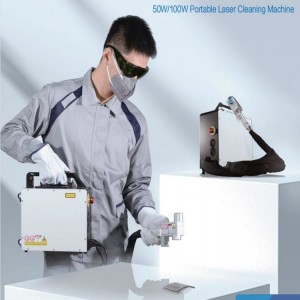

Mucheka wekuchenesa weLaser Welder we3 mu1 unobatwa nemaoko

Mucheka wekuchenesa weLaser Welder we3 mu1 unobatwa nemaoko

Zvimiro zveMuchina weLaser we3 IN 1

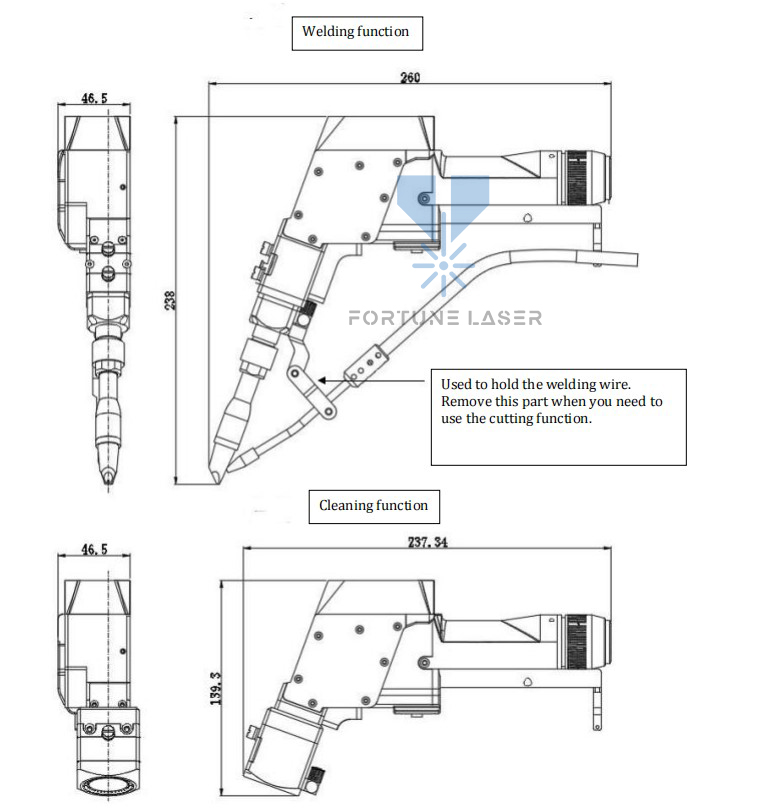

1. Hurefu hwewelding: musoro wewelding unobatwa nemaoko une fiber yepakutanga ye10M, iyo inokunda muganho wenzvimbo yebasa uye inogona kushandiswa pakuwelding panze uye pakuwelding kure;

2. Kushandiswa kuri nyore uye kunochinjika:Kushongedza nelaser kunobata nemaokoine mapururi anofamba, akasununguka kubata uye anogona kugadzirisa chiteshi chero nguva pasina nzvimbo dzakatarwa. Yakasununguka uye inochinjika, uye yakakodzera mamiriro akasiyana-siyana enzvimbo yekushandira.

3. Nzira dzakasiyana-siyana dzekushongedza: kubatanidza pakona chero ipi zvayo kunogona kuitwa: kushongedza pamakumbo, kushongedza matako, kushongedza vertical, kushongedza flat fillet, kushongedza inner fillet, kushongedza outer fillet, nezvimwewo, uye zvinogona kushandiswa pakugadzira workpieces dzine welds dzakasiyana-siyana dzakaoma uye maumbirwo asina kurongeka ekugadzira workpieces hombe. Ziva kushongedza pakona chero ipi zvayo. Pamusoro pezvo, zvinogona zvakare kupedzisa kucheka, kushongedza uye kucheka kunogona kuchinjwa zvakasununguka, ingochinja muromo wemhangura wekushongedza kuita muromo wemhangura wekuchekerera, izvo zviri nyore kwazvo.

4. Kucheka, kusanganisa, uye kuchenesa zvinowanzobatanidzwa zvakanyanya mumabasa epamusoro nepazasi mukugadzirisa simbi. Nzira yekushanda yechinyakare inowanzoda michina mitatu yakasiyana yekushandisa kuti iite maitiro matatu. Mukupindura dambudziko iri, tinopa vatengi mhinduro yakabatana uye tinotanga muchina wekucheka nekubatanidza we laser unobatwa nemaoko! Uyu mudziyo une mabasa matatu ekubatanidza, kuchenesa nekucheka we laser.

