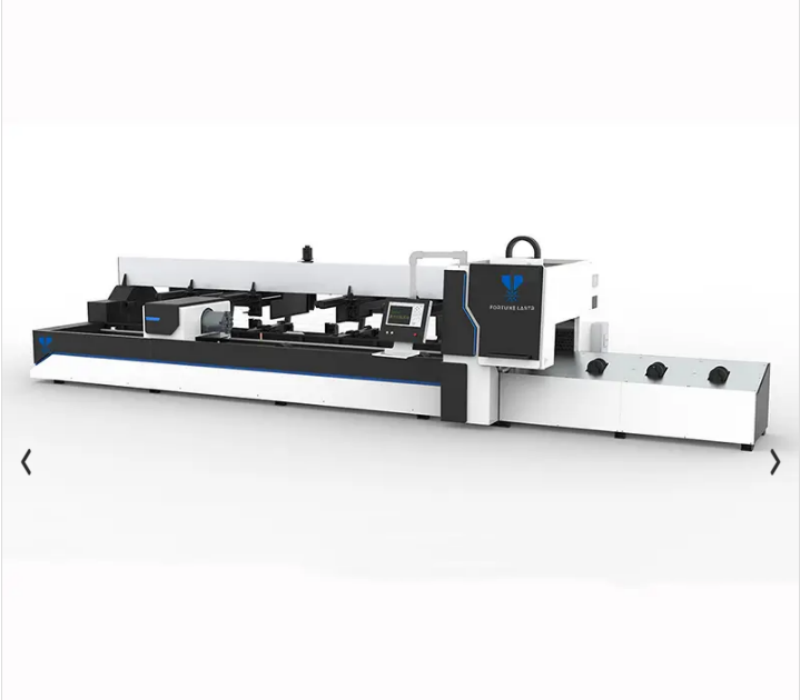

Mashiinka jarista laser-ka ee picosecond-ga gaaban ayaa loo isticmaali karaa in lagu jaro wafers-ka safayr-ka, kaas oo si wax ku ool ah u xalliya dhibka jarista safayr-ka iyo shuruudaha warshadaha LED-ka si loo sameeyo jajab yar iyo waddada jarista oo cidhiidhi ah, wuxuuna bixiyaa suurtagalnimada iyo dammaanad qaadka jarista hufan ee wax soo saarka ballaaran ee LED-ka ku salaysan safayr-ka.

Faa'iidooyinka jarista laysarka:

1, tayo wanaagsan oo goyn ah: sababtoo ah booska yar ee laysarka, cufnaanta tamarta sare, xawaaraha goynta, sidaa darteed goynta laysarka waxay heli kartaa tayo goyn oo wanaagsan.

2, hufnaan sare oo jaris ah: sababtoo ah sifooyinka gudbinta ee laysarka, mashiinka jarista laysarka guud ahaan waxaa ku qalabaysan miisas badan oo kontorool tirooyin ah, habka jarista oo dhanna wuxuu noqon karaa CNC oo dhammaystiran. Marka la shaqeynayo, kaliya beddel barnaamijka xakamaynta tirooyinka, waxaa lagu dabaqi karaa jarista qaybo qaabab kala duwan leh, jarista laba-geesoodka ah iyo jarista saddex-geesoodka ah labadaba waa la gaari karaa.

3, xawaaraha jarista waa mid degdeg ah: walaxdu uma baahna in lagu hagaajiyo jarista laysarka, taas oo badbaadin karta qalabka oo badbaadin karta waqtiga dheeraadka ah ee rarista iyo dejinta.

4, jarista aan taabashada lahayn: Tooshka jarista laysarka iyo shaqada oo aan lahayn xiriir, ma jiraan wax qalab ah oo xiran. Qaybaha qaabaysan ee qaabab kala duwan leh, uma baahna in la beddelo "qalabka", kaliya beddel xuduudaha wax soo saarka ee laysarka. Habka jarista laysarka wuxuu leeyahay buuq yar, gariir hoose iyo wasakh la'aan.

5, waxaa jira noocyo badan oo agab jaris ah: agabyo kala duwan, sababtoo ah sifooyinkooda jireed ee kulaylka iyo heerarka nuugista kala duwan ee laysarka, waxay muujinayaan la qabsiga jarista laysarka oo kala duwan.

Waqtiga boostada: Diseembar-02-2024