5. Inobvisa mafuta nekukurumidza uye zviri nyore usati wabatanidza, uye inobvisa marara uye kusviba kwemavara mushure mekusanganisa, uku ichiita maitiro ekucheka pamaplate akasiyana-siyana. Inogona kubatsira vatengi kuti vawane kushanda kwakanaka uye kusangana nemamiriro mazhinji ebasa. Upamhi hwewelding swing hwakareba se5mm, uye hurefu hwekuchenesa swing hunosvika 100mm. Inogona kucheka maplate esimbi isina ngura pasi pe6mm. Process index yakasimba, kunyanya cleaning index haina kuenzana nayo!

Muchina weFortune Laser Mini Laser Welding Basic Technical Parameters

Zviyero zvekupinda kweWelding (Zvinhu & Ukobvu hweWelding Range) zvekutarisa

| Zvinhu | Simba rekuburitsa (W) | Kupinda kwakanyanya (mm) |

| Simbi isina ngura | 1000 | 0.5-3 |

| Simbi isina ngura | 1500 | 0.5-4 |

| Simbi isina ngura | 2000 | 0.5-5 |

| Simbi yekabhoni | 1000 | 0.5-2.5 |

| Simbi yekabhoni | 1500 | 0.5-3.5 |

| Simbi yekabhoni | 2000 | 0.5-4.5 |

| Aruminiyamu chiwanikwa | 1000 | 0.5-2.5 |

| Aruminiyamu chiwanikwa | 1500 | 0.5-3 |

| Aruminiyamu chiwanikwa | 2000 | 0.5-4 |

| Pepa rakarukwa | 1000 | 0.5-1.2 |

| Pepa rakarukwa | 1500 | 0.5-1.8 |

| Pepa rakarukwa | 2000 | 0.5-2.5 |

[Mavara maviri emuchina eOrenji/Dema neChena/Bhuruu (anoratidzwa seari pamufananidzo) ndeesarudzo.]

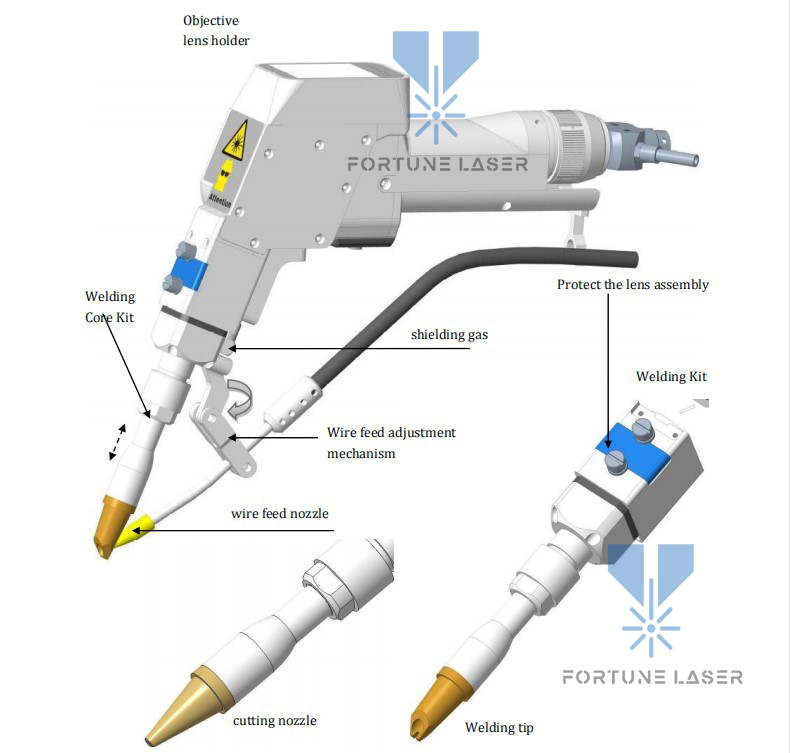

1. Musoro uyu wekunamira une mabhenefiti makuru mukugadzira simbi isingatsvi, aluminium alloy welding, uye mashandisirwo ekunamira ane simba diki nepakati. Musoro wekunamira unodhura zvishoma.

2. Musoro we welding unoshandisa lenzi inodedera yeX, Y-axis inodedera, ine nzira dzakawanda dze swing, uye swing welding inobvumira workpiece kuti ive ne welding isina kurongeka, mipata yakakura uye mamwe ma parameter ekugadzirisa, izvo zvinogona kuvandudza zvakanyanya kunaka kwe welding.

3. Chimiro chemukati chemusoro we welding chakavharwa zvachose, izvo zvinogona kudzivirira chikamu che optical kuti chisasvibiswe neguruva.

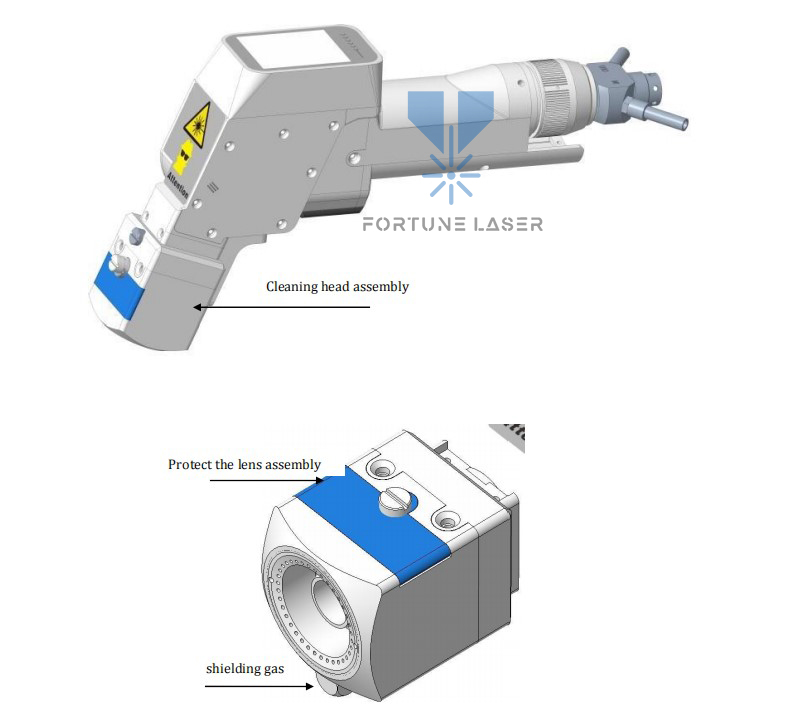

4. Zvishandiso zvekubatanidza/kucheka uye zvekuchenesa zvinogona kuita mabasa matatu ekubatanidza, kucheka uye kuchenesa.Tinewo muchina mudiki wekuchenesa une basa rakasiyana rekuchenesa)

5. Lenzi inodzivirira inoshandisa chimiro chedhirowa, chiri nyore kutsiva.

6. Inogona kugadzirirwa ma laser akasiyana-siyana ane QBH connectors.

7. Saizi diki, chitarisiko chakanaka uye kunzwa kwakanaka.

8. Sikirini yekubata inogona kushandiswa pamusoro we welding, iyo inogona kubatanidzwa ne platform screen kuti ive nani pakudzora nhare dzemunhu ne machine.

| Voltage yemagetsi (V) | 220V±10% AC 50/60Hz |

| Simba rakayerwa | 1500W |

| Kureba kwepakati kwakabatana | 75mm |

| Hunyoro hwenzvimbo yekushanda (%) | <70 |

| Kutarisa/Kuchenesa Kureba kweFocus | F150mm/F500mm |

| Nzvimbo yekushambira | 0.1-5mm |

| Nzira yekutonhodza | Chitonhodzo chemvura |

| Kufamba kakawanda | 0—300Hz |

| Huremu | 0.8kg |

| Sarudzo | Musoro wekuchenesa / Chinopa Waya / Chinochera / Chishandiso chekuwedhesa |

| Saizi yechidzitiro | Sikirini hombe yakajairika + sikirini diki ye 2-inch inosarudzwa |

| Nzvimbo yekugadzirisa yakatwasuka | ±10mm |

| Nzvimbo yekugadzirisa nzvimbo (modhi yekukwevera nemaoko) | 0~6mm |

| Nzvimbo yekugadzirisa nzvimbo (cleaningmode) | 0~50mm |

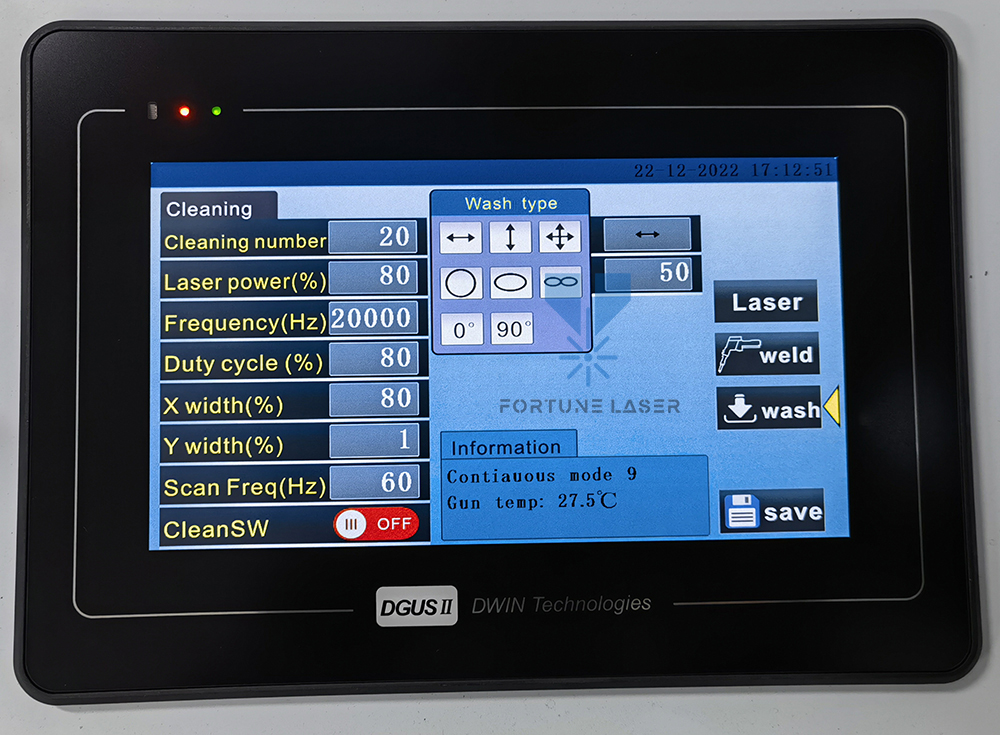

Mashandisirwo ese emuchina wedu ari nyore kunzwisisa. Sarudza maparameter aunoda kuchinja kuburikidza ne touch screen woachengeta. Mabasa ekuchenesa nekuwedera ari nyore kuchinja. Ingosarudza sarudzo dziri pamuchina uye dzichachinja kuita zvaunoda.

Uye shamwari zhinji dzisina kuishandisa dzichashamisikawo kuti dzingagadzirisa sei ma parameter. Tichaisa ma parameter akakunakira patinotumira chigadzirwa. Paunenge uchichishandisa, unongoda kuchinja simba rekushandisa. Kana uchiri kunzwa kusagadzikana, tinewo tsvakurudzo. Tafura yema parameter yakakodzera kusanganisa zvinhu zvakasiyana-siyana ndeyekutarisa vatengi vedu.

Nzira ye optical, system, hardware, nezvimwewo zvese zvakagadzirwa zvakazvimiririra. Chimiro che operation chinonzwisisika uye chiri nyore, uye mashandiro acho ari nyore. Maawa ekudzidziswa anogona kukuita kuti unzwe semuchina we welding ane hunyanzvi. Deredza mari yevashandi uku uchivandudza mhando, kugara zvakanaka, uye kugona kushanda zvakanaka.

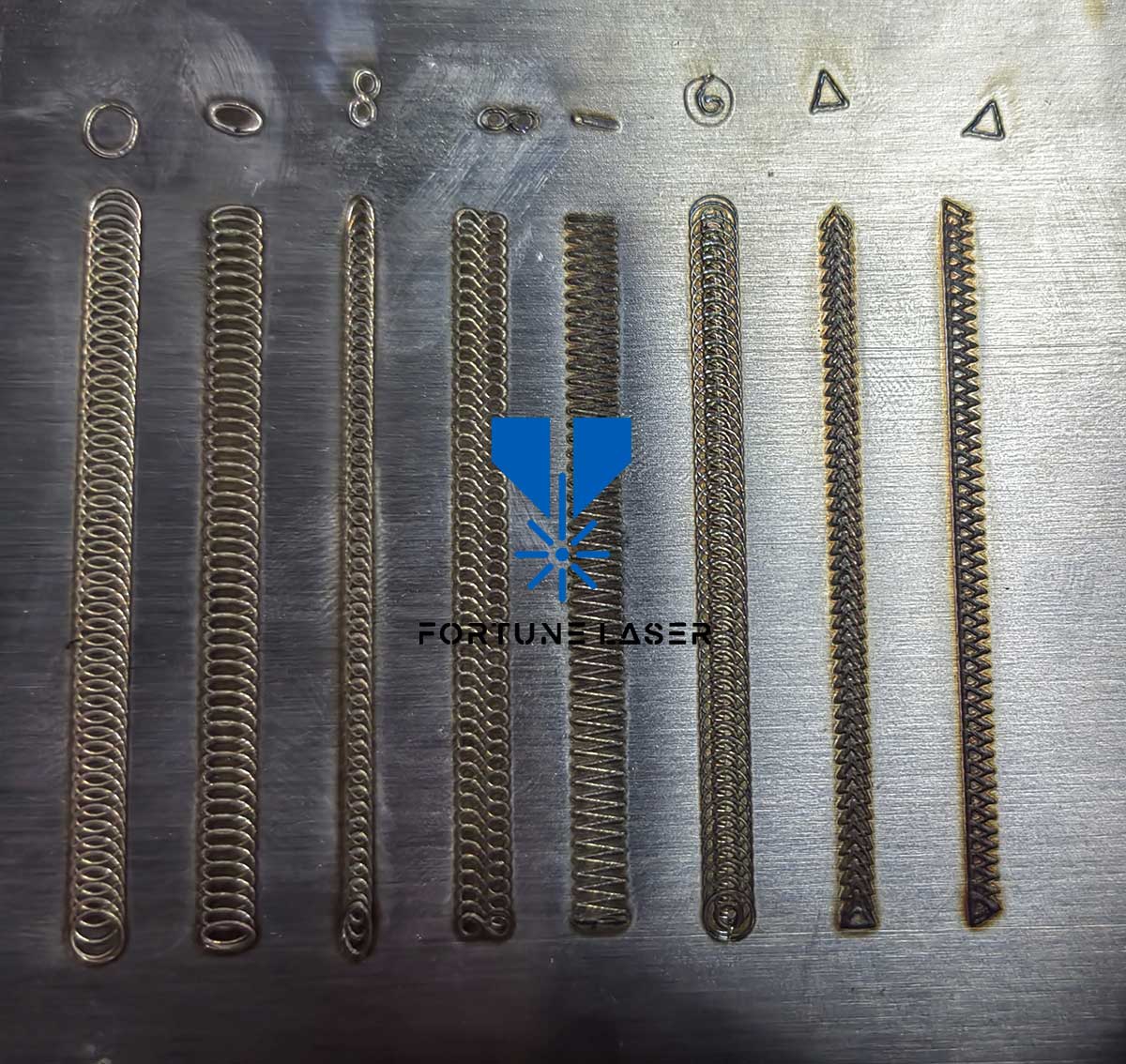

Zvichibva pa3 ne1, muchina wedu unogona zvakare kushandura marudzi akasiyana ema "spot shapes" sezvinoratidzwa mumufananidzo uri pazasi.

Mapatani akabatanidzwa nechimiro chedanda rega rega akasiyana. Maumbirwo edu edanda anosanganisira mutsetse wakatwasuka, denderedzwa, triangle, mufananidzo 8, ellipse, 90° nezvimwe zvimiro zvakafanana.

1. Musoro uyu we laser ndiwo chigadzirwa chedu chakasarudzika, hapana chakafanana nacho chiri pamusika;

2. Tine mapuratifomu akawanda ekutenga eB2B, ayo anogona kuvimbisa kuchengetedzeka kwekutenga kwako;

3. Tine rutsigiro rwehunyanzvi rwakatsaurirwa uye sevhisi yemaawa makumi maviri nemana mushure mekutengesa kuti tivandudze ruzivo rwevatengi;

4. Michina yedu yese ine waranti yegore rimwe.

5.Tinonyanya kutarisisa pakugadzira zvigadzirwa zvedu nenzira yekusika uye tinopa mamiriro ekukwikwidzana.

6. Tine timu ine hunyanzvi uye yakavimbika pabasa renyu, yakazvipira kupa sevhisi yevatengi yakagadzirirwa vatengi vedu vese.